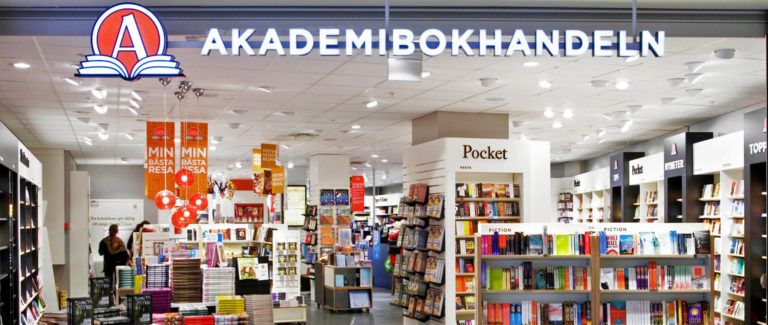

Case study: Akademibokhandeln

On top of Akademibokhandeln’s list of requirements were full centralization of its replenishment and more effective control of the Christmas sales peak.

Slash your inventory, out-of-stocks, food waste, and the amount of time you spend placing manual orders with an automatic replenishment system.

Up to 85%

reduction in stock-outs

99+%

on-shelf availability

10-40%

reduction in food waste

Automate and optimize routine replenishment and inventory allocation tasks for even the most challenging categories – from fresh and seasonal to new and promoted products.

Key features

Benefits

RELEX automatic replenishment system handles the routine work so your team can focus on tasks that require their expertise and human intelligence.

Place hundreds of thousands of accurate orders every day using machine learning-based forecasting that captures the impact of all demand drivers, including weekdays, price, promotions and cannibalization, holidays, local events, and weather.

Fill the gaps in seasonal planning by allowing RELEX to seamlessly combine pre-season ordering, initial allocations, automatic in-season replenishment, and targeted end-of-season allocations and markdowns to drive maximum value out of seasonal stock.

Take the guesswork out of distribution center replenishment by basing inventory requirements on accurate store order projections and leveraging improved goods flow visibility into proactive capacity management and resource planning.

RELEX automatic replenishment system optimizes stock levels for high on-shelf-availability and inventory turnover while reducing operational costs and supporting direct-to-shelf replenishment and full truckload deliveries.

Leverage efficient initial allocations and attribute-based forecasting of new products to improve replenishment accuracy, then perform controlled ramp-down of items to be discontinued, minimizing residual stock and facilitating smooth assortment changes.

Automate routine replenishment so your planners can focus on exception management, performance analysis, and continuous improvement while leveraging visual dashboards to keep track of KPIs and understand root causes.

Cut Food Waste. Protect Margins. Improve Profitability.

This webinar brings together experts from Deloitte, FMI, and RELEX to share how leading retailers are tackling food waste at its root—with AI-driven execution strategies that go beyond forecasting to improve inventory visibility, optimize replenishment, and reduce losses on the shelf.

We’ve accumulated a wealth of supply chain & retail expertise from our 1,500+ planning specialists.

Clients thinking of automating their replenishment processes often ask me what potential problems they should be alert to when changing their systems.

The efficiency of a business’s store replenishment operation has a major impact on profitability. Yet, it’s often overshadowed by higher profile activities such as buying, merchandising and marketing.

The biggest difference in automating replenishment of fresh products in comparison to center-store products is the increased importance of planning accuracy.

We’re happy to discuss your business needs and share how our market-leading, unified platform can help you drive profitable growth across your sales and distribution channels. Discover why top industry analysts position RELEX as Leaders in the market.