Seasonal fluctuations are retail’s biggest stress test

Every retail calendar is shaped not just by peak events like back-to-school, summer vacations, and the winter holidays—but by a continuous rhythm of demand shifts that span the entire year. Seasonal fluctuations now extend beyond major events, including sudden shifts triggered by weather, social trends, and competitive promotions. These swings are no longer exceptions – they’re the rule.

What should represent an opportunity for driving profit often brings complexity, cost, and risk. Retailers find themselves locked into long-range seasonal plans that no longer fit reality, forced into last-minute decisions that drain margins and strain operations. The problem isn’t effort; it’s that the old way of seasonal planning was never built for today’s retail dynamics.

Leading retailers are breaking this cycle by embracing AI-driven, adaptive planning systems that transform seasonal volatility from liability into a competitive advantage.

The new reality of seasonal retail

Seasonal planning today demands agility across the entire calendar—not just during peak events. Back-to-school shopping now begins in early July rather than late August. Black Friday has expanded into “Black Friday Week” with competing retailers launching promotions at different times. Holiday shopping increasingly shifts online, creating new fulfillment pressures while traditional store traffic patterns become unreliable.

External factors compound this volatility. Unseasonable weather can shift demand for entire categories within days. Social media trends can create sudden spikes in specific products. Supply chain disruptions force retailers to adapt their assortment and pricing strategies mid-season. Competitive promotional activity has become increasingly unpredictable as retailers fight for market share in a challenging economic environment.

In this environment, successful seasonal planning isn’t about forecasting a few big moments—it’s about building resilience and responsiveness into every phase of the retail year.

The cost of getting it wrong

Traditional seasonal planning approaches, built for predictable patterns and stable supply chains, are fundamentally mismatched to today’s retail reality.

Static budgets set months in advance cannot accommodate rapid shifts in consumer behavior. Historical sales patterns provide limited guidance when product ranges change annually and external factors create unprecedented demand variations.

The financial consequences cascade through the organization:

- Revenue loss from stock-outs: An empty shelf during a demand spike is a missed sale and, potentially, a customer lost to a competitor.

- Margin erosion from overstocks: Over-ordering “just in case” ties up working capital, triggers markdowns, and inflates handling costs.

- Operational inefficiency: Stores and DCs absorb the shock of unplanned deliveries and rushed changes, driving up labor costs and reducing productivity.

These challenges compound with every seasonal cycle, creating a vicious loop where poor planning leads to reactive decisions that undermine the next season’s performance.

6 key pain points retailers face during seasonal peaks

Understanding the specific challenges that derail seasonal execution is crucial for developing effective solutions. Here are six critical pain points that consistently undermine seasonal performance.

1. Seasonal volatility and demand unpredictability

Seasonal demand is increasingly unpredictable, making last year’s sales data an unreliable guide. Seasonal product ranges change year-on-year, making decision-making using historical sales more difficult. The traditional approach of applying growth percentages to historical patterns fails when customer preferences, competitive dynamics, and external factors create entirely new demand scenarios.

This challenge is particularly acute for trend-driven categories where product lifecycles have shortened dramatically. What sold well during last year’s holiday season may be completely irrelevant to current customer preferences, leaving planners with limited data to guide their decisions.

2. Disconnects between financial planning and operations

Siloed tools make it hard to align buying decisions with budget targets, leading to overcommitment or missed opportunities. Financial teams set seasonal budgets based on top-down revenue targets, while buying teams make purchasing decisions based on demand forecasts and supplier negotiations.

Without integration between these processes, retailers either exceed their planned spend or miss opportunities to invest where demand exceeds expectations. Locked-in financial plans create rigidity. Budgets and open-to-buy targets are fixed months before the season begins, making mid-course corrections nearly impossible without complex approvals.

3. Execution pressure and capacity bottlenecks

Peak seasons create intense operational pressure, and store teams often lack visibility into the upcoming workload, leading to under- or over-resourcing. In some cases, demand exceeds capacity, causing delays in picking and receiving and creating availability issues.

The consequences extend beyond immediate operational challenges. When stores cannot handle incoming merchandise efficiently, products arrive late to shelves, reducing selling time during critical peak periods. Customer satisfaction suffers when stores appear disorganized or when popular products are unavailable despite being in the building.

4. Promotional blind spots

Promotional impact is often overestimated, leading to imbalanced execution and eroded margins. Many retailers approach promotions during seasonal peaks with optimistic assumptions about uplift that don’t materialize in practice. This leads to overordering promotional inventory while underinvesting in steady-performing products that generate consistent margins.

Poor promotional planning also creates cascading effects throughout the organization. When promotional forecasts prove inaccurate, inventory allocation decisions become misaligned with actual demand, leading to stock-outs in some locations while other stores struggle with excess inventory.

5. Overstock and markdown pressure

Stock surpluses force markdowns that damage profitability and brand equity. The pressure to avoid stock-outs often leads to conservative over-buying that creates end-of-season clearance challenges. What begins as risk mitigation becomes margin destruction as retailers discount excess inventory to clear space for new seasonal ranges.

The timing of these markdowns often compounds the problem. Retailers who delay clearance decisions, hoping demand will recover, typically face steeper discounts and higher obsolescence costs. The resulting margin erosion can negate the benefits of successful product sales during the peak period.

6. Lack of root cause insight

Retailers struggle to act quickly when plans go off-track due to limited visibility into execution gaps. When seasonal performance deviates from plan, most retailers lack the analytical capabilities to quickly identify whether the problem stems from demand forecasting, inventory allocation, promotional execution, or operational constraints.

These blind spots prevent organizations from learning effectively from each seasonal cycle. Without understanding root causes, teams repeat the same mistakes season after season, missing opportunities to improve their planning processes systematically.

Smarter seasonal planning with AI-powered solutions

The solution to seasonal planning chaos lies not in working harder with existing tools, but in fundamentally reimagining how planning, execution, and analysis connect throughout the seasonal cycle. Traditional seasonal planning is no longer fit for purpose. RELEX is helping retailers turn chaos into control by shifting to adaptive, unified planning.

The shift to adaptive planning

Leading retailers are moving away from static plans and toward adaptive planning loops that continuously connect financial strategy, operational execution, and performance analysis. This transformation rests on three foundational principles:

Integration over isolation: Financial targets, demand forecasts, and execution constraints all live in one system—not across spreadsheets and siloed tools. This unified approach eliminates the delays and errors that occur when information must be manually transferred between systems.

Prediction over guesswork: AI-driven models anticipate fluctuations with more accuracy, incorporating signals that traditional methods miss. Advanced algorithms can process vast amounts of data—from weather patterns to social media trends to competitive intelligence—to generate forecasts that capture the complexity of modern consumer behavior.

Continuous improvement: Performance isn’t reviewed at season-end; it’s monitored in real time, and every insight feeds the next cycle. Rather than conducting post-mortems after seasons conclude, adaptive planning systems provide ongoing visibility into performance drivers and enable course corrections while they can still impact results.

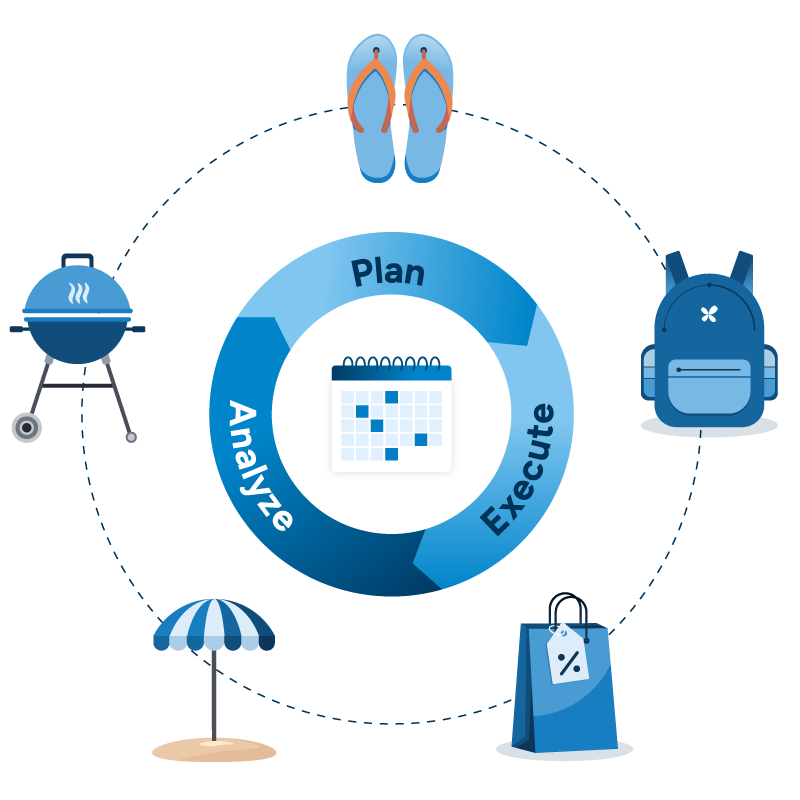

The Plan—Execute—Analyze loop

RELEX enables continuous seasonal control through a closed-loop process that connects planning, execution, and analysis in real time. This integrated approach shifts seasonal planning from a series of disconnected activities into a continuous improvement cycle.

Plan (Merchandise Financial Planning) Set strategic targets for margin, sales, and assortment that guide decision-making throughout the season. Financial planning becomes the strategic foundation that aligns all seasonal activities with business objectives.

Execute (Open-to-Buy) Track and adjust spends in real time using open-to-buy. Allocate budget toward ordering that drives sales and reduce stockholding where it doesn’t. Utilize capacity optimization to smooth inbound flow and workload to ensure that seasonal peaks are managed with minimal issues.

Analyze (Diagnostics) Quickly identify issues—from execution gaps to mismatches between actual and ERP-reported stock. RELEX Diagnostics and True Inventory provide real-world visibility, while scenario testing capabilities help teams test assumptions and model outcomes. These insights feed directly back into execution for continuous improvement.

Technology that delivers results

Rather than being victims of seasonal unpredictability, retailers with adaptive planning systems can respond quickly to opportunities while maintaining strategic focus on profitability and customer satisfaction.

The most successful seasonal planning transformations combine multiple technological capabilities in a unified platform that eliminates silos and enables real-time responsiveness. Understanding how these capabilities work together is crucial for retailers evaluating their options.

Alignment of financial and demand plans

The foundation of effective seasonal planning lies in connecting top-down financial targets with bottom-up demand realities. Traditional approaches create these plans separately, leading to misalignment that becomes evident only when it’s too late to correct.

Merchandise Financial Planning (MFP) allows users to define strategic sales, margin, and inventory targets across their categories. Unlike generic budgeting tools, MFP is specifically designed for retail dynamics, enabling planners to model different scenarios and understand the trade-offs between volume growth and margin protection.

The key advantage lies in MFP’s ability to cascade strategic objectives down to operational levels. When senior leadership sets aggressive growth targets for the holiday season, MFP translates those goals into specific category, regional, and even product-level targets that buying and merchandising teams can execute against.

Open-to-buy (OTB) enables retailers to monitor purchasing against financial targets in real time, allowing quick corrections to avoid overspending and overstock. This is particularly crucial in seasonal buying cycles. Rather than discovering budget overruns at month-end, OTB provides daily visibility into spending patterns and remaining capacity.

This real-time visibility becomes critical during volatile periods when opportunities and threats emerge quickly. When a trend-driven product category suddenly takes off, OTB enables buyers to quickly assess whether they have the budget capacity to capitalize on the opportunity without compromising other strategic priorities.

OTB also provides recommendations on which product orders can be reduced or delayed and which should be protected. It does this while modelling the lost sales impact each suggestion can expect to have, so that users can make decisions with full visibility of the consequences.

With MFP from RELEX, retailers can seamlessly align financial planning with day-to-day replenishment operations in a single system with real-time data, enhancing overall efficiency and profitability. OTB capabilities provide detailed visibility into supply chain and capacity constraints, enabling more informed, strategic decision-making.

Accurate, AI-driven replenishment and promotion forecasting

The complexity of seasonal demand patterns exceeds human capability to manage manually. AI-driven forecasting provides the accuracy and sophistication necessary to optimize inventory investment across thousands of products and hundreds of locations.

AI-powered forecasting and replenishment from RELEX enables precise seasonal demand forecasts using machine learning that incorporates weather, trends, and promotions—creating actionable plans even for new items. These sophisticated models process far more variables than traditional forecasting approaches, significantly improving accuracy.

Key capabilities include predictive modeling beyond historical sales data, machine learning-based forecasting utilizing pooled models for new or rotating products, promotion- and event-aware forecasting and replenishment, utilizing historical and contextual data, and accurate forecasts at the item/location level.

One example of the benefits of AI-powered forecasting and replenishment is SupplyHouse.com. SupplyHouse.com sought an AI-driven solution that could streamline and automate their supply chain management processes. Working with RELEX, SupplyHouse.com can leverage advanced forecasting that uses AI-powered algorithms to analyze demand drivers, such as seasonal and weekly trends, range changes, and other factors. The result is improved long-term forecast accuracy, allowing SupplyHouse.com to better align inventory with actual demand.

“RELEX has allowed us to greatly improve our efficiency in the day-to-day tasks of a demand planner. This has made room for the team to evolve into more of a strategic partner to the organization.”

Kaytee Grey, VP Fulfillment Operations, SupplyHouse.com

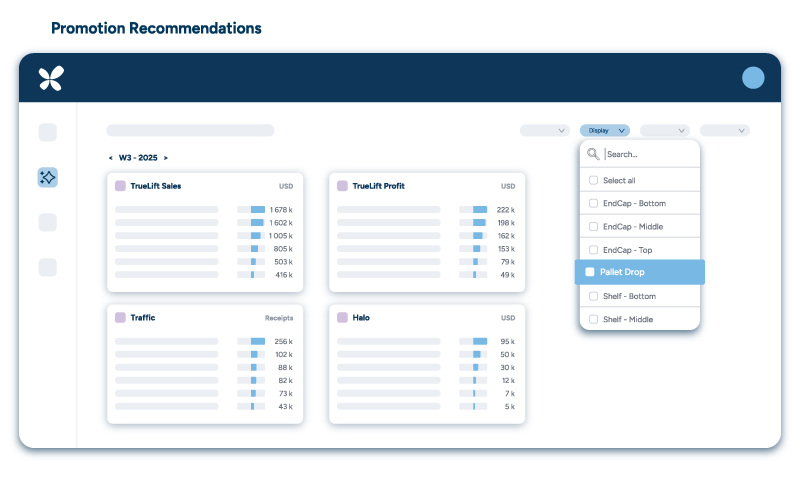

Promotion forecasting that accurately anticipates uplift from promotional activity supports balanced execution and protects margin. Rather than applying generic lift factors across promotional events, AI models learn from historical promotional performance to predict realistic outcomes for specific products, price points, and market conditions.

This capability prevents the common problem of promotional overbuying, which leads to post-promotional inventory gluts. By accurately modeling promotional lift, retailers can invest in promotional inventory where it will generate the highest returns while avoiding margin-damaging excess inventory.

Allocation of seasonal product inventory to stores must be in sync with purchasing and replenishment before, during, and after the season. Seasonal products often have limited selling windows, making allocation timing and accuracy critical to success. Advanced allocation systems consider local demand patterns, store capacity, and competitive dynamics to optimize the distribution of seasonal inventory.

Real-world results: ICA Sverige enhances inventory efficiency and forecast accuracy with RELEX

ICA Sverige AB (ICA), Sweden’s largest and leading grocery retailer, has five main distribution centers (DCs) and some 1,300 stores across Sweden. The independent ICA retailers own and operate their own stores and benefit from coordinated sourcing, logistics, market communication, and store development.

ICA adopted RELEX for their forecasting and replenishment solution in 2017 and more recently initiated a project focused on forecast accuracy and safety stock, which are essential for navigating seasonal variances and peak periods like the year-end holiday season. These strategic initiatives exceeded expectations, driving operational efficiency and cost savings, ensuring ICA remains a leader in the grocery retail business while maintaining the efficiency of its distribution network.

Key KPIs:

- 32% decrease in safety stock inventory.

- 6.69pp increase in forecast accuracy.

“Relying on RELEX Solutions to help us achieve our goals has proven to be a great choice. Not only has our collaboration produced tangible results, but working with RELEX has been easy and innovative.”

Andreas Persson, Head of Replenishment, ICA

Agility in seasonal execution

Even the best plans require adjustment as seasonal dynamics unfold. Technology that enables store teams to respond rapidly to changing conditions, turning inventory planning complexity into a competitive advantage during volatile periods.

Capacity optimization helps to smooth inbound deliveries to ensure pick/receipt limits are not exceeded during peak periods. Peak seasons create operational bottlenecks that can prevent products from reaching shelves despite being available in the supply chain. Capacity optimization prevents these bottlenecks by modeling store and distribution center workloads and adjusting delivery schedules accordingly.

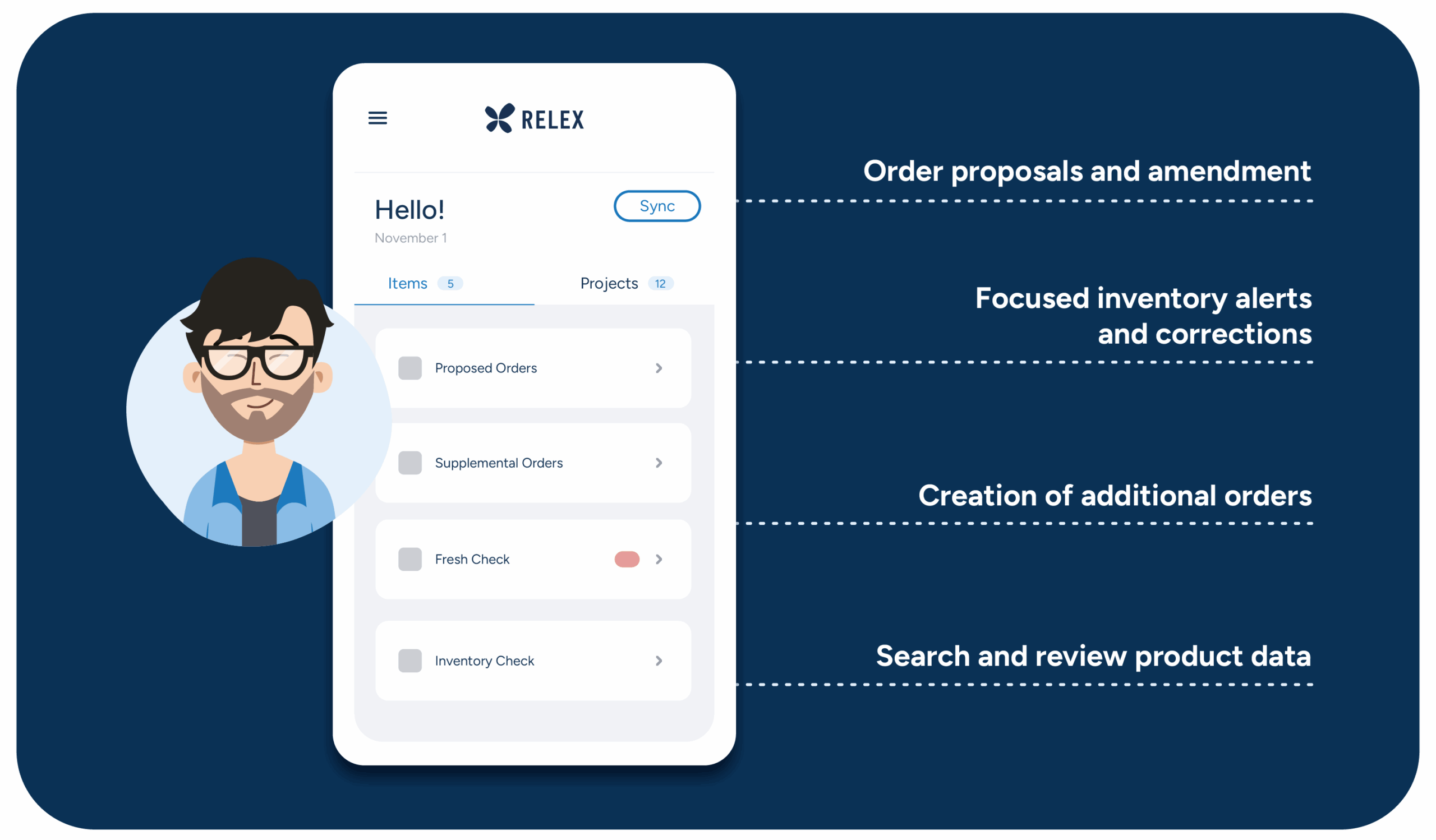

Workload forecasting and RELEX Mobile align staffing and tasks with forecasted demand, enabling better execution during peak periods. RELEX enables accurate staffing by analyzing workload drivers like customer footfall, sales transactions, and delivery volumes to forecast the time spent on different retail-specific tasks down to 15-minute intervals.

Store teams need real-time information and task guidance to execute effectively during chaotic peak periods. RELEX Mobile bridges the gap between planning systems and store-level execution, especially for products with short shelf lives, enabling teams to respond quickly to changing priorities.

Scenario planning streamlines the creation, comparisons, and management of multiple scenarios in an easy-to-use dashboard. Seasonal supply chain planning inherently involves uncertainty, making scenario modeling essential for risk management. The advanced scenario planning capabilities from RELEX enable retailers to quickly model “what-if” situations and develop contingency plans before they’re needed. Using a digital twin of your entire supply chain network, the RELEX solution shows you exactly how decisions and disruptions will impact every tier of your business in real-time.

Real-world results: Plantasjen achieves remarkable gains in availability, sales, and inventory turnover

Plantasjen, Scandinavia’s largest garden center chain, partnered with RELEX to transform their supply chain management. With 110 stores across Norway, Sweden, and Finland and an annual revenue of approximately €433M, Plantasjen aimed to address inefficiencies and improve its operations.

Plantasjen faced several challenges after rapid growth: Store personnel were responsible for manually replenishing year-round items. At the same time, a central team handled seasonal items, often pushing the entire available stock into stores well ahead of the season. Key challenges included highly seasonal demand and a wide range of products with differences in origin, shelf life, and ideal climate.

After partnering with RELEX, they introduced a “push-pull-push” strategy for seasonal items, combining pre-season allocation, in-season replenishment, and end-of-season allocation. This approach ensured high availability and attractive store presentation while minimizing residual stock.

Key KPIs:

- 10% increase in central warehouse service level in many categories.

- 32% decrease in total in-store inventory value.

- Increased accuracy of pre-season allocations enables store staff to maintain more efficient stock clearance.

“While time spent on ordering is a fraction of what it used to be, the gains in availability, sales, and inventory turnover are remarkable.”

Anna Ståhle, Nordic Supply Planning Manager, Plantasjen

Actionable insights and fast course correction

The ability to quickly identify and address performance gaps separates successful seasonal executions from failed ones. Diagnostic capabilities provide the early warning system that enables proactive management rather than reactive firefighting.

RELEX Diagnostics uses AI to proactively identify issues—such as poor availability, excess, or waste—before seasonal peaks, enabling fast course correction ahead of critical periods. Rather than waiting for problems to become visible in sales reports, diagnostic systems analyze leading indicators to predict emerging issues.

This proactive approach enables interventions while they can still impact results. When RELEX Diagnostics identifies root causes such as potential stock-out risks for a key promotional product, buyers can expedite deliveries or adjust promotional timing rather than disappointing customers and losing sales.

Clearance Optimization minimizes markdowns by aligning clearance strategies with demand forecasts. End-of-season clearance represents the final opportunity to recover value from seasonal investments. Optimization systems model different clearance strategies to minimize markdown costs while ensuring inventory is cleared in time for new seasonal ranges. RELEX enables accurate seasonal allocations, monitoring in-season performance, and optimizes clearances for products approaching the end of their lifecycle.

RELEX True Inventory reconciles system inventory records with physical reality, providing the accurate data necessary for confident decision-making during fast-moving seasonal periods. True Inventory enhances store operations, freeing staff from the burden of constant manual counting and enabling them to focus on serving customers and driving sales. Instead of being stuck perpetually reacting to events, store managers use data-driven insights that help them prevent problems before they occur.

Real-world results: KICKS unlocks supply chain visibility with RELEX Diagnostics

KICKS operates 230 stores across Sweden, Norway, and Finland, alongside a strong e-commerce presence. During the 2024 Christmas holiday season, RELEX Diagnostics proved invaluable for the KICKS team. It highlighted major drivers of lost sales, which included DC scarcity, system under-forecasting, and late or missing deliveries.

On review, they saw that a single supplier was responsible for 39% of lost sales. With this data, KICKS was able to review and amend their processes with the supplier to improve the availability of products or brands that were affected during peak periods.

Key KPIs:

- 1.8% improvement in on-time store deliveries within six months

- 34% reduction in lost sales value linked to late deliveries

A unified platform for end-to-end planning and execution

The power of these capabilities multiplies when they operate within a unified platform. RELEX recommends timely, actionable interventions—budget reallocations, delivery adjustments, stock transfers, or price updates—keeping execution ahead of volatility. This integration eliminates the delays and errors that occur when information must be manually transferred between separate systems.

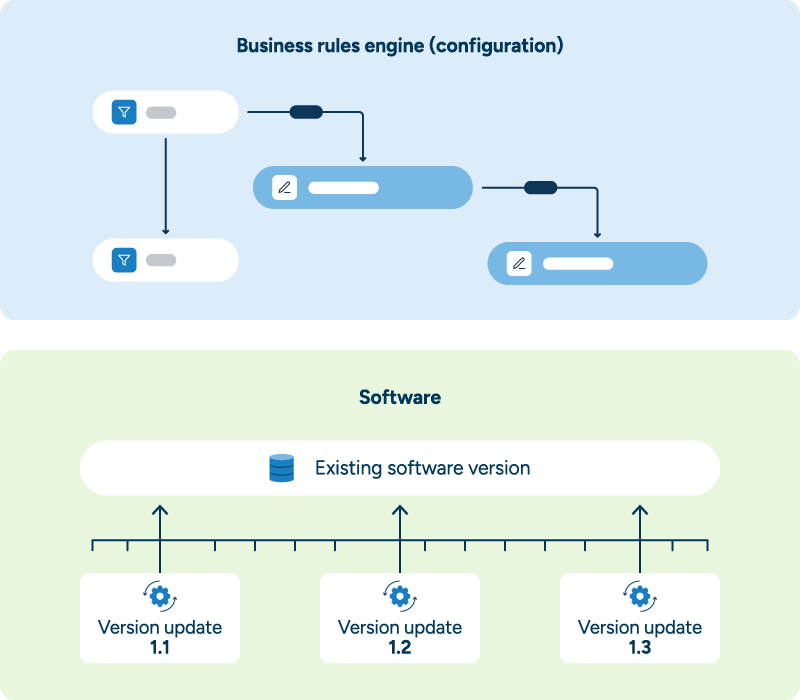

Further, self-serve configuration ensures scalability amid market and seasonal turbulence. When configurability is combined with AI capabilities and unified data streams on one platform, retailers can customize quickly for optimal results at scale. This integrated approach means that planning solutions can evolve as quickly as the companies using them, creating a sustainable framework for long-term success.

From chaos to control: Your competitive advantage

The adjustment from reactive seasonal planning to proactive seasonal mastery delivers measurable improvements across all dimensions of retail performance. Organizations embracing unified, AI-driven planning systems report significant advances in operational efficiency and financial results.

The transformation framework

| Before RELEX | With RELEX | Customer Impact |

| Seasonal budgets are set months in advance with no connection to daily operational realities. | Strategic financial goals connect seamlessly to daily execution through unified planning loops. | Customers consistently find what they need during peak periods because plans align with real demand. |

| Static plans created months ahead cannot adapt to changing market conditions or consumer behavior. | AI-driven forecasting continuously adapts to real demand signals and market changes. | Popular seasonal products remain in stock throughout peak periods, eliminating frustrating empty shelves. |

| Manual spreadsheets track spending and promotions separately, creating misaligned execution. | Real-time Open-to-Buy tracking integrates with promotion-aware planning for coordinated decisions. | Promotional offers feel timely and well-stocked because inventory aligns with marketing campaigns. |

| Teams planning inventory, promotions, and space work in isolation with conflicting priorities. | Cross-functional coordination ensures inventory, space, and promotional campaigns work together. | Store layouts remain navigable and well-organized even during busy seasonal periods. |

| Performance issues are discovered after problems impact sales and customer satisfaction. | Diagnostics proactively identify risks and gaps, enabling immediate corrective action. | Shopping experiences remain smooth and consistent across all seasons with fewer disruptions. |

The ultimate measure of seasonal planning success lies in customer experience improvements. Customers find products available when they need them, promotions feel timely and relevant, stores remain navigable during peak periods, and the overall shopping experience improves during traditionally chaotic times.

Instead of scrambling to fix issues, retailers plan with agility and execute with precision.

The path forward

Seasonal fluctuations will never disappear—but chaos can. Retailers who connect financial planning, operational execution, and diagnostics in one adaptive process gain resilience, agility, and a clear competitive edge.

The transformation begins with an honest assessment of current capabilities and clearly identifying the most significant improvement opportunities. Whether addressing demand volatility, financial plan alignment, execution bottlenecks, or diagnostic blind spots, success requires commitment to both technological advancement and organizational change.

The retailers who embrace this change will not only survive the challenges of seasonal volatility but will thrive as market leaders in an increasingly complex and dynamic retail landscape. The question is not whether seasonal planning will become more challenging—it’s whether your organization will be prepared to master those challenges through intelligent technology and unified processes.