How attribute-based planning maximizes profitability in food manufacturing

Oct 14, 2025 • 11 min

At 6 AM, a premium meat processor receives same-day orders from high-end restaurants requesting prime-grade steaks with exceptional marbling. The same processor also has orders for standard-grade meat from retail chains. Yesterday’s cattle processing yielded cuts spanning the entire quality spectrum — from premium restaurant-quality beef that commands top dollar to standard cuts suitable for everyday retail sales.

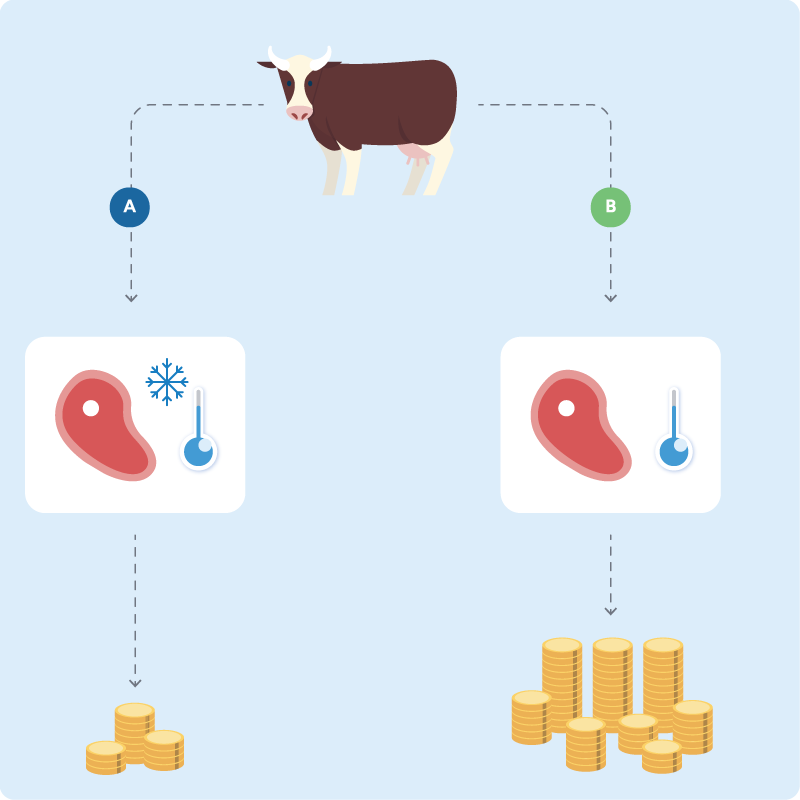

The critical decision: Should premium-grade inventory fulfill standard orders to guarantee delivery, or should it be reserved for customers willing to pay premium prices?

For food processors and manufacturers, answering this question profitably requires more than experience or intuition. It demands attribute-based planning, which treats each raw material’s unique characteristics as optimization variables. Traditional planning ignores these attributes, missing crucial profit opportunities for meat processors, poultry producers, and other food manufacturers — especially when raw materials vary in size, quality, and grade.

If companies hope to use attribute-based planning to capture the full value of every cut, they’ll need optimization software to manage the nuances of raw material variability. That’s why many are turning to RELEX: to ensure maximum profitability and customer satisfaction from every cut of meat.

What is attribute-based planning?

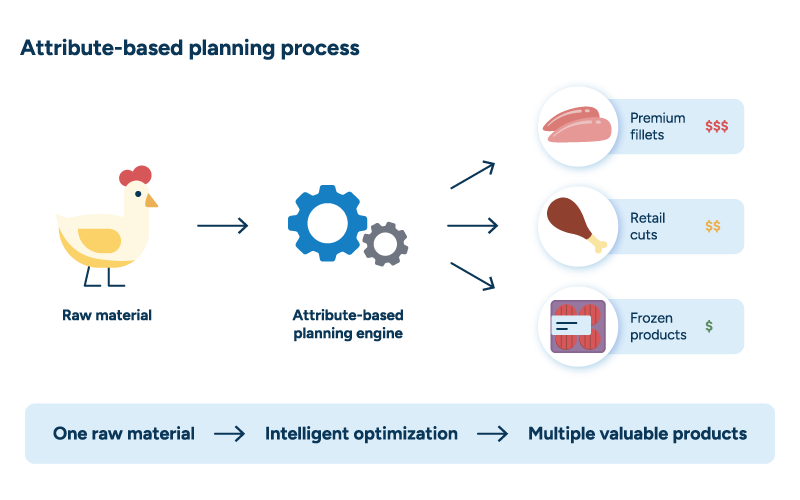

Attribute-based planning, or carcass balancing in the meat industry, is a sophisticated production planning approach that considers multiple characteristics, or “attributes”, of raw materials when determining optimal production allocations.

Rather than treating raw materials as uniform commodities, this methodology recognizes that each piece of inventory has distinct (non-uniform) properties that affect its profitability for different finished products.

The goal is to maximize profitability through intelligent resource allocation and management. Instead of following fixed recipes, it considers multiple pathways from one raw material to various finished goods through different cutting and processing decisions.

This includes factors like:

- Size variations (different fillet sizes)

- Quality grades (high-quality vs. lower-quality cuts)

- Profitability per attribute

- Customer importance and strategic value

Attribute-based planning enables dynamic decision-making through real-time choices about optimal raw material utilization based on current demand and profitability drivers. It focuses on global optimization by considering all factors simultaneously rather than making isolated, one-by-one decisions.

The planning process involves matching supply attributes with specific demand requirements across multiple dimensions. This creates a complex optimization challenge that considers not just quantity but quality, timing, customer priorities, and profitability targets. Unlike traditional planning, which relies on standard production patterns or fixed cutting plans, attribute-based planning operates at a granular level and captures the value from real-world variety in raw materials and market demands.

How attribute-based planning works in practice

Attribute-based planning transforms how food manufacturers make daily production decisions by systematically organizing raw materials and demand around specific characteristics rather than treating inventory as uniform commodities. The process begins by segmenting raw materials based on their key attributes, then establishing the planning framework that matches these attributes to customer requirements and profitability targets.

The process involves continuously matching supply attributes with multiple types of demand:

- Premium customer orders requiring top-grade cuts with strict size specifications

- Retail contracts with broader tolerances but higher volume commitments

- Strategic accounts that demand priority fulfillment regardless of immediate margins

- Secondary channels for redirecting surplus or off-specification inventory

Rather than following aggregated planning approaches or defaulting to first-in, first-out allocation rules, planners work with attribute-enabled systems that consider every unique characteristic of the raw material and determine the most profitable allocation path.

Attribute-based planning considers the entire product portfolio and customer base simultaneously. A single decision — such as assigning a premium fillet to one order — affects what’s available for others. That’s why the process emphasizes global optimization, balancing all constraints and opportunities at once to ensure the best overall outcome.

When this planning approach is embedded in daily operations, it enables food manufacturers to dynamically adapt to incoming orders, prioritize key customers, and minimize lost value through effective surplus allocation. It’s not about squeezing more out of a limited supply; it’s about directing every cut to where it drives the most value.

The benefits of attribute-based planning in optimizing manufacturing decisions

Attribute-based planning delivers measurable improvements across multiple areas of food manufacturing operations. These benefits range from immediate cost savings to strategic competitive advantages that transform business performance.

Increased profitability and revenue

With intelligent attribute-based planning, manufacturers can maximize revenue by matching raw materials with their highest-value applications. Rather than using first-in-first-out allocation strategies, the system considers profitability drivers when making assignment decisions. Premium raw materials are directed to premium products, while lower-grade inventory serves standard market segments.

This optimization can deliver significant profit improvement opportunities that manual allocation approaches often miss. Manufacturers report increased sales of fresh products, reduced freezing costs, and improved customer service levels through more precise demand fulfillment.

Reduced surplus and waste

When the attributes of non-uniform raw materials are optimized during planning, manufacturers can better balance supply and demand across their entire product portfolio. The system identifies surplus situations early and suggests production adjustments to minimize excess inventory. When a surplus is unavoidable, optimization algorithms determine the best products for excess allocation to minimize financial impact and product spoilage.

This reduction in surplus directly improves operational efficiency, reduces storage costs, and minimizes shortages that lead to missed sales opportunities. Less inventory requires less freezing time, resulting in lower energy costs and improved cash flow through faster inventory turnover rates.

Operational efficiency

Manual planning consumes a tremendous amount of time that optimization software can complete in minutes. It improves order fulfillment by more effectively matching the right products to customer requirements. This enables production planners to make faster, more informed decisions using real-time data and insights about raw material utilization. With automated attribute-based planning, food manufacturers can reduce costly manufacturing downtime and optimize production processes.

Enhanced planning capabilities

Attribute-based planning software provides a holistic view of all production variables simultaneously, offering a speed of analysis and rescheduling that would be unachievable using manual planning methods alone. With this comprehensive approach, production planners can ensure that they make optimal decisions that benefit the entire production system rather than making isolated choices with unintended consequences.

The challenges food manufacturers face in implementing attribute-based plans

Attribute-based planning unlocks significant margin potential, but it’s not easy to execute. Food manufacturers commonly encounter key obstacles when implementing this approach. Understanding these challenges helps companies prepare for successful deployment and avoid common pitfalls.

Data granularity

Attribute-based planning requires detailed raw material data, including size distributions, quality grades, processing yields, and other attributes that drive production decisions. While this data may exist in ERP systems or reside in planners’ experience and knowledge, the challenge lies in effectively utilizing this information for optimal planning decisions.

Many manufacturers have historically failed to differentiate cuts by quality, treating all products as equivalent. This prevents companies from capturing essential attribute data needed for profitable optimization.

Creating data infrastructure represents a significant implementation hurdle. Organizations must establish processes for collecting, validating, and updating data while training staff on granular information systems. Finding the right planning granularity requires striking a balance between detail and execution capabilities.

Technical and process complexity

Matching raw materials with demand across multiple dimensions, such as size, quality, timing, customer priority, and profitability, creates a problem too complex for traditional tools or heuristics. Food processors may handle thousands of allocation decisions across multiple lines daily, and each additional variable creates exponentially more possible production plans.

Real-time demands create additional pressure. For example, restaurants order premium steaks the morning before delivery, requiring immediate inventory and capacity assessment. The perishable nature of food makes timing critical, with narrow processing windows for quality and safety. Food manufacturers face the ongoing challenge of identifying the most optimal solutions rather than settling for the first feasible option that meets basic requirements.

Excel-based planning can become increasingly slow, complex, and difficult to maintain when scaling to vast amounts of products across multiple processing lines and diverse portfolios. Manual approaches that work effectively for small operations often fail to deliver results within the short timeframes required by modern food manufacturers, leading to reliance on simplified heuristics that may miss optimization opportunities.

The best attribute-based planning systems use sophisticated optimization algorithms to present clear, actionable results for planners. This allows planners to focus on strategic decisions rather than getting bogged down in difficult calculations.

Execution and capability matching

Planning sophistication must align with operational capabilities. When sales teams can fulfill customer needs with broader product specifications or less granular classifications, highly detailed attribute planning may not add significant value. Companies need execution processes that support their planning precision.

The key is ensuring that added intricacy delivers genuine value. Rather than implementing attribute-based planning for its own sake, manufacturers should focus on areas where detailed optimization generates meaningful profitability improvements. Some companies may find that simpler balancing approaches already meet their needs effectively, and there’s no requirement to add unnecessary complications to functioning processes.

Industry-specific challenges

Certain food manufacturing sectors face distinct attribute-based planning complexities that amplify implementation challenges.

Poultry processing deals with natural size variation across each batch of birds. For instance, breast fillets must be precisely sorted by weight ranges—frozen packages requiring 160-180 gram pieces cannot be substituted with 200-220 gram alternatives. Processors must balance competing customer priorities and price premiums while minimizing costly surplus that requires freezing. Strategic accounts may demand prioritized service regardless of immediate profitability, creating additional optimization constraints.

Red meat processing introduces quality grading complexity where premium cuts with excellent marbling command significantly higher prices than standard grades. The same physical cut can be sold at multiple quality levels. A premium cut can be downgraded to standard pricing, but standard cuts cannot be upgraded to premium pricing. Additionally, fresh meat commands substantially higher margins than frozen alternatives, making freezing a last resort that immediately reduces profitability. This forces meat processors to balance fulfilling standard orders while reserving premium-grade inventory for premium sales channels.

Fish processing combines quality grades and size variations with strict shelf-life constraints. Like red meat, fresh fish products command premium pricing but have limited processing windows, while frozen alternatives offer operational flexibility at reduced margins. Processors must optimize across multiple constraints while maintaining quality standards and regulatory compliance, making real-time attribute-based decisions critical for maximizing profitability from each catch or farmed batch.

How RELEX solves attribute-based planning concerns

RELEX supply chain planning software is designed to address the complex attribute-based planning challenges that food manufacturers face. Informed by industry-specific expertise, our comprehensive approach tackles data management, computational complexity, and real-time operational requirements.

Optimization algorithm

The RELEX optimization engine forms the foundation of effective attribute-based planning in manufacturing environments with non-uniform raw materials. With this optimization algorithm, manufacturers can achieve global optimum solutions rather than using simplified heuristics that only consider local decisions. Manual planning methods typically focus on selecting the highest-value products first, which leads to missing better overall combinations.

RELEX evaluates thousands of allocation combinations across products and customer requirements within minutes. The system considers all variables simultaneously, including customer priorities and strategic relationships, to maximize total profitability.

Reverse BOM automation

Traditional planning systems struggle with these reverse bill of materials (BOMs) scenarios, where one raw material produces numerous outputs. For example, a single cow creates multiple finished products, like mincemeat and premium marble cuts.

RELEX automatically handles these complex one-to-many production relationships that are common in food manufacturing. The platform automatically calculates demand for primal products and updates projections for subprimal products without manual intervention. This ensures efficient inventory management, allowing manufacturers to maintain optimal product mix ratios and process hundreds of animals daily across multiple product lines.

User interface and results management

RELEX provides specialized interfaces for capturing planning master data that don’t exist in standard ERP systems. Manufacturers can easily input all necessary data, including:

- Size distributions

- Quality grades

- Customer-specific requirements

The platform maintains this critical planning data alongside standard ERP information. Production planners can easily update attributes, pricing, and specifications as business requirements evolve. This ensures optimization algorithms always work with current, accurate data while reducing dependency on individual expertise.

RELEX translates optimization outputs into clear, actionable production plans. Planners can set priority frameworks within the application and see how decisions align with profitability drivers. The system generates complex algorithmic recommendations for daily production planning, which are explained by allocation logic, allowing planners to understand why specific decisions maximize profitability. This transparency builds confidence in optimization results and helps planners make rapid adjustments when required.

Surplus optimization

RELEX strategically manages excess inventory rather than defaulting to freezing or discarding it as waste. The platform identifies where surplus should be allocated to maintain profitability, whether through alternative product channels or strategic inventory positioning. When excess supply occurs, the system prioritizes the most valuable utilization options.

Smart surplus management reduces freezing costs and maximizes fresh product sales, which generate higher margins. The system determines whether to freeze excess inventory, redirect it to alternative finished goods, or coordinate with sales teams for promotional activities. This prevents automatic waste while maintaining optimal product mix and profitability.

Leverage raw material variability to maximize profitability

Rising input costs and unpredictable supply chains are squeezing profit margins across the food manufacturing industry. Every misallocated cut, every batch sent to freezing, and every missed optimization opportunity directly impacts the bottom line. Under current market pressures, manufacturers cannot afford to forfeit potential revenue through inefficient raw material utilization.

As supply chain disruptions become the norm rather than the exception, companies with advanced attribute-based planning capabilities will consistently outperform competitors relying on manual approaches. Using intelligent attribute-based planning software, food manufacturers maximize profitability from every animal, cut, and customer relationship. This methodology embraces the unique qualities of non-uniform raw materials and turns a traditional planning problem into an optimization opportunity.

RELEX combines proven optimization algorithms with deep industry expertise to deliver attribute-based planning solutions that work in real-world manufacturing environments. The platform enables food manufacturers to make raw material variability one of their strongest competitive differentiators and a source of measurable profit improvement.

Attribute-based planning FAQ

What is the difference between attribute-based planning and recipe optimization?

Attribute-based planning focuses on optimally allocating raw materials with varying characteristics to different finished products, while recipe optimization typically involves selecting between fixed production formulas. Attribute-based planning is particularly relevant for industries such as meat, fish, and poultry processing, where a single raw material yields multiple products with distinct attributes.

How does attribute-based planning improve profitability?

The approach maximizes profitability by matching raw materials to their highest-value applications based on quality grades, size specifications, and customer requirements. This reduces surplus inventory, minimizes freezing costs, increases fresh product sales, and improves customer satisfaction through better order fulfillment.

What is the difference between uniform and non-uniform raw materials?

Uniform raw materials, such as granulated sugar or standardized flour, are consistent in terms of quality, size, and composition, making them easier to use in production processes. Non-uniform raw materials, like fresh vegetables or whole fish, vary in these aspects and often require sorting or preparation to meet production standards. This distinction is crucial for maintaining efficiency and quality in food manufacturing.

What industries benefit most from attribute-based planning?

Attribute-based planning can benefit any industry where a single raw material is used to create multiple finished products with varying attributes. In particular, food manufacturing industries that utilize non-uniform raw materials, such as poultry processing, meat cutting, seafood operations, and dairy processing, benefit most from this approach.

What is a reverse BOM?

A Reverse Bill of Materials (Reverse BOM) starts with a primal product (a whole cow) and breaks it down into subprimal products (steak, ground beef). Using attribute-based planning, food manufacturers can forecast demand for subprimal products based on attributes like cut type or fat content, then calculate how much of the primal product is needed to meet that demand.

In contrast, a regular BOM works the other way around, starting with an end product (a gift basket) and calculating the demand and replenishment needs for its components (chocolates, wine), often leveraging attributes like size or brand to refine planning.