On the planning horizon: A manufacturer’s guide to mastering end-to-end planning

May 20, 2025 • 10 min

Many manufacturers play a constant game of catch-up when it comes to strategy-driven planning and execution. Their tech stacks keep them chained to short-sighted strategies, but at the same time, lack the responsiveness to meet rapid demand shifts. In the long term, their technical debt hampers their ability to anticipate future needs. In the short term, it leaves them vulnerable to challenges like unpredictable demand, labor shortages, capacity limitations, and disruptions.

So, how do they solve this problem? The answer lies in how effectively they can organize their planning and make the right decisions in the right planning horizons. Each horizon needs a clear decision framework, supported by an organized process that turns decisions into actions at every tier of decision-making. This company-wide synchronization requires an end-to-end planning platform with three distinguishing attributes:

- AI and optimization capabilities that adapt quickly to market changes.

- Easy data-sharing and cross-functional integration to align decisions across teams.

- Automation designed for business-specific requirements, more responsive supply chains, and better productivity

This unified platform provides both the broad perspective required for higher-level strategy and the granular control necessary for accurate daily decisions. Its visibility across the company allows teams to monitor supply chain performance and adjust accordingly.

With clear directives and the technology to carry them out, businesses can raise customer service levels, optimize stock holdings, and improve labor efficiency, thereby increasing their margins.

Defining the planning horizon

A planning horizon is the period over which a company plans its operations, resources, and strategies. Each horizon addresses different aspects of planning to ensure smooth and efficient operations.

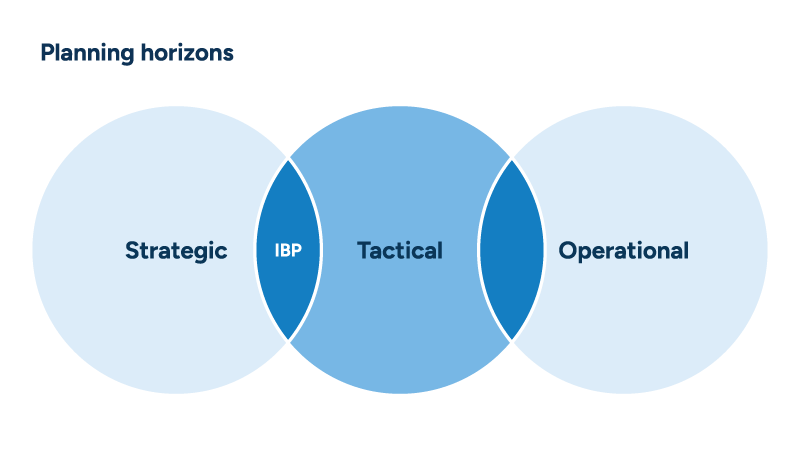

There are three types of planning horizons: strategic, tactical, and operational.

The length and frequency of each horizon can shift depending on the industry. For instance, manufacturers that deal with fresh products and contend with faster spoilage rates may have shorter horizons. On the other hand, manufacturers planning items with stable shelf lives have more leeway and can stretch the length of each planning stage.

While there is some overlap between planning decisions and timeframes may shift to fit industries, products, and businesses, the basic framework of each planning horizon remains consistent. Let’s take them one at a time.

Strategic planning

Strategic planning has the longest horizon, involving product portfolio management, revenue growth, network design and optimization, sourcing strategy, and overall business targets. The process usually spans quarters to years and focuses on decisions that determine the need and feasibility of business developments, such as:

- Expanding into new markets or distribution channels.

- Investing in new production capabilities, storage, or logistical capacity.

- Searching for new ways to source.

- Introducing new products.

- Finalizing make-or-buy decisions.

For instance, say you’re a global beverage company. If you notice growing demand in an emerging market, you may need to decide if, where, and when to build a new plant. Perhaps you’re considering sustainability goals, like transitioning to biodegradable packaging, which requires new machinery and supplier partnerships. Maybe you want to launch a new line of beverages, so you’d need to invest in R&D, source new ingredients, and adjust production lines.

For long-term planning like this, a company might use scenario planning to test the impact of different decisions during the integrated business planning stage.

Integrated business planning connects strategic and tactical horizons

Integrated business planning (IBP) primarily focuses on strategy-level decisions, but it also bridges the gap between strategic and tactical horizons through scenario planning.

Scenario planning helps manufacturers evaluate and align their supply, demand, and financial plans. It enables decision-makers to simulate “what-if” scenarios and assess the business impact of factors like demand fluctuations, supply disruptions, or cost changes.

For instance, let’s say a manufacturer wants to measure the impact of a new promotion on capacity, availability, and maintenance. By running scenarios, the team can predict how different decisions will affect margins and service levels before committing to a course of action.

An advanced, automated scenario planning tool easily integrates data from across planning functions, speeding up the comparison process and ensuring scenarios use accurate, up-to-date information for better outcomes. It increases company-wide visibility and efficiency by:

- Providing tools and workflows to improve cross-departmental collaboration.

- Using dashboards to review and monitor performance, aligning short-term plans with long-term strategic targets.

- Determining sufficient stock levels and production resources to meet market demand.

Thanks to scenario planning, IBP helps decision-makers evaluate risks, prioritize actions, and choose the most optimal plan based on business objectives and constraints.

Tactical planning

Tactical planning is the medium-term planning horizon that focuses on balancing supply and demand. It typically spans weeks to months, but when thinking about horizon lengths, here’s a general rule: Tactical planning should match the longest lead time of critical purchased ingredients and cover the next major planning period, such as summer vacation or a big promotion.

The tactical horizon determines decisions around overall promotion strategy and planning, long-term demand planning, high-level capacity modelling, supplier management, and KPI reviews. It also kicks off plans that will later be refined through operational planning, including:

- NPI and phase-outs.

- Inventory planning.

- Demand planning and sensing.

- Demand and supply optimization.

- Distribution planning.

- Production planning and scheduling.

- Purchase planning.

- S&OE.

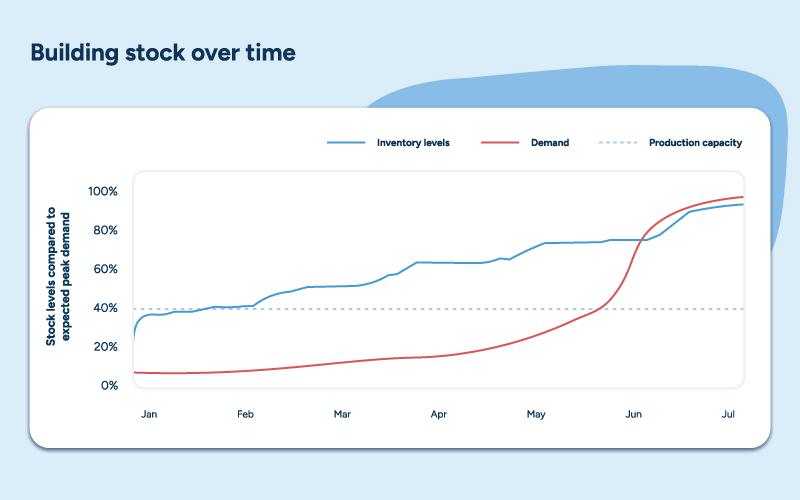

For each of these, tactical planning handles the higher-level decisions. For instance, in terms of inventory planning, the team is thinking about strategic stock builds and capacity requirements. For demand planning, they’re gathering input and approvals for a consensus forecast. They’ll also make medium-term decisions around contingency plans, promotions, product launches, logistical coordination, and raw material requirements.

For instance, let’s say a food manufacturer’s bread products have varying shelf lives – white bread must be fresh, cupcakes last longer, and some items can be frozen before hitting shelves.

As the manufacturer gears up for summer and starts prepping hamburger buns, they use the tactical horizon for capacity planning, aligning production with demand while monitoring inventory levels. They start building stock in advance because they know they’ll lack the capacity to produce all the hamburger buns they’ll need immediately before the sales period. They’ll manage warehouse capacity, track expiration dates, forecast raw material needs, and coordinate with suppliers to ensure all the necessary stock is available when grilling season begins.

Whatever function the team is addressing, they’re looking to anticipate, identify, and address gaps between strategic goals and actual supply chain performance before they become critical.

Operational planning

Operational planning is the short-term planning horizon that covers boots-on-the-ground planning activities and daily decisions. It concentrates on real-time monitoring, addressing exceptions, and coordinating immediate cross-functional responses to sudden disruptions.

The operational horizon begins by taking the tactical plans discussed above and adjusting them to current market conditions. For instance, operational teams handle last-minute changes in supply or demand and monitor real-time demand fluctuations. They also refine distribution orders, production schedules, and purchase orders.

In addition to these plan refinements, the operational horizon holds the reins to:

- Customer order management and forecast consumption, using customer orders to adjust production plans and align supply with real-time demand.

- Transport order management, planning, tracking, and optimizing the movement of goods across the supply chain for on-time, cost-effective deliveries.

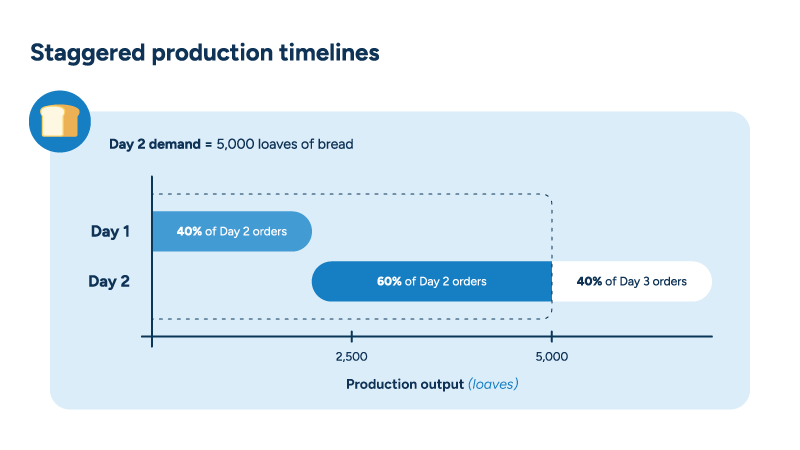

As an example, let’s look at how a fresh goods manufacturer might use the operational planning horizon to manage production challenges and strict delivery deadlines.

A manufacturer knows that trucks for two major retailers will be leaving at 11 a.m. and 1 p.m. tomorrow, but they don’t have the exact order quantities, so they set pre-production amounts based on the next day’s forecasted demand.

For instance, if tomorrow’s forecast predicts 5,000 loaves of fresh white bread, the manufacturer may only produce about 40% of that forecast. This partial production allows the company to fill early morning deliveries and continue producing throughout the day to fulfill the later deliveries. This strategy allows the manufacturer to control inventory and minimize the risk of producing surplus goods that would spoil.

This is a complex process, coordinating hundreds of orders with various delivery times while managing production capacity and maintaining freshness. Teams need the up-close visibility and control of the operational planning horizon to balance daily production scheduling, order fulfillment, and logistics coordination.

How to evaluate your planning process

With the framework for each planning horizon established, let’s talk about how manufacturers should approach decision-making to ensure accuracy, efficiency, and long-term planning success.

In other words, what should your planning process and the technology that powers it enable you to do?

A horizon-to-horizon planning process should allow every team at every stage to:

- Adapt quickly to changes in the supply chain, from broader demand shifts to sudden disruptions.

- Align planning functions, ensuring easy data transmission and collaborative decision-making.

- Automate processes, taking advantage of AI, optimization, and automated workflows to improve productivity, speed, and accuracy.

To achieve and maintain a process this agile, manufacturers need a well-equipped planning solution that enhances supply chain visibility and drives fast, data-backed decisions.

The RELEX platform: The tech behind synchronized planning horizons

The RELEX platform provides an end-to-end suite of interconnected planning tools with the innovation, data, and collaborative capabilities manufacturers need to keep up with the industry’s complexity.

First, let’s define our terms and look at the technology working behind the scenes of every planning module.

The toolkit: Machine learning, optimization, and heuristics

RELEX uses an array of technologies to achieve different functions and objectives. For instance, the specialized AI found across the RELEX platform uses machine learning (ML) algorithms to perform specific tasks with superhuman speed and accuracy. These algorithms work in tandem with mathematical optimization and heuristics to achieve optimal results and drive efficiency.

For instance, machine learning is the predictive function, rapidly analyzing vast amounts of granular data, detecting trends, and calculating probable outcomes. Then, it’s up to mathematical optimization to weigh those outcomes and determine the best option according to its impact on the business. In less complex scenarios, these capabilities are complemented by heuristics, simple but effective mechanisms that power quick decisions, keeping plans aligned and the supply chain moving.

Interconnected planning modules for end-to-end planning

The RELEX solution weaves these technologies into each of its planning modules, equipping every planner with the innovations needed to achieve KPIs and bringing all your planning teams to the same table.

Let’s start with forecasts. RELEX machine learning-based forecasting and replenishment consumes and processes massive amounts of data to recognize demand patterns and improve predictions. Demand sensing complements this forecast, analyzing POS data, weather, cannibalization and halo effects and quickly responding to short-term changes.

Now imagine that these forecasts connect to the rest of your supply chain decisions. For instance, a clear picture of demand helps purchase planners procure raw materials more efficiently, considering lead times and costs. Production planners align manufacturing output with demand forecasts and stock builds to optimize capacity and minimize waste. Production schedulers can then create detailed, time-phased schedules that account for constraints like machine availability, setup times, and delivery priorities.

As we head downstream, the distribution planning team synchronizes the flow of goods across the network, optimizing transportation modes and ensuring on-time deliveries. Inventory planning underpins these processes, optimizing safety stocks and replenishment frequencies to balance holding costs and service levels.

Meanwhile, IBP links the tactical and strategic horizons, aligning medium-term plans with financial targets with scenario simulations for price optimization and capacity planning.

All these modules talk to each other in real-time, keeping data and plans up to date for optimal supply chain planning, scheduling, and decision-making. Together, these solutions empower manufacturers to maximize efficiency, reduce costs, and meet demand while driving profitability.

Touchless planning and user empowerment

RELEX combines this integrated planning environment with user-controlled automation and gen AI-driven assistance so teams can make the most of their data and time.

In terms of automation, RELEX has a built-in business rules engine (BRE) that allows users to configure the solution to business-specific needs and processes without costly and time-consuming customization projects. This “configure, don’t code” approach means users can automate processes and manage decisions by setting or selecting rules that scale with the business. With automation handling the grunt work, teams can focus on managing exceptions, and companies can begin incorporating touchless planning for better planner productivity and faster response times to market shifts.

At the same time, RELEX continues to develop innovative tools like new diagnostic and AI capabilities. For instance, RELEX developed Rebot, the first supply chain AI assistant on the market. Users already leverage Rebot every day to speed up onboarding and answer daily industry- and solution-specific questions. RELEX is actively developing Rebot into an AI agent that can analyze business data and take action under human supervision for even better insights and responsiveness.

Widening your horizons with end-to-end planning

By breaking down silos and equipping teams with automation and AI-enhanced calculations, an end-to-end planning solution allows manufacturers to align strategic, tactical, and operational horizons and objectives while responding dynamically to supply chain changes. A unified platform makes it possible to adapt, align, and automate processes – at scale – so every team can optimize decisions and drive business growth while delivering a competitive customer experience.