Supply chain scenario planning: Gaining clarity into uncertain futures

Jul 22, 2025 • 14 min

Picture a room of planners at an ice cream manufacturing company on a cold February day, staring at weather forecasts and demand projections for the upcoming summer. Although the temperature may be below freezing outside, they must commit to planning decisions such as packaging materials and production capacity to prepare for the hot months ahead.

So, how do they actually plan how much ice cream to make for the summer season? Sure, the manufacturer can use their data and forecasting to calculate averages and inform product quantities. But:

- Is a summer ever “average?”

- What if it’s scorching hot and demand far exceeds the forecasts?

- What if it’s unusually cool and lots of unsold stock goes to waste?

These dilemmas reflect a broader reality: manufacturers across various industries face impossible choices as long planning horizons collide with unpredictable market conditions. Traditional single-point planning methods struggle to address these mounting complexities. Fragmented systems and manual processes leave companies “duct taping” their supply chains together — a strategy that works until scale and complexity overwhelm these makeshift solutions.

Manufacturers can approach this uncertainty in two ways: as a strategic liability or as a competitive advantage. Those aiming for the latter need advanced supply chain scenario planning capabilities to rapidly model multiple potential futures, transforming uncertainty from liability into strategic advantage.

What is scenario planning in supply chain management?

Scenario planning is a supply chain planning practice that involves modelling different potential outcomes in a controlled environment to prepare for alternative futures. It enables manufacturers and other supply chain partners to better understand uncertain planning horizons and make confident decisions in various different situations. The aim is to use the best available algorithms to find the most profitable plan that supports the company’s business strategy, covering as many eventualities as required.

Unlike traditional forecasting, which relies on single-point predictions, scenario planning explores multiple potential “what if” situations to inform future planning decisions.

Examples of scenarios that planners may test include:

- What if demand exceeds expectations?

- What if a key supplier faces disruptions?

- What if new regulations change trade routes?

- What if we need to adjust capacity for seasonal peaks?

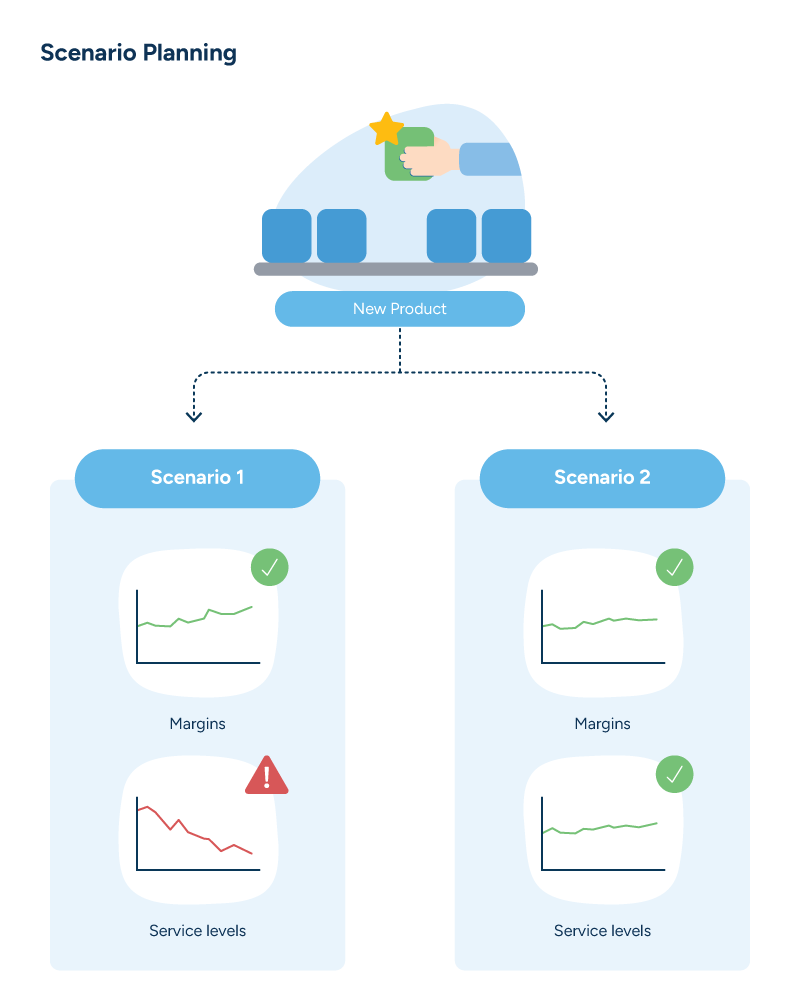

Properly executed scenario planning allows teams to compare different plans for responding to a singular scenario and determine the best course of action from many potential options. Planners can test changes to demand forecasts, production schedules, supplier arrangements, and other factors without disrupting existing plans.

The team can also compare the outcomes of certain actions to understand the implications of best and worst-case scenarios and how much they differ. Understanding the pros and cons of any given supply chain decision helps planners react quicker to the resulting consequences and informs their next action in the process.

Common manufacturing use cases for scenario planning include:

- Capacity planning for seasonal demand.

- Evaluation of new product introduction.

- Stress-testing supply chain changes.

- Preparing for market disruptions.

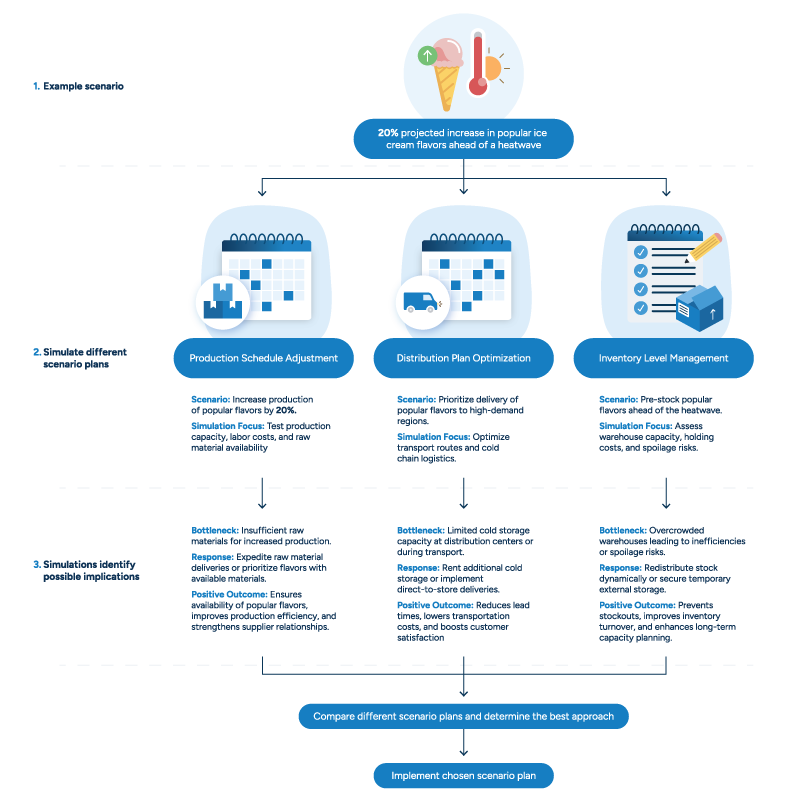

For instance, an ice cream manufacturer facing a forecasted heatwave might test scenarios with 20% increased demand for popular flavors. They adjust production schedules, distribution plans, and inventory levels within the simulation to reflect the increased requirements.

The system reveals potential bottlenecks across different scenario plans, such as insufficient cold storage or raw material shortages. Planners compare outcomes and select the optimal approach, whether expediting procurement or expanding temporary storage capacity.

RELEX Scenario Planning leverages digital twin technology that creates a virtual representation of a customer’s entire supply chain. Planners can simulate, analyze, and compare “what-if” scenarios using live production data within a secure working copy, allowing them to experiment with different conditions and constraints without affecting actual business operations. This digital approach enables rapid testing and comparison of multiple scenarios to identify optimal strategies.

Ultimately, planners can experiment with different scenarios in a safe space — and use their findings to turn uncertainty from being a business threat into a manageable planning variable.

The importance of scenario planning in modern-day manufacturing supply chains

Manufacturing faces unique challenges that make supply chain scenario planning an essential business function for success. Globalization has increased supply chain interdependencies, making manufacturers more vulnerable to geopolitical conflicts, pandemics, and climate disruptions. Meanwhile, rising customer expectations for faster delivery and customization — combined with new technological complexities — have made traditional reactionary approaches insufficient.

Companies that struggle with these challenges due to poor planning decisions often find themselves dealing with:

- Lost sales opportunities during high-demand periods.

- Excess inventory write-offs when demand disappoints.

- Inefficient supplier relationships and procurement costs.

- Inability to respond quickly to market changes.

To make matters even more dire, these challenges frequently multiply at scale as business complexity increases.

Understanding complex trade-offs

Manufacturing decisions rarely exist in isolation. For example, choosing to run a promotion with one customer reduces capacity for other opportunities. Meanwhile, extending a product line may limit resources for existing products.

These interconnected decisions create complex trade-offs that human planners struggle to evaluate manually. RELEX Scenario Planning uses AI and automation to process multiple variables simultaneously and suggest planning solutions, often within minutes, accelerating decision-making.

With advanced software, planners can quickly identify risks between different scenario plans and decide the best approach while accepting potential issues arising from their choices.

Strategic business decision making

Modern manufacturing success depends on building resilient and profitable supply chains that can adjust to market volatility and unexpected disruptions. But doing so is complicated by necessarily long planning horizons — often between 12 and 24 months to implement capacity changes and strategic adjustments. This reality creates an inherent tension: the need to balance existing supply chain concerns with long-term strategic planning in an environment where conditions can shift faster than plans can adapt.

Scenario planning transforms strategic decision-making from reactive guesswork into proactive, data-driven planning. Modeling multiple potential futures enables manufacturers to make confident and informed business decisions concerning considerations such as:

- Capacity investments, such as adding production lines, expanding facilities, or shifting manufacturing to alternate sites.

- Supplier relationships, like diversifying sources, renegotiating contracts, or nearshoring critical components.

- Market expansion, including entering new geographies, launching new product lines, or adjusting go-to-market strategies.

- Resource allocation, like reallocating labor, optimizing transportation assets, or prioritizing high-margin SKUs.

Companies can use these models not only to explore potential outcomes but also to evaluate trade-offs and test the impact of different strategic choices before committing to them. This makes it easier to close forecasting gaps, uncover opportunities within uncertainty, and build resilience that protects against downside risks. Aligning plans to a range of possible futures helps manufacturers navigate change with greater agility and confidence.

Scenario plans also support long-term strategic initiatives by testing the viability of different growth paths and investment strategies. Rather than committing resources based on single-point forecasts, manufacturers can evaluate how strategic decisions perform across various market conditions, ensuring their supply chains remain profitable and competitive regardless of external pressures.

Cross-functional alignment

Effective manufacturing planning requires alignment across multiple departments. However, this can be challenging to achieve when different departments have conflicting priorities.

Sales teams focus on demand forecasts and growth opportunities, while supply chain and operations emphasize capacity constraints and feasibility. Without proper tools, it can be difficult to communicate scenario implications and get teams aligned on the risks and benefits of manufacturing planning decisions.

Scenario planning resolves this by visualizing outcomes that are easy to understand and compare across both supply and demand perspectives. Teams can create scenario plans collaboratively. Sales can share opportunities with demand planners, who then coordinate with the supply chain to confirm feasibility and capacity. This collaborative workflow turns siloed decision-making into a shared process.

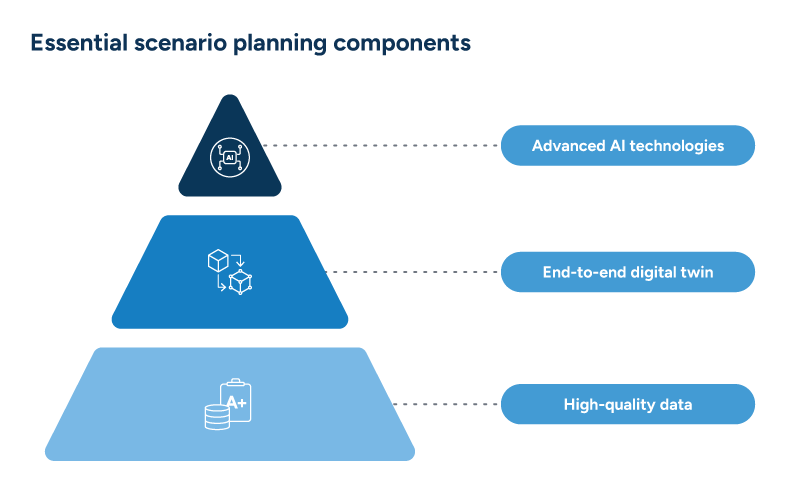

The 3 foundational layers of effective supply chain scenario planning

Successful supply chain scenario planning is built on a three-layer foundational structure that must be built in sequence.

High-quality data

Access to up-to-date, accurate, and reliable data forms the bedrock of successful scenario planning. Manufacturers need comprehensive data across three critical areas- demand data, supply data, and network and logistics data.

Demand data provides the forward view, encompassing historical transactions, forecast inputs, promotional calendars, assortment details, and external demand drivers such as weather or inflation. This helps companies model how different factors may shift consumer behavior or regional demand.

Supply data reveals what’s operationally feasible. This includes material availability, production capacity, labor and equipment constraints, pricing agreements, and lead times — all of which shape how quickly and cost-effectively a company can respond.

Network and logistics data closes the loop, showing how goods move through the supply chain. Plant and production line profiles, transportation modes, supplier networks, delivery timelines, and regulatory considerations all play a key role in scenario feasibility.

While these areas represent the core data domains needed for operational planning, effective scenario modeling may also draw on financial, market, or strategic data, depending on the decisions at stake.

End-to-end digital twin

Effective scenario planning requires an end-to-end digital twin that captures the complete supply chain network, including all facilities, production lines, suppliers, and interdependencies. This comprehensive digital representation enables manufacturers to model their entire operation as an integrated system rather than isolated components.

Without this holistic view, planning remains fragmented with disconnected departmental analyses that miss critical interactions. The digital twin serves as the foundation for running scenarios by providing a unified model where changes in one area automatically reflect their impact across the entire network, enabling more accurate and comprehensive scenario analysis.

READ MORE: Digital twins in supply chain management: What companies often get wrong

Advanced AI technologies

Advanced AI algorithms enhance scenario planning capabilities by processing more variables simultaneously than human planners can manage. These technologies identify patterns in historical data and external signals, enabling more sophisticated predictive modeling and optimization.

AI integration allows for rapid scenario calculation, automated constraint analysis, and intelligent recommendation generation. Machine learning algorithms continuously improve forecasting accuracy and optimization results, while generative AI assists planners in interpreting complex scenario outcomes and identifying optimal strategies.

Essential software features for supply chain scenario planning

Scenario planning has been standard practice among intelligent supply chain planners for decades. But in the modern age, sophisticated software capabilities are essential for optimal results. Manual methods limit reaction speed, restrict variable analysis, and create fragmented decision-making across disconnected systems and processes.

Legacy systems cannot rapidly process millions of variable combinations, lack proper visualization tools for comparing complex scenarios, and fail to enable real-time cross-functional collaboration between stakeholders. Without integrated software, planners must rely on manual translation processes that could lead to errors and delays when turning chosen scenarios into operational plans.

RELEX provides the all-in-one software solution that addresses these limitations with unified scenario planning capabilities across the entire supply chain.

Core scenario management

RELEX supports unlimited scenario creation with both private and shared options. Users can duplicate scenarios to create variations and combine multiple scenarios together. The platform offers static snapshot modes that preserve scenario integrity during analysis, plus dynamic updates when fresh data is needed. This gives planners complete freedom to test a whole host of hypotheticals in a sandbox setting.

Collaboration and comparison

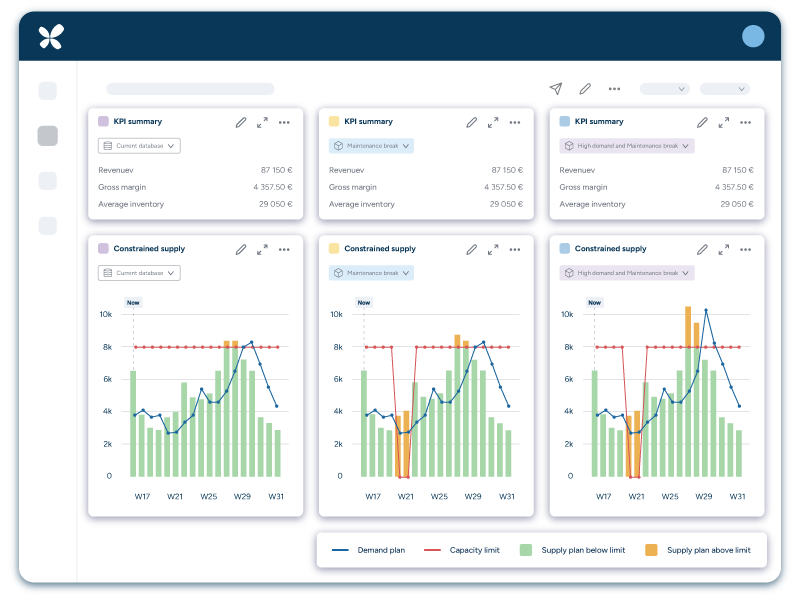

The system provides flexible scenario comparison through tables, charts, KPI panels, and single-view dashboards. Cross-functional teams can collaborate in real time, sharing scenarios and working together on iterative development. Sales teams can propose demand scenarios while the supply chain evaluates and modifies based on capacity constraints.

Superior platform and business logic

The RELEX platform’s proprietary in-memory database rapidly handles millions of variable combinations with battle-tested computational power. The platform’s underlying forecasting engines and optimization models deliver superior accuracy and performance. RELEX provides granular planning down to the SKU level with advanced business logic that powers more precise scenario simulations.

End-to-end AI integration

RELEX combines unified workflows spanning demand forecasting, supply planning, and production scheduling on one platform with specialized AI algorithms that have been a core part of our solution for many years. These algorithms are embedded throughout each process, providing comprehensive scenario planning that fragmented systems cannot deliver.

Rebot, the RELEX generative AI assistant, is the first supply chain gen AI assistant on the market. Rebot helps users answer general supply chain questions and provides solution-specific assistance through access to a comprehensive knowledge base of documented best practices.

However, this is just the beginning. Eventually, Rebot will evolve to play a more collaborative role in scenario planning, generating custom, company-specific insights by referencing customer data while maintaining complete security and privacy. This enhanced version will help users interpret complex scenario results, automatically create scenarios based on opportunities and risks, and offer personalized recommendations based on their unique business context.

Implementation and integration

With RELEX, scenario plans can be implemented in just one click, seamlessly merging chosen scenarios into active operational plans. This eliminates manual translation steps that introduce errors and delays. Approved scenarios become actionable plans immediately, streamlining the transition from strategy to execution.

Scenario planning and RELEX: Planning for success

RELEX scenario planning is designed for both rapid tactical decisions and comprehensive strategic planning. Whether a team needs a quick answer to an urgent question or wants to conduct thorough collaborative analysis for long-term planning initiatives like Integrated Business Planning (IBP), the platform adapts to their timeline and requirements.

For immediate planning needs, scenarios can be created and analyzed within minutes. A planner can quickly test “what if we accept this promotion opportunity?” or “what if this supplier faces delays?” and get actionable insights almost instantly. This agility enables real-time decision-making when opportunities or challenges arise.

For more complex decisions requiring cross-functional input, scenario planning becomes a powerful collaboration tool. The same scenario can be shared across departments, allowing sales teams to propose demand changes, supply chain teams to assess capacity constraints, and finance teams to evaluate profitability implications. This shared analysis ensures everyone works from the same data and assumptions.

The flexibility that RELEX provides is valuable for manufacturers operating in today’s fast-paced, uncertain environment where both speed and strategic depth are essential for success.

The RELEX approach

Our scenario planning process follows a streamlined four-step workflow that can be completed quickly or expanded for detailed analysis:

Step 1: Create

Start by creating a new scenario and defining your inputs. Enter the changes requiring analysis, such as adding a promotion, changing supplier lead times, considering demand variations, or modifying production capacities. You can create scenarios for any use case configured in the system, providing maximum flexibility for unique planning needs.

Step 2: Calculate

Run the appropriate business rule workflows configured in your system to calculate the scenario results. The system processes demand forecasts, supply optimization, and constraint analysis simultaneously, leveraging the platform’s advanced machine learning algorithms. This calculation happens rapidly, often within seconds or minutes.

Step 3: Analyze

Review and interpret what the scenario reveals by comparing it with the current plan and other created scenarios. Examine visualizations of the results to understand the implications, trade-offs, and potential outcomes. Multiple stakeholders can access and analyze the same scenario simultaneously, facilitating collaborative discussion and decision-making.

Step 4: Decide

Compare scenario plans, identify the most effective course of action, and select the optimal path forward. Approved scenarios can be implemented directly into the active operational plan with a single click, eliminating manual translation steps. Scenarios may also be saved for future reference, shared with stakeholders, or removed if no longer needed.

Vita Coco: Optimizing global operations through supply chain scenario planning

Coconut water company Vita Coco operates in 31 countries, with 15 factories and over 20 warehouses worldwide. Synchronizing this complex, asset-light supply chain while maximizing profitability presented significant planning challenges. The company needed integrated planning capabilities to model its entire network of suppliers, co-packers, and distribution centers.

Vita Coco partnered with RELEX to create a comprehensive digital twin of its supply chain. The model captures every node, constraint, and cost across its global network, including varying supplier costs, capacity constraints, minimum order volumes, shipping routes, and import tariffs.

The company regularly uses RELEX to simulate different business scenarios that inform strategic decision-making. For example, their planners can model tariff changes and determine optimal supplier selection by geography. These scenario planning capabilities prove especially valuable during financial planning and budgeting processes.

The RELEX supply chain optimization tool is a first-class decision support tool. We can simulate pretty much any supply chain scenario and find out how it will likely impact our costs and delivery performance.

Jonathan Burth, COO, The Vita Coco Company

Vita Coco leveraged RELEX to achieve over $3 million in cost savings during the first year of implementation. RELEX has helped them create an optimized 18-month supply plan that guides production scheduling and logistics operations. Their S&OP process became significantly more efficient with everyone working from integrated, optimized plans.

RELEX: Your partner in navigating supply chain turbulence

As uncertainty becomes the new normal, manufacturers must fundamentally shift from treating scenario planning as a periodic activity to embracing it as a continuous capability. The old way of reacting to disruptions with fragmented systems and manual processes simply cannot keep pace with today’s volatile environment. The real competitive advantage now belongs to manufacturers who can model, interpret, and act on complex data faster than their competition, turning uncertainty from a liability into a strategic weapon.

This transformation demands investment in the right technology, but it also requires new behaviors and a cultural shift towards collaborative problem solving. Manufacturers must institutionalize “what-if” thinking, embedding scenario exploration into everything from daily operations to executive decision-making. Successful supply chain planning becomes less about reacting to surprises and more about continuously anticipating disruptions and rehearsing multiple futures.

The companies that will thrive in this “new normal” will look beyond trying to predict what comes next and instead focus on being ready for anything. When uncertainty is permanent, manufacturers need software that makes continuous scenario planning both possible and effortless —and they’ll need an advanced platform like RELEX to do it.

Scenario planning FAQ

How does scenario planning differ from traditional forecasting?

Traditional demand forecasting produces single-point predictions based on historical data and trends. Scenario planning goes beyond this by modeling multiple “what-if” situations simultaneously. Instead of just predicting what will likely happen, scenario planning helps manufacturers prepare for various possible futures—from best-case to worst-case scenarios.

What is a digital twin in supply chain scenario planning?

A digital twin is a virtual representation of your entire supply chain network that captures every node, constraint, cost, and interdependency in your operations. In supply chain scenario planning, the digital twin includes your facilities, production lines, suppliers, transportation modes, capacity constraints, lead times, and business rules—essentially creating a mathematical model of your real-world supply chain.

Digital twins serve as a “sandbox environment” where you can safely test different scenarios, like changing supplier arrangements or adjusting production capacity, without disrupting actual operations. It enables the system to automatically calculate the ripple effects of any change across your entire network, providing accurate insights that would be impossible to achieve through manual analysis or fragmented systems.

How does scenario planning support Integrated Business Planning (IBP)?

Integrated Business Planning (IBP) is a collaborative decision-making process that aligns an organization’s business functions with its financial goals and long-term strategy, typically over an 18–24 month horizon. It integrates strategic, tactical, and operational planning layers to ensure alignment and feasibility across the supply chain.

Scenario planning supports IBP by enabling businesses to simulate and compare multiple demand or supply scenarios to understand risks, trade-offs, and opportunities. The results of scenario plan tests inform IBP decision-making cycles to optimize KPIs like revenue, margin, and service levels.