Why production line optimization is a manufacturing must in 2025

Aug 27, 2025 • 14 min

Successful businesses constantly strive to increase efficiency, reduce costs, and maximize output. And with material costs surging and supply chains constantly buckling, manufacturers need every operational edge they can get.

Whether it’s increasing labor costs, supply chain volatility, manufacturing complexities, or heightened customer expectations, the stakes are rising and pressures are mounting. The ripple effects of production issues hit harder and faster than ever before, and every inefficiency now carries amplified consequences that directly impact the bottom line.

Production line optimization technology has emerged as a critical differentiator for high-achieving manufacturers. Manual processes are simply too slow and error-prone to cope with the demands of modern manufacturing. Advanced software is required to react to disruptions, process vast quantities of data, and help planners identify efficient solutions.

Optimizing production lines is about more than just maximizing efficiency. It also involves creating resilient, adaptive systems that can maintain service-level commitments. RELEX planning software facilitates informed optimization decisions that help manufacturers stay one step ahead of issues on the production line.

What is production line optimization?

Production line optimization, also referred to as production optimization, is the strategic process of maximizing the efficiency, capacity, and overall performance of production operations.

This encompasses various functions, including:

- Minimizing setup times and changeover periods.

- Coordinating material and packaging availability.

- Managing workforce capacity and labor allocation.

- Balancing production efficiency with service level requirements.

- Reducing downtime and waste.

- Optimizing product mix and sequencing.

Achieving production line optimization requires aligning production schedules, resources, and equipment to minimize manufacturing downtime, reduce waste, and effectively meet demand.

Modern manufacturers use AI-driven production planning and scheduling to optimize production sequences and reduce lead times. These advanced systems improve resource utilization across industries, from beverage manufacturing with complex tank scheduling to discrete manufacturing with equipment coordination.

4 disruptions that slow down production lines

In modern manufacturing, disruptions rarely announce themselves. Often, they cascade through operations in predictable patterns. The manufacturers who thrive are those who recognize these patterns and build systems resilient enough to absorb the shock.

1. Capacity constraints and the efficiency vs service level dilemma

Capacity limitations affect a manufacturer’s ability to produce at optimal levels. Machine breakdowns, equipment bottlenecks, product sequencing inefficiencies, and labor shortages directly reduce available production capacity. Modern factories rely heavily on skilled operators for complex machinery, making workforce availability critical. Technology failures in manufacturing execution systems can also create widespread capacity disruptions across facilities.

Too often, manufacturers face an impossible strategic choice between production efficiency and service level maintenance. Running long production series maximizes efficiency and minimizes setup time, but creates dangerous inventory imbalances. Shorter, more frequent production runs maintain better service levels but significantly reduce operational efficiency and increase costs.

Manufacturers face an impossible strategic choice between production efficiency and service level maintenance.

This fundamental dilemma traps manufacturers in a cycle of inefficiency where they constantly react to problems rather than proactively maximizing operational capabilities. The cumulative effect transforms manufacturing operations from strategic growth engines into reactive cost centers that drain resources and limit expansion potential.

2. Planning estimation errors

Planning disruptions stem from incorrect assumptions or poor data quality in production schedules. Demand fluctuations that exceed forecasting models can strain and create scheduling conflicts. These errors occur when manufacturers plan correctly but base decisions on flawed assumptions or outdated information. The challenge lies in distinguishing between planning mistakes and data quality issues.

3. Material issues

Material disruptions occur when manufacturers lack the inputs needed for production. Supplier delays, product quality defects in raw materials, and transportation issues can halt entire production lines, making it difficult to hit service level commitments.

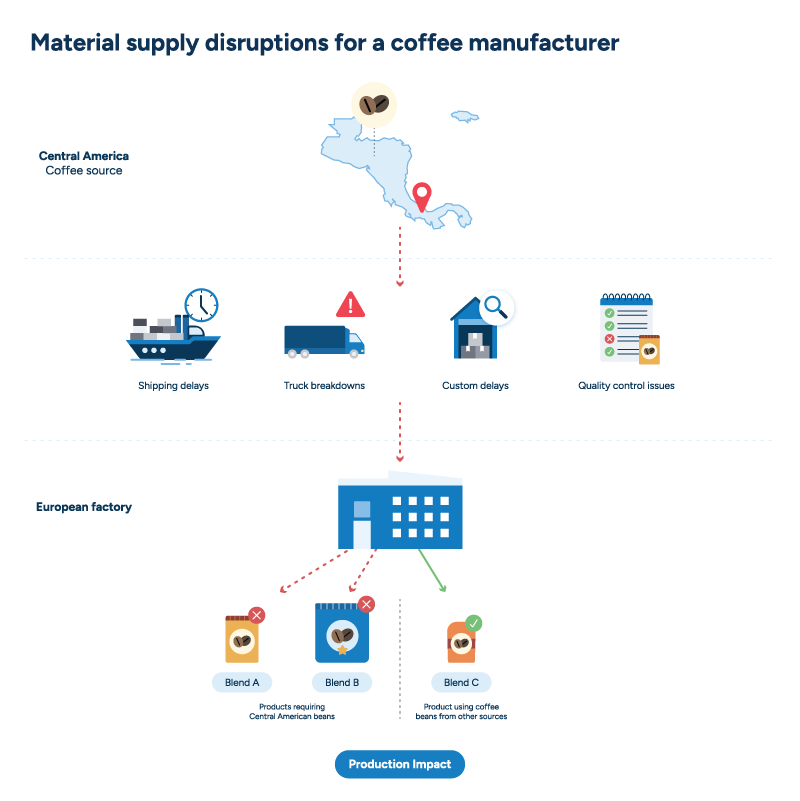

Consider a European coffee manufacturing operation that sources beans from Central America. When a shipment arrives late, it restricts production options for all products containing those specific coffee beans. Truck breakdowns, customs delays, or supplier quality issues can trigger immediate shortages.

Missing packaging materials or key ingredients force manufacturers to pause operations until supplies arrive or search for alternatives. These disruptions are particularly challenging in food manufacturing, where shelf-life constraints create added time pressure.

4. External factors

Manufacturers must contend with forces entirely outside their control — disruptions that can’t be managed through better supplier relationships or inventory buffers.

This includes:

- Natural disasters

- Political instability

- Regulatory changes

- Energy supply interruptions

- Unpredictable weather conditions

These external shocks arrive without warning and often overwhelm traditional contingency planning. Unlike other disruptions that can be anticipated or mitigated through careful planning, external factors demand a different kind of resilience. They require systems flexible enough to pivot instantly.

Manufacturers may need to switch suppliers across continents, reroute shipments through different ports, or completely reconfigure production schedules. The manufacturers who survive this chaos are those whose systems can adapt as quickly as the world changes around them.

How unoptimized production hurts manufacturers

Every production disruption carries a price tag, and it’s often much higher than manufacturers realize. Beyond the obvious costs of downtime and waste, unoptimized production lines create hidden expenses that compound over time: damaged retailer relationships, compromised quality, and underutilized assets that drain profitability.

Service level failures and their implications on retailer relations

Production disruptions create constant service level challenges that directly threaten revenue streams. When manufacturers minimize inventories to manage costs, any production issue becomes more likely to cause stockouts and missed sales. These service failures leave manufacturers vulnerable to losing market share to more reliable competitors.

The damage to the relationship extends far beyond individual missed orders, particularly with promotions. Retailers invest heavily in promotional campaigns, treating them as strategic initiatives to drive customer traffic. When manufacturers fail to deliver promotional products on time, retailers face serious operational problems after already committing resources to marketing materials and store layouts.

As a worst-case scenario, prolonged production issues can result in retailers permanently replacing manufacturers with more reliable alternatives.

Missing promotional deliveries triggers immediate retailer retaliation that can permanently damage business relationships.

Consequences can include:

- Cancelled future promotions.

- Reduced shelf space allocation.

- Strict contractual penalties with significant costs.

- Sudden drops in sales.

In competitive retail markets, losing shelf space can immediately reduce product sales by around 20-30 percent. As a worst-case scenario, prolonged production issues can result in retailers permanently replacing manufacturers with more reliable alternatives.

Operational waste and quality compromises

Unoptimized production creates substantial waste, particularly in industries with time-sensitive processing requirements like food manufacturing. Products must be processed within narrow time windows or risk contamination, spoilage, or expiration. For example, roasted coffee beans must be packaged within specific hours before the oils oxidize and flavors deteriorate.

Poor product quality emerges from inefficiencies like improper sequencing, rushed processes, or equipment overuse that compromise consistency and precision. Inadequate maintenance or misaligned schedules cause machinery to operate below optimal conditions, affecting product standards. Companies that make bakery items face specific challenges, such as allergen contamination or glaze residues, that require careful sequencing to maintain quality.

Production delays in heavy industries like steel manufacturing require reheating large metal pieces at enormous expense. This reheating process costs thousands of pounds per piece and can potentially compromise the final product’s quality.

Poor asset utilization and workforce dependencies

Many production sites operate at suboptimal capacity levels, running at only 70% utilization despite having available resources. This underutilization represents missed opportunities to generate additional revenue from existing investments.

Additionally, modern factories have paradoxically increased their dependence on highly skilled operators while reducing overall workforce numbers. When these critical operators become unavailable, entire production lines can shut down immediately. Unlike previous decades when managers could operate simpler equipment during workforce disruptions, today’s complex machinery requires specialized expertise.

5 ways to optimize production with AI-powered planning software

The gap between struggling with disruptions and thriving despite them ultimately comes down to having the right tools to see problems coming and respond instantly. Modern AI-powered planning software transforms how manufacturers handle the inevitable challenges of production.

RELEX leverages a comprehensive approach to production line optimization that helps manufacturers improve efficiency, strengthen collaboration, reduce waste, and generate profit. The platform combines advanced AI capabilities with real-world manufacturing expertise to deliver measurable operational improvements.

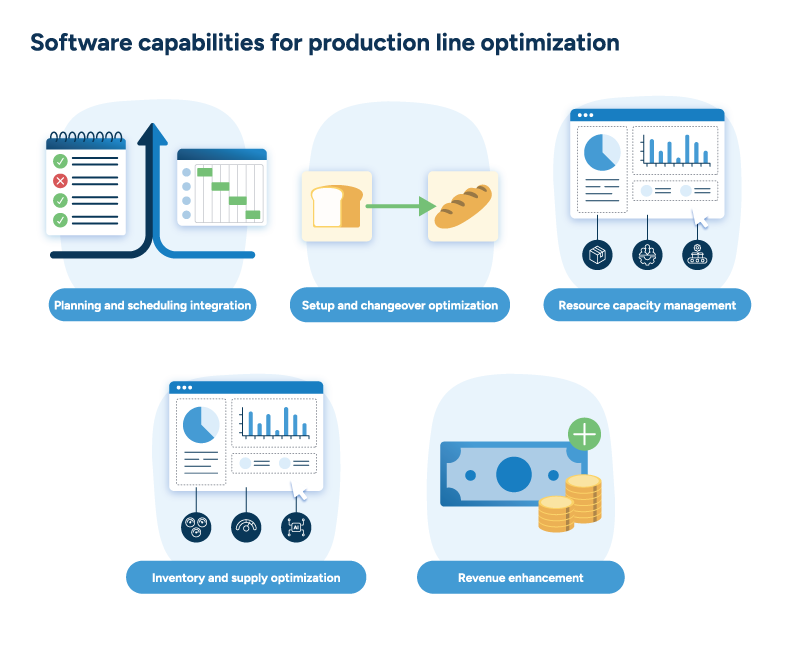

1. Planning and scheduling integration

When production disruptions occur, manufacturers must respond immediately. But traditional systems create costly delays. Weekly production plans require multiple data transfers before reaching machine-level schedulers, often taking hours or days to complete the loop. By the time planners can assess feasibility and adjust schedules, valuable production time is already lost.

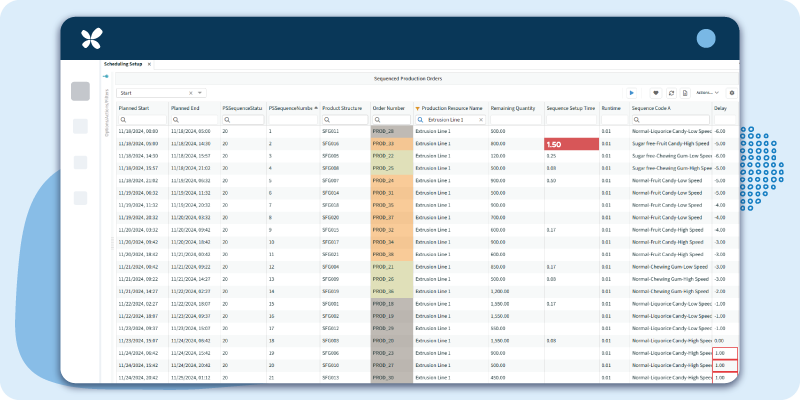

RELEX eliminates this disconnection entirely with its modern AI-powered supply chain planning systems. Weekly production planning connects directly with detailed machine-level production scheduling, creating a seamless optimization environment where disruptions trigger instant recalculations. No more waiting for data transfers between systems or discovering that planned production isn’t actually feasible.

The platform’s touchless automation goes beyond simple recommendations. With RELEX, planners are not forced to manually sequence every product and resource decision; intelligent algorithms continuously optimize production flows based on real-time constraints and performance data. Instead, planners can focus on strategic decisions while the system handles routine optimization tasks.

Most importantly, this integration enables true agility. When a machine breaks down or materials arrive late, manufacturers can instantly reallocate resources and minimize waste, maintaining service levels even in volatile environments.

In the near future, RELEX robust scheduling will use AI to analyze historical reliability statistics for different operations and machines. Like supply chain scenario planning, this capability will create inherently resilient production plans that anticipate potential disruptions and minimize impact. Adopting predictive resilience will transform reactive firefighting into proactive optimization for sustained operational excellence.

2. Setup and changeover optimization

Every minute spent changing between products is a minute not generating revenue. These non-productive changeover periods represent some of the most expensive downtime in manufacturing, yet traditional planning methods fail to provide manufacturers with optimal production sequences.

RELEX discovers patterns that eliminate guesswork in production scheduling, significantly boosting overall equipment effectiveness and production throughput rates. In the future, AI algorithms capable of leveraging historical performance data will enhance this function by identifying the most efficient transitions over a prolonged period.

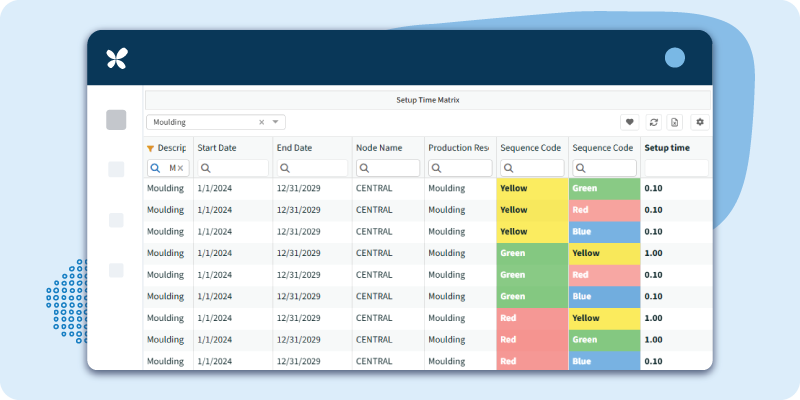

Changeover matrices capture exact transition times between different products on each production line, but the real intelligence comes from continuous machine learning. As actual changeover performance data feeds back into the system, optimization algorithms become increasingly accurate at reflecting real-world operational constraints and capabilities.

Smart product mix optimization takes this a step further by strategically grouping compatible products. Rather than scheduling complicated products back-to-back on the same day, creating unnecessary setup complexity, RELEX sequences production to maximize productive time while maintaining quality standards.

This strategic approach transforms what was once a source of inefficiency into an optimization opportunity. Manufacturers can dramatically increase their productive capacity without investing in additional equipment by making smarter decisions about when and how to sequence their production runs.

3. Resource and capacity management

Manufacturing success heavily relies on precise timing. Materials must arrive exactly when needed, skilled operators must be available to operate complex machinery, and production lines must run at optimal capacity. Without coordination, even minor misalignments can create bottlenecks with far-flung consequences.

Instead of leaving planners to manually juggle countless variables, RELEX automatically synchronizes supply deliveries with production schedules and workforce availability. Bottlenecks disappear, idle time drops, and the entire production ecosystem flows seamlessly.

Dynamic line utilization instinctively recommends which production lines should operate and when. For instance, when demand fluctuates, the system might suggest closing specific lines while maximizing output on remaining equipment. This both optimizes labor allocation and energy costs without sacrificing production targets.

Key resource coordination capabilities include:

- Real-time monitoring of production status with instant deviation alerts.

- Automated synchronization of materials, labor, and capacity schedules.

- Intelligent recommendations for line utilization based on current demand.

- Proactive identification of potential bottlenecks before they impact operations.

This comprehensive visibility enables rapid response to issues before they escalate into larger operational problems. Planners can spot variances immediately and take corrective action, maintaining production flow even when unexpected challenges arise.

4. Inventory and supply optimization

Manufacturers constantly risk either carrying too much inventory or running out of critical materials. Excess stock ties up working capital and risks wastage, while shortages halt production lines and damage customer relationships. Traditional approaches force companies to choose between financial efficiency and operational reliability.

Supply chain optimization eliminates this false choice by calculating optimal buffer levels that balance investment against risk. RELEX trades static safety stock formulas for advanced statistical models and machine learning to understand demand variability, lead times, and service requirements across the entire operation.

RELEX optimizes inventory levels across multiple categories:

- Raw materials arriving precisely when production schedules require them.

- Work-in-progress inventory flowing smoothly between production stages.

- Finished goods positioned to meet customer demand without excess carrying costs.

- Packaging materials synchronized with production sequences.

- Critical components buffered appropriately based on supplier reliability.

These capabilities allow manufacturers to transform inventory from a necessary evil into a strategic asset. Materials appear exactly when needed without excessive working capital investment, while production continuity remains protected against supply disruptions.

Above all, this optimization happens continuously. As demand patterns shift and supplier performance changes, inventory targets adjust automatically to maintain the optimal balance between cost and service.

5. Revenue enhancement

Most manufacturers accept idle production capacity as an inevitable cost of doing business, but it’s possible to turn this operational drain of underutilized hours into profit opportunities. The challenge lies in knowing exactly how to do so.

RELEX reveals hidden revenue opportunities by connecting unused capacity with possible promotions. When utilization drops below optimal levels, the platform flags the inefficiency and suggests specific products that could benefit from additional manufacturing for promotional activities.

This intelligence creates multiple revenue streams:

- Extra production during slow periods to support future promotional campaigns.

- Strategic overproduction of high-margin products when capacity becomes available.

- Opportunistic manufacturing of seasonal items ahead of peak demand.

- Building promotional inventory when raw material costs are favorable.

- Capitalizing on unexpected capacity from improved efficiency gains.

The result transforms idle time from a cost burden into a profit center. Instead of watching expensive production assets sit unused, manufacturers can proactively generate additional revenue while maintaining operational efficiency standards.

How Finsbury Food Group used RELEX to optimize production in complex production environments

Finsbury Food Group faced extraordinary challenges in bread manufacturing that demanded exceptional production line optimization. Every day, the company receives customer orders in the morning and must deliver finished products by the afternoon. This compressed timeline leaves no room for production disruptions or scheduling errors. The challenge was balancing production efficiency with service level requirements, given bread’s extremely short shelf life.

Some sites featured highly automated processes, while others relied on labor-intensive operations requiring precise workforce scheduling. Time-sensitive processes like fermentation and proving demanded exact timing coordination across production lines.

Finsbury used RELEX to make rapid production planning and scheduling adjustments without disrupting overall operations. RELEX’s real-time feedback mechanisms kept production aligned with actual customer demand rather than static forecasts.

RELEX also enabled Finsbury to factor in capacity constraints, labor availability, sequencing rules, and material availability to determine optimal production sequences. This replaced their previous reliance on spreadsheets and manual planning methods.

The results demonstrated the power of optimized production line management. Finsbury achieved a 5% service level improvement while maintaining production efficiency standards — a significant improvement given the industry’s demanding operational constraints.

The company also reduced net working capital by £1.6 million through smarter production planning and optimized inventory management. Most notably, Finsbury’s planning teams doubled their productivity while adding only one additional team member. This efficiency gain freed planners from manual tasks, allowing them to focus on strategic value-added activities.

Get ahead of the curve with RELEX production line optimization

From service level failures to operational waste, the consequences of unoptimized production hit harder and faster than in previous years. Traditional manual planning and reactive problem-solving are no longer viable for sustaining the demands of modern manufacturing.

Production line optimization has become an essential survival requirement for today’s manufacturers. The integration of AI-powered planning with real-time execution creates unprecedented optimization opportunities. These intelligent platforms transform production operations from reactive cost centers into proactive profit generators.

Modern manufacturers need robust solutions that combine strategic planning with tactical execution capabilities. The RELEX integrated AI-powered approach delivers both in a single platform that eliminates unnecessary waste and maximizes production time and revenue. Our powerful software transforms manufacturing efficiency and strengthens manufacturers’ competitive position.

Production line optimization FAQ

What are the benefits of production line optimization?

Beyond maximizing efficiency, production line optimization involves creating systems that are resilient to disruptions and adaptable to changing demand. Advanced tools like RELEX Production Planning and Scheduling allow manufacturers to align their operations with strategic goals while maintaining service-level commitments.

The chief benefits of optimized production lines include:

- Improved service levels and customer satisfaction.

- Cost savings.

- Increased resilience and adaptability.

- Enhanced demand alignment.

Ultimately, production line optimization builds a foundation for long-term manufacturing success. Manufacturers can proactively address challenges, reduce waste, and ensure their production processes are both efficient and future-ready, empowering businesses to meet customer expectations while driving sustainable growth.

What makes a production line more efficient?

Production line efficiency is crucial for manufacturers facing rising costs, supply chain volatility, and demanding customer expectations. Understanding the key factors that drive efficiency can help manufacturers transform their operations from reactive cost centers into competitive advantages.

Key factors that make production lines more efficient include:

- Integrated planning and scheduling systems that connect weekly production plans directly with machine-level operations, eliminating costly delays and enabling instant responses to disruptions.

- Optimized changeover sequences that minimize non-productive time between products.

- Synchronized resource coordination that ensures materials, skilled operators, and equipment availability align perfectly with production schedules.

- Smart inventory optimization that maintains the ideal balance between having enough stock to meet demand.

- Maximum asset utilization that converts traditionally idle production hours into revenue opportunities.

Why is planning software essential for achieving production line optimization?

Manufacturers face increasing pressures from supply chain volatility, rising costs, and customer demands for faster delivery, and manual planning methods can no longer keep pace. Modern production environments require sophisticated tools to manage complexity and maintain competitiveness.

Planning software is essential for optimizing production lines because it provides the tools to balance efficiency, capacity, and demand. Integrating data on production capacities, shift patterns, maintenance schedules, and material availability using AI-powered planning software ensures that manufacturers can create feasible and accurate schedules.

When used correctly, the right planning software helps identify bottlenecks, prioritize tasks, and allocate resources effectively, reducing downtime and maximizing throughput while maintaining service-level commitments. Additionally, planning software enables manufacturers to adapt to disruptions and changing market conditions. Features like scenario planning and real-time updates allow businesses to simulate alternative strategies, assess risks, and make informed decisions.