Teaming up for impact: Where AI-powered operations deliver profitability and sustainability

Jan 22, 2026 • 7 min

The progress on sustainability across retail, wholesale, and manufacturing is worth applauding. Companies are tracking emissions, sourcing responsibly, and improving efficiency, providing proof that commitments can translate into real results. Corporate responsibility and procurement teams have led much of this effort, partnering across the business to turn ambition into action. Now, there’s a chance to build on that momentum. By bringing supply chain, operations, and merchandising teams into the effort, companies can move from meeting goals to multiplying their impact. When these teams work together, sustainability shifts from an initiative to a growth engine. One that strengthens operations and delivers measurable impact.

Building on this foundation requires a structured approach that connects sustainability ambitions with the day-to-day decisions. The following three-step playbook outlines how companies can turn progress into scalable operational impact.

The three-step playbook for scaling sustainability impact:

- Understanding your starting point: Identify where your biggest emissions and sustainability risks come from and recognize the greatest potential for meaningful impact.

- Optimizing operations for financial and environmental benefits: Create operational efficiency that reduces emissions, waste, and costs. Generate savings that can improve profit and fund longer-term sustainability initiatives and business transformation.

- Building long-term resilience through transformation: Futureproof your business by engaging in a gradual transformation of offering, assortment, and sourcing to meet customer preferences and tightening regulations.

Making progress across all three steps requires visibility and coordination to connect sustainability goals with everyday business decisions.

The organizations making the fastest progress are those giving their supply-chain, operations, and merchandising teams a shared, end-to-end view of data and decisions. With AI and machine learning, they can see how business decisions affect inventory, demand, profitability, and emissions.

Step 1: Understanding your sustainability starting point

Every sustainability journey begins with clarity. Thanks to corporate responsibility (CR) and sustainability reporting, most companies are already aware of their key emission sources and sustainability risks. The real challenge is that a company’s sustainability improvements are often still seen as something the CR department should be driving. In reality, sustainability is a shared responsibility.

Just as business leaders are expected to understand their company’s profit and loss (P&L) statement, they should also be fluent in the organization’s key sustainability metrics.

In the case of P&L, finance teams may have the technical expertise to produce it, but business leaders are accountable for the decisions that shape it. The same principle applies to sustainability. CR teams bring specialized knowledge, but it’s the broader business functions whose decisions drive performance against those metrics.

Cross-functional collaboration is where meaningful impact begins. Some cross-team opportunities deliver quick wins (see Step 2). Others lay the groundwork for long-term resilience (see Step 3).

Done well, Step 1 creates a foundation for momentum. It ensures that quick wins in Step 2 are not isolated fixes but part of a bigger plan. These first two steps then build up to the transformational changes in Step 3 that enable the business to stay ahead of evolving demands.

Step 2: Finding profitability and sustainability win-wins

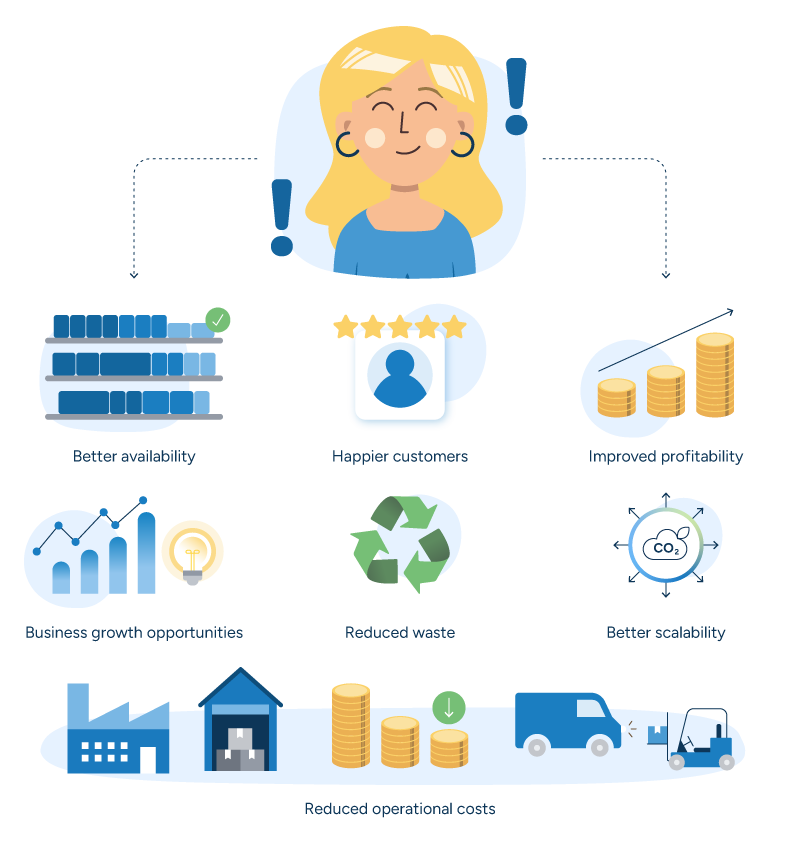

Once your major emission sources and sustainability risks are mapped, the next step is to address the inefficiencies that drain profitability. In supply chains, operational efficiency almost always goes hand in hand with sustainability. Improved demand planning streamlines inventory and distribution, while aligning production and sourcing with demand reduces emissions, cuts waste, and lifts margins.

Retail: Identifying profitability–sustainability win-wins

Retailers who invest in demand forecasting, replenishment, allocation, and merchandising planning reduce the risks that drain profitability: overstock, costly store transfers, markdowns, and obsolescence.

Across retail operations, connected planning creates measurable gains for both the business and the environment:

- AI-powered automation of forecasting and replenishment reduces waste and emissions while simultaneously improving on-shelf availability and sales.

- Markdown optimization enables more timely and accurate markdowns, reducing the risk of obsolete stock.

- Predictive promotion analytics and optimization eliminate ineffective promotions that generate waste and improve margins on well-performing ones.

- Smarter allocation of seasonal products removes costly transfers between stores and increases sales.

- AI-assisted space and assortment optimization ensures that visual minimums don’t drive overstocks in stores, while pruning out poorly performing products.

To balance availability with short shelf lives and volatile demand, a convenience retailer adopted RELEX AI-powered forecasting and replenishment solutions to optimize their supply chain operations. Factoring in weather and optimizing store orders led to 67% fewer stockouts, a two-point margin lift, and 30% less waste. These results are proof that better planning pays off in both profit and sustainability.

A grocery retailer used the RELEX platform for replenishment as well as space and assortment planning tools to tailor shelf space and assortments to store-specific demand. By rightsizing space for perishables and optimizing planograms, the retailer reduced food waste by several percentage points. They were also able to improve shelf availability, and cut the time required for restocking within the first few months of implementation.

Distribution: Optimizing operations for financial and environmental benefits

In distribution networks, poor planning often leads to excess storage needs, risk of obsolescence, and inefficient transportation.

The opportunities for improvement span the entire distribution operation:

- Improved forecasting accuracy reduces the need for excessive safety stock, lowering overall inventory levels and easing pressure on storage space. This allows growing businesses to delay investments in additional facilities or repurpose existing space more efficiently.

- Smarter inventory management prevents product obsolescence, markdowns, and waste while reducing the need for costly, emission-intensive express deliveries to resolve stockouts.

- More accurate distribution planning enables fuller trucks and fewer trips. The result is lower transportation costs and reduced emissions, both inbound from suppliers and outbound to stores.

A pharmaceutical distributor used RELEX to transform their distribution network through intelligent inventory planning. By implementing RELEX Forecasting and Replenishment, the company improved service levels, lowered inventory levels, and reduced their carbon footprint. With less excess stock to hold, the distributor no longer needed to expand its distribution network. The need for fewer facilities also reduced vehicle requirements and ongoing facility-related emissions.

A multinational producer of branded food and beverage products, implemented advanced forecasting and capacity planning with RELEX to optimize inventory placement and streamline operations across their supply chain. As a result, the company achieved a 100% reduction in both outside storage costs and DC-to-DC transfer costs. This transformation is part of their broader strategy to enhance supply chain efficiency and sustainability.

A leading grocery wholesaler implemented Forecasting and Replenishment from RELEX to improve visibility and synchronization across its 17 distribution centers. With machine learning-driven demand insights, the company reduced fresh waste by 33% in one quarter of 2025 alone. The initiative demonstrates how upstream supply chain improvements can deliver significant financial returns while advancing sustainability goals.

Production: Minimizing waste through integrated planning

Integrated master planning and production scheduling reduce waste by ensuring that production aligns with demand and available capacity.

- Integrated master planning considers constraints such as capacity limits, maintenance windows, and changeovers to generate feasible plans. This alignment minimizes overproduction, prevents waste, and increases resilience by enabling rapid replanning when demand shifts.

- Connected production scheduling optimizes product sequencing to reduce downtime and avoid waste from frequent changeovers, while ensuring efficient use of energy and production resources.

- Upstream and downstream alignment ensures raw materials and finished goods are available at the right time, reducing bottlenecks and unnecessary inventory buildup.

A large coffee manufacturer, needed to balance long procurement lead times with highly variable demand. By implementing RELEX Demand Planning and Production Scheduling, the company gained forward-looking visibility into demand and production capacity. This improved planning reduced excess inventory and minimized waste across the supply chain. With greater confidence in their forecasts, the business was also able to avoid reliance on spot-market purchases.

A leading food manufacturer, partnered with RELEX to optimize their supply chain processes. By leveraging RELEX advanced Forecasting and Replenishment solutions, the company achieved a 70% reduction in couriered raw materials. More efficient and planned transportation lowered their environmental impact while ensuring consistent supply chain performance.

A poultry producer transitioned from manual, spreadsheet-based planning to the RELEX unified platform to improve forecasting accuracy and production visibility. With better alignment between demand, production targets, and scheduling, the company was able to ensure that raw materials were used as efficiently as possible and overall inventory waste was lowered.

Collaboration: Partnering across the value chain

The most meaningful sustainability gains happen when companies move in sync with partners across the value chain. Collaboration creates stability and trust that strengthens the entire network over time.

When retailers and suppliers work from a shared view, responsiveness improves and planning becomes a joint effort.

For example, a vertically integrated food retail is leveraging the RELEX Forecasting and Replenishment tools to share both short- and long-term forecasts with suppliers and internal teams. This proactive collaboration reduced spoilage, refined crop harvest planning, and streamlined packaging and production processes.

Similarly, the pharmaceutical distributor used RELEX Supply Chain Collaboration to transparently compare future forecasts with suppliers. This visibility allowed issues to be identified sooner and resolved earlier.

This proactive coordination helps reduce product waste from expiration and minimize environmental costs associated with last-minute corrective actions. Every partner is equipped to respond with agility and act on shared sustainability and profitability goals.

Learn more about how the RELEX platform helps you make every step of your supply chain more sustainable.