Reducing manufacturing downtime through supply chain planning

Aug 6, 2025 • 12 min

The phrase “time is money” strongly resonates with today’s manufacturers, specifically regarding manufacturing downtime. With per-hour costs dramatically rising, more and more manufacturers are looking to cut down on lost production time as a matter of necessity.

When considering how to reduce downtime in manufacturing, most manufacturers focus on mechanical breakdowns and preventative maintenance. However, they often miss the underappreciated yet vital connection between machine downtime and supply chain planning.

In fact, a significant portion of unplanned downtime stems from supply chain planning gaps that have nothing to do with parts shortages or mechanical failures. These downtimes occur when strategic plans fail to translate effectively to day-to-day operations on the factory floor, resulting in inefficient scheduling, improper sequencing, and misaligned resources.

Manufacturers can no longer afford to treat production planning and supply chain planning as separate functions. To reduce and optimize controllable downtime, manufacturers should implement AI-powered integrated planning software that effectively connects strategic goals with everyday execution on the shop floor.

The increasingly detrimental cost of downtime in manufacturing

Over the past five years, downtime in manufacturing has become an increasingly costly issue for businesses across all sectors. According to reports from IDS-INDATA and Siemens, the financial impact on major manufacturers is severe and growing rapidly. UK and European manufacturers are set to lose more than $103.2 billion in 2025 due to downtime, with unplanned downtime costing the world’s 500 biggest companies 11% of their revenues ($1.4 trillion total). [Note: all values from the IDS-INDATA report have been converted into US Dollars]

Some sectors have been hit harder than others, notably the automotive and heavy industries. Since 2019, costs in these respective industries have doubled and quadrupled, outpacing general inflation. Nowadays, an hour of downtime in the automotive sector costs $2.3 million, or $600 per second.

Across all sectors, the average large plant loses approximately $253 million annually due to unplanned stoppages.

Even industries with lower per-hour costs feel the cumulative impact. Food processing operations may lose $23K -$32K per hour, and frequent stoppages add up to billions in annual losses. In the pharmaceutical sector, where regulatory compliance is critical, hourly costs can reach $1.29-$6.45 million, with facilities experiencing 225-400 hours of downtime yearly.

Across all sectors, the average large plant loses approximately $253 million annually due to unplanned stoppages, underlining the importance of manufacturers pursuing innovative solutions to reduce lost revenue. The ability to prevent and quickly resolve downtime events has become pivotal to the survival and success of all manufacturers.

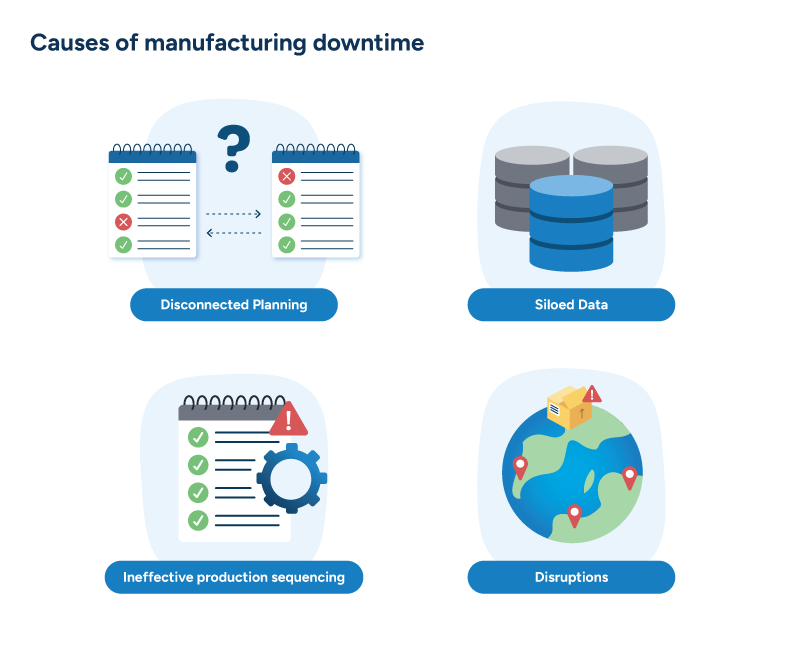

What planning challenges cause manufacturing downtime in the modern supply chain?

Multiple factors cause planned and unplanned downtime in manufacturing, some of which may be more apparent than others. When production disruptions strike, the first thing most people point to is the machinery on the factory floor. Production machinery naturally wears over time, and a certain amount of downtime is expected for scheduled maintenance and fixing sudden equipment failures, parts breakdowns, or mechanical issues.

Taking a proactive approach to equipment monitoring and maintenance can certainly decrease the likelihood of major machinery malfunctions. But it would be short-sighted to just focus on hardware health when reducing manufacturing downtime.

Let’s look at how supply chain planning gaps can cause downtime.

Disconnection between high-level planning and shop floor execution

A significant yet often overlooked cause of manufacturing downtime is the gap between high-level planning and shop floor execution. Many manufacturers create excellent monthly and weekly plans but struggle to translate them for day-to-day use. When this translation isn’t automated, someone must manually convert these plans into spreadsheets, introducing time lags and human errors that cause downtime.

Without planning horizons, production can’t be planned effectively, leading to inaction from human operators and machines, who don’t know what’s next in the production sequence.

Siloed data and ineffective planning systems

Poor demand forecasting compounds planning execution problems. When forecasts don’t align with actual demand, manufacturers either:

- Overproduce, creating excess inventory that sits idle.

- Underproduce, leaving machines inactive due to material shortages.

This directly contributes to unplanned downtime and inefficient resource utilization across production facilities.

Data and visibility gaps further exacerbate planning challenges. Without real-time inventory or production data, planners make decisions based on outdated information, creating misaligned schedules that don’t reflect actual conditions. This misalignment between planned activities and operational realities leads to inefficient resource allocation and unexpected production stoppages.

Even when production planning is automated, downtime occurs when workforce scheduling doesn’t match machine availability. Downtime becomes inevitable when production systems don’t include constraints like operator certifications or machine qualifications required in regulated industries.

Production sequencing and recipe management

Production scheduling, sequencing, and recipe management challenges vary significantly across process industries, shaped by unique operational constraints and regulatory requirements. The nature of these challenges — from contamination risks to chemical compatibility — depends heavily on the specific industry and its products.

For instance, industries like food, beverage, and chemical manufacturing see setup time for recipe changes representing a major source of downtime. Production scheduling must account for these changeovers to minimize idle time between batches. Without proper sequencing, manufacturers face unnecessary delays when switching between product types.

Contamination concerns drive many changeover requirements in process manufacturing, especially with allergens. Certain production plans cannot be executed back-to-back because ingredients or compounds from one recipe might contaminate the next. Cleaning and preparation between incompatible recipes adds significant time that must be factored into scheduling.

Meanwhile, industries such as pharmaceuticals must wrangle chemical compatibility issues in their production planning. Complementary compounds can be manufactured in sequence with minimal downtime.

However, significant shifts between chemical families require extensive changeover procedures that increase idle time. These changeover parameters must be modeled within planning software to optimize production sequences and minimize unnecessary downtime.

Modern supply chain disruptions and external factors

Besides everyday practicalities and planning issues, increasingly complex, interdependent global supply chains cause unprecedented challenges. Disruptions cascade rapidly through production networks, triggering bottlenecks and delays that lead to idle time. Various external factors have made downtime significantly more expensive for manufacturers worldwide.

Geopolitical instability and changing tariffs force manufacturers to reconfigure operations, often establishing new supplier relationships that look viable on paper but tend to fail in practice. The uncertainty caused by political unrest, climate disasters, and related incidents is making it difficult to manage supply chains without some lost production time at some point.

How RELEX addresses manufacturing downtime with AI-enabled planning software

As the cost of downtime has risen exponentially, manufacturers have urgently sought technological solutions to reduce lost production hours. Predictive maintenance and condition monitoring technologies have helped address equipment-related failures; however, these solutions don’t address the planning and scheduling inefficiencies that cause a significant portion of downtime in manufacturing.

This is where AI-powered planning software from RELEX brings substantial value to manufacturers. Rather than focusing on predicting machine failures, RELEX Production Planning and Scheduling optimizes the controllable elements of production planning and scheduling that often cause unnecessary downtime. The RELEX solution complements existing maintenance technologies with intelligent automation that ensures machines run the right products in the right sequence at the right time. Using our industry expertise to address downtime caused by supply chain planning gaps.

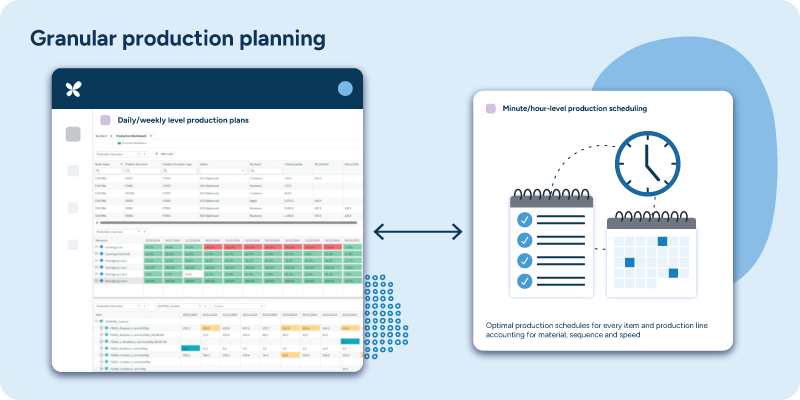

Granular production planning and scheduling

At the core of RELEX’s approach to production planning is the ability to plan and schedule at unmatched granularity — down to hourly levels rather than weekly or monthly horizons.

This detailed planning enables manufacturers to seamlessly translate high-level strategic plans into day-to-day operational schedules without information loss or manual intervention. The system handles complex workforce scheduling, machine availability, and certification requirements as integrated constraints.

This integrated approach ensures that all resources are coordinated through parallel operations, synchronizing labor scheduling with machine and tool availability. The platform’s touchless planning approach leverages specialized AI to automate complex optimization decisions across multiple variables. It implements a “golden touch” philosophy where human intervention occurs only where it truly adds value.

Rather than solely focusing on reducing downtime, RELEX looks to use available production time more effectively. The system analyzes production capacity and the manufacturing demands of each product, accounting for lead times, shelf life, and other considerations to determine optimal production scheduling. With RELEX, manufacturers can get more out of every day, hour, and minute of production time on the factory floor by consistently manufacturing the right products at the right times.

READ MORE: Touchless planning: A manufacturer’s guide to AI-driven supply chain excellence

Mastering scheduled maintenance periods

In addition to optimizing production capacities, the RELEX solution tactically manages planned downtime by scheduling maintenance windows based on operational realities. Granular modeling at hourly rather than weekly intervals ensures efficient asset utilization while eliminating downtime caused by production planning gaps.

The system distinguishes between quick reconfigurations (2-hour adjustments) and comprehensive overhauls (8+ hour services), suggesting optimal timing for each. For instance, a manufacturer may schedule major maintenance after seasonal peaks when demand subsides and manufacturers have adequate buffer stock levels.

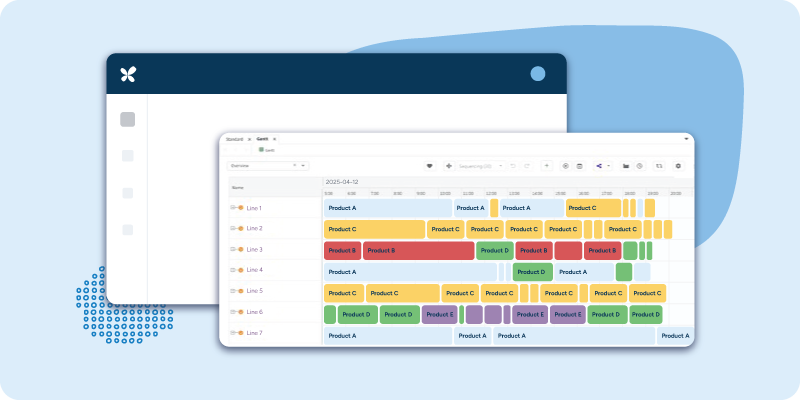

Intuitive sequence optimization

RELEX uses mathematical algorithms and heuristics to calculate logical production sequencing and minimize setup times. The system employs a setup time matrix that defines exact changeover requirements between different product attributes, automatically finding the most efficient production sequences.

In food and beverage manufacturing, the system optimizes production sequences and reduces cleaning time between runs. The software ensures proper sequencing, such as running white bread, then brown bread, then seeded products in the right order, while establishing optimal patterns for recurring production cycles. This systematic approach can save hours daily by reducing the frequency and duration of production line changeovers.

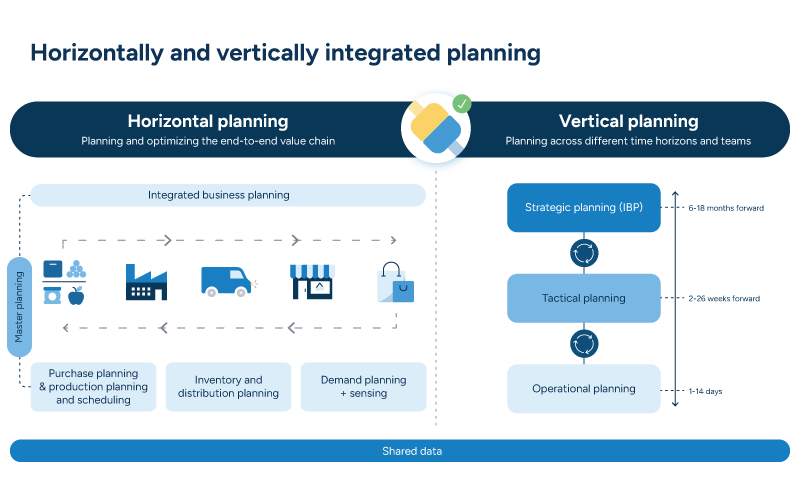

Strategic planning and integration

For longer-term downtime management, RELEX provides Integrated Business Planning (IBP) capabilities that deliver both horizontal and vertical planning integration. Horizontally, the platform optimizes the end-to-end value chain by connecting purchase planning, production scheduling, inventory management, and demand sensing through shared data. This ensures that downtime planning decisions made in one area automatically cascade across all related functions.

Vertically, RELEX integrates planning across different time horizons and organizational teams—from strategic IBP planning (6-18 months forward) down to tactical planning (2-20 weeks) and operational execution (1-14 days). This multi-level integration enables manufacturers to seamlessly connect strategic ‘corner office’ goals with shop floor execution.

The system’s scenario planning capabilities allow manufacturers to model “what-if” situations across these integrated horizons, such as supply chain disruptions or demand changes, determining their impact on production capacity and maintenance scheduling. Manufacturers can use these insights to optimize planned maintenance windows during low-demand periods, coordinate capacity utilization across the value chain, and build strategic inventory buffers that minimize idle time.

This horizontally and vertically integrated approach transforms traditional reactive maintenance into proactive, cross-functional planning, enabling faster decision-making when downtime occurs. The result is a systematic reduction in both the frequency and duration of manufacturing interruptions while maximizing production capacity across the entire operation.

Finsbury Food Group: Optimizing production planning to reduce downtime in manufacturing

Finsbury Food Group is one of the UK’s leading specialty bakery manufacturers and has been a RELEX customer for multiple years. Across its cake and bread divisions, Finsbury operates a complex network of highly automated and labor-intensive factories. With time-sensitive processes like fermentation and proving, plus diverse operational constraints at each site, its production planning previously relied heavily on manual spreadsheets and legacy tools. This created inefficiencies and potential downtime as planners struggled to optimize sequences and capacity across their varied production environments.

With RELEX planning software, Finsbury Food Group has reduced working capital by $2.1 million, doubled workload capacity, and is now targeting IBP.

Finsbury implemented RELEX production scheduling optimization across all production sites. The system takes daily and weekly production plans and determines optimal production sequences, factoring in capacity constraints, labor availability, sequencing rules, and material requirements. RELEX’s advanced algorithms replaced manual planning processes, enabling automated sequence optimization that minimizes setup times and maximizes equipment utilization.

As a result of this transformation in planning approach, Finsbury achieved an incredible $2.1 million reduction in working capital through smarter procurement and optimized safety stocks [Note: above value has been converted into US Dollars]. Organizationally, their planning teams have doubled their workload capacity with the same resources, requiring only one additional team member despite handling twice the operational complexity.

“Finsbury is on a journey, and we are happy to have RELEX onboard. We now have the people, system infrastructure, and process maturity to take on IBP.”

Liam McVey, Group Demand Planning Manager, Finsbury Food Group

Planners at Finsbury can proactively identify capacity constraints, optimize labor allocation, and make real-time adjustments to production sequences. This operational agility has enabled them to capitalize on available capacity that would otherwise go unused. The enhanced production scheduling has eliminated the functional disconnects that caused delays and downtime. Finsbury now intends to proceed with IBP to tie day-to-day operations back to longer-term strategic planning.

Use RELEX to master planning controllables

Given the realities of planned maintenance and unplanned disruptions, manufacturers cannot eliminate downtime entirely. However, they can take complete control of how they plan for and respond to these events, so no further time is lost due to inefficiency.

The disconnect between strategic planning and shop floor execution creates unnecessary idle time that forward-thinking manufacturers are learning to master. They must move beyond reactive maintenance approaches and embrace integrated planning solutions that give them control over the controllables.

AI-powered planning software from RELEX transforms both planned and unplanned downtime management while maximizing production capacity utilization. Through granular scheduling, sequence optimization, and scenario planning capabilities, organizations can reduce downtime in manufacturing processes, anticipating inevitable disruptions ahead of time. With this smarter approach to production planning, manufacturers will be equipped to take on downtime challenges whenever they arise.

The question isn’t whether manufacturers can afford to invest in integrated planning software — it’s whether they can afford to lose control of what they can actually manage.

FAQs

What is manufacturing downtime?

Manufacturing downtime refers to periods when production processes are halted and equipment or systems are not operational. This lost productivity can occur due to planned events like maintenance or upgrades, or unplanned issues such as equipment failures, supply chain disruptions, or operator errors. Minimizing downtime is critical for maintaining efficiency and meeting production targets.

What's the difference between planned and unplanned downtime?

Planned downtime includes scheduled maintenance, equipment changeovers, and other necessary production interruptions that are factored into planning. Unplanned downtime occurs due to unexpected events, such as equipment failures, human error, supply chain disruptions, or power outages.

How does poor production planning cause downtime?

Production planning serves as the critical link between strategic business objectives and day-to-day manufacturing operations. When this connection breaks down, manufacturers experience costly downtime that could have been avoided through better coordination and scheduling.

Poor production planning can cause downtime in several ways:

- Inadequate translation of high-level plans to daily operations.

- Improper sequencing of production runs.

- Failing to account for changeover requirements.

- Misalignment between workforce scheduling and machine availability.

- Inefficient material planning.

- Unoptimized capacity utilization.

How does AI help reduce manufacturing downtime?

AI transforms how manufacturers approach downtime reduction by processing vast amounts of operational data and identifying optimization opportunities that would be impossible to spot manually. Rather than reacting to problems after they occur, AI-powered systems can anticipate and prevent downtime through intelligent automation and predictive capabilities.

AI helps reduce manufacturing downtime by:

- Optimizing production scheduling across multiple constraints simultaneously.

- Predicting potential disruptions through scenario planning.

- Automating complex planning tasks through touchless planning.

- Providing easier access to planning information through natural language interfaces.

What is touchless planning?

Touchless planning is an approach in which AI-driven algorithms automate optimization across demand planning, supply planning, and production scheduling with minimal human intervention. The system automatically handles routine planning decisions, allowing human planners to focus only on exceptions where their expertise adds significant value— what RELEX calls “golden touches.”