The case for agile, AI-powered planning amidst retail volatility

Retailers face multiple headwinds: shifting store formats, fleeting consumer habits, inflation, and tightening regulation. Add leadership’s push for higher margins and stronger performance, and the reality becomes clear: ill-equipped businesses will struggle to meet the moment.

Outdated planning processes simply can’t keep up. Siloed systems, disconnected data, and delayed decisions fall short in a world shaped by geopolitical shifts, economic turbulence, and climate change. But retailers who respond with nimble, well-informed decisions can find opportunity amid market turmoil.

This requires replacing legacy systems with technology built for speed and precision. RELEX delivers exactly that: real-time forecasting, diagnostics, and purpose-built AI on one unified platform that allows for connected, responsive decisions.

But technology alone isn’t enough. Success also requires the right partnership. RELEX focuses on how our solution works best for your people, freeing them to focus on higher-value, strategic work. The result: 100% successful implementations and a 97% retention rate.

Retailers need steadfast strategies for an uncertain future

With internal and external pressures coming from every direction, retailers must find new ways to increase margins while reducing waste, improve performance while minimizing risk, and balance inventory and capacity in an increasingly volatile market.

These challenges aren’t temporary or anomalous. And retailers will face plenty more in the future, including managing more channels, responding to faster competitor price adjustments, complying with stricter ESG mandates, and handling new supply chain shocks. The highly mutable nature of our globalized, interwoven world requires ongoing adaptation.

We see four forces in the market today breaking legacy supply chains:

Economic volatility and price sensitivity: With shoppers prioritizing price, retailers struggle to protect margins and meet expectations when disconnected pricing and inventory systems cause availability issues.

Supply chain complexity and disruption: Volatile demand and global trade dynamics need fast adaptation, but legacy systems built on static assumptions and manual processes cause costly delays.

Evolving consumer and operational expectations: Shoppers want localized assortments, seamless availability, and sustainability while retailers struggle through staff shortages and fatigue, multiplying channels, and shifting trends.

Regulatory and ESG imperatives: Food waste reduction and carbon reporting have moved from nice-to-have to must-have, and retailers need real visibility to meet both compliance and consumer expectations.

State-of-the-art features that turn the supply chain into an intelligent network

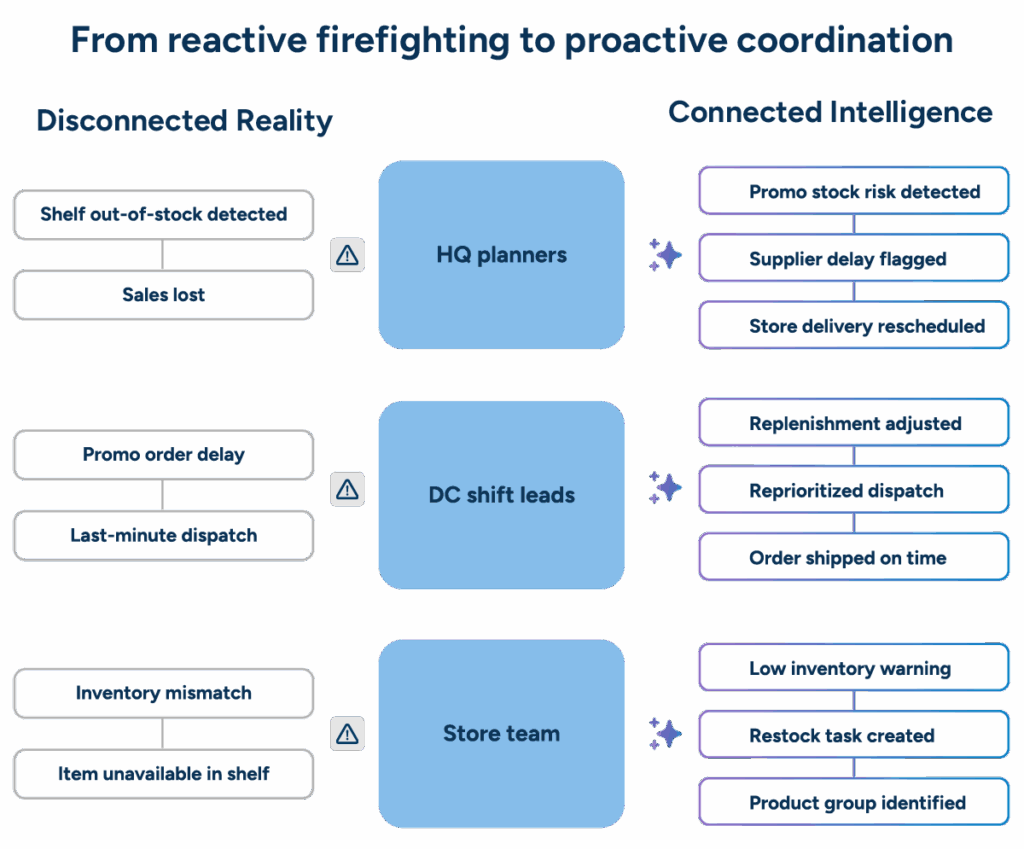

Combating the forces breaking traditional supply chains demands more than incremental improvements. To escape reactive cycles, retailers must rethink how their supply chains operate. Those who successfully overcame these complexities share three operational capabilities:

- Adaptive intelligence that continuously learns and responds to complexity.

- Unified operations that connect every decision from supplier to shelf on one platform.

- Exception-based execution that anticipates and prevents problems before they impact operations.

The RELEX platform provides the capabilities retailers need to operate with speed and precision in a time of uncertainty. Each is specially designed to work within a unified system—where forecasting informs pricing, diagnostics trigger action, and store execution closes the loop. The table below outlines the core features that enable connected decision-making across your retail value chain.

| Feature | Capabilities | Benefits |

| Forecasting & Replenishment | Generates accurate, automated demand forecasts using real-time data across internal operations, supplier signals, and external factors; creates optimized replenishment plans at store and SKU level. | Provides the foundation for availability, margin protection, and agile response to demand shifts; reduces lost sales and excess inventory. |

| Diagnostics | Continuous root-cause analysis from portfolio to store level; explains stockouts, spoilage, and excess inventory with drill-down visibility and forward-looking prevention insights. | Replaces weeks of manual investigation with instant, explainable insights; prioritizes highest-value fixes; provides the analytical foundation for intelligent automation. |

| RELEX Mobile | Delivers order proposals, inventory alerts, and planogram updates to store devices; enables on-the-spot counts, adjustments, and exception management; supports iOS, Android, and web. | Empowers store teams with real-time data and guidance; improves availability up to 6 percentage points; increases inventory turns; reduces phantom stock. |

| Pricing & Promotion | Models price elasticity and cross-category effects; optimizes promotional offers and timing; enables scenario testing with confidence scoring; coordinates pricing with inventory and space. | Increases profitable promotions and true lift; protects margin during volatility; prevents promoting out-of-stock items; aligns pricing with demand and supply reality. |

| Space & Assortment | Creates demand-informed, store-specific planograms; optimizes SKU mix and shelf allocation; automates layout adjustments based on local signals. | Increases sales and availability; reduces inventory in targeted categories; gives prime space to proven winners; improves shopper navigation. |

| Supply Chain Collaboration | Extends forecast visibility to suppliers and distribution centers; highlights upstream risks; enables proactive coordination across the supply network. | Aligns production and fulfillment with demand; reduces supply chain friction; prevents overstock from misaligned plans. |

| CO₂ Analytics | Tracks and reports carbon impact across operations; provides ESG visibility and compliance reporting; quantifies waste reduction outcomes. | Supports sustainability targets and regulatory compliance; demonstrates measurable progress on food waste and emissions goals. |

| Unified Platform | Connects all capabilities through one AI-native system with shared data, one forecast, and coordinated workflows across functions. | Eliminates silos; enables cross-functional teams to act from a single source of truth; scales reliably without integration complexity. |

This is the difference between wrestling with disruption and thriving through it. Your teams will have the tools to untangle complexity at scale, make informed trade-offs quickly, and learn from each challenge to strengthen your system over time.

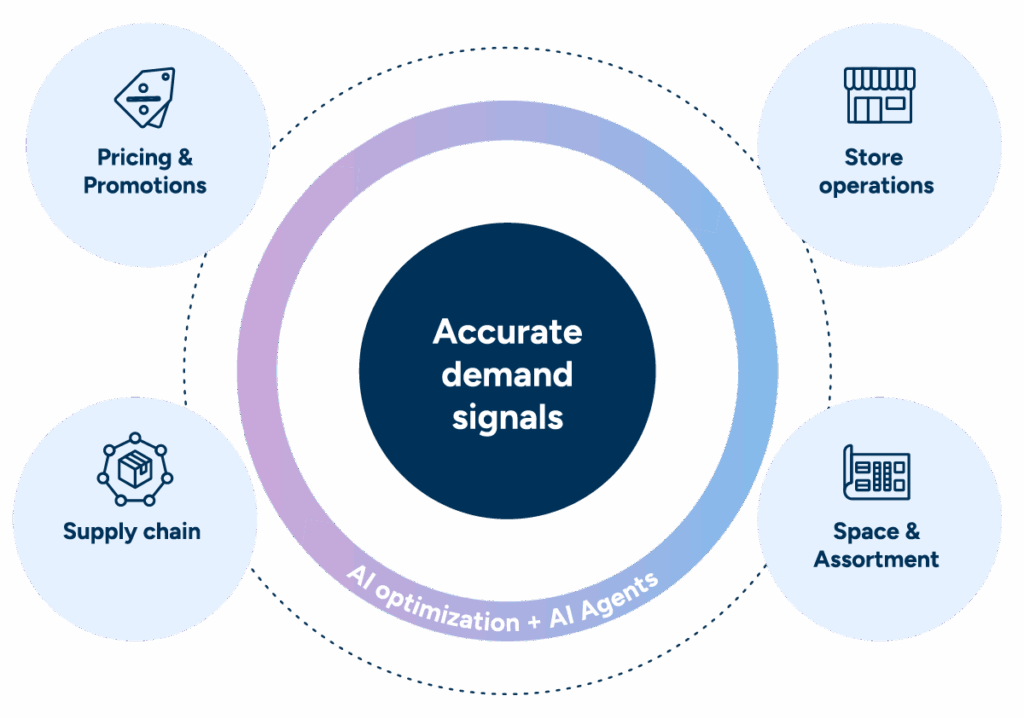

Why forecasting must come first in supply chain transformation

The most powerful AI technologies are only as effective as your ability to train them on accurate information. For retailers, that ability starts with knowing what will actually sell: not yesterday’s average, but tomorrow’s reality. Without accurate base forecasting, you’re optimizing chaos. Insights lead to misfires. Automation amplifies the errors. This is why successful retailers start by sharpening their forecasts before doing anything else.

The foundation of intelligent retail

At the heart of the unified RELEX platform sits Forecasting & Replenishment (F&R)—the foundation that makes every other function precise, profitable, and responsive.

Critical intelligence flows through your entire operation: F&R detects demand shifting toward fresh categories, Diagnostics flags the spoilage risks, Pricing adjusts to accelerate sell-through, Space recalibrates case packs, and Store Operations receives optimized handling instructions.

AI coordinates all of this automatically within minutes.

Since these aren’t separate systems but integrated capabilities on one platform, each improvement amplifies the other. F&R provides the truth about demand that every other system needs to function. Pricing & Promotions protect margins based on this truth. Space & Assortment optimize locally using it. Store Operations execute against it. Supplier Collaboration aligns upstream partners with it. Without forecasting accuracy, retail AI becomes expensive conjecture.

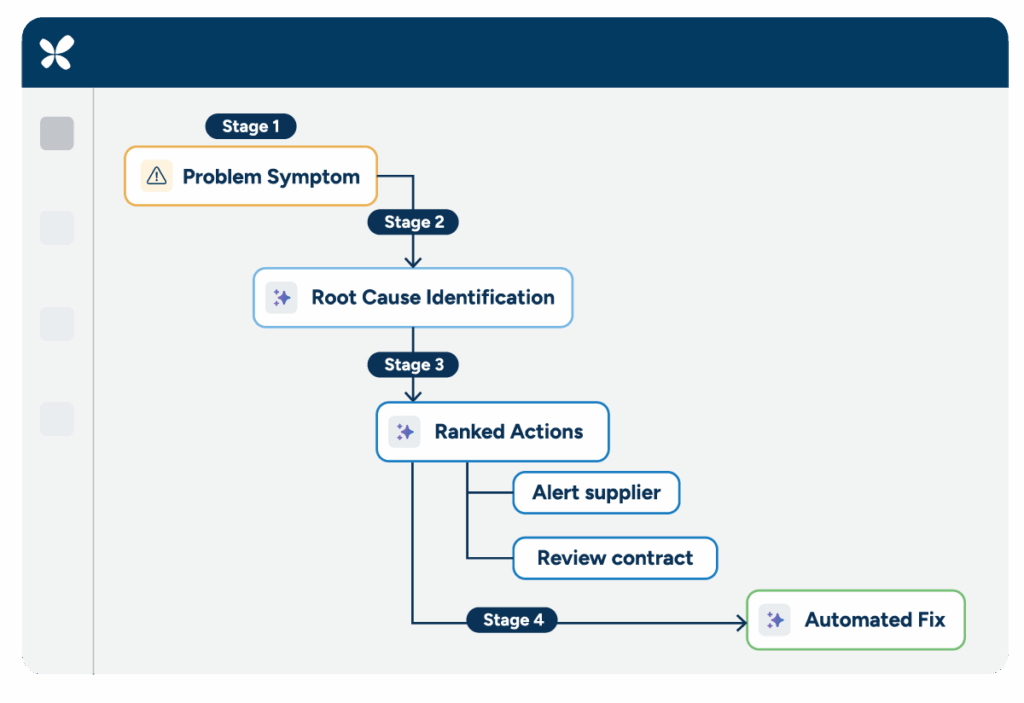

RELEX Diagnostics helps you spot problems before they erode profit

Every day, retail operations bleed profit through phantom inventory triggering stockouts, late supplier deliveries caught only when shelves empty, and promotional conflicts destroying margin. Traditional root-cause analysis arrives weeks late, after manually digging through spreadsheets to understand yesterday’s problems while today’s issues multiply.

RELEX Diagnostics changes this. It’s an always-on analyst layer that continuously examines every product, store, and supplier relationship—identifying root causes behind performance gaps before they erode profit. Unlike BI dashboards that report symptoms (“sales are down 5%”), Diagnostics identifies exactly why issues occur and ranks them by business impact, covering stockout analysis, spoilage drivers in fresh categories, excess inventory composition, and forward-looking prevention insights.

RELEX Diagnostics provides multiple lenses through which to address different operational challenges:

- Root-cause analytics: Automatic analysis of order proposals and inventory to explain stockouts and their relative importance.

- Spoilage diagnostics: Comprehensive analysis of waste drivers in fresh categories.

- Inventory diagnostics: Understanding current and future inventory composition and underlying causes of excess stock.

But what makes RELEX Diagnostics transformational?

Firstly, as it’s deeply embedded in the RELEX platform, insights live where planning is done. Detected issues trigger corrections, which planners can carry out manually for exceptionally complex cases. Alternatively, for ultimate speed and efficiency, agentic AI can automatically complete routine adjustments.

| Agentic use | Capabilities | Benefits |

| Diagnostics | Autonomously prioritizes detected issues by impact to profit and triggers recommended actions; continuously learns from resolutions to refine future recommendations without requiring new implementations. | Frees planners from manual investigation to focus on high-value strategic work; ensures critical issues receive immediate attention based on business impact. |

| Configuration | Autonomously adjusts business rules and planning parameters in response to detected issues; automatically tunes safety stock, lead times, and allocation logic when conditions change. | Accelerates response to market disruption; minimizes manual rules management; keeps plans aligned with current reality without planner intervention. |

| Store Operations | Independently identifies execution gaps at shelf level; surfaces availability issues and conflicting plans; triggers alerts and recommended actions for store teams. | Maintains shelf availability by catching execution gaps before they impact sales; ensures central plans reflect what’s happening across the store network. |

The face of genuine retail intelligence

Many vendors claim “AI-powered” solutions. Here’s how to recognize agentic AI that transforms retail operations versus AI washing that merely automates existing processes.

AI washing looks like:

- Black-box algorithms you can’t explain or trust.

- Generic models retrofitted for retail use cases.

- Chatbots that provide information without taking action.

- “Insights” requiring manual interpretation and intervention.

- Isolated AI tools creating new data silos.

RELEX Agentic AI delivers:

- Multi-agent system: Rebot, the RELEX AI Assistant, serves as a gateway to the agentic ecosystem, coordinating AI agents system-wide.

- Autonomous decision orchestration: Multiple specialized agents work together identifying issues, adjusting parameters, executing changes—all without manual handoffs.

- Retail-native intelligence: Purpose-built agents that understand the nuances of forecasting, replenishment, pricing, and merchandising.

- From insight to automated action: Agents don’t just detect problems; they trigger corrections, adjust rules, and coordinate responses across your entire network.

- Continuous learning and adaptation: Each decision improves the system’s understanding, creating compound intelligence gains.

- Unified agent ecosystem: All agents operate on one platform, sharing context and coordinating actions for maximum impact.

Traditional automation and agentic AI are worlds apart in terms of capabilities. Traditional automation follows rigid rules, while machine learning makes predictions. Agentic AI, on the other hand, has truly upended how retail decisions are made.

But how?

Traditional root-cause analysis is severely limited. With this approach, when a diagnostics dashboard flags supplier delays, planners must manually investigate the issue, adjust parameters across potentially hundreds of affected SKUs, and wait to see if the changes work.

RELEX Agents autonomously rectify detected issues through efficient collaboration. Diagnostics Agent automatically escalates high-priority supply issues to Configuration Agent, which adjusts safety stock and lead times for impacted products. Simultaneously, the Store Operations Agent reallocates available inventory to protect business-critical locations. The system monitors outcomes continuously, learning from each intervention to prevent similar issues from recurring.

As described, RELEX Agentic AI prevents disruptions before they reach shelves, keeping availability high and waste at a minimum even as market conditions shift.

Agentic AI is particularly critical to executive decision-making. For retail executives evaluating AI investments, four factors set it apart:

- Speed: Agentic AI operates at machine speed while maintaining human oversight for strategic decisions.

- Scale: Agents handle millions of micro-decisions that would overwhelm human planners.

- Consistency: Every decision follows best practices while adapting to local context.

- Evolution: The system becomes more intelligent with every interaction, without requiring new implementations.

What RELEX AI is doing for customers today

These companies adopted RELEX to tackle their most pressing supply chain challenges. Each faced different issues—from availability gaps and inventory bloat to operational inefficiencies and margin erosion. The results of each one show what’s possible when retailers commit to forecast-based transformation.

When forecasting becomes the foundation: Porta’s inventory optimization

How unified planning delivered higher availability with 10% less stock

Manual planning was causing Porta’s planners to struggle with balancing high-value, slow-moving furniture with fast-moving accessories across 142 stores, leading to frequent stockouts and excess inventory. Legacy processes lacked automation and couldn’t handle their complexity: dynamic assortments with 20% annual turnover, omnichannel operations, and the need for service-level management across diverse product categories.

RELEX unified forecasting across all brands and categories, automatically generating thousands of order proposals weekly while planners focused on strategic exceptions and supplier relationships.

- 7.8% increase in availability

- 8.9% increase in sales

- 9.8% decrease in inventory value

- 70% of orders automated

“With our constantly evolving furniture assortment, we needed a solution that could keep pace with our dynamic business. RELEX has helped us better manage our inventory while maintaining high product availability for our customers.”

– Stephan Hermes, Managing Director Purchasing, Porta

From Diagnostic insight to automated action: KICKS prevents 34% of lost sales

Root-cause visibility turned supplier chaos into systematic solutions

Finnish beauty retailer KICKS struggled with frequent stockouts and limited visibility into what drove lost sales. Manual analysis consumed time while problems multiplied unseen.

RELEX Diagnostics automated root-cause analysis, surfacing the truth behind every stockout and ranking issues by business impact. During the 2024 Christmas season, the system revealed that a single supplier accounted for 39% of lost sales. Additional drivers included under-forecasting during campaigns and unexecuted deliveries.

With quantified supplier performance data, KICKS restructured processes with the underperforming supplier and introduced a 24-hour delivery completion requirement. The system now flags risks before they reach customers, transforming reactive firefighting into proactive prevention.

- 34% reduction in lost sales value linked to late deliveries

- 1.8% improvement in on-time store deliveries within six months

- Real-time exception-based workflows targeting the highest-impact SKUs

“By prioritizing RELEX Diagnostics, we have already taken swift action on under-forecasting and are working exception-based to tackle the products with the highest impact on lost sales each week.”

- Sara Vennerström, Team Manager, Supply Chain Planning, KICKS

When planning meets execution: R-Kioski’s Mobile transformation

Real-time shelf intelligence closed the HQ-to-store gap without adding headcount

Finnish convenience chain R-Kioski struggled with seemingly perfect HQ plans that were failing at the shelf. Store teams worked from outdated information while phantom inventory triggered false replenishment.

The transformation came through RELEX Mobile replenishment, which pushed real-time order proposals directly to store associates’ devices. Teams now make informed adjustments based on local events and correct inventory discrepancies immediately, with changes instantly feeding back into the replenishment system.

- +6pp in product availability

- +6% inventory turns

- -6% average days of supply

- Zero additional store labor required

“With the help of RELEX, we have great opportunities to develop both store work and customer experience further, and we will seize them.”

– Maria Sjöroos, IT & HR Director, R-kioski

Connected pricing intelligence: How Mathem turned promotions profitable

Linking inventory, demand, and pricing eliminated margin-destroying campaigns

Online grocer Mathem was bleeding margin through promotions that cannibalized full-price sales and promoted out-of-stock items. Within six months of implementing AI-powered pricing optimization, everything changed.

The key? Connecting pricing decisions to real inventory and demand signals. The system predicts actual lift (not hopeful guesses) and accounts for cannibalization effects.

- +56% increase in profitable promotions

- +32% true lift (accounting for cannibalization)

- -17% reduction in unprofitable campaigns

- +20% gross promotional sales

“RELEX gave us an automated, integrated system that provides our teams with a much deeper understanding of the factors behind successful campaigns.”

– Carl-Johan Sagner, Promotional Strategy Manager, Mathem

Local intelligence at scale: East of England Co-op’s 5-point availability leap

Store-specific planograms proved local doesn’t mean manual

East of England Co-op was trapped by generic planograms that ignored local preferences and wasted prime shelf space on poor performers.

Their breakthrough came in the form of demand-driven space optimization that automatically creates store-specific planograms based on local sales patterns, seasonality, and space constraints. Localization doesn’t require local complexity—it requires intelligent automation that scales merchandising expertise across every store.

- 93-98% increase in availability

- +2.2% increase in sales

- -20% reduction in inventory for targeted categories

“RELEX has given us visibility into our actual availability figure and our products within stores and, for the first time, it’s also given us visibility of our actual store space.”

– Chris Murray, Head of Retail Stock & Planning, East of England Co-op

When suppliers and retailers plan as one: Atria’s promotional transformation

Shared demand visibility turned money-losing promotions profitable—for both partners

Meat producer Atria Finland and retailer Minimani were trapped in a negative cycle. Fresh products arrived too early or late, resulting in spoilage or overstocks. Every joint promotion lost money for both companies despite good intentions—disconnected forecasts made profitable execution impossible.

RELEX Supplier Collaboration extended unified demand forecasts upstream. Minimani’s promotional plans—validated through AI-driven demand sensing—now flow directly to Atria’s production scheduling. Both partners work from the same demand truth, synchronized in real time. Fresh products arrive precisely when campaigns launch, maximizing shelf life and sell-through.

- +3pp promotional availability increase

- Fresher products delivered closer to campaign start

- Mutual profitability on promotions that previously lost money

“With RELEX, the transparency into our retailers’ forecasts has put us on the pulse of end-customer demand. Seeing changes almost in real time gives us more time to adjust production accordingly.”

– Mikko Soinio, Planning Manager, Atria Finland

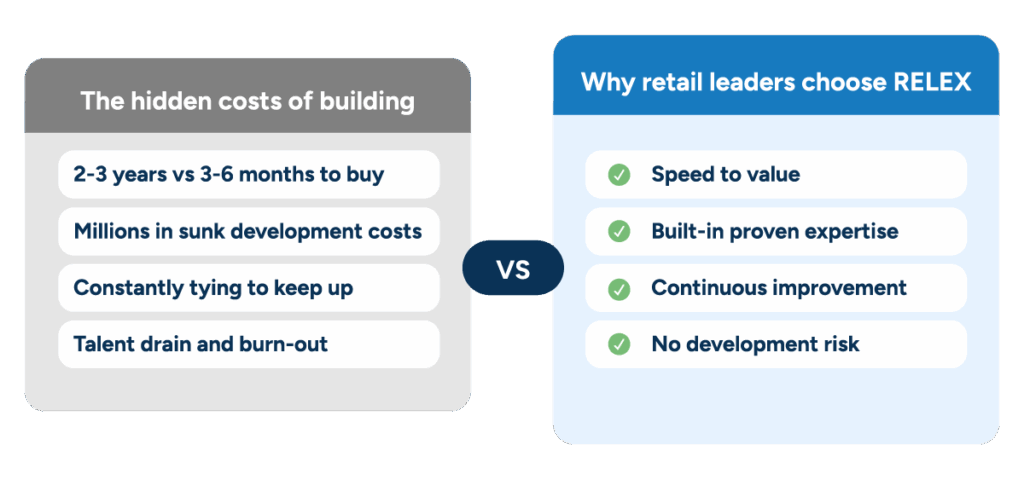

The right path to future-proof your retail supply chain

Because RELEX is truly unified, there’s no single “right” path. Start where you hurt most, then expand based on results and your next priorities. The best path for your company is the one that delivers immediate value while building toward large-scale transformation.

Your journey starts with choosing the approach that matches your most urgent needs. All paths lead to unified, AI-powered retail operations, but each offers different quick wins and acceleration points.

The foundation-first approach

Best for retailers ready to fix the root cause

When disconnected planning is cracking across your operation, you should start by building a proper foundation. This approach delivers comprehensive transformation by establishing accurate demand signals first, then expanding systematically.

Your roadmap:

- Phase 1: Implement F&R for accurate demand foundation.

- Phase 2: Add Diagnostics to identify improvement opportunities.

- Phase 3: Expand to Pricing & Promotions to protect margins.

- Phase 4: Scale with Space optimization, then supplier collaboration.

Expected results: Significant improvement in forecast accuracy, which helped Porta increase availability by 7.8% while reducing inventory value by 9.8%. This path creates the strongest foundation for long-term transformation, with each new capability building on increasingly accurate demand signals.

The problem-solver approach

Best for retailers who need answers now

When you’re plugging holes but don’t know where to start, let the data guide the transformation. Start with diagnostic insights to identify your biggest pain points, then target solutions precisely where they’ll deliver maximum impact.

Your roadmap:

- Phase 1: Deploy an F&R foundation, adding Diagnostics to surface root causes.

- Phase 2: Optimize F&R based on diagnostic insights.

- Phase 3: Target specific modules based on diagnostic findings.

- Phase 4: Let ongoing data guide expansion priorities.

Expected results: Rapid identification and resolution of critical issues, like KICKS’ 34% reduction in lost sales value from supplier delays. This path ensures every investment targets a proven problem with measurable impact.

The customer experience approach

Best for retailers focused on the shopping experience

When customer satisfaction is your north star, start with capabilities that directly impact the shopping experience. Focus first on availability and execution, then expand to optimize the entire customer journey.

Your roadmap:

- Phase 1: Implement F&R to ensure product availability.

- Phase 2: Add Space & Assortment for demand-driven layouts.

- Phase 3: Deploy Mobile execution for shelf reality.

- Phase 4: Expand to Pricing optimization and supplier collaboration.

Expected results: Immediate customer-facing improvements, like East of England Co-op’s availability increase from 93% to 98% and 2.2% sales growth. This path delivers visible wins that build organizational momentum.

Regardless of which path you choose, transformation accelerates. Your second module is simpler to implement than your first, and your third delivers more value than your second. This acceleration is fueled by a unified platform, so each capability multiplies the value of those already in place.

Why do the approaches always start with forecasting and replenishment? Without knowing what will sell, you can’t optimize how to sell it, where to place it, or what to charge for it. Accurate demand forecasting is the prerequisite for solving availability problems, optimizing space, and protecting margins.

There’s no better time than the present

Every day you delay transformation, disruptions erode profits, while the gap between you and market leaders widens. The progress (or lack thereof) your company makes in the next 12 months can be a make-or-break outcome.

Three irreversible shifts are reshaping retail competition:

1. Disruption is constant, and each one exposes the fatal weakness of disconnected systems: they can’t adapt fast enough. While you’re assessing impact, AI-powered retailers have already adjusted forecasts, reallocated inventory, and protected margins.

2. The talent exodus accelerates as the best planners see what modern tools can do. Another year of spreadsheet reconciliation isn’t just inefficient—it’s a resignation trigger for top performers who want to work strategically, not tactically.

3. The learning curve compounds when, every day, AI systems get smarter, and starting a year from now means competing against systems with exponentially more intelligence. The gap doesn’t grow linearly—it explodes.

The question is not, “Can we afford to transform our business?” It’s, “Can we afford not to?”

While you’ve been reading this guide, retailers using RELEX have automatically:

- Prevented stockouts through predictive analytics.

- Adjusted pricing based on real-time elasticity.

- Corrected inventory imbalances before they impacted sales.

- Freed planners from routine tasks to focus on growth.

This isn’t some future situation. It’s happening today, across the industry.

Do not vacillate and stop progress just to “wait and see”. In retail, standing still is not an option. Now is the time to take the plunge and build a sturdy supply chain for the future.

Real AI. Real results. Right now.

Act today with AI that delivers measurable results—from smarter forecasting to coordinated execution. Scale with Agentic AI that adapts and learns with every decision.

See how RELEX can help you diagnose, act, and improve.