Touchless planning is critical, not optional

In today’s manufacturing landscape, the convergence of volatile demand, increasing operational pressures, complex global trade dynamics, and persistent talent shortages has created a perfect storm that traditional planning approaches simply cannot weather.

Legacy planning systems—built on static assumptions and heavily dependent on manual effort—are increasingly insufficient for the challenges of modern supply chain planning. The move toward intelligent automation is no longer just a strategic advantage; it’s an operational necessity.

This is where touchless planning enters the picture.

What is touchless planning?

At its core, touchless planning represents intelligent automation where human intervention only occurs when it adds meaningful value. Rather than relying on planners to make routine adjustments across thousands of SKUs or hundreds of production lines, touchless planning leverages artificial intelligence to handle the bulk of planning decisions, freeing human experts to focus on strategic exceptions and value-adding activities.

Touchless planning is not a luxury or a futuristic concept; it’s necessary for modern manufacturers who wish to remain competitive.

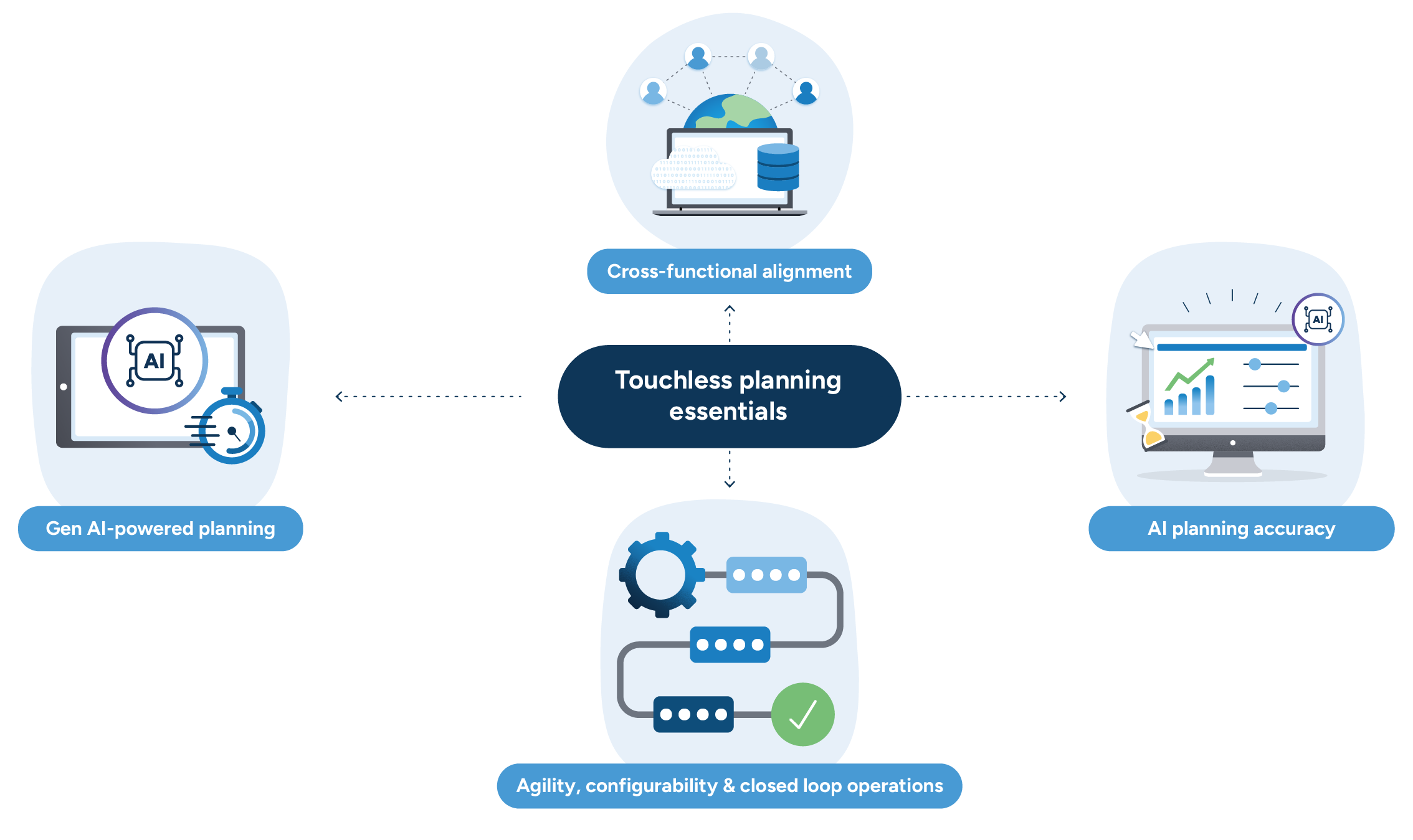

The RELEX approach to touchless planning centers around “golden touches,” where human intervention is precise, purposeful, and adds value. By combining proven AI-powered demand planning and sensing with robust supply planning capabilities, RELEX enables manufacturers to achieve previously impossible levels of planning efficiency and accuracy.

The current state: Planning challenges facing manufacturers

Today, manufacturers face numerous challenges in their planning processes that create inefficiencies, waste valuable resources, and ultimately impact the bottom line.

Manual overrides and planner fatigue

Legacy planning solutions cannot offer sufficient granularity, such as SKU or planning horizon levels, at the speed required. The constant need for human intervention not only consumes valuable time but also leads to burnout among planning professionals. When planners are overwhelmed with routine adjustments, their capacity for strategic thinking diminishes, and the quality of planning decisions suffers.

Disconnected legacy systems and operational silos

When different departments use separate tools that don’t communicate effectively, data silos emerge, and conflicting plans become inevitable. The result is poor collaboration, duplicated efforts, and sub-optimal plans that fail to account for cross-functional dependencies.

For example, a production plan that doesn’t align with demand forecasts or inventory strategies will inevitably lead to excess inventory or stockouts, both costly outcomes for manufacturers. This disconnection increases the need for planners to intervene, which is cumbersome and can lead to erosion of trust in the system’s capabilities.

Three key issues caused by manual, disconnected planning

These planning challenges translate into tangible business problems that affect manufacturers’ competitive position and profitability.

1. Operational inefficiency and higher costs

When forecasts are inaccurate, production schedules are inefficient, or inventory levels are misaligned with demand. Manufacturers face unnecessary costs in the form of expedited shipping, overtime labor, excess inventory carrying costs, or lost sales due to stockouts. In industries with thin margins, inefficiencies that arise due to manual intervention and or planning siloes lead to the difference between profitability and loss.

2. Planner turnover and knowledge loss

When planning roles consist primarily of monotonous, repetitive tasks, job satisfaction suffers, and turnover increases. Each time an experienced planner leaves, valuable institutional knowledge is lost – knowledge that often only exists in the mind of the person who learned to navigate the complexities of the business over time. Businesses need systems that learn from past decisions, capturing institutional knowledge and ensuring that skilled planners are focused on strategic decisions rather than mundane tasks and chasing knowledge.

3. Inability to adapt to ever-changing markets and scale to meet them

Manual planning processes can’t keep pace with the speed of change in today’s turbulent market, leaving manufacturers either reacting too slowly or making hasty decisions without proper analysis. Further, without advanced capabilities, manufacturers often find keeping up with market shifts, let alone growing their business, necessitates a proportional increase in planning headcount. Even in the best of times, recruiting, training, and retaining skilled planners is costly and time-consuming, which is unsustainable for long-term success.

Touchless planning: Key capabilities and real-world results

Effective touchless planning isn’t achieved through a single technology or approach but requires several integrated capabilities working in concert. At RELEX, we drive value for our customers through a unified, AI-driven platform that enables these essential touchless planning capabilities.

AI-driven automation forms the foundation of touchless planning, handling the complex and heavy work across both demand and supply planning functions. This automation enables manufacturers to plan at scale with minimal manual effort while focusing human attention on exception-based workflows.

Cross-functional alignment and unified data that drives efficiency and speed

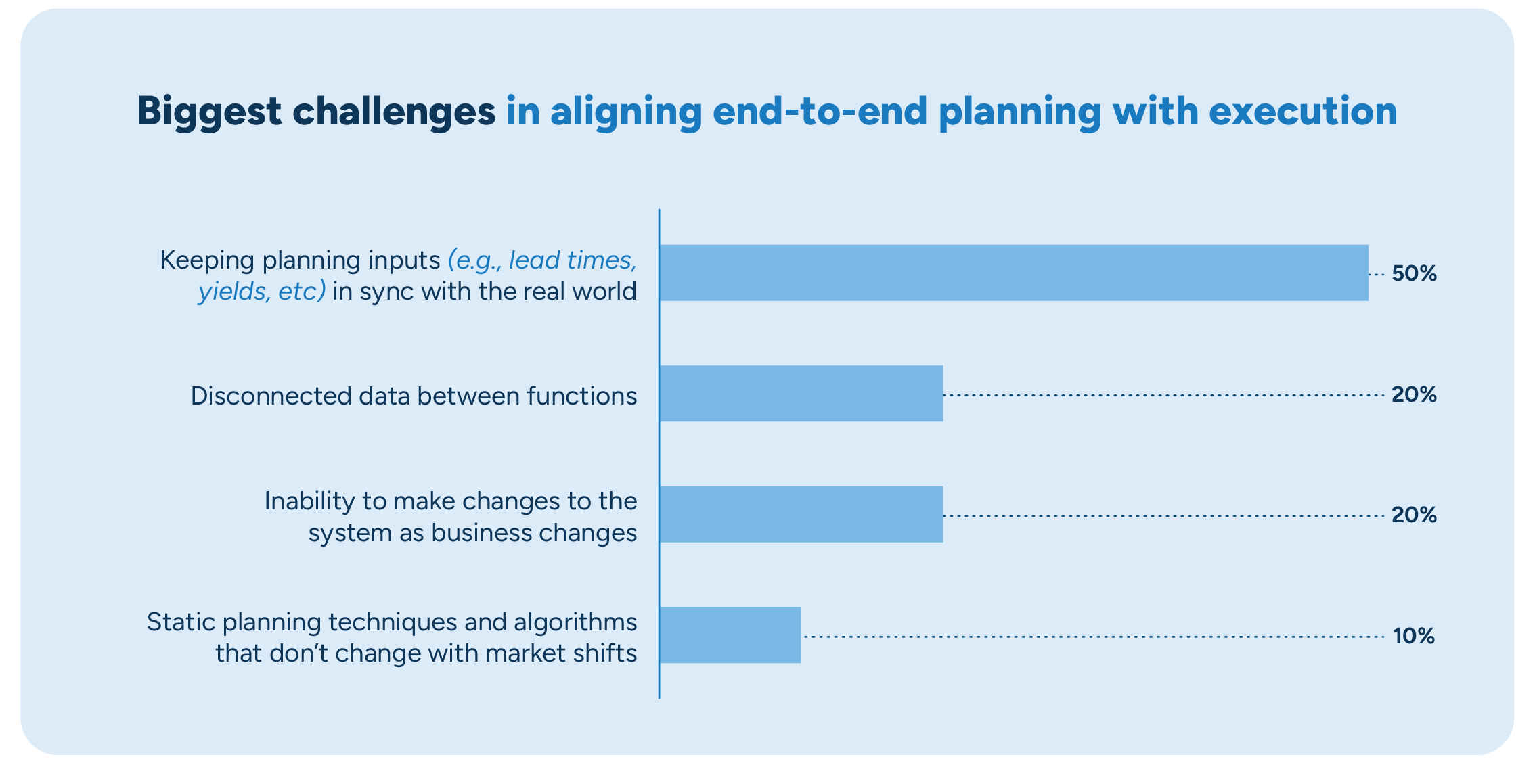

Unified data and planning tools eliminate silos by integrating demand and supply planning across the value chain into a single collaborative platform with intuitive dashboards. This integration addresses one of the most pressing challenges facing manufacturers today.

50% of CPG companies report that keeping planning inputs in sync with the real world is their biggest challenge when it comes to end-to-end planning and execution.

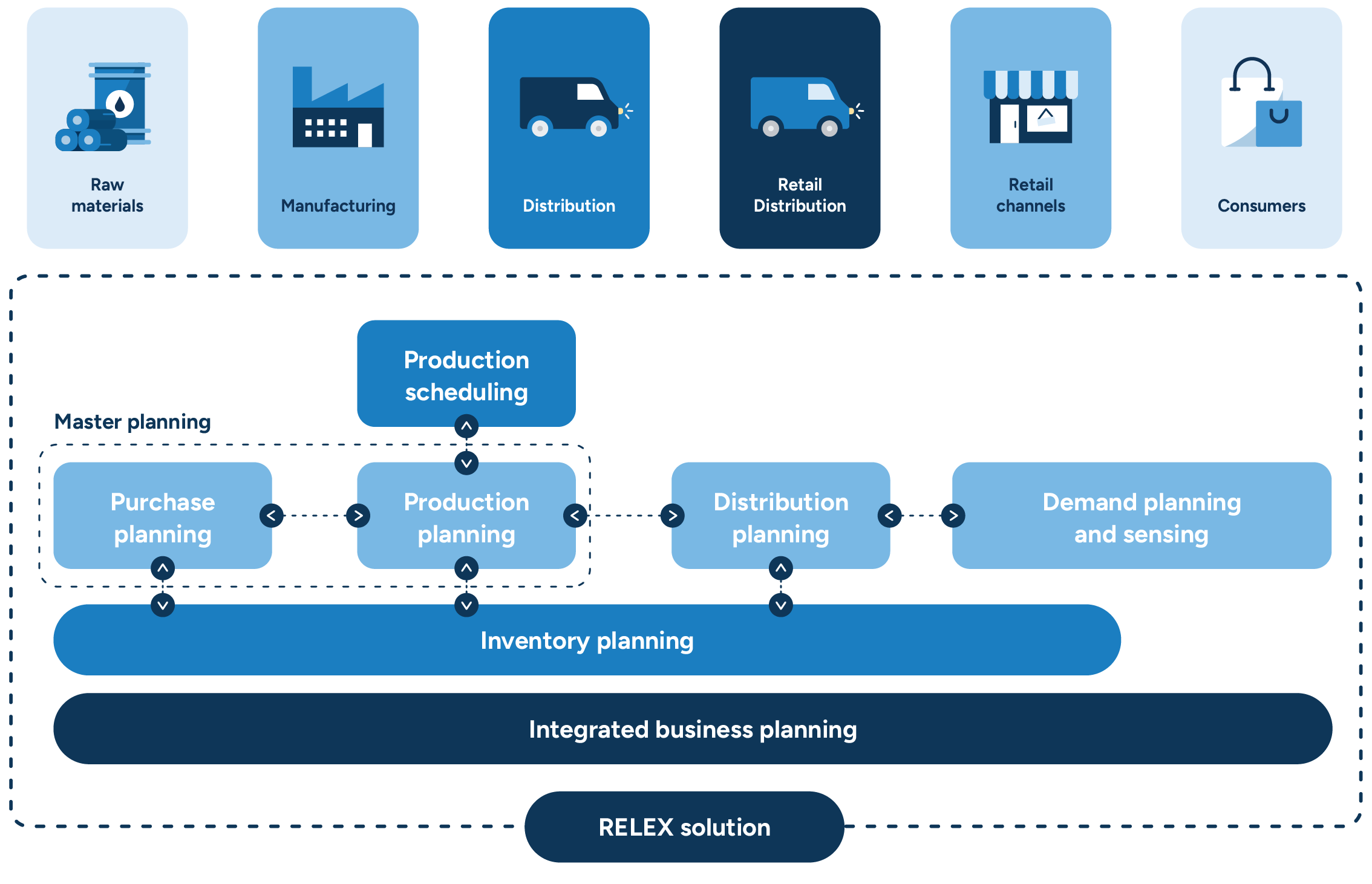

An end-to-end platform like the RELEX solution is vital for manufacturers. RELEX gathers all those planning functions onto a single unified platform, linking them to a shared pool of real-time data and equipping teams with advanced AI-driven capabilities that rapidly assess demand signals, calculate optimal responses, and continuously adapt to changes.

This approach makes it possible to share data with external partners like suppliers and retailers. Unified planning enables true supplier collaboration, a strategic process where retailers and suppliers share information to optimize their operations. This two-way exchange focuses on vital data such as demand forecasts, inventory levels, and point-of-sale (POS) data. The transparency gained from this practice ensures that both parties align their processes more effectively, enhancing supply chain efficiency.

Ensuring that all stakeholders work from a single source of truth – or, put another way, avoiding conflicting sources of truth – prevents the negative impacts and errors that come from disconnects between internal and external stakeholders Using the same solution from day-level operational planning to long-term strategic planning ensures seamless synchronization across time horizons, creating consistency that traditional systems cannot achieve.

RELEX provides scalable, proprietary in-memory columnar database technology, enabling businesses to navigate millions of data points easily and perform rapid calculations across numerous combinations of supply chain nodes, such as product-shelf, store-DC, or product-supplier-transport-factory combinations.

Real-world examples from RELEX customers

The Ametller Origen Group based in Catalonia, is the leading regional provider of fresh food and quality processed products.

Ametller Origen’s forecasts are shared weekly with their suppliers and agricultural department, enabling them to react promptly to meet customer demand. They are also able to optimize pick-up and shipping resources in their warehouses, improving availability and reducing waste and spoilage rates.

“Having RELEX as the single source of demand foresight helps us optimize all our processes within the supply chain, in the broadest sense of the word. Every step in our supply chain has been improved, from our suppliers and agricultural processes, up to the final step in the chain when the customer takes the product home to enjoy it. End-to-end supply chain optimization is the differentiating value of RELEX,” says José Ramón Franco, Ametller Origen’s Purchasing Director of Dry and Refrigerated Products.

The Vita Coco Company is today the world’s largest brand in coconut & plant waters with operations in 31 countries and an annual turnover of 428 MUSD (2022).

However, synchronizing a supply chain spanning 15 factories (and growing), 20+ market warehouses on several continents, servicing every major customer in the US and Europe is challenging.

Jonathan Burth, COO of The Vita Coco Company, says, “Finding the right vendor was crucial. We needed an integrated planning solution capable of modelling and optimizing our entire supply chain. With so many nodes, constraints, and alternative supply routes, the only way to maximize profitability is by using true optimization technology. This is exactly what RELEX offers.”

The ability to create optimized plans that consider costs, real-world constraints, and business preferences has led to significant cost reductions at Vita Coco. Burth confirms this, saying, “RELEX has helped us to unlock millions of dollars in cost of goods value, mainly owing to better sourcing and distribution planning. However, it’s worth noting that this only accounts for reduced landed costs. Improved tactical and strategic decision-making is harder to quantify, but likely accounts for much larger savings.”

Atria Finland, a market-leading company in the meat industry and a RELEX client since 2013, expanded its use of the system in 2022 to enhance collaboration with its many retail partners, such as Minimani.

To improve shelf life and minimize spoilage, the company replaced its previous pre-ordering system and introduced retail data integration as part of its demand forecasting solution. Thanks to access to retail forecasts, Atria gained greater visibility into promotional planning, saved time on manual tasks, and improved collaboration with retailers.

Minimani noted a 3 percentage point increase in promotion availability of Atria products, which are now freshly delivered closer to the start of any given campaign. “With RELEX, the transparency we have into our retailers’ forecasts has genuinely put us on the pulse of the end-customer demand,“ said Mikko Soinio, Planning Manager, Atria Finland. Seeing the changes in short-term demand—almost in real time—gives us more time to adjust and time our production accordingly.”

AI that takes planning accuracy and agility to new levels

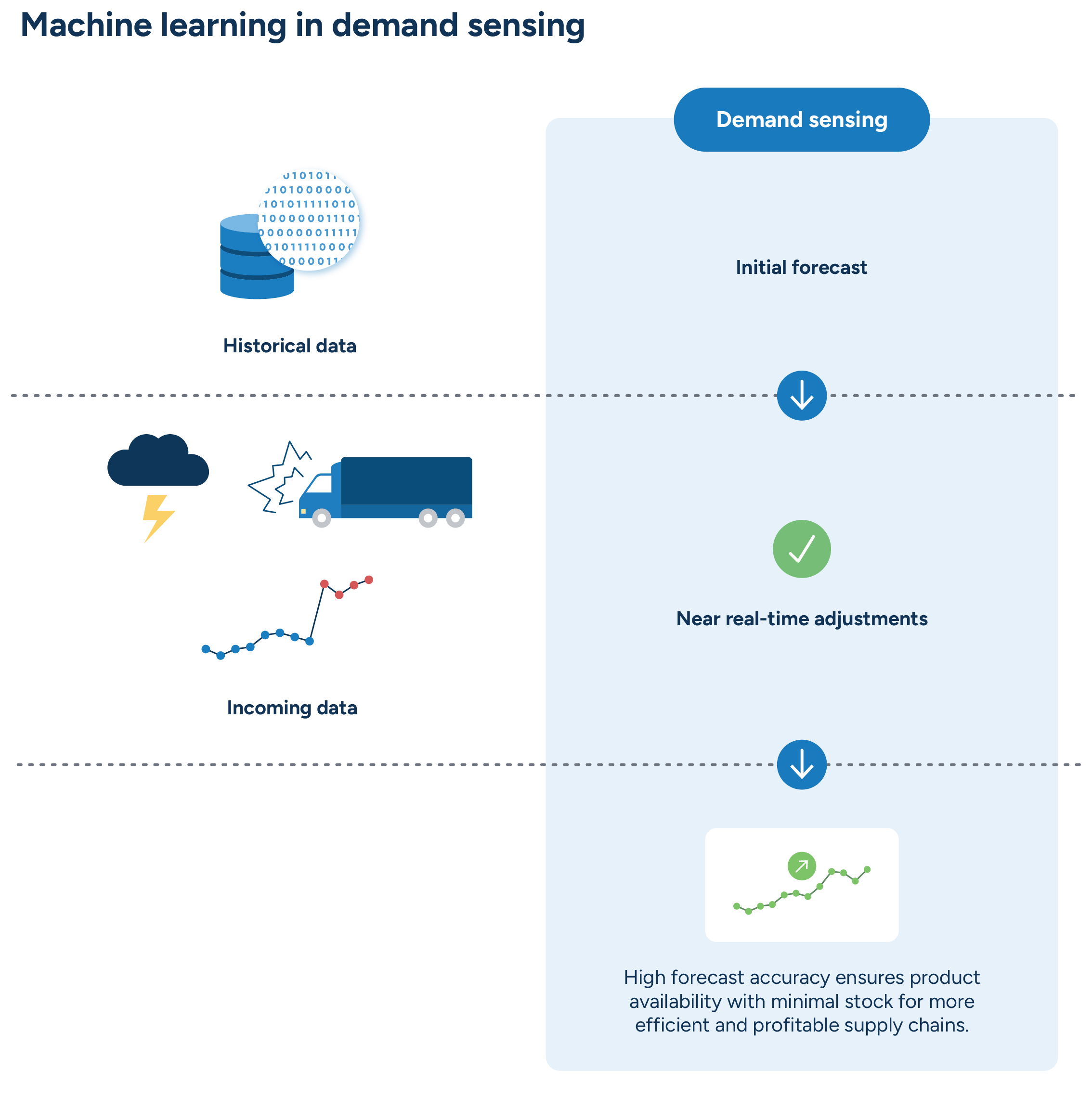

ML-based demand planning and sensing drive accurate forecasts with minimal manual intervention. By leveraging machine learning algorithms that continuously learn from patterns and relationships in historical data, manufacturers can achieve forecast accuracy levels that would be impossible with traditional statistical methods alone.

The demand planner role has transformed from basic forecasting into a sophisticated, technology-driven leadership position that shapes core business strategy. Over the decades, demand planners have evolved from “educated guessers” in siloed environments to data scientists and business insights experts who translate technical forecasting insights into business recommendations.

Adding demand sensing capabilities allows the system to incorporate real-time signals that improve short-term forecast accuracy. The benefit of demand sensing and machine learning-driven forecasting solutions over more manual, legacy approaches like simple rule-based heuristics is the ability to quickly and accurately process vast amounts of data from numerous sources, including external and POS retail data.

Built for speed, demand sensing immediately integrates data for rapid responses to market changes, making it a heavy hitter in short-term demand planning, which is critical for FMCG companies.

Constant data updates and automated adjustments prevent a strict adherence to dated forecasts, and machine learning continuously improves performance. Demand sensing software also considers factors like current trends, retailer decisions, POS data, market conditions, and even external events like inclement weather to improve forecast accuracy.

Real-world examples from RELEX customers

Blount Fine Foods, a manufacturer of premium fresh prepared foods, implemented RELEX demand planning and supply chain optimization solutions across their seven distribution centers and manufacturing operations. These AI-driven solutions helped Blount forecast demand, plan supply, and optimize inventory and production according to their unique production environment’s complexities and constraints.

The company achieved:

- 5% annual increase in production pounds, streamlining operations, and boosting output without changing capacity.

- 35% reduction in finished goods waste, leading to significant cost savings and sustainability benefits.

- 50% reduction in forecast error over two years, improving demand planning accuracy and aligning production with actual needs.

“Having the ability to see how changes to sales forecasting or manufacturing capacity availability impact potential service levels on a longer horizon has allowed us to strategize in advance before the situation arises,” said Jonathan Wells, Sr. Director of Demand Management at Blount Fine Foods. “This has allowed us to make better decisions and explore alternate paths while linking all of our constraints within our manufacturing and supply chain ecosystem together to realize the true impact of a decision throughout the process.”

Norgesmøllene, a Norwegian food producer with roots dating back to 1866, embarked on an ambitious upgrade to their entire supply chain planning infrastructure, choosing RELEX for its robust capabilities and industry expertise.

The transformation centered on implementing advanced demand planning capabilities that generated precise 18-month weekly forecasts across all business areas. The system’s ability to automatically select optimal forecasting algorithms significantly improved demand visibility and forecast accuracy:

- Achieved precise 18-month weekly forecasts across all business areas.

- Significantly improved demand visibility through automated algorithm selection.

- Streamlined S&OP process with enhanced cross-departmental collaboration.

Beyond the numbers, the new system enhanced cross-departmental discussions and streamlined their S&OP process. For a company with over 150 years of history, this technological leap forward ensures they’ll remain competitive for generations to come.

Automated production planning and optimization balance demand forecasts and supply constraints into executable plans optimized to meet strategic business objectives. Whether optimizing production, purchasing, distribution, or inventory planning, these capabilities ensure that supply decisions are feasible and aligned with strategic goals like service levels, cost minimization, or profit maximization.

Through greater efficiency and reduced costs, optimal production planning ensures the best use of available time and resources, safeguards quality assurance, fulfills demand, and maximizes profitability.

At RELEX, we help customers create feasible and executable plans through:

- Comprehensive constraint modeling, including the modeling of inverse Bills of Material for specific industries, that takes the production plans to the day-level

- A tightly integrated production scheduling solution that breaks down the production plan and makes it “executable” by breaking it down to hours and minutes

Tegel Foods uses RELEX to generate demand forecasts and weekly production plans for the entire business.

Each production facility maintains control of the production scheduling, allowing for more local control of detailed day-to-day operations while aligning with company-wide objectives and processes. By incorporating scheduling into overall supply chain planning, the company has improved the S&OP process, increased forecast accuracy and production throughput, and reduced inventory and waste.

“RELEX is a tool that allows us to run the business better,” said Arijit Saha, General Manager of Supply Chain at Tegel. “If you consistently make better business decisions, the financial side will take care of itself. In our case, it certainly has.”

Finsbury Food Group, one of the UK’s leading specialty bakery manufacturers, sought to optimize a diverse network of factories with varying levels of automation and time-sensitive processes.

Finsbury selected the RELEX unified planning solution, with transformative reults. The AI-driven demand forecasting and production scheduling optimization enabled Finsbury to make proactive planning decisions and identify necessary adjustments in labor and resource capacity. Results include:

- £1.6 million reduction in net working capital through smarter procurement.

- Doubled planning team productivity with minimal staff additions.

- 5% Improvement in service levels year-over-year.

Planning teams now work twice as efficiently, handling double their previous workload with the addition of just one team member. Real-time insights have improved collaboration between demand and supply planners, while enhanced scenario planning capabilities help them capitalize on available capacity and optimize working capital deployment.

Agility, configurability, and AI-powered diagnostics

Configurability and closed-loop operations allow the planning system to learn and adapt continuously. Manufacturers can maintain accuracy even as market conditions evolve by leveraging machine learning that dynamically adjusts to shifting conditions in demand and inventory planning.

RELEX has a built-in business rules engine (BRE) that allows users to configure and adapt the solution to business-specific needs and processes and quickly create and modify dashboards without costly and time-consuming customization projects. This “configure, don’t code” approach means users can automate processes and manage decisions by setting or selecting rules that scale with the business. With automation handling the grunt work, teams can focus on managing exceptions, and companies can begin incorporating touchless planning for better planner productivity and faster response times to market shifts.

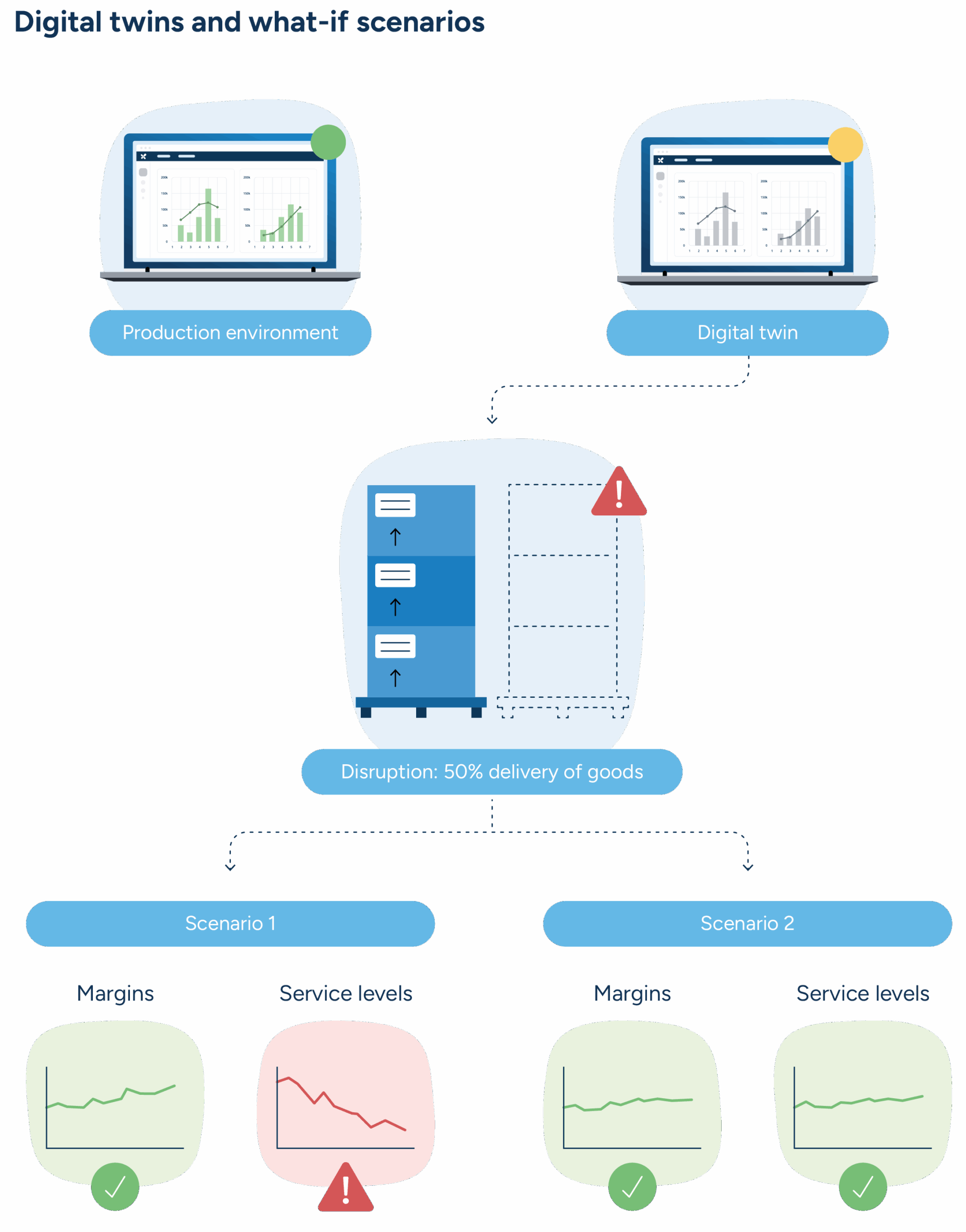

Proactive scenario planning utilizes a digital supply chain twin, a sandboxed environment utilizing real-world supply chain data, to model uncertainties and determine the expected business impacts before plans are implemented.

The importance of scenario planning as a proactive means to mitigate issues cannot be denied. Scenario planning enables decision-makers to simulate “what-if” scenarios and assess the business impact of factors like demand fluctuations, supply disruptions, or cost changes. By running scenarios, teams can predict how different decisions will affect margins and service levels before committing to a course of action.

Advanced AI-driven diagnostics capabilities help planners focus on meaningful exceptions rather than routine adjustments and provide guidance on root causes when intervention is necessary.

RELEX Diagnostics surfaces root causes of plan deviation and flags exceptions in real time to maintain planning integrity, enabling continuous improvement and alignment with real-world conditions. This includes correcting data integrity challenges through anomaly detection and correction, as well as leveraging probabilistic models to correct for inventory inaccuracies.

Gen AI-powered planning assistance

A pivotal step toward touchless planning technology, gen AI systems leverage large language models (LLMs) to summarize and condense data for users, driving faster, easier, and more accurate decision-making.

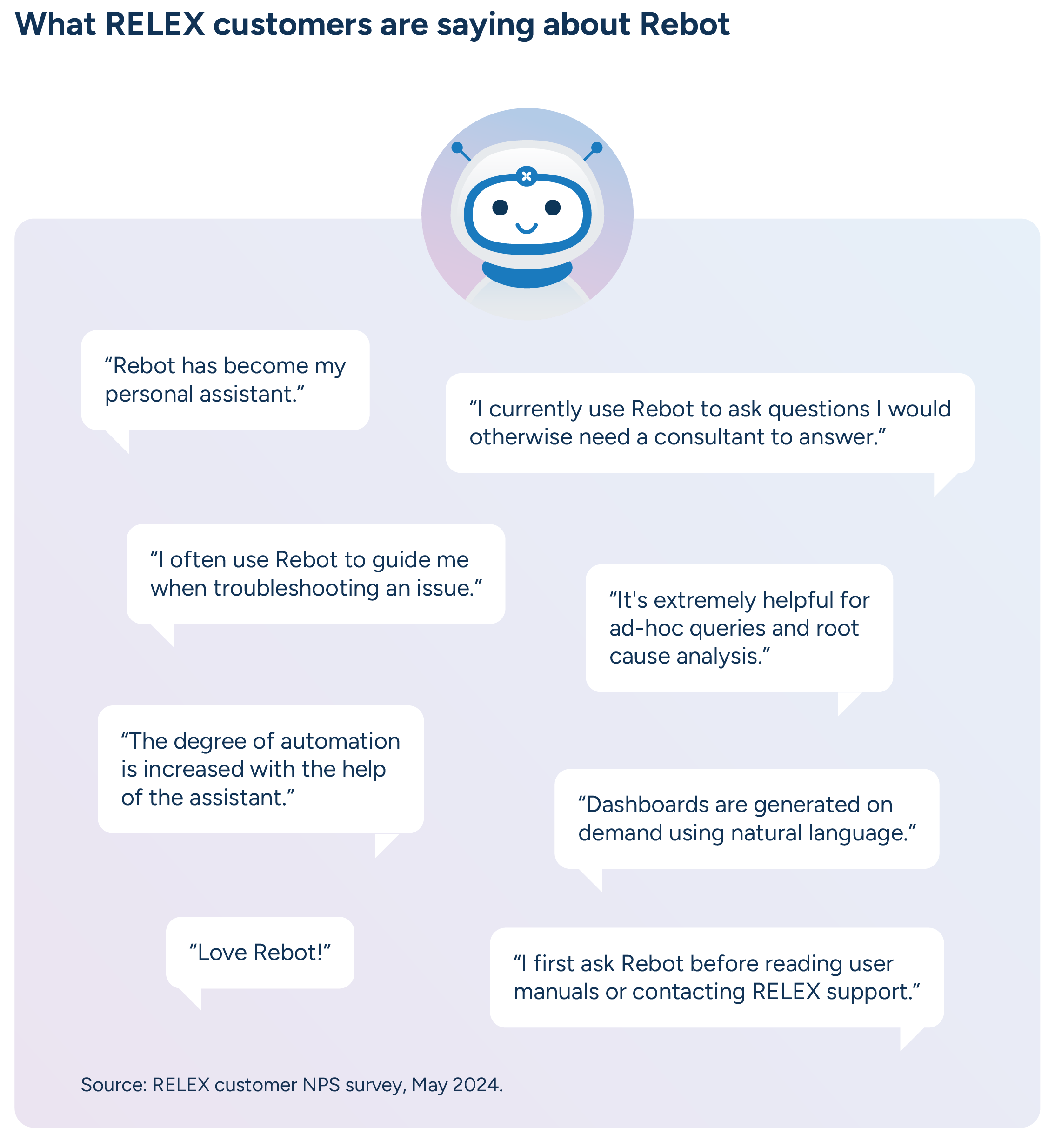

At RELEX, we’ve developed Rebot, which pulls from an established knowledge base of industry- and solution-specific best practices and draws insights from the data in context. Making this information easy to access and understand accelerates employee onboarding, smooths daily operations, and provides continuous learning and process improvement opportunities.

As AI-enabled systems evolve, they will leverage agentic AI that provides company-specific recommendations and proactively assists planners in anticipating and countering market disruptions and shifts. This evolution will transform the profession into a more rewarding and intellectually engaging discipline through unprecedented efficiency, enhanced auditability and transparency, and revolutionary data acquisition capabilities.

RELEX is already integrating these agentic systems into supply chain planning. For example, RELEX Diagnostics analyzes data and identifies the root causes of supply chain issues that might otherwise go unnoticed and unaddressed, helping users prioritize tasks and plan more effectively. In the future, Rebot will be able to answer customer-specific questions regarding demand shifts, planning anomalies, and recommended actions.

The transformative impact of touchless planning

The business impact of touchless planning extends far beyond theoretical benefits, delivering measurable improvements.

We’ve seen manufacturers achieve up to 98% touchless forecasts in certain categories. When AI handles nearly all forecasting decisions automatically, human planners focus only on the small percentage of exceptions that truly require their expertise. Further, planning systems that generate higher-quality plans from the start dramatically decrease the need for manual adjustments.

This level of automation reduces the risk of human error and ensures greater consistency in planning outputs, dramatically increases planning efficiency while typically improving forecast accuracy.

Another significant benefit is waste reduction across production and inventory, directly impacting the bottom line. By matching supply with demand more accurately, manufacturers minimize overproduction, decrease inventory obsolescence, and reduce the need for markdowns or disposals. For food manufacturers, this waste reduction is particularly valuable, with some reporting up to a 35% reduction in production waste.

Enhanced capacity utilization without additional capital expenditure creates “free” capacity that supports growth. When waste is eliminated and production planning is optimized, manufacturers often discover they can produce significantly more with their existing assets.

The strategic value of touchless planning

Scaling business without proportional headcount increases enables profitable growth. Companies like Finsbury Food Group have doubled their revenue while only marginally increasing their planning team, demonstrating that touchless planning breaks the traditional correlation between business growth and headcount requirements.

More gratifying planner roles focused on high-value activities improve talent retention and development. When freed from monotonous data manipulation and endless adjustments, planners can focus on strategic decision-making, scenario planning, and continuous improvement initiatives.

Enhanced resilience against market volatility and disruptions provides a competitive advantage in uncertain times. With touchless planning, manufacturers can quickly forecast, reoptimize, and adapt to changing conditions—whether a demand spike, supply disruption, or shift in global trade policies. This agility is increasingly essential in today’s volatile business environment.

Better cross-functional alignment and decision-making emerge when all stakeholders work from a unified planning platform. Decisions become more coordinated and effective when sales, operations, finance, and supply chain teams share the same view of demand, capacity, and inventory. This alignment eliminates the “functional silos” that plague many manufacturing organizations and lead to sub-optimal outcomes.

From manual to touchless planning: the path to digital transformation

The journey to touchless excellence begins with an honest assessment of your current planning maturity and a commitment to progressive improvement. Whether you’re just beginning to explore automation opportunities or looking to take an existing touchless planning initiative to the next level, the path forward requires both technological capability and organizational readiness.

Maturity journey

Implementing touchless planning is best approached as a phased journey rather than a binary switch.

Assessment of current planning maturity provides the starting point for any touchless planning initiative. Understanding the current state of planning processes, systems, data quality, and team capabilities helps organizations identify the most valuable opportunities for improvement and develop a realistic roadmap.

A phased approach to implementation effectively manages change and builds momentum through early wins. Most successful implementations begin with specific planning domains (e.g., demand planning for stable products) where touchless approaches can deliver quick value and gradually expand to more complex areas as capabilities and confidence grow.

Measuring success through operational KPIs and business outcomes ensures that touchless planning initiatives remain focused on value creation. Key metrics might include forecast accuracy, planner productivity, inventory levels, service levels, and waste reduction. Monitoring these indicators helps organizations track progress and demonstrate the return on investment from touchless planning initiatives.

Building trust and adoption

The journey to touchless planning requires careful attention to trust-building and change management.

Explainable AI builds trust in automated planning by providing visibility into complex calculation assumptions and key performance indicators.

Unlike “black box” algorithms that provide no insight into their decision-making, explainable AI allows planners to understand why specific recommendations are being made. This transparency reduces the need for gut-feeling-based overrides and helps planners develop confidence in the system. Furthermore, GenAI-powered insights and assistance boost planner productivity and system adoption by providing intelligent guidance when needed.

Digital assistants providing planner guidance enhance the user experience and accelerate the learning curve. These assistants, powered by generative AI, can answer questions, explain system recommendations, and guide planners through complex tasks. As one leader described it, “You have your digital colleague, for lack of better words, that is helping you along the way.”

Change management and culture building are foundational elements of touchless planning. True touchless planning hinges on removing approval layers, especially for key decisions. Empower your planners and trust them to make choices aligning with company interests, rather than pushing decisions up the hierarchy.

The competitive advantage of touchless planning

The imperative for manufacturers is clear: touchless planning is essential for staying competitive in today’s complex, volatile, and fast-paced business environment. Organizations that cling to manual, disconnected planning approaches will increasingly be at a disadvantage compared to competitors that have embraced intelligent automation.

In an increasingly complex world, touchless planning isn’t just about efficiency; it’s about creating capacity for growth and innovation. By freeing planners from routine tasks and enabling more accurate, adaptive planning processes, manufacturers can respond more effectively to challenges and opportunities alike. In this sense, touchless planning isn’t merely a planning approach; it’s a strategic advantage that enables manufacturers to thrive in an environment where agility, precision, and scalability are paramount.

Touchless planning FAQ

What is touchless planning?

Touchless planning refers to the use of AI, automation, and advanced analytics to handle routine supply chain decisions without manual intervention. It enables systems to automatically generate forecasts, replenish inventory, and respond to changes in demand using real-time data. The result is a faster, more consistent planning process that improves operational efficiency.

Rather than relying on human planners to review and adjust data daily, touchless planning shifts the burden to intelligent systems. This allows businesses to scale their planning capabilities while reducing the risk of human error. Planners can then focus on strategic decision-making and managing exceptions that require human judgment.

How is touchless planning different from traditional planning methods?

Traditional planning relies heavily on manual analysis, rule-based decision-making, and periodic updates. It’s often reactive, requiring teams to spot issues and respond after the fact. In contrast, touchless planning continuously monitors data streams and makes adjustments automatically, often before problems arise.

With traditional planning, teams are burdened by repetitive tasks like updating forecasts or adjusting replenishment parameters. Touchless planning eliminates much of this manual work, enabling faster and more agile responses. It transforms planning from a manual, time-consuming process into a streamlined, proactive capability.

What are the main benefits of implementing touchless planning?

Touchless planning dramatically improves efficiency by automating repetitive tasks and accelerating decision cycles. This leads to faster responses to demand shifts, reduced inventory waste, and better alignment with customer needs. It also helps businesses operate more consistently at scale.

In addition to operational benefits, touchless planning empowers planners to focus on higher-value activities like strategy and exception management. It reduces the cognitive load and stress associated with manual workflows, improving job satisfaction and performance. Ultimately, it drives profitability by improving accuracy, speed, and resource utilization across the supply chain.