How rough-cut capacity planning (RCCP) helps manufacturers optimize long-term profitability

Oct 2, 2025 • 11 min

When smarter technology emerges, yesterday’s best practice becomes today’s limitation. For decades, planning a long-distance car journey meant drivers had to carefully study paper maps and estimate travel times. This manual approach meant navigating traffic issues in real time, guessing at an arrival time, and having no basis for adjusting their route if they got lost or hit a road closure.

And then, in the 2000s, navigation was revolutionized by the popularization of GPS. Maps were digitized and route planning optimized, making the previous method virtually obsolete.

Manufacturing capacity planning has followed a similar technological evolution. Like calculating a route on a paper map, carrying out rough-cut capacity planning (RCCP) on legacy ERP systems provides static capacity views that quickly become outdated. When production overloads occur, these systems alert planners without offering solutions or alternatives. They’re disconnected and use a trial-and-error methodology that can’t adjust quickly when conditions change.

Manual planning in an environment marred by workforce shortages, supply chain disruptions, and elevated material and transportation costs exposes companies to avoidable operational chaos and leaves money on the table. To succeed, manufacturing production planners need strategic and operational views represented as different perspectives of a single synchronized plan; that is, they need integrated capacity planning.

This unified approach changes capacity planning from sequential problem-solving to continuous strategic optimization. RCCP capabilities from RELEX provide the required visibility to eliminate guesswork and make optimal capacity decisions at all times.

What is rough-cut capacity planning (RCCP)?

Rough-cut capacity planning (RCCP) is a tactical, long-term planning process that evaluates whether a business has sufficient production capacity to meet demand forecasts. As the name suggests, the aim is to provide an initial projection based on estimates of high-level capacity information rather than conducting in-depth analysis.

Unlike detailed production scheduling that focuses on granular day-to-day details, RCCP operates at a broader, aggregated level. Think of it as a snapshot view of production capacity across longer time horizons, typically spanning 8 weeks up to 18 months into the future.

In this process, planners analyze capacity constraints, simulate scenarios, and optimize production plans over long planning horizons to ensure efficient resource utilization and meet demand. It assesses the availability of key production departments, major equipment groups, and labor pools rather than individual machines or workers. For example, RCCP might evaluate an entire painting department’s capacity, while detailed capacity planning would examine each painting station separately.

RCCP is particularly valuable for those managing complex production processes or seasonal demand fluctuations. It helps supply chain planners and operations managers at manufacturing companies identify potential capacity constraints early in the planning process, enabling certain critical decisions.

This includes:

- Scaling operations up or down.

- Subcontracting production.

- Smoothing demand to avoid bottlenecks before they impact customer delivery.

- Investing in new production capacity.

- Reallocating resources.

- Adjusting demand expectations.

For companies experiencing growth, entering a new market, or managing dynamic demand patterns, this form of advanced planning can ensure management teams are making informed choices that benefit the company’s future.

Modern planning systems like RELEX integrate RCCP with other capacity planning levels, ensuring all planning horizons remain synchronized and up-to-date. Like the GPS in a car, the best RCCP platform will factor in all the necessary variables and rapidly make adjustments when required.

What’s the difference between RCCP and CRP?

To understand RCCP’s strategic value, it’s helpful to contrast it with the more operationally focused Capacity Requirements Planning (CRP)—two terms that are similar yet serve distinctly different purposes in modern integrated planning systems.

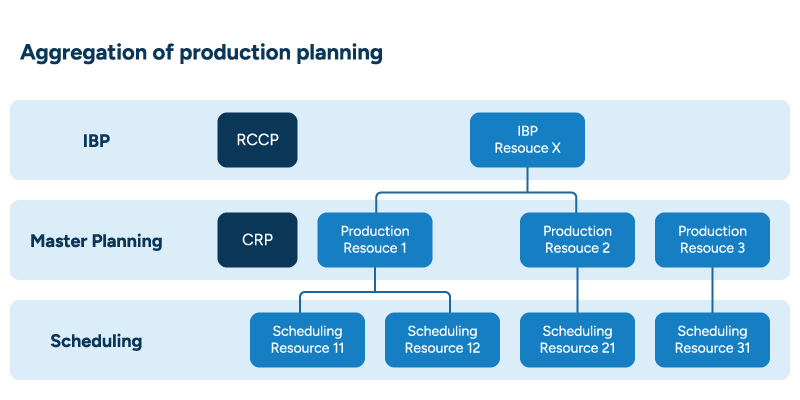

CRP and RCCP both serve the same core function of capacity analysis, although they differ primarily in aggregation levels and time horizons. CRP focuses on detailed, granular capacity analysis for shorter time periods, whereas RCCP provides strategic, high-level capacity visibility for longer planning horizons. CRP examines production lines, machines, and workstations, while RCCP analyzes capacity at the department, plant, or regional levels.

CRP functions on shorter timeframes, typically covering 8 to 16 weeks with weekly planning intervals. RCCP extends much further, spanning from those initial weeks out to 18 months ahead, using monthly time buckets for this longer-range view.

RCCP serves strategic management decisions about major capacity investments and long-term production planning, while CRP supports operational planners making day-to-day decisions. For instance, senior management uses RCCP for equipment purchases or workforce expansion, while production planners use CRP for immediate operational choices, such as overtime scheduling and shift adjustments.

The benefits of optimized rough-cut capacity planning

Effective rough-cut capacity planning enables manufacturers to strategically shift their approach to capacity management. Rather than reacting to capacity constraints after they impact operations, optimized RCCP enables proactive planning that prevents disruptions and maximizes revenue.

Early constraint identification

RCCP prevents costly manufacturing downtime and missed delivery commitments by revealing capacity bottlenecks before they impact production schedules. This foresight allows manufacturers to address preventable constraints through resource reallocation or capacity adjustments rather than scrambling to meet commitments.

Smarter decision-making

RCCP streamlines strategic capacity investments by providing executives with high-level capacity insights without operational complexity. Based on clear capacity projections, leaders can confidently decide whether to outsource production to external partners, recruit additional staff, or expand facilities.

Insightful scenario planning

What-if simulations enable strategic scenario planning that reveals how different business changes impact capacity. Manufacturers can model growth scenarios, new product introductions, or market expansions to understand their effects on existing capacity constraints. These insights directly inform future capacity planning decisions and investment priorities.

Improved company-wide visibility

RCCP improves decision-making alignment across multiple organizational levels by providing tailored capacity insights. Senior management gains broad capacity overviews suitable for strategic planning, while plant managers access operational constraints within a strategic context. This shared understanding ensures strategic decisions align with operational realities.

The challenges of rough-cut capacity planning

The benefits of RCCP are significant, but implementing it effectively is far from simple. Capacity planning involves countless variables, and without the right tools, even experienced planners struggle to keep pace. Manual approaches simply cannot process the thousands of interdependent variables that impact production capacity.

These challenges illustrate why intelligent production planning systems have become essential for competitive capacity planning.

Accurately calculating capacity factors

For RCCP to be successful, capacity must be continuously configured and updated. Capacity is calculated using the following key factors:

- Shift patterns determine available working hours, whether equipment operates 40 hours weekly or scales to 80 hours with additional shifts.

- Efficiency rates measure equipment throughput and fluctuate as operators learn new machines, equipment ages, or maintenance needs arise.

- Utilization factors account for breaks, cleaning time, changeovers, and other productivity impacts that reduce actual working capacity.

These factors change constantly and interact in complex ways. Manual tracking becomes impossible to complete accurately or promptly, especially when managing hundreds of resources across multiple time horizons.

Determining optimal aggregation levels

Organizations must decide which capacity entities to analyze at each planning level. Larger manufacturers might start with countries and factories for RCCP and then drill down to individual production lines for CRP. Establishing meaningful hierarchies requires careful discussion between planners and management.

The challenge intensifies with scale. Global companies often need 10 or more aggregation levels that cover everything from individual machines to large-scale regional operations.

Achieving system integration

Many manufacturers struggle with disconnected planning systems. Using separate applications for IBP, master planning, and production scheduling creates synchronization nightmares. For example, when a maintenance window gets scheduled at the detailed level, those capacity changes must instantly flow up to strategic planning views.

Without integrated databases, planners must manually update multiple systems. This creates timing delays and data inconsistencies that undermine planning accuracy.

Identifying true bottlenecks

Production plants contain numerous resources, but only certain constraints actually limit throughput. Focusing modeling efforts on true bottlenecks maximizes planning value, while spending time perfecting non-constraining resource models provides minimal benefit.

Bottleneck identification requires analyzing complex production flows and interdependencies. Manual analysis can often miss the actual constraints that limit profitability.

Managing forward-looking complexity

Capacity planning requires accurate projections across 18-month horizons. Optimization models must process a multitude of variables simultaneously while considering business rules and profitability constraints. Variables range from forecast increases and product mix shifts to new equipment ramp-ups and supplier constraints. Additionally, manufacturers have to factor in the fact that, over time, equipment efficiency changes, workforce skills evolve, and maintenance schedules shift.

Manual planning cannot handle this temporal complexity. Even simple scenarios with two products require extensive calculations that optimization software solves instantly.

How to leverage AI-powered planning features to optimize RCCP

While the complex nature of capacity planning proves challenging for manufacturers, companies that address it intelligently and efficiently can gain a substantial advantage over competitors. This requires sophisticated optimization software to handle the inherent complexity.

RELEX Solutions addresses RCCP challenges through an advanced mathematical optimization engine and emerging AI capabilities. The platform continuously processes capacity constraints and business rules to maximize profitability. These AI-powered features enable manufacturers to allocate optimal capacity while maintaining strategic visibility across all planning horizons.

Bottleneck identification and analysis

RELEX automatically identifies and ranks production bottlenecks by constraint impact on revenue. The system analyzes resource loading across all time periods to determine which capacity limitations most restrict throughput. Bottlenecks are ranked numerically, showing planners exactly which constraints to address first for maximum profitability gains.

The optimization engine simulates capacity increases at each bottleneck to quantify revenue impact. This analysis shows planners precisely how much additional profit they could generate by increasing specific resource capacity.

AI-powered scenario planning

RELEX enables sophisticated supply chain scenario planning to test capacity scenarios before implementation. Planners can model various what-if simulations to gauge system-wide impacts, such as:

- Forecast increases and their bottleneck implications.

- Product mix changes that shift constraints between production resources.

- Capacity additions through additional shifts or investments in new equipment.

- New customer orders and their impact on existing bottleneck rankings.

- Subcontracting decisions when internal capacity becomes insufficient.

The optimization engine considers complex interdependencies that manual planning cannot process.

AI agents will soon be able to run hundreds of scenarios automatically overnight. These agents will identify the most promising capacity optimization opportunities and compile summary reports for morning review. This eliminates the time planners currently spend manually configuring and waiting for scenario results.

Automated replanning

With its intelligent mathematical optimization engine, RELEX creates plans that maximize revenue subject to finite capacity constraints. Like a GPS reroutes a car, the system runs constantly optimized plans daily, automatically reallocating capacity as demand changes or production deviates from schedule.

When equipment breakdowns or planned maintenance occur at the scheduling level, or when supply chain disruptions require production shifts between facilities, these changes instantly flow up through CRP and RCCP views, ensuring all planning horizons remain synchronized. Automated capacity aggregation instantly rolls up detailed scheduling resources to higher-level RCCP entities.

Business rules integration ensures plans remain implementable across the organization. The optimization balances profit maximization with practical constraints, like maintaining customer relationships. Firm and locked horizons prevent excessive schedule changes in the short term while optimizing beyond the locked period.

Integrated capacity synchronization

Integrated planning keeps every decision anchored in the same up-to-date data, reducing errors and delays. Operating within a single database, capacity updates flow instantly across scheduling, master planning, and Integrated Business Planning (IBP). A change at the detailed scheduling level automatically recalculates RCCP availability, so minute-by-minute schedules and 18-month strategic plans remain seamlessly connected.

This integration eliminates the synchronization problems of using separate systems for different planning functions. Unlike traditional approaches requiring manual updates across disconnected applications, RELEX maintains real-time capacity accuracy across all aggregation levels and time horizons.

Customer success: How Orkla Foods reached capacity planning excellence with RELEX

Orkla Foods, the largest division of the leading branded consumer goods company in the Nordic region, faced complex planning challenges across nearly 50 production facilities. With hundreds of brands, extensive SKU variety, seasonal campaigns, and fluctuating demand, their previous ERP system generated plans that ignored production capacity constraints, requiring extensive manual adjustments to create executable schedules.

After implementing RELEX at its Arna factory pilot site, Orkla revamped its approach to capacity management. The system automatically generates constraint-based plans that account for actual production limitations, eliminating the need for manual capacity reconciliation. Management now uses integrated dashboards during Sales & Operations Planning meetings to evaluate long-term capacity scenarios and strategically allocate resources.

The solution enables instant “what-if” analysis, allowing leadership to assess the impact of capacity changes, new product launches, or market expansions. This shift from reactive capacity management to proactive strategic planning helped Orkla achieve 98% delivery performance while positioning its planning process as a decision-support tool for enterprise-wide capacity investment decisions.

Key KPIs:

- 98% Customer service levels

- 98% Delivery performance

Rough-cut capacity planning: propelling manufacturers towards a prosperous future

Manufacturers continuing to rely on legacy ERP systems for capacity planning face the same competitive disadvantage as drivers using paper maps in the GPS era. The days of manual calculations and reactive bottleneck management are ending, replaced by integrated rough cut capacity planning that delivers predictive visibility and maximizes profitability at every decision point.

The companies thriving in today’s market chaos have embraced automated capacity optimization that drives superior operational performance. And this shift from reactive management to predictive optimization contributes to a future where manufacturing decisions, from daily schedules to long-term investments, are guided by profitability and foresight.

Rough-cut capacity planning FAQ

What does “rough-cut capacity” mean?

The phrase “rough-cut capacity” refers to an approximate, high-level estimate of how much production output a manufacturer can achieve with its available resources. It’s “rough-cut” because the calculation is not detailed down to each machine or worker. Instead, it’s an aggregated view used to see whether overall capacity is likely to meet demand over a longer horizon.

What does rough-cut capacity planning (RCCP) usually involve?

Rough-cut capacity planning typically looks at broad capacity groups—such as departments, major equipment, or labor pools—rather than individual machines or operators. Planners use it to:

- Compare forecasted demand against available capacity over 8–18 months.

- Identify where resources may be overloaded or underutilized.

- Explore options such as subcontracting, adding shifts, or smoothing demand.

- Support long-term decisions on staffing and capital investments.

In practice, RCCP helps planners spot capacity gaps early, test adjustment options, and guide strategic decisions before issues disrupt day-to-day operations.

What's the difference between RCCP and capacity planning?

Capacity planning encompasses all levels of capacity analysis from detailed scheduling to strategic planning. RCCP focuses explicitly on high-level, long-term capacity visibility. Both are essential components of comprehensive manufacturing planning.

Can RCCP integrate with existing ERP systems?

Yes, most modern RCCP solutions are designed to work alongside ERP systems. Rather than replacing them, RCCP tools add advanced optimization capabilities that ERP systems typically lack. This integration keeps data consistent while giving planners high-level visibility and better long-term decision support.

Can RCCP handle multiple levels of aggregation simultaneously?

Yes, RCCP can show capacity at different levels, from individual machines up to global operations. This flexibility is especially important for large manufacturers, who may need to zoom out for strategic planning and then drill down for operational details—all within the same system.