Retail sales & operations execution (S&OE): 4 foundational capabilities for managing disruptions

Feb 22, 2021 • 8 min

Boxing legend Mike Tyson once said, “Everybody has a plan until they get punched in the mouth.” A retailer’s sales & operations execution (S&OE) capabilities determine whether they’ll get knocked out when their plans are disrupted—or whether they’ll be able to adjust quickly and turn it to their own advantage by capturing market share from less agile competitors.

What Is Retail S&OE?

So, what is retail sales & operations execution? The S&OE process aims to ensure that short-term demand for the upcoming 0–3 months can be fulfilled as cost-effectively as possible. The starting point is a very granular demand forecast on the SKU-channel-day level. Detailed inventory, capacity, and resource requirements throughout the supply chain are derived from the demand forecast. This end-to-end visibility is used to continuously identify and resolve resource bottlenecks and deal with unplanned exceptions as they arise. If the problems cannot be fully remedied, the next best action enabling the highest possible customer satisfaction and profitability is chosen.

Although retail S&OE is often described as a cadence of cross-functional meetings, retailers cannot excel at S&OE without proper technology. Human expertise and human-to-human communication remain vital parts of the process, but retailers need to leverage AI and digital twin technology for real-time visibility into demand, supply, capacity, and resources throughout their operations to be able to continuously optimize them accordingly.

So what are the four foundational capabilities retailers need to excel in S&OE?

1. Good S&OE is built on accurate, detailed demand forecasts

An effective S&OE process starts with the most accurate and detailed demand forecasts possible. In retail this means forecasting on the SKU-store/channel-day or even intra-day level.

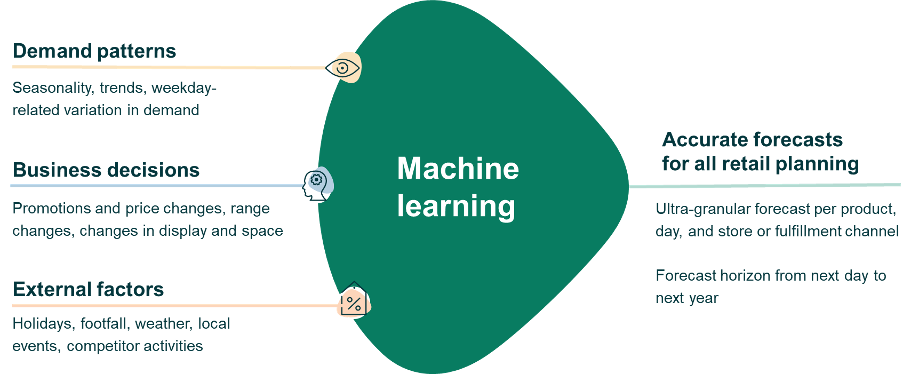

All available information on demand-influencing factors needs to be considered in the forecasts:

- Recurring demand patterns, such as weekday-related or seasonal variation in demand

- Business decisions, such as promotions, price changes, and changes in assortment and space

- External factors, such as local weather forecasts, local events, and local changes in consumer footfall

Machine learning-based demand forecasting allows retailers to consider hundreds of demand-influencing factors and their local impact on demand with a high level of precision and automation, keeping the billions of forecasts they need continuously updated.

2. S&OE requires visibility into inventory, capacity, and resource requirements

To identify and proactively resolve operational bottlenecks, retailers need to understand how the forecasted demand will impact inventory, capacity, and resource requirements throughout their supply chains.

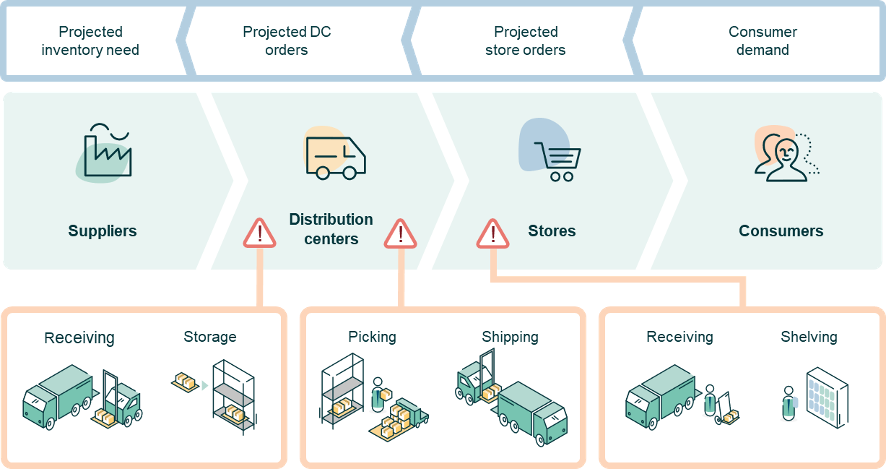

Digital twin technology enables retailers to continually monitor the impacts of business decisions and disruptions on their operations. From an inventory perspective, this means translating consumer demand into detailed inventory requirements throughout the retail supply chain—stores, distribution centers, fulfillment centers, and suppliers (see the upper part of Figure 2).

Furthermore, digital twin modeling gives retailers visibility into resource needs, such as shelving work in stores or order picking in distribution centers, as well as capacity requirements, such as the need for warehouse space (see the lower part of Figure 2).

This end-to-end visibility into retail operations drives many S&OE benefits, including:

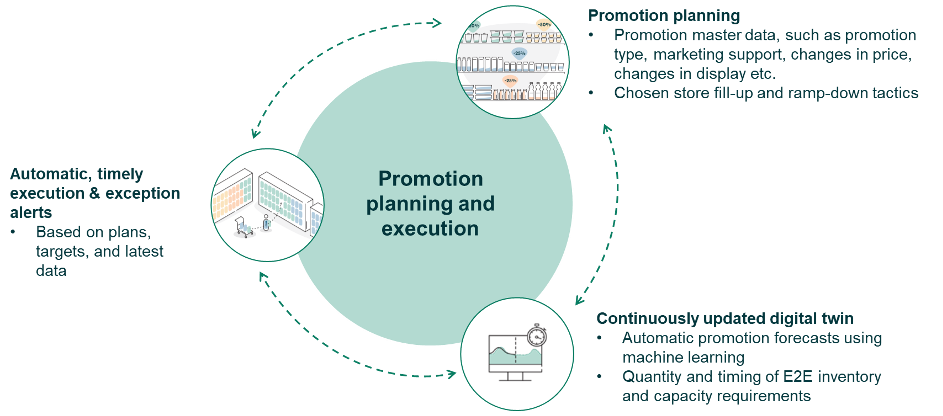

- Cross-functional alignment: The impact of business decisions made in one function are instantly visible across all functions and accounted for in their planning. For example, the expected impact of a planned promotion is immediately visible in all local demand forecasts as well as in the projected inventory and resource requirements throughout the supply chain. This means that business decisions like promotions only need to be planned once for automatic execution (see Figure 3).

- Proactive exception management: Constant visibility into current and future inventory, capacity, and resource requirements throughout the supply chain enables automatic detection of bottlenecks. For example, if the timing of upcoming promotional stock-ups and seasonal allocations creates too large a delivery peak, planners can proactively resolve the problem before it begins congesting store backrooms or exhausting picking capacity in distribution centers.

- Effective contingency planning: Digital twin modeling allows retailers to compare the impact of different scenarios throughout the supply chain, providing a deeper understanding of their decisions. For example, suppose a sales region is growing quicker than its fulfillment capacity. A distribution planning team could easily see when and how they should start shifting fulfillment for some of this regional demand to another fulfillment center, thus balancing capacity requirements in their distribution network.

3. Autonomous exception management is central to efficient S&OE

When dealing with millions of goods flows, tens of thousands of employees, hundreds of vendors, frequent promotions, and price and assortment changes, there are bound to be exceptions to any retailer’s plans. Many of these exceptions require immediate attention and quick adjustments to avoid or minimize any negative impact on S&OE.

By leveraging AI and advanced optimization, most of these deviations can be resolved without human intervention. Best-in-class, autonomous issue resolution increases the speed and accuracy with which a retailer can manage exceptions by:

- Autonomously rebalancing inventory in the supply chain by, for example, triggering optimized scarcity allocations and force-outs in line with the retailer’s business priorities. Another example might be re-optimizing store orders on the fly in accordance with a pick-to-zero fulfillment approach.

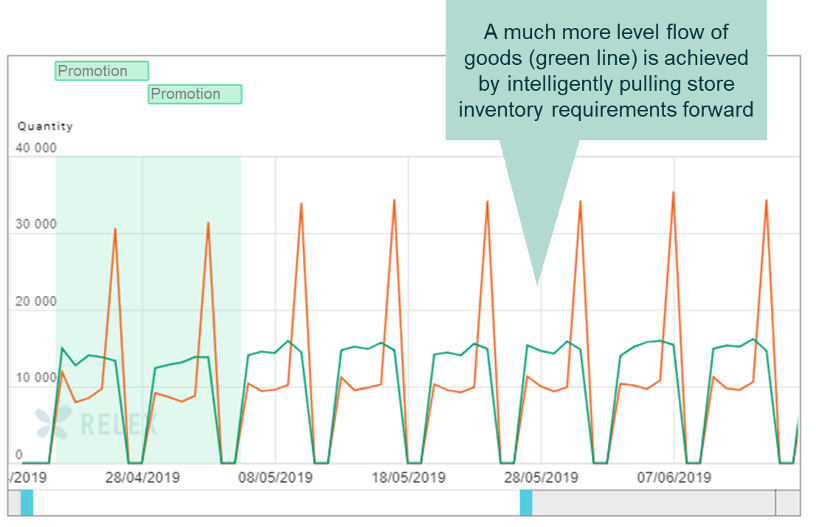

- Ensuring throughput and efficient use of capacity by proactively smoothing out fluctuations in goods flows (see Figure 4), continuously optimizing replenishment and space to minimize in-store goods handling, and optimizing workforce deployment based on continuously updated workload forecasts.

- Recommending corrective or “next best” actions, such as automatically suggesting optimal markdowns to clear excess stock from the supply chain.

4. Human expertise remains essential for S&OE success

Although most of this paper discusses technology, human expertise still plays an immense role in successful retail S&OE. Never has this been clearer than in the most intense phases of the COVID-19 pandemic, where many retailers faced disruptions in all facets of their operations: demand, supply, capacity, and resources.

The best retailers were able to combine human expertise with technology, quickly adapting to the situation and implementing new business priorities at scale. A good case example of this is German drug store retailer Rossmann, who were able to set up new planning configurations prioritizing the delivery of essential products to stores in just two days.

Even in more normal times, though, human expertise is highly valuable. In S&OE, human expertise is needed for:

- Innovative solutions: Although the combination of digital twin modeling and AI allows for autonomous exception management, humans are still needed for innovative problem-solving. Examples include picking up the phone to find an alternative supplier for a product or using the company chat to crowdsource an emergency delivery.

- Contingency planning: Retailers sometimes face potential, but uncertain events, such as a hurricane that may or may not hit a region or a strike that may or may not affect supply. In these situations, a retailer’s business experts absolutely must be involved, for example to define what investments they’re willing to make in buffer stock to secure operations. Digital twin modeling allows retailers to quickly compare different scenarios and action plans, helping them understand the impact of their decisions—but ultimately, the decisions need to be taken by the retail experts.

- Ownership and fine-tuning of planning technology: No matter how smart their technology is, retailers have constant opportunities to fine-tune their automated optimizations to drive further benefits and ensure business priorities are accurately reflected. For example, human experts must plan how goods should be allocated in scarcity situations—whether to maximize sales, prioritize small stores with narrower assortments, or prioritize flagship stores. When experts clearly define the business priorities, a retail planning system can then automatically execute the day-to-day business decisions on an ongoing basis.

- Collaboration with internal and external stakeholders: A retail planning system is only as good as the work processes surrounding it. Typically, there are endless opportunities to improve how functions work effectively together and how retailers work with their suppliers and service providers. Usually, the most impactful process innovations stem from multiple stakeholders working together. Retailers that manage to unlock this potential have a real competitive advantage over competitors who remain stuck in their silos.

To maximize the value of human expertise, retailers need to ensure that their experts’ days aren’t filled with managing routine exceptions that an intelligent retail planning system could handle. Furthermore, it’s absolutely critical that their retail experts have a transparent view into how the system’s automation and optimization works. Only with that level of understanding will they trust the system to automatically handle routine decisions and have the confidence to fine-tune the system in line with how their business and priorities develop.

Retail S&OE Has Never Been More Important

Retail S&OE is where the rubber meets the road. Even the best-laid plans are worthless if they cannot be properly executed. An effective S&OE process ensures retailers meet their sales plans without suffering from poor product availability or costly operational firefighting. Successful retail S&OE is key to high on-shelf availability, efficient use of work hours and capacity throughout the supply chain, and the ability to quickly adapt to market changes, be it due to global pandemics or local weather.

By putting technology to good use, retailers can go beyond merely optimizing performance within their separate functions. Instead, they can achieve cross-functional alignment and optimization, maximizing the benefit to both their customers and their business.

The best retailers allow their business experts to act as their supply chain’s brain, defining business priorities, innovating, and driving continuous improvement. They leverage technology to act as a nervous system that continually collects data on its environment, executes the deliberate actions planned by the brain, and autonomously runs and readjusts core processes like forecasting and replenishment. Technology-savvy retailers are best positioned to take full advantage of their business acumen, and this certainly applies to excelling in retail S&OE.