More effective chain operations through department store replenishment automation

Jun 12, 2009 • 7 min

This article focuses on stock replenishment from the perspective of department store operations. If you have not familiarized yourself with RELEX’s article on automatic replenishment in general, we recommend reading it.

By improving the efficiency and accuracy of outlet-specific ordering, results can be increased in all types of retail trade. The accuracy of ordering and order batches affect shelf availability and, by extension, sales. Ordering also affects the work and stocking expenses. In department store trade, loss and discount costs that are related to product stocking play an important role, as seasonal products lose their value extremely rapidly. As a result, the opportunities for improved efficiency are often greater than in other areas of retail trade as the environment is genuinely challenging.

Department Store Retail Is Demand-oriented and Seasonal

When automatic replenishment is being discussed, the operations are often compared to grocery retail. Department store retail is vastly divergent from grocery retail in terms of product-specific differences as well as its seasonal nature. While in grocery retail supply can be adjusted based on demand, in all forms of specialty retail and department store retail, supply is used to significantly affect demand. However, it should be kept in mind that many product areas are very similar to grocery retail in terms of their operating models.

The following lists the special characteristics that influence product replenishment in department store retail:

- Product quantities and turnovers are very high

- A large number of seasonal products that are provided only for a single season

- A large number of suppliers all the way down to retail outlets, and often fragmented supply routes

- Considerable differences in product displays

- Backroom stock plays a significant role

Different Supply Models Must Be Considered in the Department Store Environment

What we can conclude from the above is that, due to the variety of operating models involved and the seasonal nature of product demand, department store retail is an extremely difficult environment for product replenishment. Therefore, as a result of the diversity of product areas and needs, product replenishment in department store retail requires multiple operating models. A single model is insufficient to successfully automate the entire operations.

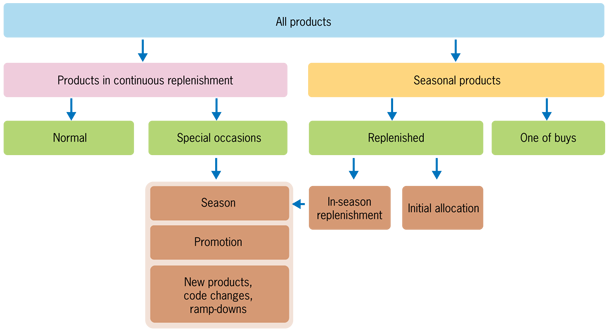

From the perspective of product replenishment, products can be divided into two primary supply models: seasonal products and continuously replenished products. The latter remain in an outlet’s product selection beyond a single season, and they are typically replenished several times within their service life. However, there can be special circumstances that affect continuously replenished products. In other words, their demand can fluctuate significantly due to, for example, campaigns or seasons. Seasonal products are in turn included in an outlet’s selection only for a particular season, and they are often ordered in a single batch, at least for the main warehouse.

For the replenishment of department store products, it is essential to construct suitable solutions for both alternatives. It is easier to automate the entire ordering process of continuously replenished products, whereas the replenishment of seasonal products can be supported by demand-based orders following the initial replenishment. If a seasonal product must be reordered, a good option is to employ the so-called PUSH-PULL-PUSH control logic, which functions as follows:

- The first batch is allocated to outlets based on a forecast or total purchase quantity (=PUSH)

- Upon the commencement of sales, the process automatically transitions to demand-based replenishment, in which orders from the main warehouse are made as necessary (=PULL)

- At the end of the season, any possible surplus is allocated to those department stores where it is predicted to sell the most (=PUSH)

In the initial replenishment of seasonal products, the role of the replenishment itself is rather small – management of selection, pricing, purchasing and even campaigning take the center stage. As such, the automation of replenishment calculation yields relatively minor benefits.

Product Handling in Outlets Must Support Ordering

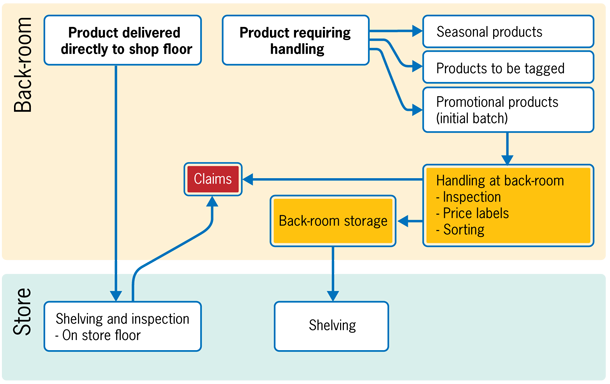

In department store retail, the route by which products arrive on the shelves can be considerably complex.

As in many things, simplicity is key because every time a product is handled it significantly increases the overall costs.

Some of the handling work in department stores is mandatory. Pricings, alerts and, in some respects, inspections are measures that are directly linked to product attributes.

In the last decade, however, these operations have largely been moved backwards in the supply chain to industry or the wholesale sector.

As with the separation of the order flows described above, the physical handling of products must be segregated according to product attributes. If the products that require handling are delivered to the outlet mixed in with the direct-to-shelf products, the entire bulk of products must be sorted one cargo unit at a time. In practice, this method forces continued backroom stocking of products, which means that the benefits of automated product replenishment are lost.

The segregation of the flow of goods effectively, means that continuously replenished products are ordered according to demand and shelved immediately upon arrival, preferably directly from the cargo unit in which they were delivered. Correspondingly, products that require handling are delivered to the outlet separately with consideration of the time required for the handling. The majority of products that require handling are seasonal.

The Visual Appearance of the Outlet Must Be Considered in Replenishment

More often than not, the aim of automatic replenishment is to reduce inventories and achieve a new level of efficiency, whereas the aim of retail trade is to sell products.

Therefore, it is by no means unheard of that automated replenishment in turn results in there being more shelves and racks on display than actual products. This problem is pronounced in department store retail as the wide product selection includes a great deal of items with a relatively low turnover. Moreover, in the department store concept, it is vital to sales that the products are displayed in an appealing manner.

One possible solution is to increase the products’ period of storage or backup stocks, whereupon the visual presentation of the products can be improved. The problem with this is that the measures will simultaneously increase the stock quantities of products that do not require higher stock volumes, and, on the other hand, the increase in the in-store display of small and inexpensive products (such as socks) may still be insufficient. A more functional solution is to implement product-specific shelf minimums. In this way, a sufficient quantity of products for an appealing display can be maintained in stock even if the product demand is relatively low. At the same time, implementing a shelf minimum for a product in no way prevents the product from being replenished based on demand. Shelf minimums can be placed manually for each respective outlet (for example, with a PDA device) or, if shelf images are used, automatically based on face data.

Exception Management Brings Efficiency to Product Discontinuations

Managing the final phase of a product’s service life is a pivotal issue with regard to obtaining profitable results in department store retail. However, producing sufficiently accurate demand forecasts for seasonal products is extremely difficult due to a high product turnover and long forecasting horizon.

It is often necessary to order the products in one batch based on the initial forecast. Although it is always prudent to strive for the highest possible accuracy in forecasting, this alone will not yield the desired results.

Product management at the end of a product’s service life must be based on continuous monitoring and the channeling of the supply to where the demand is. Therefore, there is no sense in flooding the outlets with the entire product batch. It is likely that product sales will vary between different outlets, which mean that it is a good idea to leave, for example, 20% of the products in the main warehouse and replenish the outlets as necessary. This naturally requires the product to be suitable for storage at the main warehouse or that it is available from the supplier without any imposed limitations. Traditionally, the problem has been that monitoring the stock status more or less manually is largely impossible. However, automatic replenishment allows for this work phase to be automated. Moreover, with system-based management of deviations, situations relating to overstocking, for example, can be highlighted and automatic measures can be implemented to handle them. In practice, this means that the person in charge of product recalls only needs to work on those exceptions that can plausibly be handled within the prevailing time constraints. This ensures that, upon stock shortage, products are automatically directed to where the demand is. The arrangement also enables efficient and early responses to overstocking. The end result is that fewer write-offs are made as mandatory seasonal discounts.

A Logistical Operating Model Does Not Affect an Outlet’s Automatic Replenishment

In department store retail, there are usually a large number of suppliers and the number of direct deliveries is high. Many think that a product must be stored in the main warehouse for its automatic replenishment to be possible, but this is actually incorrect. If the supplier makes its deliveries at defined intervals, the product can be automatically replenished directly from the supplier. As regards direct suppliers, however, it is true that entering products as income and managing balances is often more challenging, which also affects ordering operations.

RELEX Solutions for Department Store Replenishment

RELEX solutions create significant benefits. The following lists the typical benefits for retail replenishment:

- Considerable improvement of shelf availability

- Increased level of automation and less time spent on ordering

- Reduced handling costs for outlets by means of efficient order batches and optimal delivery intervals

- More accurate forecasts of challenging situations, such as seasons and campaigns

In department store retail, RELEX solutions primarily focus on the replenishment of continuously replenished products as well as on handling the outlet replenishment of the remaining batches of seasonal products. Although, if measured by the number of articles, clearly more than half of the selection comprises seasonal products, 60-80% of the flow of goods typically consists of continuously replenished products. The same ratio also applies to the work involved.

The most essential benefits that RELEX solutions provide for department store retail are:

- Combining the improved visual presentation of department stores with reduced stock quantities by means of minimum stocks and automatically updated control parameters

- Individual forecast and replenishment models that are suitable for campaign management as well as filtration of campaign demands from the normal sales forecasts

- Optimized replenishment of products requiring different handling by means of flexible cost parameterization (including the replenishment of the main warehouse)

- Life cycle management of products by means of exception management

- Increased replenishment intervals, particularly for large products, by means of a high level of automation

- Accurate and efficient seasonal forecasts also for novelty products by means of demand modeling