How manufacturers sustain growth amid inflation and market tumult

May 9, 2025 • 8 min

Profitable growth hinges on how well a company can defend its margins. Inventory costs, cash efficiency, carbon footprints, and service levels all form the perimeter guarding those margins. Optimal inventory levels help you meet demand without clogging up cash flow, and in an age of value- and planet-conscious consumers, availability and quantifiable sustainability results are keys to market differentiation.

Manufacturers must weigh these KPIs, being careful not to prioritize one to the significant detriment of another, but even in the best of times, this is a precarious balancing act. What happens when sudden disruptions and relentless inflation tip that balance?

Profitable and efficient supply chains require visibility, coordination, accuracy, and speed to deflect the impacts of market forces and disruptions. By implementing strategies that protect margins from multiple angles and activating the digital solutions required to make them successful, CPG companies and manufacturers can continue to drive profit and growth, even in turbulent markets.

Why previous tactics and remedies won’t work

In response to inflation and rising costs, 31% of companies report introducing cost-saving measures and efficiency improvements, and another 31% report increasing their prices.

However, when inflationary cycles restart or new disruptions compound supply chain problems, many companies have already played their two most common cards. The first is the “shrinkflation” tactic of maintaining prices while reducing the size or amount of a product per unit. The second is the “premiumization” approach that focuses on a luxury or specialty product’s appeal to command a higher price point—luxuries some consumers may not even be considering.

Now, companies are at the point where they must decide which costs they absorb and which they pass on to the consumer. Even if a company were to perfect their pivot strategy, market conditions and policies can change suddenly, rendering those plans null and keeping manufacturers one step behind the markets.

Five growth strategies, backed by high-velocity tech

Businesses contend with news cycles and markets that move rapidly, often keeping companies on the defensive. But with tech that can match market speeds, manufacturers don’t have to be reactionary.

Here are five strategies that help them narrow their focus and take decisive action, proactively monitoring and improving their most important KPIs.

1. Don’t lose sales opportunities

Let’s start with increasing revenue. To grow your top line, you need to ensure availability so you don’t miss a single sale. Availability depends on a reliable forecast that helps position the right quantity of the right products in the right place.

For this, you’ll need a forecasting and replenishment solution that can quickly process and analyze granular data for a keen understanding of local demand and broader trends. With machine learning (ML) algorithms tackling the calculations determining which option best serves different objectives, companies can anticipate and fulfill orders, even amid uncertainty.

Learn more: AI in supply chain – A toolkit for business leaders

It would be all the better if these forecasts were augmented and improved with rapid demand sensing capabilities that help companies react swiftly and accurately to sudden market shifts. Demand sensing pulls signals from internal and external data sources, like retail POS data, so manufacturers can keep their finger on the pulse of demand and avoid the dreaded bullwhip effect.

Rapid demand sensing capabilities help companies react swiftly and accurately to sudden market shifts.

Better forecasts also help you avoid out-of-stocks, so you can deliver on promises to your customers every time.

2. Invest in inventory wisely

Improved forecasting also helps manufacturers optimize their inventory, determining the right amount of safety stock for each SKU and identifying products that regularly convert into cash. The last thing you want to do is tie up working capital in the wrong inventory, driving up storage costs and preventing you from investing in high-demand products.

Optimized inventory planning allows you to better serve your customers by maintaining the right pools of inventory to meet demand. You’re also reducing your carbon emissions because you’re not wasting materials, producing excess stock that could end up in landfills, or increasing transportation emissions with expedited shipments.

3. Reduce costs across the supply chain

Cost reduction relies on squeezing every ounce of value out of your existing asset base. Forecasting and inventory optimization certainly contribute to that reduction, but every node of your supply chain has opportunities for efficiency gains.

For instance, master planning and production scheduling help you refine purchase plans and avoid under- and over-producing, limiting waste across the production process while fulfilling customer SLAs. So, you won’t lose sales by being unable to deliver, and you won’t lose money trying to move overstock through costly markdowns and discounts.

Other solutions, like truckload optimization, maximize fill rates so you’re fully utilizing transportation capacity. You can also optimize routes and fleet planning to help lower labor costs as well as fuel consumption, with the added bonus of reducing carbon emissions.

4. Embrace scenario planning

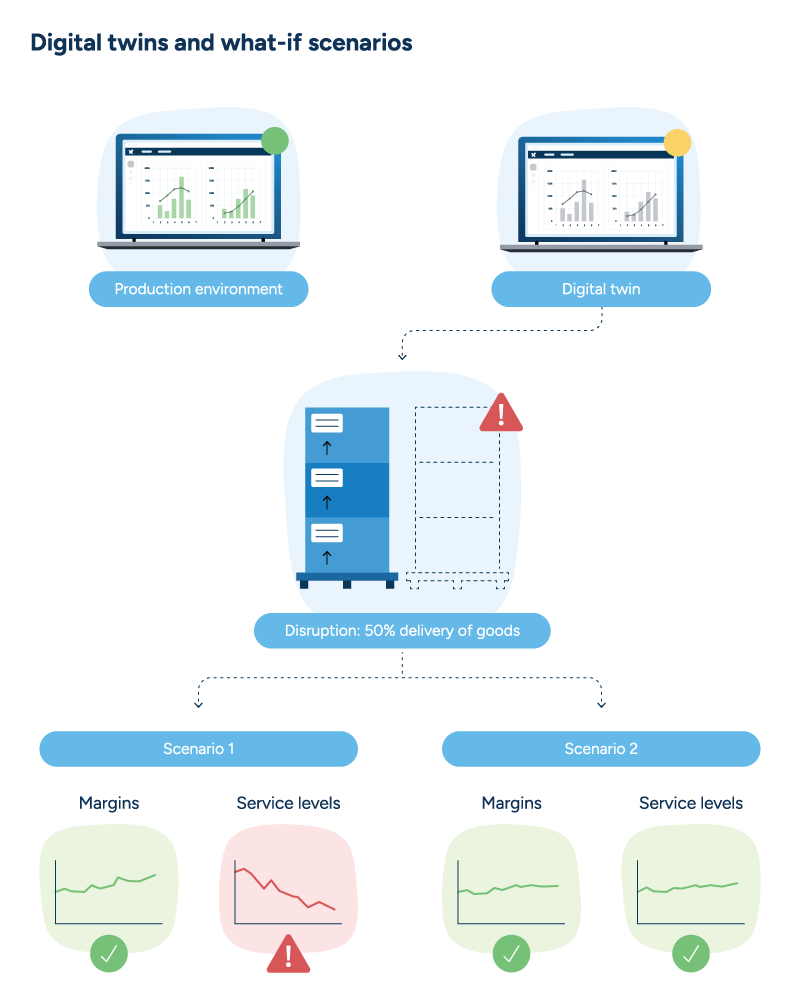

The importance of scenario planning cannot be underplayed. Scenario planning helps you answer and prepare for all your “what-if” questions. What if a tariff jumps from 30% to 70% or is lifted overnight? What if raw materials don’t arrive on time from a distant supplier? What if unforeseen, severe weather wipes out a crop, delays a shipment, or raises demand for an item?

Alongside these questions, manufacturers have a lot of constraints to consider, and the best way to balance all of these factors is with a digital twin.

A digital twin is a replica of the physical end-to-end supply chain that planners can use to run scenarios. They can model all the costs of a possible situation and calculate the effect on forecasts, so they know exactly how to respond to market surprises and align output with capacity and demand. The tool helps them get a clearer picture of how decisions will affect KPIs and the business as a whole, helping teams collaborate within and across companies and balance competing objectives.

5. Invest in an end-to-end platform that grows with you

Speaking of collaboration, let’s talk about end-to-end supply chain planning.

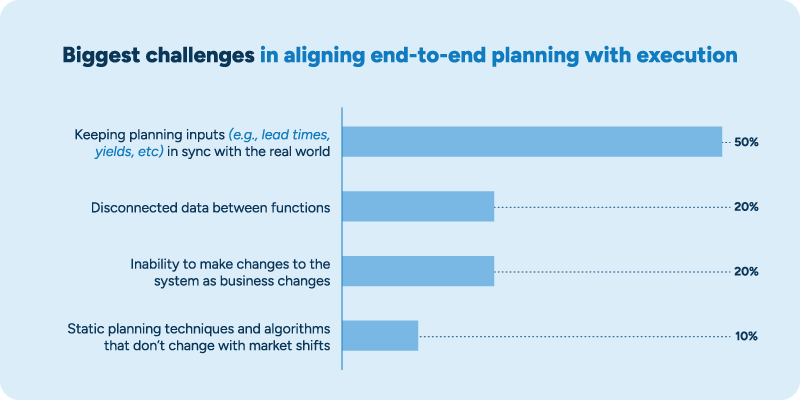

50% of CPG companies report that keeping planning inputs in sync with the real world is their biggest challenge when it comes to end-to-end planning and execution.

And they’re right. Poor data, siloed planning, and rigid, outdated solutions keep manufacturers from executing profitable, efficient, and customer-focused supply chain decisions.

An end-to-end platform like the RELEX solution is vital for manufacturers. RELEX gathers all those planning functions onto a single unified platform, linking them to a shared pool of real-time data and equipping teams with advanced AI-driven capabilities that rapidly assess demand signals, calculate optimal responses, and continuously adapt to changes. It even makes it possible to share data with external partners like suppliers and retailers.

Plus, the system is built for the long haul. Its configurable business rules engine allows users to customize processes, automate tasks, trigger strategic responses, and monitor decisions for smoother, faster supply chain planning. This configurability makes it easy to adapt the solution to specific business needs and market conditions. RELEX also continuously develops and integrates AI innovations into the platform so companies don’t miss out on technology that can keep them ahead of the competition.

Learn more: The manufacturing demand forecasting revolution

The platform combines visibility, collaboration, accuracy, and speed to help teams control inventory levels, improve process efficiency and decision-making, and meet demand. With RELEX, you protect your working capital and reduce waste while ensuring availability and delivering an enhanced customer experience.

Real-world use cases

Let’s look at how manufacturers have put the RELEX solution to good use.

Blount Fine Foods, a manufacturer of premium fresh prepared foods, implemented RELEX demand planning and supply chain optimization solutions across their seven distribution centers and manufacturing operations. These AI-driven solutions helped Blount forecast demand, plan supply, and optimize inventory and production according to their unique production environment’s complexities and constraints.

The company achieved:

- 5% annual increase in production pounds, streamlining operations and boosting output without changing capacity.

- 35% reduction in finished goods waste, leading to significant cost savings and sustainability benefits.

- 2% improvement in production efficiency, reducing waste and getting the most out of production assets.

- 50% reduction in forecast error over two years, improving demand planning accuracy and aligning production with actual needs.

“Having the ability to see how changes to sales forecasting or manufacturing capacity availability impact potential service levels on a longer horizon has allowed us the ability to strategize in advance before the situation arises,” said Jonathan Wells, Sr. Director of Demand Management at Blount Fine Foods. “This has allowed us to make better decisions and explore alternate paths while linking all of our constraints within our manufacturing and supply chain ecosystem together to realize the true impact of a decision throughout the process.”

Rastelli, another RELEX customer and a leading supplier of premium meats and seafood, has earned a reputation for trust and reliability among fine hotels, restaurants, and retailers across the globe. As the company grew, they understood they needed a dedicated system that could help them move from reactive processes to proactive planning. They implemented demand forecasting in just six weeks, improving visibility and raising forecast accuracy at the customer level.

Then they went live with production planning and inventory optimization, generating $3.5 million in cost savings — not accounting for reduced warehousing, transportation, and packaging costs. The company now enjoys better visibility across their supply chain, better alignment between production and customer orders, and an improved S&OP process.

Outpacing competition and markets with RELEX

So, where to start?

At RELEX, we know from decades of experience that an accurate forecast is the heartbeat of a supply chain, so it’s the first investment companies need to make.

Our forecasting and replenishment solution feeds time-sensitive data and demand insights into the rest of the supply chain ecosystem, pumping this information throughout our suite of AI-driven, industry-recognized planning solutions. Because RELEX provides an end-to-end platform, replete with continuous AI innovations, each investment you make can easily integrate with existing solutions, ensuring long-term return on your tech investments.