How data best practices can improve inventory management and forecast accuracy

Jul 2, 2025 • 6 min

Grocery shoppers now expect seamless experiences whether they’re browsing aisles, ordering online, or receiving home deliveries. Behind every successful customer interaction lies a critical foundation: accurate, up-to-date inventory data that flows seamlessly from upstream planning to downstream execution.

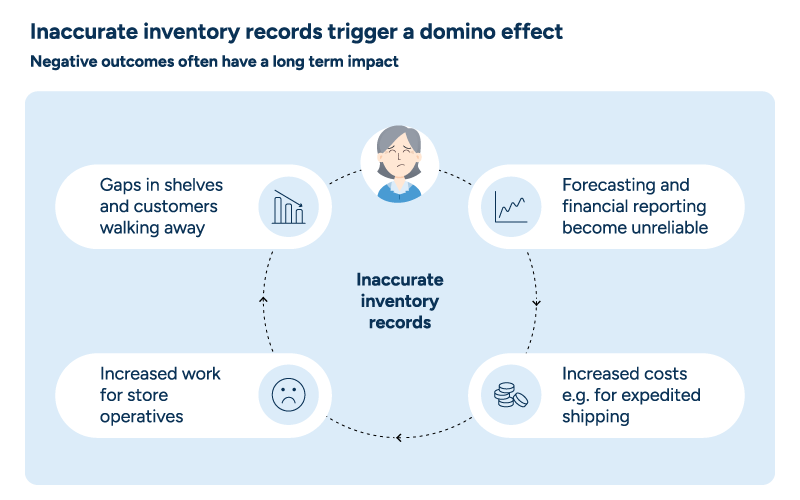

While sophisticated planning and fulfillment systems can optimize operations, they’re only as effective as the data feeding into them. When inventory data is inaccurate, delayed, or inconsistent across channels, it negatively impacts internal operations, customer trust, delivery promises, and the bottom line.

Accurate data is critical in an omnichannel environment

When a customer sees an item available on a retailer’s app but discovers it’s out of stock during curbside pickup, or when an online order fails because inventory counts were wrong, the result is immediate customer disappointment and eroded trust.

Yet, maintaining accurate inventory data is more difficult than it’s ever been before. The same inventory now serves customers shopping in-store, ordering through retailer apps, or using aggregator platforms (like Instacart or Shipt). Each channel makes product availability promises based on the same underlying inventory data. An inventory discrepancy that might have once meant a missed sale in-store can now cascade into failed deliveries, cancelled orders, and negative reviews across multiple platforms.

The stakes are particularly high for fresh goods. If the system shows 20 bananas in stock but there are actually 100, those 80 bananas risk spoiling before they can be sold through any channel. Conversely, if the system shows 100 bananas available for online ordering when only 20 remain, the result is disappointed customers, failed orders, and potential loss of future business.

These data discrepancies scale dramatically across store networks. A premium item like steak with a recorded stock count of 100 units worth $700, but an actual count closer to 200, creates significant budgetary inconsistencies. Multiply that across 50 or 100 stores, and the financial impact becomes substantial. More critically, when this inaccuracy affects customer-facing availability promises, it undermines the reliability that omnichannel grocery depends on.

The expanding web of operational complexity

Modern grocery fulfillment operates across an increasingly complex ecosystem of digital touchpoints. Retailers must now synchronize inventory data across:

- Retailer-owned channels like Tesco, Walmart, Kroger, Carrefour, and Sainsbury’s apps, where customers expect immediate availability and accurate delivery windows.

- Aggregator and integration platforms such as Instacart, Shipt, Buymie, and Snappy Shopper, which connect directly to retailer systems but may not always sync quickly enough.

- Delivery-first platforms like Uber Eats, Deliveroo, and Just Eat, which have expanded into grocery and require their own inventory feeds and fulfillment coordination.

- Smart commerce layers, including Amazon Alexa, Google Assistant, and automated workflows through IFTTT or Zapier, where voice commands or triggered events can initiate grocery orders.

With agentic AI emerging, the complexity facing grocers will continue to grow, with even more possibilities to consider. Each platform often connects directly to POS and inventory systems, but not always with immediate synchronization. This fragmentation creates enormous pressure on grocers to maintain consistent, reliable data across multiple systems simultaneously.

Five key sources of inventory data inaccuracy

While inventory data challenges have always existed in retail, the omnichannel environment amplifies the consequences. Issues that once affected single transactions now ripple through entire customer ecosystems. Identifying these key sources of inaccuracy enables retailers to address root causes before they compromise customer trust across channels.

1. Merchandising and catalog complexity

Products with multiple varieties — like soups with 12 different flavors — create 12 opportunities for miscounting that can break availability promises across every digital touchpoint.

If store personnel scan the wrong labels during physical counts, those errors don’t just affect in-store customer experience, they affect online catalogs, mobile app displays, and third-party platform listings. Checkout scanning errors, whether at traditional registers or self-service stations, impact not just immediate sales but also inventory feeds to online channels. Monitoring checkout accuracy becomes critical when the same inventory data serves multiple fulfillment methods.

2. Multi-location product management

Products distributed across multiple locations throughout the store create counting challenges that are amplified in omnichannel operations. Chocolate bars might be stocked near registers, in the candy aisle, and in a click-and-collect staging area. Dark stores, micro-fulfillment centers, and dedicated online order prep areas add additional locations that must be accurately tracked.

The assumption that stock is in its designated location becomes problematic when the same inventory serves multiple fulfillment methods. Loose items like fruit, bulk products, or even secondary displays can be overlooked during counts, but now those discrepancies affect not just store availability but online order fulfillment capabilities too.

3. Delivery and fulfillment timing complexity

The coordination between stock counts and deliveries becomes exponentially more complex when serving multiple channels with different cut-off times. A traditional store might manage one delivery schedule, but omnichannel operations often involve early morning deliveries for online orders as well as standard replenishment deliveries and emergency stock transfers.

If inventory counts occur at 10:00 AM but fresh produce deliveries arrive at 11:00 AM, the discrepancy affects not just store availability but online ordering systems, delivery slot planning, and customer communications across all channels. Quick decision-making requires properly sequenced data updates across all systems.

4. Unrecorded internal consumption

Internal stock usage has expanded beyond traditional in-store cafes and bakeries. Online order preparation, sampling programs, promotional activities, and staff training all consume inventory that must be accurately recorded. When an in-store restaurant uses 10 packages of pineapples for prepared fruit bowls and the bakery uses another five in desserts, it must be properly documented or those missing items will affect availability promises made to online customers.

The challenge intensifies when the same products serve multiple purposes—items that could be sold directly to customers, used in prepared foods, or allocated for promotional activities must be tracked accurately across all use cases.

5. Cross-channel inventory allocation

A new complexity emerges from managing inventory commitments across channels. When customers add items to an online cart, should that inventory be immediately reserved? How long should items be held for incomplete transactions? These allocation decisions affect availability displayed to other customers across all channels, creating new opportunities for data inconsistencies.

Modernizing data collection and accuracy

These evolving complexities require updated approaches to data accuracy. Retailers can leverage several emerging best practices to improve inventory reliability:

- Mobile-based stock updates enable fast corrections from the store floor, allowing staff to immediately update inventory discrepancies as they’re discovered, ensuring all channels reflect accurate availability.

- Exception-based alerts proactively identify data inconsistencies before they impact customer experience, flagging unusual patterns like items with positive stock records but no recent sales, or sales volumes exceeding recorded inventory.

- Integrated data-sharing protocols improve synchronization across systems, reducing the lag time between inventory changes and availability updates across all customer touchpoints.

While automated solutions like RFID tracking and advanced shipping notices can significantly improve accuracy, retailers can also analyze their own inventory data to identify patterns indicating errors. Building reports to monitor stock adjustments, identify items with sales larger than stock records, or flag products with availability mismatches across channels helps catch inaccuracies before they affect customers.

A comprehensive retail planning solution should leverage available data to create views and alerts that make these patterns visible, helping retailers maintain proactive rather than reactive inventory management.

Depending on data as critical infrastructure

Retailers should establish proactive data quality measures that prevent inefficiencies and customer disappointment before they occur. Monitoring product areas with consistently poor inventory accuracy helps identify root causes early, allowing companies to adjust supply chain policies and prevent negative customer experiences.

The complexity of modern grocery operations will only continue to grow as new channels and touchpoints emerge. Retailers who invest in robust data practices now will be better positioned to deliver the seamless experiences customers expect, while those who treat data accuracy as an afterthought will struggle with the operational disruptions and customer dissatisfaction that poor data inevitably creates.