Improve product availability by taking better control of your supply

Mar 1, 2024 • 6 min

Supply chain performance and end-to-end visibility have never been more in the spotlight. As global markets face unprecedented challenges, ranging from inflationary pressures to logistical bottlenecks, the need for greater supply chain control has become vital across industries.

These recent challenges have highlighted the critical role of supplier/retailer collaboration in ensuring product availability. From manufacturing to distribution, every link in the supply chain is now under scrutiny, requiring a cohesive approach that mitigates risk and optimizes operational efficiency.

This blog post will delve deeper into the key pain points and strategies businesses can explore to position themselves for success in an increasingly uncertain world.

Best practices for addressing supply constraints in replenishment

With ongoing supply constraints and disruptions, retailers must rethink their inventory management and procurement approaches. Embracing strategies that enhance flexibility, resilience, and efficiency within the supply chain emerges as a necessity rather than a choice.

Diversifying supplier bases, fostering collaborative relationships, maintaining agility in material flows, and optimizing capacity management are among the most pivotal strategies employed to reduce the impact of unreliable or inconsistent supply:

1. Diversify your supplier base

Many retailers continue to grapple with inventory scarcity due to rigid sourcing strategies. To better manage adversity, retailers are diversifying their supplier base by reducing reliance on long lead-time purchasing and over-dependence on a single supplier or sourcing region. Diverse supplier agreements provide greater resilience when upstream shortfalls occur, and even in the absence of disruption, better agility can still help improve purchase margins.

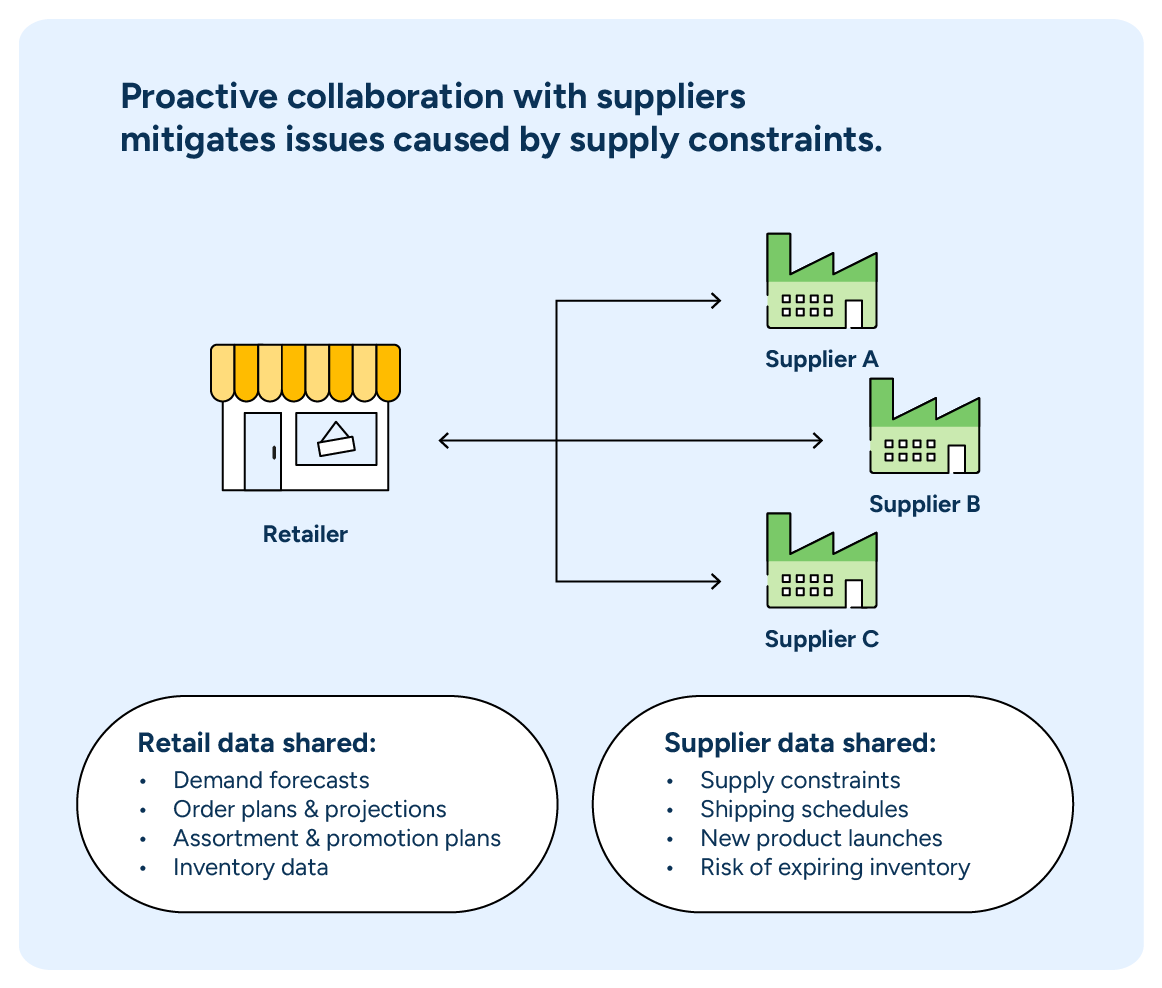

2. Create collaborative relationships with suppliers

The importance of strong partnerships with suppliers has become increasingly evident amidst inventory shortages. Retailers that foster collaborative relationships with vendors benefit from enhanced visibility and timely stock delivery. Proactively sharing demand forecasts upstream and early warnings into stock availability downstream contributes to more robust service levels and operational efficiency.

3. Be flexible to changing material flows

Adapting material flows can be valuable for retailers navigating supply disruptions and imbalances. Quick changes in delivery methods, such as cross-docking, internal DC transfers, or direct supplier-to-store deliveries, are sometimes helpful in mitigating bottlenecks and maintaining operational continuity.

4. Safeguard what you can

Retailers must accept that they cannot save every sale during severe disruption. Calculating the knock-on impacts on availability as early as possible allows them to consider where to prioritize (which stores/products are to be protected). And as a result, retailers can decide what shortfall they need to make up with suppliers.

To execute these practices effectively, a central planning team will need the support of technological investment and access to the right toolkit.

How tech can enhance end-to-end supply chain performance

A retailer has ordered a large quantity of strawberries from their supplier to keep up with the strong spring season demand within their stores. Unfortunately, due to a change in weather that damaged the crop, the supplier is unable to deliver as planned and a shortage is now imminent. This impacts the ability of stores to meet customer demand – losing sales and damaging customer perception.

This is a typical scenario where supply chain technology can step in to mitigate potential losses. A good planning system can help retailers collaborate with suppliers early, simulate potential impacts quickly, re-plan for shortages, and share updated demand to further supply chain resilience.

Collaborate

A robust collaborative planning portal allows near real-time communication and data sharing between vendors and key stakeholders. This communication fosters improved responsiveness to changes or disruptions in the supply chain, effectively leveraging vendors as an extension of the planning team.

In the previous scenario, the vendor would use a collaborative portal to communicate the possible shortage with the retailer at the first sign of an issue with the strawberries.

A collaborative portal allows vendors to:

- Add specific supply constraint limits

- Discuss closure dates and order blocks

- Or comment on how much they can provide, by when, etc.

Together, they could review the projected demand for the affected period and compare the current plans and capacities.

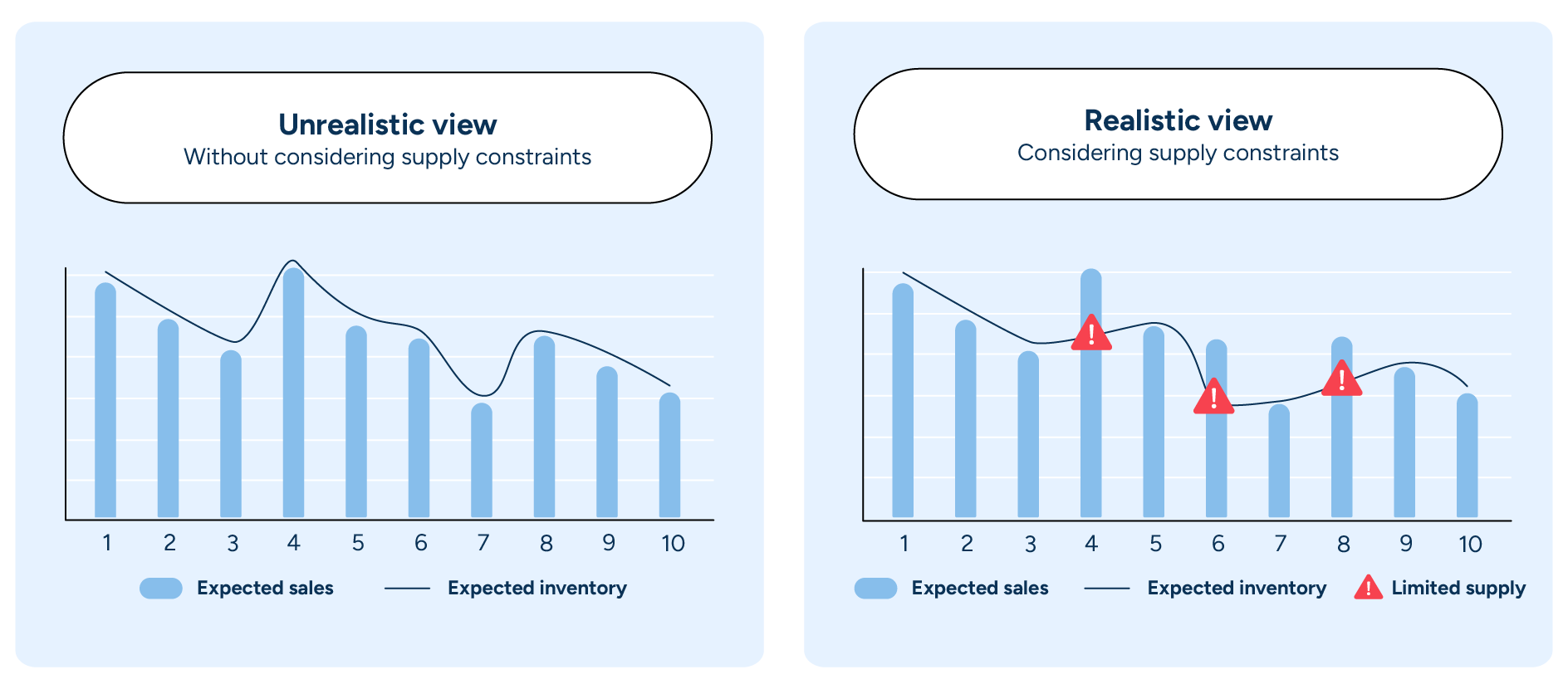

Simulate

The most important next step is to assess the impact of any upstream issues on your customers. A planning platform capable of simulating the effect of scarcity / surplus of supply on your stockholding- and ultimately your sales- is essential in achieving this.

Importantly, this is a two-way process with two-way benefits:

Upstream -> Downstream

The near-term reality of upstream supply is simulated against downstream demand.

Downstream -> Upstream

Downstream under/over fulfilment leads to a change in future-term upstream demand.

In our strawberry shortage, a retailer should project the most optimal scarcity allocation to stores, simulate how many sales could be endangered, then assess whether the size of that impact necessitates mitigative action.

Re-plan

If disruption is severe, businesses should take action to minimize losses. A sound planning system can help here in a few ways:

Automatically responding to the bullwhip effect

Previously simulated downstream scarcities are built into future upstream order volumes. If the supply disruption has eaten into presentation or buffer stock, then that stock needs to be built back up in the subsequent order opportunities. An automated replenishment system will respond immediately (within the confines of delivery schedules) as soon as the supply constraint is modelled.

READ MORE: How to reduce the bullwhip effect in the supply chain

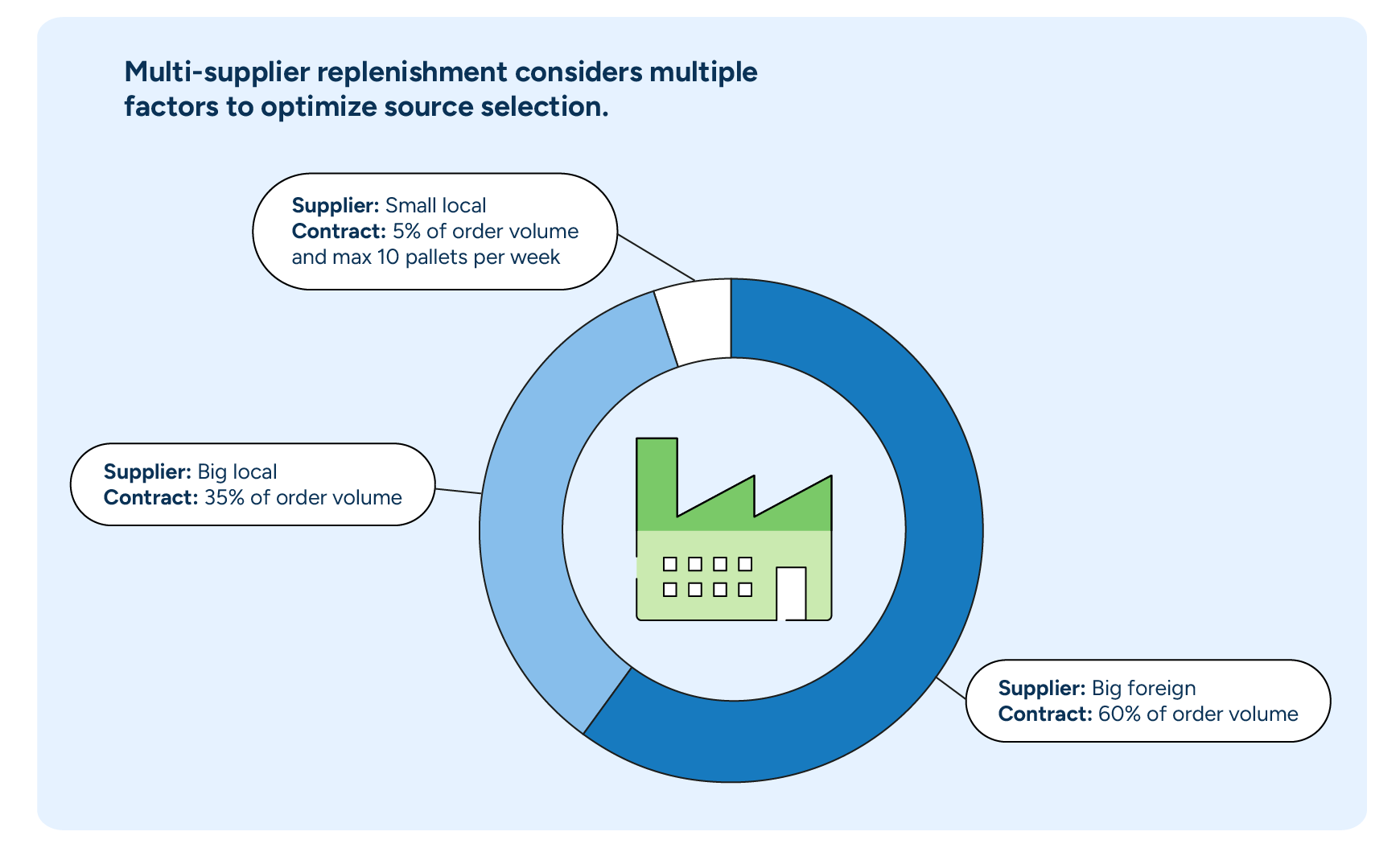

Seeking alternative supply

Sometimes, arranging alternative sourcing can reduce the immediate loss of sales. Modern planning systems allow purchasing users to indicate supplier preferencing, quotas, and even simultaneous split agreements. Users can instruct the system to switch suppliers, or if these agreements are up to date with the supply constraints, the system can switch supply automatically.

Model future order volumes

Realistically projected future order volumes must reflect any containerization or minimum/maximum limits enforced by suppliers, enabling them to adequately prepare before placing orders.

In our strawberry example, the system may have identified alternative growers and then calculated the number of additional containers/pallets needed due to the temporary shortfall before reverting to business as usual with the permanent supplier.

Share

Then, the process comes back full circle.

Retailers should share the updated order predictions with suppliers to decrease the likelihood of future disruptions.

The strawberry vendor can rely on consistent and early volume projections (outside of lead-time), allowing them to build up their own contingency/buffer provisions, leading to a more robust supply chain.

Conquering the supply cycle

The challenges posed by supply constraints demand proactive strategies and agile responses to ensure product availability and customer satisfaction. Navigating the complexities of supply chain management requires a comprehensive approach that integrates collaboration and technology.

This integrated approach not only mitigates risks but also drives efficiency and competitiveness across the end-to-end supply chain.