Unified retail space optimization drives tangible value

May 2, 2024 • 6 min

Customers may take seamless shopping experiences for granted, but retailers know better.

Space planners labor over shelf space management, even as ever-changing consumer demand constantly complicates the task. If retailers can’t get their space allocation right, they risk consequences ranging from potential stock-outs and lost sales to excess stock and high waste levels. These issues further impact store staff, who spend additional time on in-store tasks like re-shelving rather than focusing on enhancing customer experience.

Traditional approaches to these challenges can offer many benefits. Category or cluster-level planogramming are straightforward approaches that can improve brand consistency, customer shopping experience, and merchandising compliance. However, these approaches aren’t tailored to an individual store’s unique requirements.

Too many retailers — even enormous, sophisticated companies — are still at this level despite numerous opportunities for improvement.

Some retailers have been implementing store-specific planograms for about two decades and still struggle to achieve consistent success across all categories. Store-specific planogramming is hard to get right without a solution to automate and optimize the process, taking much of the calculation work out of planners’ hands. However, the benefits are significant. An automated solution that creates store-specific planograms can typically drive improvements such as:

- 1-3% sales increase

- 5-10% waste reduction

- Increased product availability

Store-specific planograms can generate remarkable benefits, but it’s unfortunately impossible to consistently guarantee these targets. Too many factors outside a retailer’s control can impact these traditional KPIs — from unseasonable weather to a competitor opening a store down the street.

Fortunately, retailers can take steps to see assured benefits from their space planning — specifically, by adopting unified retail space optimization to efficiently manage shelf space and align product placement with consumer demand.

Unified retail space optimization generates consistent, tangible benefits

Unified retail space optimization allows businesses to enhance category management and build a more tangible business case by breaking down functional silos. Retailers can combine space, inventory, supply chain, and even workforce planning into a single unified solution to realize the benefits of store-specific planograms.

The two most apparent tangible benefits of unified retail space optimization arise from:

- The reduction of excess stock, mitigating the need for employees to move inventory that doesn’t fit shelves to backroom storage.

- The use of order proposal optimization to reduce delivery frequency at the product level and improve product handling efficiency.

These two tangible benefits work to remove product handling costs across the supply chain — in both DCs and stores — reducing a product’s overall cost to serve.

Excess stock reduction

Consider what happens when space and supply chain planning teams have little or no visibility into each other’s data and plans. The space planner creates a planogram with the right products in the right amounts for a store — but the supply chain team generates an entirely different, higher forecast based on how those products will actually sell.

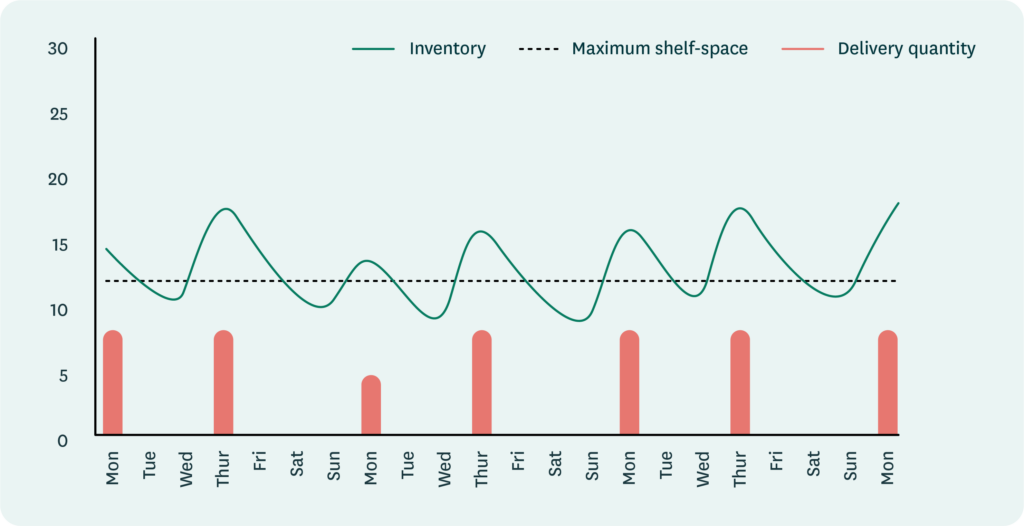

When the delivery arrives, store staff discover a difference between the amount of product the supply chain team ordered for the store and what the space team laid out in the planogram (Figure 1). With too much inventory to fit the allotted shelf space, staff must figure out how to handle the excess inventory levels.

There are only a few ways to deal with this disconnect, including:

- Cramming items into the sides and tops of the shelves

- Creating messy displays

- Moving excess inventory across the store into backroom storage.

Further, if the shelf empties too quickly, employees must identify the gap, return to the backroom to check availability, and replenish the shelf if inventory is available.

Retail stores often suffer unnecessarily high operational costs when staff cycle through this never-ending process of moving inventory from storage to shelves. They also risk losing sales when the staff can’t identify the empty shelves quickly enough, locate products quickly in the backroom, or if the supply chain team sends too little stock to fill the shelf to begin with.

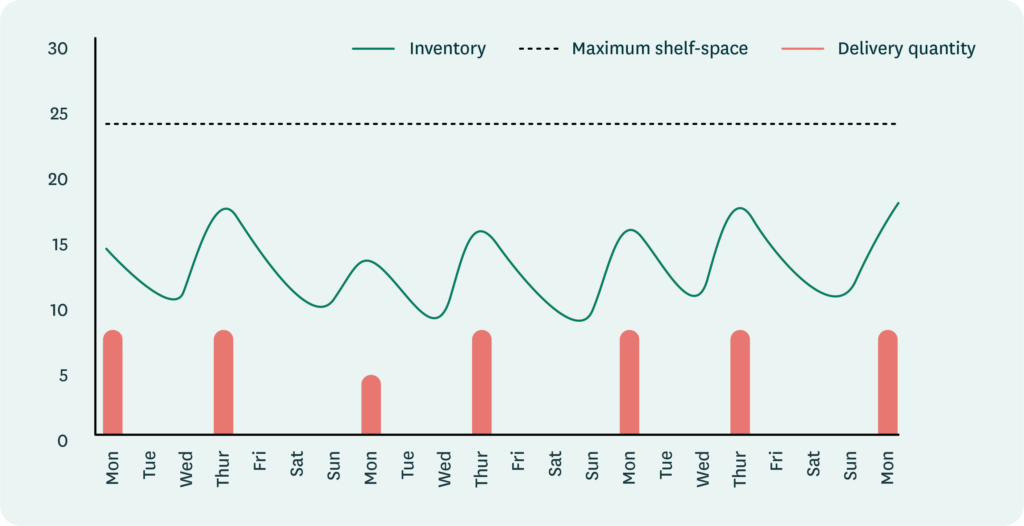

Unified planning improves visibility into space plans and constraints, enabling supply chain and ordering teams to optimize both order quantities and how frequently distribution centers need to pick items. On the other hand, space planning teams can build more accurate planograms from store-level sales forecasts that include weekday or seasonal variations and any planned promotional activity.

Order proposal optimization

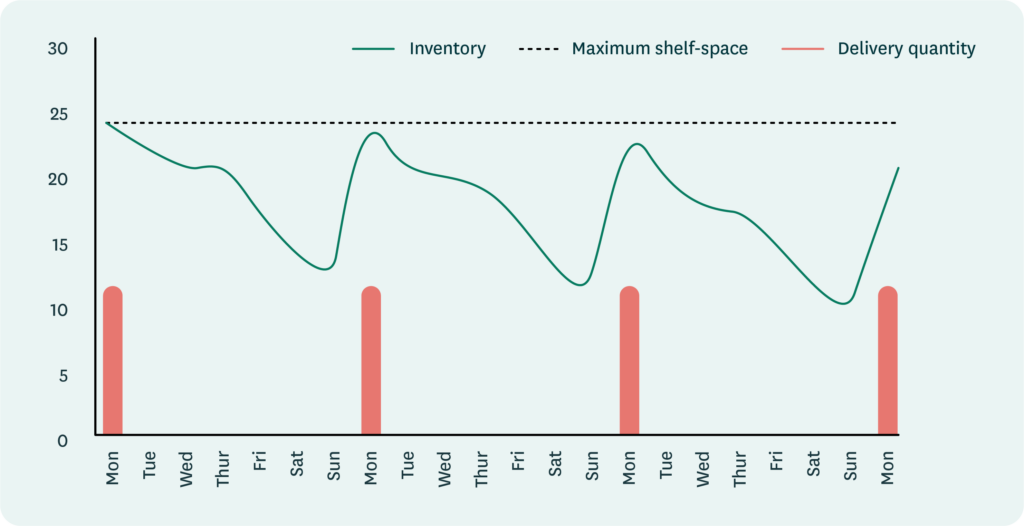

Accurate, automated direct-to-shelf replenishment through unified retail space optimization doesn’t demand excessive manual calculation work from planners. The same applies to the frequency of product-store deliveries or the number of times employees pick items in distribution centers.

Just as direct-to-shelf replenishment improves operational efficiency in retail stores, reducing product-store deliveries improves operational efficiency in distribution centers. If the supply chain solution has access to space planning data—what space is available at each store and what products are shelved in what quantities—it can optimize the number of times items must be picked at the distribution center, enhancing order proposal optimization.

This efficiency level is essential for fast-moving items, which should be picked less often and in larger quantities to last through delivery cycles. Distribution centers can feed space information into supply chain planning to send larger quantities of fast-moving items to stores with less frequency, reducing the number of times they need to pick them.

Measurable results: The benefits of unified planning

Successful unified retail space optimization efforts allow businesses to see all the benefits of localized space planning. Companies like East of England Co-Op have seen a 2.2% sales increase through store-specific planogramming, while others have seen a 12% improvement in inventory turnover. Circle K saw over 10% inventory reduction in their most challenging category, tobacco, and a 2% increase in availability.

Beyond these traditional, difficult-to-guarantee KPIs, unified planning provides tangible operational cost reductions by reducing shelf breaches and product-store deliveries. In our experience, retailers can see up to 1% OPEX savings from direct-to-shelf replenishment, a 25-35% reduction in product-store deliveries, and a 15-25% reduction in overstock. Retailers selling products with expiry dates can see 5-10 % waste reductions through optimized facings. Finally, with store staff relieved of time-consuming shelving and re-shelving tasks, they have more time to focus on achieving high levels of customer satisfaction.

Most importantly, a sophisticated unified planning solution can deliver all these benefits while allowing retailers to adapt quickly to changing business conditions and strategies. The right solution can automate planograms and optimize for any fixture—not just standard shelving—while considering product additions and deletions.

RELEX develops solutions with a “configure, don’t code” approach that considers how different needs can be between retailers or even categories within a single business. Retailers using a modern solution no longer need to outsource their back-end coding work whenever they want to adjust their processes. Today’s planning teams can innovate and experiment through flexible configurations, amending their automation and optimization processes quickly and efficiently.