Sales and operations planning (S&OP): From data to information to decision-making

Jun 10, 2013 • 11 min

Sales and operations planning (S&OP) has been a hotly debated topic in recent years. Some think it’s simply a collection of old ideas under a new name that’s designed to sell consultancy services. Others swear by S&OP process development and point to all the benefits that have flowed from it.

We believe we can reconcile both sides in this debate and that, in many respects, both are right. S&OP process models have been in development since the 1980s and they largely draw upon familiar and proven ideas. On the other hand, these processes have become increasingly topical throughout many sectors, and not just among managers in large global corporations.

This topicality is driven by an ever increasing need for planning:

- In traditional industries, falling margins are driving the search for efficiencies which, in turn, translates into reduced buffers. When there are no longer storage or capacity buffers, good forecasting and planning are needed to maintain good service levels.

- Shorter product life cycles and faster changing markets expose companies to increased risks which, again, increase the need for good forecasting.

- In many industries, intense consolidation has led to the creation of larger corporations. The management of extensive production and distribution networks necessitates moving from unit-specific planning, to planning that applies across the entire corporation.

- The shift to Asia of production and procurement has forced many companies to extend their advance-planning period.

At the same time, significant advances in collecting, processing and communicating data have made the benefits of developing S&OP processes available to a wide range of businesses, not just the very largest corporations.

In this article, we take a brief look at what sales and operations planning actually means and explain how data systems affect the execution of S&OP processes.

S&OP’s Goal: Better Decisions

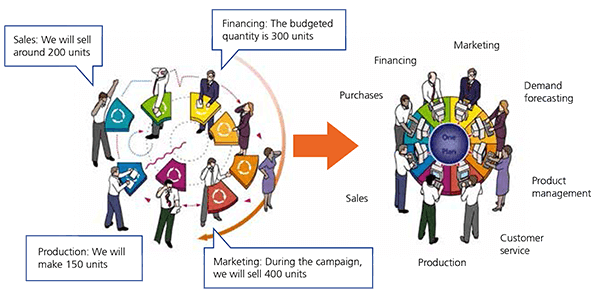

The aim of sales and operations planning is to get the whole company working from the same plan. Instead of having separate objectives and forecasts for sales, production, procurement, and the financial department, the S&OP process aims to create a coherent plan for the company that combines all these elements, that reflects the chosen strategy, that can be executed in practice, and is as comprehensive as possible.

Identifying and solving any problems related to realising plans or achieving goals is essential to the S&OP process. A sales plan that promotes rapid growth may, for example, lead to resourcing problems in production. When this happens a company needs to examine its options, for instance increasing production capacity (perhaps through additional work shifts) or prioritisation between product families (for example, accepting the risk to the service levels of another product family as a result of temporarily lowering its stock level to create capacity elsewhere). When making such decisions, it’s important to consider the overall picture – i.e., the company’s strategy and the effects of the decisions on customer satisfaction, costs, and profitability. Instead of leaving the production department on its own to solve the resourcing problems caused by the growth of sales, the company should foresee the likelihood of additional sales and plan a response beforehand in case production capacity becomes a bottleneck.

Although a good S&OP process is an excellent way to improve of the flow of information between various parts of a business, the primary benefit of the S&OP process is the action-related decisions that stem from it. If the S&OP process does not directly result in improved decision making then, to put it bluntly, you’re wasting your time.

The S&OP Process in Practice

There are plenty of examples of S&OP processes out there. We suggest that you familiarise yourself with them and use those that are most appropriate to support your development process. Of course every company has its own ways of working so don’t be afraid to adjust these to your specific needs. A good benchmark when developing processes is to weigh workload and time requirements against the significance and quality of the resulting decisions and ensure they are in balance.

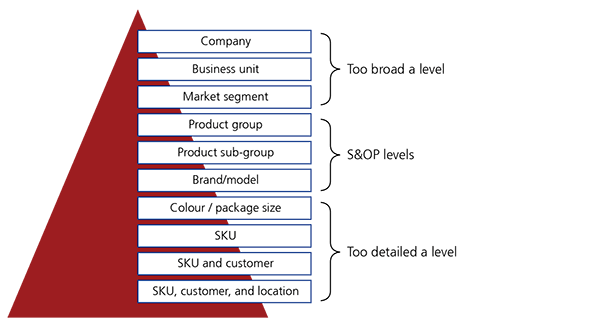

Arguably the greatest challenge is in deciding on the right degree of detail with which to engage: planning and discussion need to be kept on topic and on track, yet decisions should be based on sufficient and accurate information, so you are across everything you need to know to make that decision.

Regardless of what the S&OP process structure is in other respects, it is always based on specific planning phases: sales planning and capacity and resource planning.

The sales plan should include proposed sales-related activity such as campaigns, new-product launches, and product discontinuation, but also factor-in the likely impact of significant changes in markets and customer accounts. In practice it is rarely possible to have detailed and accurate information about external factors, such as changes in customers’ product selection, very far in advance. The further one looks into the future, the less one can be sure, even about the company’s own activities. For example, the times for planned product launches may change in response to the progress of the product development process.

Dealing with unreliable information is the greatest challenge in creating any sales plan. Rules about what should be included in the sales plan, including how unreliable the information and estimates may be, can be arrived at through diligence and persistence; keep refining it until it’s working well.

The capacity plan is created on the basis of the sales plan. In the medium term, the capacity plan can be created through turning the sales plan into a rough production and distribution plan. In longer-term planning, even rougher estimates are used and the sales plan will be compared, for example, to various objectives and capacity limits by product family or product line on a quarterly level.

The greatest challenge in capacity planning is that there are so many kinds of capacity, from production capacity and availability of raw materials to financing and resources for storage and logistics. Bottlenecks or excess capacity may arise in different situations in different parts of the company.

To enable sensible decisions to balance demand and supply, companies should identify where problems may arise, what can be done to achieve balance, and estimate what effect these actions are going to have on sales, capacity, costs, customer satisfaction, and profitability.

Data systems in S&OP Process Development

The development of an S&OP process is not an IT project. As with all wide-ranging projects that encompass several departments, the greatest challenges relate to the flow of information, to responsibilities and to decision-making. The creation of good S&OP processes require clear ideas of what the goals are, a great deal of change-management, a readiness to learn through experiments and mistakes, and the adaptation of serviceable processes as the prerequisites for operations evolve.

Since the planning of sales and operations is information-intensive, the S&OP process does make demands on your systems. Excel can be used to outline the S&OP process, but this approach is almost always too labour intensive to be an ongoing solution. The vast majority of effort, 90% or more, will go into gathering and organising information leaving little time for analysing plans and finding solutions. In the long run this risks compromising the entire process. Good system support will almost certainly be critical if the whole process is to be carried out smoothly and efficiently.

The following parts of the S&OP process are particularly closely connected to data systems:

- Efficient and accurate sales planning and forecasting

- Support for decision-making

- Monitoring of changes and results

Efficient and Accurate Sales Planning and Forecasting

Preparing a sales plan is a stage by stage process. First you need to create a base forecast for all your products. This is pretty straight forward but time consuming. The base forecast is an estimate of sales, including normal variations, seasons and trends but excluding special factors such as promotions etc.

It is often a good idea to create a separate forecast for each customer group. This allows your team to take decisions – such as to institute a customer-specific campaign or change the product selection – on an account-by-account basis – and it makes it easier to assess the likely impact of any such decisions.

If forecasts are made by customer group, the number of forecasts required quickly multiplies. For example let’s take a company that has 500 active products and 10 customer groups needing forecasts. That equals 5,000 forecasts. Now supposing that weekly forecasts are needed 18 months ahead to support planning, that means around 39,000 forecasts that require continuous updating!

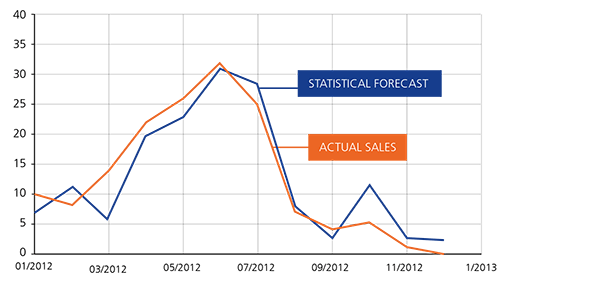

Using automatically calculated statistical forecasts as your base forecasts makes the process far more efficient. Computers don’t get tired or bored. This sort of repetitive yet detailed workload is exactly what they were designed to handle; forecasts by the thousand or even by the hundred thousand without sleep, without complaint and with unswerving accuracy and quality. Forecast accuracy also improves because high-quality statistical forecasting often takes seasonal fluctuation and trends into account better and more objectively than humans can. Statistical models or, at the very least, clear reports on the outcomes of earlier campaigns, are also really useful in campaign forecasting.

Tip: Enhance your planning process through statistical forecasting. When base forecasts are created automatically, the focus of forecasting work can be shifted from routine updating to evaluating the effects of truly important activities and changes. At the same time, forecasting can be performed on a more detailed and specific level, such as customer group level, to help evaluate the impact of campaigns and changes in product selection.

Our clients have found this works in practice too. One company we work with now generates 95% of its forecasts automatically using statistical methods and says that their accuracy has increased accordingly.

Support for Decision-making

As we pointed out earlier, there are many kinds of capacity. Bottlenecks and excess capacity can occur in production, procurement, distribution, and financing. Therefore it’s important to be able to examine forecasts flexibly on various levels.

In the short or medium term, production companies typically create rough production plans to identify production and procurement needs. Similarly, in wholesale and retail, forecasts can be converted into order and distribution plans that can be used as a basis for estimating logistics requirements, capital tied up in stock, etc.

How about the longer term? Well we know that the further we peer into the future the less reliable our ability to predict becomes. However we can improve our long term forecasting by working harder (and smarter) and that means we need to be able to able to dig into our data every which way. Here, a good system that allows completely flexible data analysis becomes really effective.

Think of a forecast like a digital photograph. As you zoom in the clarity of the image relies on the amount of data. If you want to see detail you need quantity of information. Too little information and the image soon dissolve into meaningless blobs. Yet zoom right in and you can’t see the whole picture. You need the ability to zoom out or to change your focus so you can switch between an overview, a partial view or a detailed view.

By the same token, to be most effective, forecasts need to be made on a sufficiently detailed level to enable managers to zoom in on short and medium term changes and zoom out to get an overview.

For example you can look at a given set of forecast data according to predicted volumes by production line in comparison with line-specific production capacity; predicted sales, in Euros (or Sterling or Dollars), by customer group in comparison with sales objectives or budget; and predicted volumes by product family or by packaging type to help determine purchasing requirements.

If bottlenecks are spotted it’s important to be able to look at the forecast in greater detail. For example the risks associated with new products and campaigns are generally higher than with established products so it’s good to be able to separate these out from the full forecast. Also if a particular production line has a capacity bottleneck, it’s important to be able to see which products are planned for production and what their expected volumes are.

Tip: When all the information needed is all found on one system, it takes less time to create reports and the company can focus on analysing data, identifying alternatives, and making decisions.

One of our clients presents upper-level reports directly from the system during the company’s S&OP meetings and can call up more detailed information, or edit the time period under review in real time and get instant results.

Monitoring of Changes and Results

Continuous monitoring and improvement is central to the S&OP process’s development.

Sales plans in practice are never exactly the same as sales plans on paper. You simply have to live with a degree of uncertainty. However, it is important to monitor whether there are systemic errors in a plan affecting, for example, a particular customer, and to get to the bottom of any recurrent problems. It is also important to understand which parts of a plan are relatively reliable and which are more prone to errors. When a company is aware of the unreliability of a plan in advance, it can be prepared for issues to arise. For example, one company we work with has contingency plans for both procurement and production for any significant product launch. It produces a forecast based on the most likely result, but it also estimates best case sales volumes and aims to keep the delivery chain sufficiently flexible to respond to higher demand levels.

Changes made to plans must also be tracked effectively. If a plan goes through significant changes from meeting to meeting, these changes should be monitored and reviewed, with additional scrutiny being applied when new results shed additional light on their impact.

Tip: Good system support makes gathering and processing arising from results and changes much more effective. In an Excel-based process, it is often very difficult to track a plan’s development over time, for example.

Data as a Source of Information, Information as the Basis for Decisions

Off-the-shelf S&OP process models are available, but each company needs to find the best way to make use of them. It is important to remember that a plan, however comprehensive, has no value on its own. You will never have perfect information and the S&OP process does not eliminate business risks. However, a good S&OP process does make risk management significantly more effective.

An S&OP process is there to guide business operations and its purpose is to prompt and inform actions. If the process doesn’t lead to decisions, and to better decision making, you’re wasting your time. In setting up the process it is important to focus on those elements that require decisions, on making those decisions within the available time periods, and on the information needed to make them.

The development of an S&OP process is not an IT project, yet data systems must be used in developing the process. Those involved quickly become demotivated if the process becomes bogged down in generating basic data and there’s not enough time left for analysis and decision-making.

Reference: Wallace, Thomas F. and Robert A. Stahl. Sales and Operations Planning, 3rd edition, 2008.