Make a difference: Cutting food waste and carbon footprint through optimized forecasting and replenishment

Mar 4, 2020 • 12 min

Every year, about a third of all the food the world produces is lost or wasted. The figures are staggering. So is the impact that this level of waste has on climate, water, land, biodiversity, hunger, the economy, food security, and even political stability. Reducing food waste is a key opportunity to mitigate the negative environmental impacts of the food supply chain. Luckily, awareness of the impact of food waste is growing, and people, businesses, and governments are starting to respond. In 2015, for example, the US pledged to reduce food waste by 50% by 2030.

Most food waste occurs after it’s been bought by the consumer. However, the sheer scale at which retailers work means that they’re in a position to make a much larger impact on the problem than individual shoppers can. In the US, grocery retailers are directly responsible for about 10% of the country’s food waste; that’s about 43 billion pounds (19.5 billion kg) each year. However, by improving their supply chain visibility and planning processes, retailers could reduce their food waste by up to 40%. That’s 17.2 billion pounds (7.8 billion kg) of food that would otherwise spoil that retailers could save each year — and that’s just in the United States. Reducing waste doesn’t just benefit the environment, it’s also money straight back to the bottom line.

A recent survey by RELEX Solutions and EnsembleIQ, Planning for Every Future in Grocery Retail, shows that two out of every three grocers surveyed are losing over 1.5% of their business’s annual revenue to expired and spoiled products. Put another way, a typical grocer with $1 billion in revenue will lose more than $15 million to spoilage alone each year.

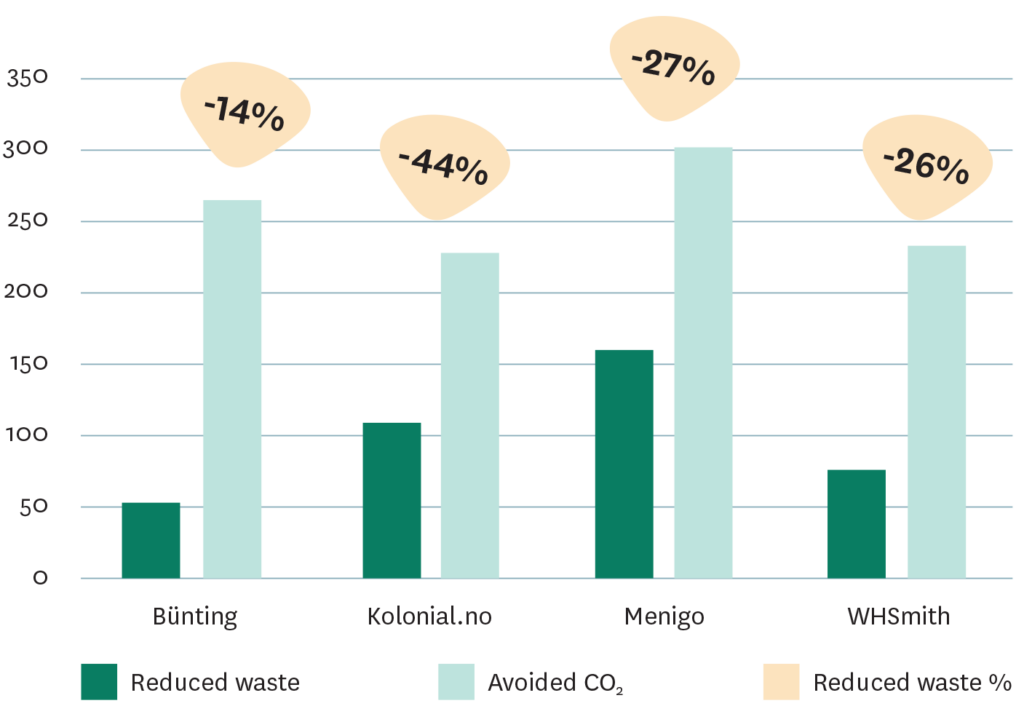

Food waste is something that RELEX has extensive experience addressing. Since 2011, we’ve been using advanced forecasting and automated replenishment to make dramatic inroads into food spoilage levels. Working with scores of fresh food retailers around the world, we’ve cut spoilage for each of them by between 10% to 40%. Not only does that significantly add to their profitability but it also makes a very valuable contribution to their efforts to cut their carbon footprint.

We could say that RELEX helps its partners save more than 8,800,000 kg of food waste each year, or a CO2 equivalent of 70,000 NYC-Paris flights.

This survey looks at just four of RELEX’s grocery, convenience, and food service customers — a representative sample, but less than 5% of the total number of RELEX customers. If we were to extrapolate the results achieved by those four to all our customers selling fresh products, we could say that RELEX helps its partners save more than 8,800,000 kg of food waste each year, or a CO2 equivalent of 70,000 NYC-Paris flights. As businesses everywhere target the climate crisis with increasing urgency, that figure isn’t just something we can be proud of, it’s something that should give us hope.

Study Overview

RELEX Solutions partnered with Gaia Consulting to conduct an independent review of the climate impact of implementing RELEX’s forecasting and replenishment solutions. We have always measured the quantity of food waste we’ve helped to cut and its financial impact, but we wanted to know with a high degree of confidence how that would translate into environmental benefits such as CO2 emissions avoided. The study specifically looked at the effect of reducing spoilage of fresh food items at four of RELEX’s forecasting and replenishment customers — Bünting, Kolonial.no, Menigo, and WHSmith. This report outlines how these four companies have led the charge toward environmentally responsible business practices while significantly improving both their operations and their cost-effectiveness.

We’ve used two methodologies to calculate carbon emission reduction – spend-based and weight-derived. As the latter are consistently more reliable and conservative, we’ve chosen to highlight those figures. We’re confident that, with the help of the right technology, almost any business trying to cut spoilage of fresh produce could replicate these results.

Background

This study has set out to calculate the reductions in food spoilage at four businesses representing traditional grocery, online grocery, food service, and convenience — and to translate those savings into a reduction of CO2 emissions.

Because the four companies operate four different business models, there are limits to the comparisons that can be made between them.

However, the results give a good indication of the potential to reduce waste and improve sustainability across grocery businesses.

The four businesses are Bünting, a supermarket group in northwestern Germany; Kolonial.no, the Norwegian online food retailer; Menigo, a Swedish food wholesaler; and WHSmith, famous as a bookseller and stationer but also a major retailer of food-to-go.

This report’s calculations are based on high-quality retail data. All four businesses have maintained detailed records of every item purchased and sold and are thus able to track waste in great detail across their businesses.

There are a few things to bear in mind while reading this report:

- We focused on food waste and its impact on CO2 emissions. All four companies reduce emissions in other ways, such as optimizing their distribution logistics and thus cutting the amount of carbon they produce, but that is outside the scope of this report.

- The sample is small. RELEX has more than 250 customers, and this report studies just four of them. However, the four, coming from different sectors of food supply — supermarkets, e-grocery, wholesale, and convenience — reflect the diversity of the sector. Their results are certainly not outliers compared with other RELEX customers.

The final figures are conservative. There is a lack of detailed and standardized carbon footprint measurements for food items. Therefore, we needed to estimate the impact on CO2 reduction by category rather than by SKU. As different sources suggest different carbon footprints, we preferred to err on the side of underestimating rather than overestimating, meaning that we consistently used conservative carbon footprint estimates. We compared pre- and post-implementation figures (of RELEX’s software) and used sales and spoilage figures to calculate a spoilage value per product group. That was then translated into kilos of waste for each group and finally into CO2 equivalents utilizing standardized CO2 emission factors for the selected product groups. More detailed information about the methodology can be found at the end of the PDF document.

Bünting

Bünting, a traditional, family-owned business, is one of Germany’s major regional food retailers. They operate more than 200 supermarkets under the Combi, Jibi, and Famila banners in the country’s northwest, supplied by four distribution centers (DCs).

The supermarket group introduced RELEX’s forecasting and replenishment system with the intention of centralizing its supply chain planning and increasing availability, while simultaneously cutting inventory and waste.

Bünting is a carbon-cutting hero, having reduced transportation miles between its DCs and stores by almost a quarter after introducing RELEX and increasing the fill-rate of their trucks. However, this report just focuses on the CO2-lowering impact of reducing food waste.

With RELEX’s forecasting and replenishment solution in place, Bünting was able to reduce the cost of food spoilage by 14%.

With RELEX’s forecasting and replenishment solution in place, Bünting was able to reduce the cost of food spoilage by 14%. By our calculations, that means there was 53,000 kg less food waste in 2018 compared to pre-RELEX levels.

That 53,000 kg resulted in emissions of 265,000 kg CO2equivalents being avoided in 2018. Using RELEX’s illustrative beefsteak scale, the 265,000 kg of carbon dioxide that was not emitted as a result of Bünting’s efforts is equivalent to the carbon footprint of 120,411 beef steaks.

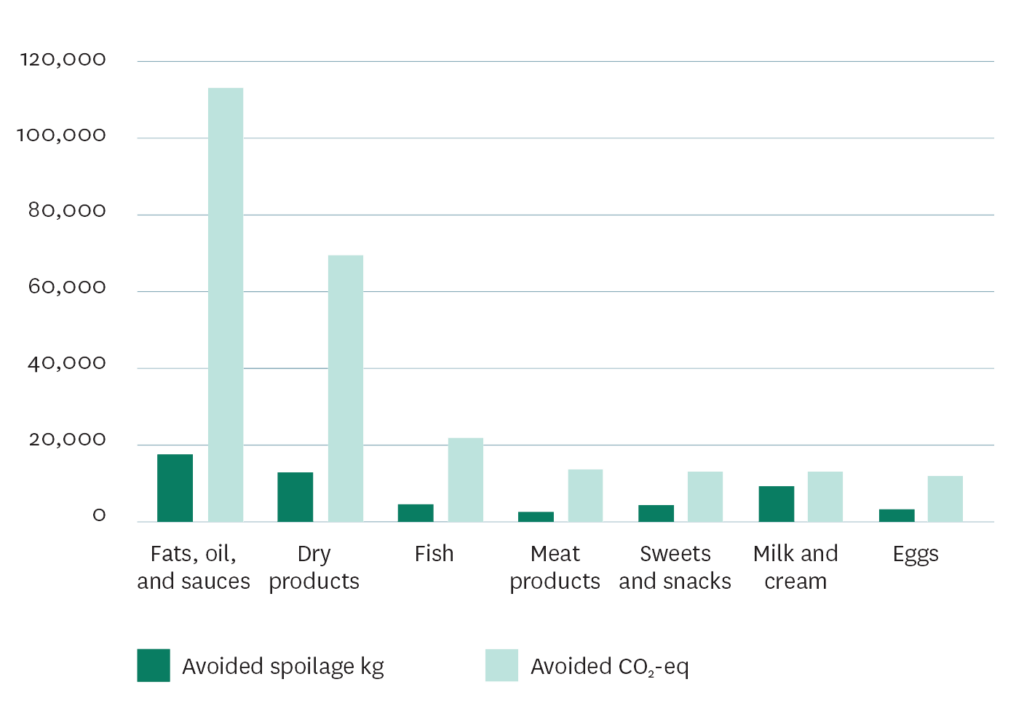

The figure above shows the product categories where Bünting’s waste reduction efforts have had the biggest CO2 impact. Typical products within the categories include fats: mayonnaise, oil, and margarine; dry products: instant meals; fish: herring fillets and canned fish; meat products: sausages and ham products; sweets: confectionary and salted snacks; and milk: includes long-life milk.

The most significant reductions in CO2 emissions were achieved by cutting spoilage of fats, oils and sauces, dry products, and fish.

The most significant reductions in CO2 emissions were achieved by cutting spoilage of fats, oils and sauces, dry products, and fish. In bread, spoilage increased slightly. This has been accounted for in the overall results.

Kolonial.no

Kolonial.no is Norway’s largest online grocery retailer and one of the country’s fastest growing businesses. It offers a range of more than 6,000 products delivered from a 36,000m central warehouse outside Oslo to customers’ homes or to pick-up points.

Along with rapid growth, Kolonial.no has had to manage challenges faced by e-grocers everywhere. Consumers expect e-grocers to pick the best produce on their behalf, so freshness is critical. Kolonial.no turned to RELEX to help improve availability while simultaneously cutting costs and waste through better forecasting and replenishment.

Since implementing RELEX’s forecasting and replenishment solution, Kolonial.no has been able to reduce the cost of food spoilage by 44%.

Since implementing RELEX’s forecasting and replenishment solution, Kolonial.no has been able to reduce the cost of food spoilage by 44%. We’ve calculated that this reduction of 109,000 kg in food waste in 2018 is the equivalent of 228,000 kg of CO2.

In illustrative terms, 228,000 kg of carbon dioxide corresponds to the carbon footprint of 103,743 beef steaks.

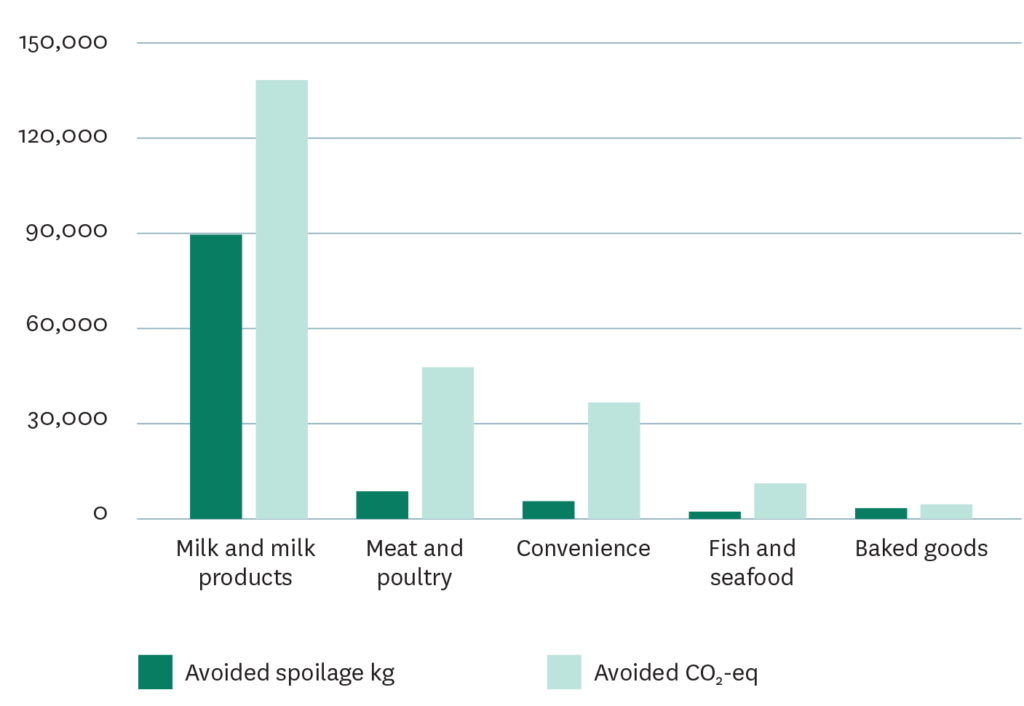

The figure above shows the product categories where Kolonial.no’s waste reduction efforts have had the biggest CO2 impact. Typical products within the categories include meat: chicken, minced meat, and sausages; convenience: ready meals; fish: fresh fish; and baked goods: bread and buns.

The most significant reductions in CO2 emissions were achieved in milk, chicken, minced meat and sausages, and ready meals.

The most significant reductions in CO2 emissions were achieved in milk, chicken, minced meat and sausages, and ready meals. In the cheese category, spoilage increased slightly between the comparison periods 2017 and 2019. This has been accounted for in the total results.

Menigo

Menigo is one of Sweden’s major food suppliers — a leading food service company delivering ingredients, beverages, and equipment to 15,000 clients. It operates eight regional warehouses and employs around 1,000 people, turning over around €570M per year.

Menigo’s core offering to its customers is its high availability levels across a wide selection of products; if a customer wants it, Menigo aims to have it. However, high availability, especially with fresh products, has traditionally resulted in waste. Menigo introduced RELEX in order to maintain its lead in availability while simultaneously cutting inventory and spoilage.

Implementing RELEX’s forecasting and replenishment solution, Menigo was able to reduce the cost of food spoilage by 27%.

By implementing RELEX’s forecasting and replenishment solution, Menigo was able to reduce the cost of food spoilage by 27%. This amounts to an estimated 160,000 kg in reduced food waste in 2018.

By reducing the amount of food that spoils, Menigo also cut its carbon footprint by 302,000 kg of CO2. Using RELEX’s illustrative beefsteak scale, that’s the carbon footprint equivalent of 137,320 beef steaks.

The figure above shows the product categories where Menigo’s waste reduction efforts have had the biggest CO2 impact. Typical products within the categories include minced meat: minced meat and meatballs; fruits: bananas and lemons; vegetables: herbs, tomatoes, and mushrooms; potatoes: peeled potatoes; and pork: frozen lamb fillet and ribs.

The most significant reductions in CO2 emissions were achieved in minced meat and pork and lamb, as well as in the fresh fruit and vegetable categories.

The most significant reductions in CO2 emissions were achieved in minced meat and pork and lamb, as well as in the fresh fruit and vegetable categories. Spoilage increased slightly between 2016-2018 in the sauces and dressings category. This has been accounted for in the overall results.

WHSmith

WHSmith is the world’s oldest store chain. It made its name selling newspapers and books at railway stations. It’s still a fixture for travelers, with WHSmith Travel offering fresh sandwiches, beverages, pastries, and more to people on the move at airports as well as bus and train stations.

WHSmith turned to RELEX for help managing their food-to-go products in some 370 stores across the UK, many of them at transport hubs. Previously, fresh product replenishment had been managed by the company’s supplier. When WHSmith took procurement and replenishment in-house, they sought to improve availability and reduce waste at the same time. RELEX offered accurate forecasting and the ability to maintain high availability levels while minimizing inventory as well as managing split deliveries, promotional forecasting, and holidays — all of which significantly cut waste.

Since introducing RELEX, WHSmith has cut food spoilage by 26%.

Since introducing RELEX, WHSmith has cut food spoilage by 26%. We’ve calculated that the company reduced food waste by 76,000 kg in 2018.

Based on the quantities of food waste cut from its various categories, that 76,000 kg resulted in emissions of 233,000 kg CO2equivalents being avoided in 2018.

Using RELEX’s illustrative beefsteak scale, that 233,000 kg of carbon dioxide is equal to the carbon footprint of 106,087 beef steaks.

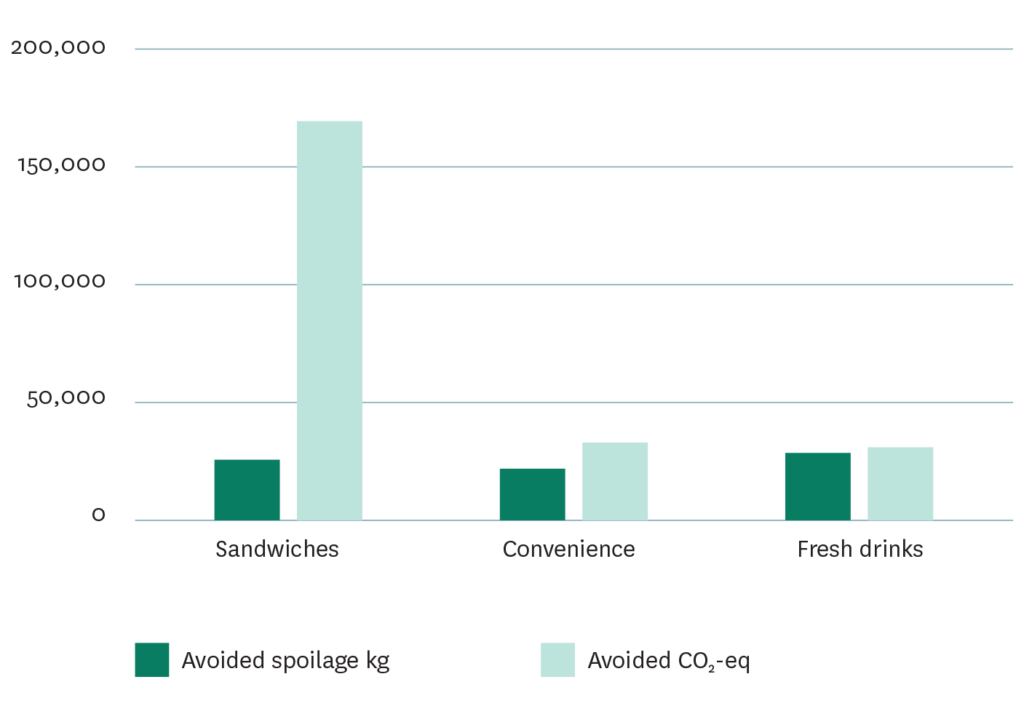

The figure above shows the product categories where WHSmith’s waste reduction efforts have had the biggest CO2 impact. Typical products within the categories include convenience: milk and milk- and meat-based snacks (yogurts); and fresh drinks: fruit juices, smoothies, and milkshakes.

The most significant reductions in CO2 emissions were the result of cutting the number of expiring sandwiches, wraps, cartons of milk, fresh juices, and smoothies.

The most significant reductions in CO2 emissions were the result of cutting the number of expiring sandwiches, wraps, cartons of milk, fresh juices, and smoothies.

Summary

One of the main findings, based on the narrow scope of our study, is that the entire food sector — producers, wholesalers, and retailers alike — could have a massive impact on global food waste by following the lead of the four companies studied in this report. Not only would doing so cut the amount of carbon being released into the atmosphere but it would also have an impact on pollution resulting from waste packaging. And while consumers are also responsible for a huge proportion of food waste, retailers are extremely well placed to take the lead and are likely to be well regarded for doing so.

The even better news is that sustainability doesn’t require great sacrifices from the grocery sector. In our survey Planning for Every Future in Grocery Retail, we found that the most successful respondents in the study — those who kept spoilage costs to under 1.5% of annual revenue — relied on a range of supply chain technologies to help do so. Thankfully, the outlay for the cutting-edge forecasting and replenishment tools that make this scale of waste reduction achievable is quickly recouped from savings made.

Waste comes straight off the bottom line. Preventing it means a healthier balance sheet and planet.

The four companies we looked at in this study did not have to compromise their service levels — indeed they generally rose even higher. So too did profits, because in an industry where margins are tight, it requires several sales to recoup the cost of a single spoiled item. Waste comes straight off the bottom line. Preventing it means a healthier balance sheet and planet.

Lastly, from a sustainability point of view, some product groups have an impact on the environment disproportionate to their sales value. For instance, beef is increasingly a luxury in environmental terms. The least we can do, surely, is to not waste any. Making sure these high-impact products are well optimized leads to a strong impact when it comes to cutting CO2. We work closely with all our grocery customers to figure out which categories have the highest impact, and we would encourage all grocery businesses to do the same.

RELEX exists to help our customers be more efficient and serve their own customers better. And while we’re a business with business goals, we’re also people who care about issues like sustainability and protecting the planet that we live on — just like our customers. We think that we’ve found a way of aligning both business and environmental goals. By promoting efficiency and refusing to tolerate waste, retail can take a lead on issues that are of ever-growing concern to all of us.