Customer video: AutoZone

Annie Hook, AutoZone VP of Replenishment, sat down with us to share insights into why they partnered with RELEX to streamline forecasting and replenishment for their distribution centers and boost vendor collaboration.

RELEX helps wholesale distributors of automotive parts and tools improve planning across different functional areas, from forecasting and replenishment to workforce optimization. Distributors can eradicate silos and optimize cost reductions with improved supply chain visibility and updated labor requirements.

98%

availability

Improved

efficiency through automation of manual work

High

availability without excess stock

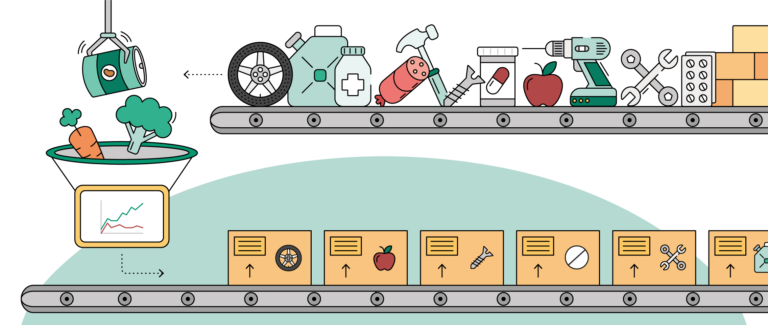

Wholesalers of automotive parts and tools face complex challenges including new product introductions, seasonality, slow movers, price changes, supplier restrictions, and strict delivery schedules.

For automotive parts wholesalers, the challenges of inventory turnover and low availability can lead to high costs and lost sales. A reliance on manual processes and disconnected legacy systems can make overcoming these challenges difficult.

The flow of goods received from suppliers needs to be aligned with available labor at distribution centers to avoid expensive overtime and ensure deliveries align with warehouse capacity.

A broad assortment, including slow movers and seasonal products (with long lead times and fluctuating demand) can make it difficult to generate accurate forecasts.

The misalignment between supply chain and operations planning, caused by a lack of transparency across departments, can result in lost sales, diminished profits, and dissatisfied customers.

Use the power of automation and AI-driven solutions from RELEX for accurate supply chain planning to improve efficiency and capacity planning, increase sales, and drive down the cost of inventory.

We’ve accumulated a wealth of supply chain & retail expertise from our 1,500+ planning specialists.

FTZ replaces legacy system to get a more efficient supply chain, better process support and, above all, to guarantee high availability throughout the entire organization.

Discover how wholesalers can tackle challenges and improve wholesale supply chain efficiency to increase margins.

We’re happy to discuss your business needs and share how our market-leading, unified platform can help you drive profitable growth across your sales and distribution channels. Discover why top industry analysts position RELEX as Leaders in the market.