Meatier margins: How supply chain technology improves meat industry profitability

Feb 8, 2024 • 11 min

1. Introduction

Finding a supply chain as complex as the meat industry is hard.

Breeding, slaughtering, processing, packaging, distribution — the steps required to get meat products from farm to fork go on and on. Producers grapple with the same big-picture difficulties as perishability and volatile customer demand that impact other food manufacturers. Throw in breeding and slaughtering, and the complications compound quickly.

Each added layer of complexity in meat supply chain management is a chance for carefully laid plans to fail — and for already razor-thin margins to further erode. But each layer is also an opportunity for meat producers to optimize their processes to create new opportunities, provide new insights, and address existing production and delivery challenges. Higher visibility into the end-to-end supply chain allows companies to make more strategic and cost-effective business decisions that bolster profitability.

Traditional supply chain management solutions can’t deliver the adaptability and visibility that meat producers require. As more constraints continue to affect supply, processing capacity, and demand, companies need a unified view of their supply chain that is visible to everyone across the organization.

Meat producers must implement advanced, scalable supply chain planning systems to succeed in the future and ensure both growth and profitability. These solutions must utilize and analyze all supply chain data available to provide optimized production and profitability plans.

Meat producers face many unique challenges

Meat producers face the difficult task of planning within thin margins in an increasingly complex market — and the limitations of traditional methods like spreadsheet-based planning only magnify these difficulties. Planning challenges stem from a complex interplay of factors such as supply volatility, shifting consumer demand, and stringent food safety regulations, all of which require a more holistic and agile approach to supply chain management.

1. Traditional planning limitations

Producers must take an end-to-end look at their supply chain if they ever hope to manage them efficiently. Holistic visibility leads to more accurate and automated planning, allowing companies to anticipate and respond strategically to changing market conditions.

Producers must take an end-to-end look at their supply chain if they ever hope to manage them efficiently.

This is easier said than done for the many producers still reliant on spreadsheets and other traditional planning methods. Such methods make it difficult or even impossible to account for basic constraints on supply and demand. Traditional, manual approaches cannot incorporate the variables affecting the supply chain, limiting companies’ abilities to gain insight into which outputs to produce to maximize returns.

These variables include:

- Short order cycles

- Long-term supply agreements

- Supply fluctuations and uncertainty

- Expiration and aging problems

- Optimal product mix decisions

- Consumer demands shifts

- Food safety legislation

- Retail competition

2. Supply headaches

Meat producers must constantly determine what supply they need, how much they need, and when they need it. This task is incredibly challenging due to the industry’s long planning horizons. The decision to increase the number of breeding animals will take years before they are available for slaughter.

The inherent volatility of the supply side in the meat processing industry further complicates matters. The availability and quality of livestock are constantly affected by weather, seasonality, and competition for stock from rival companies.

Dwindling supply has sparked fierce competition for stock among meat‑processing companies. Many companies pay more to procure extra livestock and grow market share. Companies often find it difficult to gauge how much it is worth paying to secure supply, as they must balance their urge to fulfill orders against their desire to maximize profitability.

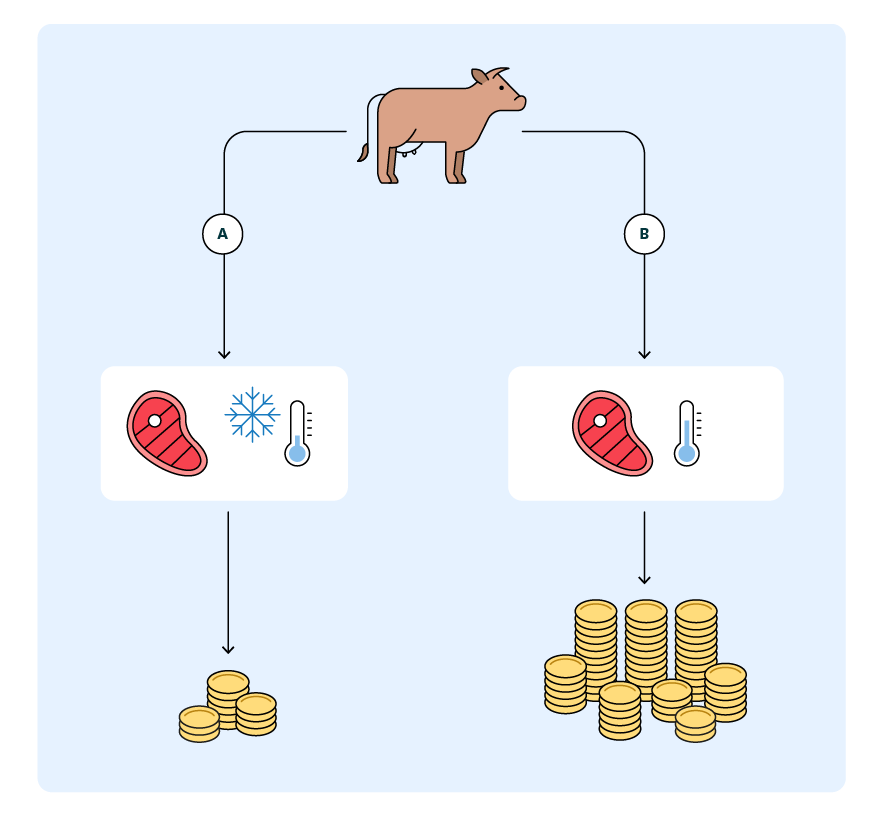

Securing livestock is only half the battle. Companies can’t know they’ve purchased a suitable animal for their chosen output until it is delivered and on the hook. A carcass that doesn’t fit the need as expected might force a snap decision that could eat into profitability. For instance, the company may have to sell off stock with a lower grade or a shorter shelf life below market rate. It might also need to sell the goods frozen, missing out on the premium prices achieved by chilled products.

3. Demand volatility

Demand‑side obstacles add further wrinkles of complexity to meat supply chain management. Changing consumer appetites and fluctuating foreign exchange rates influence demand, which varies by cut.

Producers must adapt their plans in response to these demand shifts, but the tendency for restaurant, fast food, and supermarket chains to place large orders with short lead times makes such adjustments difficult. The meat producer may lack the livestock, production capacity, or shipping availability to fulfill a larger-than-expected customer order on time, forcing them to delay delivery.

The rising dependence on the export market also exposes meat producers to demand volatility. Meat-processing companies cater increasingly to emerging economies like Mexico, Brazil, and Colombia as beef consumption per capita declines in USA and Western Europe. This dependence subjects companies to trade tariffs and fluctuations in foreign currency exchange, further complicating the planning process.

A complete match between supply and demand is nearly impossible, but striking the right balance will help companies achieve sustained profitability. A better balance minimizes margin erosion and maximizes carcass utilization, enabling producers to derive profits for each cut and cover some of the costs associated with the product process.

4. Carcass balancing

Producers strive to achieve the highest value from each carcass, but determining maximal yield means grappling with the added complexity of carcass balancing. Carcass balancing involves identifying the specific cut plan that will translate to the optimal product mix. The practice balances demand over time while taking advantage of varying price positions from different markets.

Digital planning solutions play a significant role in determining the optimal cut plan to maximize profit and balance demand over time.

A spreadsheet-based approach lacks the end-to-end visibility and control over the meat supply chain required to identify the optimal carcass balance. This is especially true for processed meat producers, whose complex carcass balancing efforts require them to consider alternative recipes.

Digital planning solutions play a significant role in determining the optimal cut plan to maximize profit and balance demand over time. These planning tools allow companies to react faster to market needs and find opportunities for surplus meat. This makes a fully integrated and customized platform that fosters collaboration essential to carcass balance maximization.

7 ways to maximize profitability with supply chain planning and optimization software

Improving margins in the meat industry hinges on effective supply chain planning and optimization. Planning and optimization software can break down departmental siloes and intuitively adapt to market fluctuations to transform a company’s meat production process. These seven strategies underscore the critical role of advanced software solutions in navigating the complex dynamics of the meat production supply chain.

1. Enable higher cross-departmental supply chain visibility

Supply chain visibility provides an accurate, real-time picture of demand signals and supplier inventory levels. This visibility enables meat producers to track carcasses, cuts, and finished products at various points in the supply chain.

Better supply chain visibility has been linked to better business performance for two big reasons:

- A prompt exchange of information between all stakeholders leads to better planning and coordination.

- Transparency and information integration are powerful competitive weapons in increasingly volatile markets.

Unfortunately, many organizations still plan individually within each department. This often leads to conflicting plans between the livestock/meat procurement, production, and marketing divisions. A lack of cross‑functional visibility can cause relationships to become adversarial, and planning meetings can spark debates over accountability.

Imagine that a company’s procurement team cannot secure the intended livestock. This company may waste money on surplus production capacity, forcing them to shelve marketing campaigns.

A lack of cross‑functional visibility can cause relationships to become adversarial, and planning meetings can spark debates over accountability.

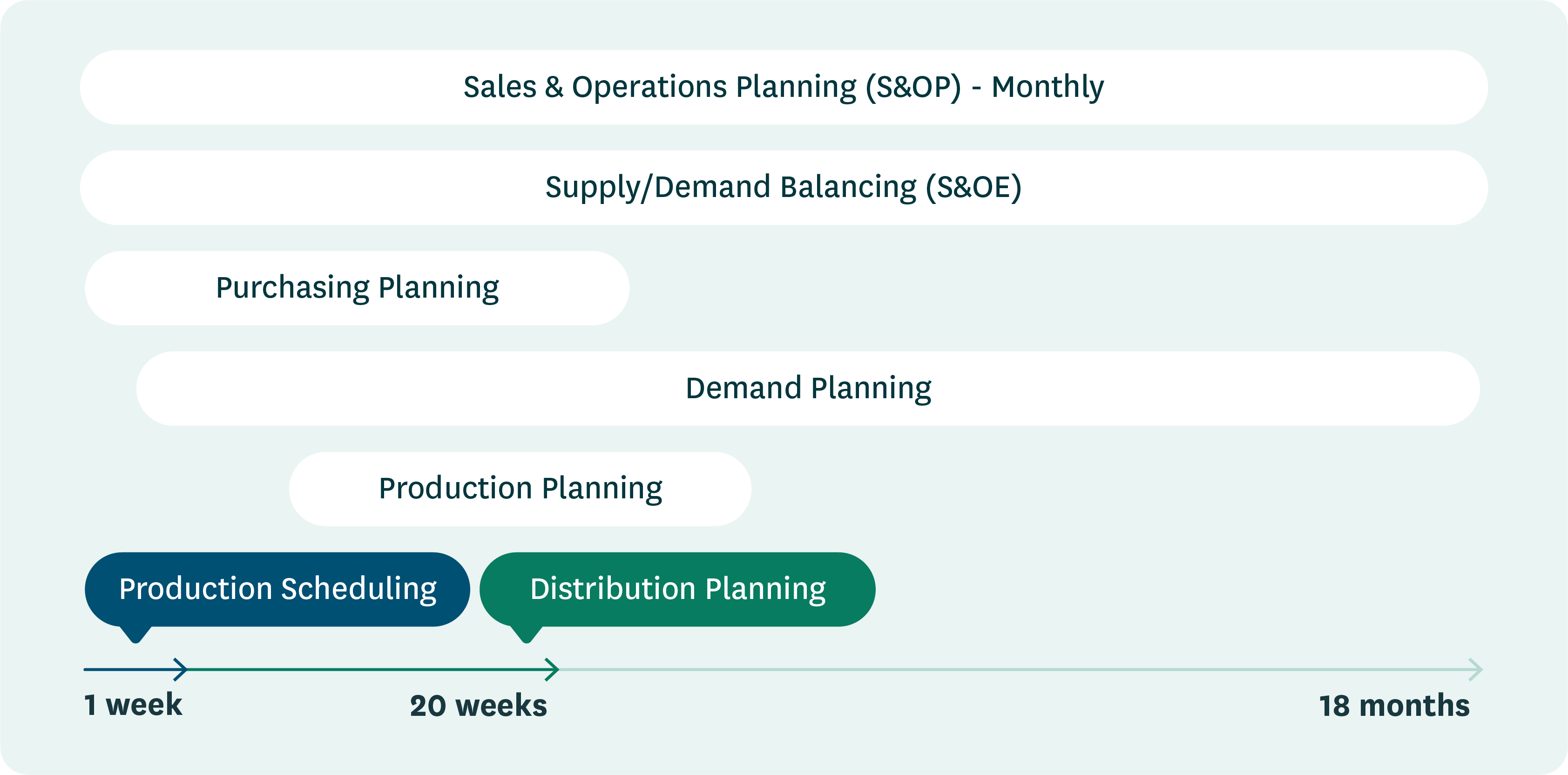

A supply chain planning and optimization solution supports the entire planning process, fully integrating supply chain, production, sales, demand, and livestock forecasting. The software delivers complete, end-to-end supply chain visibility across all departments and empowers organizations to plan over any period.

2. Break down siloes to enable faster decision-making

Livestock sourcing, production, and marketing departments often end up planning in siloes. Priorities disperse between various teams, who can’t share relevant information about goals, tools, and processes between departments.

This insulated decision-making leads to slower, inconsistent planning and execution. Companies can’t factor in all the variables that affect supply and demand, impacting forecast reliability and making it hard to match supply and demand. Despite these negative impacts, this silo mentality has nearly become the norm for many meat producers.

Teams need a holistic picture of all processes and projects to develop a flexible course of action in their decision-making process without sacrificing stability, reliability, and control. Otherwise, they will likely deal with constant bottlenecks that halt productivity and affect clients.

Software designed to break down this silo mentality optimizes workflows and prevents delays that arise from information exchanges among teams. Meat‑processing companies can then think of customer‑centric solutions and manage operations at a new level of speed and scale.

3. Set realistic customer expectations

Meat processing companies must adapt and respond to changing market trends, especially those concerning increasingly volatile demand. Producers and retailers exchange weekly forecasts, but some orders can be revised only 24 hours beforehand. Since the meat industry is highly competitive, companies must attain optimal service levels to secure future orders and cement profits.

The proper planning solution allows companies to meet customer requirements and consider all variables to prioritize orders properly. Effective use of such planning tools helps teams identify and anticipate potential shortages or surpluses and adjust customer expectations accordingly, establishing higher reliability in service. The result is higher customer satisfaction and increased profitability.

The proper planning solution allows companies to meet customer requirements and consider all variables to prioritize orders properly.

The supply chain continues to evolve alongside market needs. Meat producers need capable supply chain planning and optimization software to react to fluctuating customer demands, assess required capabilities, and design a roadmap to meet all desired orders. The ability to better respond to dynamic customer expectations means companies can get their products into customers’ hands faster.

4. Establish longer planning horizons

Spreadsheet-based planning allows most companies to forecast around a week in advance. Customer orders typically have two to four weeks of lead time, meaning meat-processing companies frequently accept orders before they know whether they can fulfill them.

This is especially problematic when it comes to chilled versus frozen goods. Manufacturers generally prefer to sell chilled products, which generate a higher return than frozen ones. Short planning horizons create a lack of visibility into surpluses. This forces manufacturers to freeze the stock to extend its shelf-life, store it while the company formulates a plan, and then sell it for a lower price.

Modern planning software enables meat producers to extend their planning horizon, helping them identify and correct production surpluses and bottlenecks sooner. Earlier identification and corrective action allow companies to:

- Ship more goods chilled rather than frozen, cutting storage time and costs.

- Give greater certainty to customers and suppliers.

- Achieve higher margins, reduce inventory levels, and gain a competitive advantage.

5. Help producers anticipate potential business scenarios

Meat producers strive to achieve and maintain a competitive edge, often quantifying potential business outcomes to devise long-term strategies. Supply chain executives must perform what-if analyses and study how specific roadmaps might affect performance to obtain accurate business forecasts. They might study how profits would be affected by procuring more supply, selling cuts chilled or frozen, offering discounts, or running marketing campaigns. Deeper insights into potential outcomes enable companies to fine-tune business processes and reshape their decision‑making around analytics and hard data rather than gut feelings.

A robust supply chain planning and optimization solution can ease the burden of forecasting sales. Decision‑makers can use statistical analysis based on historical trends and seasonality, reducing uncertainty on the demand side and enabling companies to find a good market for all the cuts in a carcass. Any compromise will result in an impacted profit, so creating alternative plans is essential in empowering executives to foresee market changes and respond accordingly.

6. Build more strategic marketing campaigns

Marketing teams play an increasingly vital role in supply chain management. They provide the necessary demand information that helps balance livestock/meat procurement and hold essential data on details such as:

- Promotions

- Products and availability

- Prices

- Order tracking

- Incentives

- Marketing campaigns

- Sales information

Optimizing supply chain planning strengthens the marketing department. It helps companies make more accurate forecasts, which in turn helps the marketing and sales departments plan more strategic campaigns.

However, active contribution to the supply chain planning process requires marketing teams to obtain inside information to build relationships that help improve operational supply chain efficiency. This information must flow automatically to marketing and key account managers so they can coordinate sales activation efforts accordingly. For instance, a marketing team that receives notice of extra raw material on the supply side can plan sales activation efforts that result in minimized spoilage and a reduced need to freeze the meat.

This end-to-end visibility and cross-functionality also benefit marketers directly. Visibility into supply availability can help marketers make more strategic decisions concerning accepting or rejecting promotion suggestions to maximize profitability.

Imagine a scenario where the software forecasts a production surplus of a specific cut. The marketing and sales departments could plan promotions accordingly, liaising with customers to help sell the stock for a higher price while it is still chilled. This situation would strengthen the company’s competitive position and support the successful distribution of all cuts from the carcass.

7. Adapt intuitively to a fluctuating environment

The fluctuating market environment requires companies to adapt and promptly respond to different variables. Any delay in operations might impact the competitive edge, making easy customization the key to reacting to market trends without impacting operations.

Yet, employees often struggle when asked to switch frequently between scenarios, devise new strategies, and adjust variables. Constant context-switching takes a toll on employees who cannot deal with sophisticated processes simultaneously, and any mistake along the way can have serious consequences.

A comprehensive supply chain management solution makes operations more intuitive for employees. The right solution is much easier to use than spreadsheet-based planning. Employees don’t need to be experts in supply chain planning to formulate accurate planning initiatives because the software will take care of most of the work. This encourages employees to test different scenarios and devise innovative solutions that will positively impact operations.

Plan for an optimized future

Supply chain complexities present both significant challenges and opportunities for meat producers. Adopting advanced planning software is not just a technological upgrade — it’s a strategic imperative for those seeking to navigate the intricate balance of supply and demand and to capitalize on market opportunities. These tools offer a pathway to streamline operations and enhance decision-making, ensuring that every step from farm to fork contributes to greater efficiency and profitability.

The meat production industry must continue to evolve, embracing innovative solutions to stay ahead in a competitive and fluctuating market. Producers can harness the power of sophisticated planning solutions to optimize every facet of their operations, from forecasting and procurement to marketing and sales, to improve margins and ascertain a stronger market position.

Optimize your meat supply chain