How manufacturers can reduce the bullwhip effect in the supply chain

Jun 9, 2025 • 10 min

As the Dalai Lama wisely noted, “Just as ripples spread out when a single pebble is dropped into water, the actions of individuals can have far-reaching effects.”

In supply chain management, small ripples caused by the bullwhip effect can cascade into major disruptions. Limited visibility and poor data access cause slight shifts in consumer demand to snowball as they move upstream, ultimately hitting manufacturers the hardest.

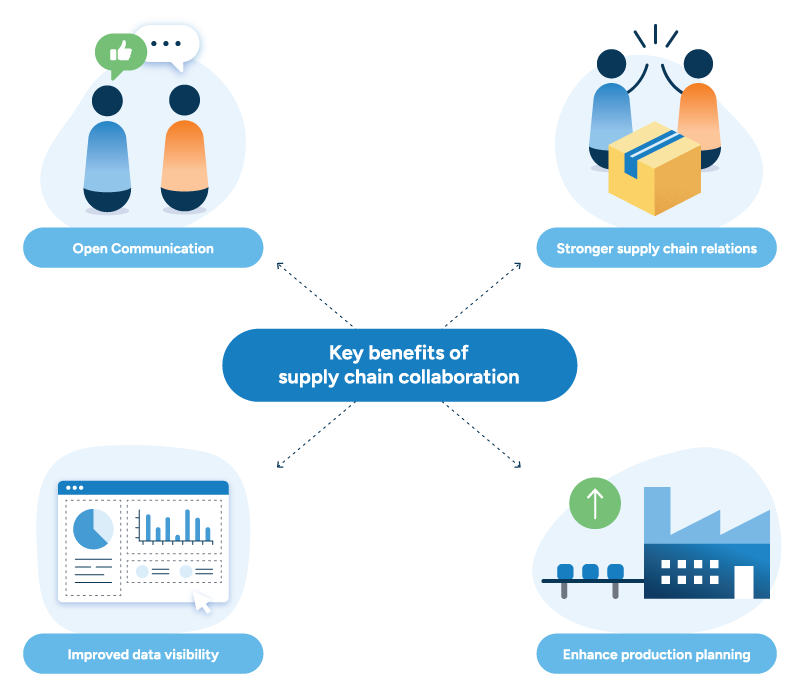

Manufacturers looking for how to reduce the bullwhip effect in their supply chain should strengthen collaboration with their retail and wholesale partners. Implementing robust supply chain planning software is the first step to creating a cooperative platform where information flows freely and accurately across the supply chain.

What is the bullwhip effect in the supply chain?

The bullwhip effect is a supply chain phenomenon in which small, temporary changes in consumer demand at the retail level create larger fluctuations upstream for wholesalers and manufacturers. These fluctuations disrupt manufacturing planning and daily operations and have a knock-on effect on production, inventory, and logistics.

The bullwhip effect can be caused by several different issues, including:

- Misinterpreted demand signals that skew forecast accuracy, amplify upstream fluctuations, and drive over- and under-ordering.

- Large, infrequent order batching that creates uneven demand patterns.

- Price fluctuations from promotions or discounts that cause temporary spikes in demand, leading to overreactions in replenishment.

- Longer lead times that amplify the impact of demand changes, as upstream actors adjust orders based on outdated information.

- Poor coordination between supply chain partners that result in misaligned responses to demand changes.

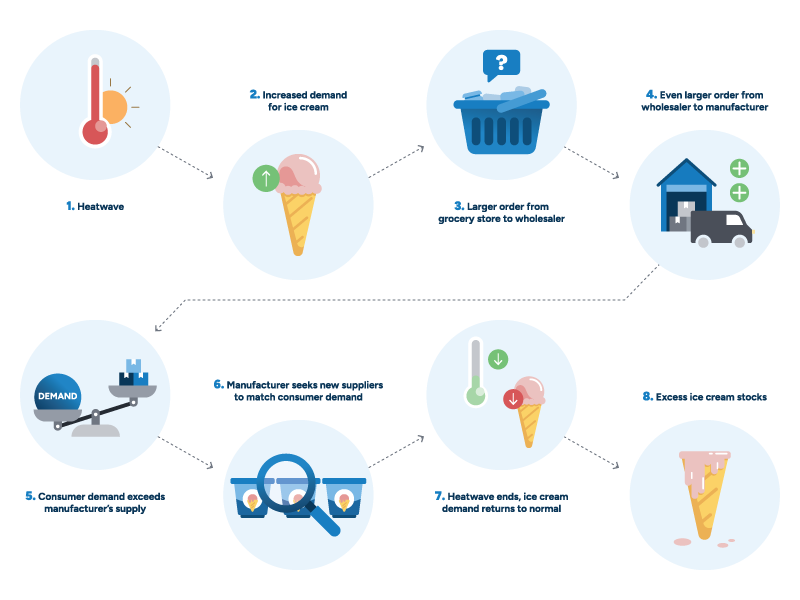

Imagine a sudden heatwave increases consumer demand for ice cream as people seek relief through cool treats.

Noticing the spike in sales, the grocery store places a larger-than-usual order with the wholesaler to avoid running out of stock. The wholesaler interprets this as a long-term surge in demand and places an even larger order with the manufacturer to ensure they meet future needs.

As demand exceeds supply, manufacturers face a raw material shortage, making them scramble to find new suppliers at a higher price or lower quality. This majorly impacts production costs for the manufacturer as they overproduce to match the artificial demand.

But when the heatwave ends and consumer demand returns to normal, all that’s left is excess stock of a highly perishable product that’s either wasted or sold at a loss.

How the bullwhip effect disrupts supply chains

The bullwhip effect creates significant financial and operational burdens across the supply chain. Distorted demand signals cause companies to swing between surplus and stockouts, leading to waste, lost sales, and customer dissatisfaction.

These inefficiencies drive up costs through expedited shipping, overtime labor, and additional storage requirements.

Perhaps most concerning of all is the instability that the bullwhip effect brings to long-term supply chain management. Constantly adapting to erratic adjustments makes it even harder for manufacturers to conduct accurate demand forecasting, further prolonging the cycle of excess and scarcity.

On a human level, frequent and unexpected order changes strain relationships between supply chain partners. The confusion and disruption suppliers face make it harder to plan production, allocate resources, and maintain service levels. Over time, this unpredictability erodes trust between partners, something that’s vital for effective collaboration and long-term supply chain resilience.

Why mitigating the bullwhip effect is more critical than ever

Anyone involved in supply chain planning can attest to just how challenging the bullwhip effect is for supply chain stakeholders. However, manufacturing companies often bear the brunt of these challenges compared to retailers and wholesalers.

Operating upstream and away from actual consumer demand signals exposes manufacturing companies to the most severely amplified and distorted order variances. These distorted demand signals make production planning exceptionally difficult for manufacturers, often leading to significant overproduction or underproduction scenarios that create costly operational inefficiencies.

Raw material procurement becomes particularly problematic, as manufacturers must either secure excessive materials to meet artificially inflated demand forecasts or scramble to acquire emergency supplies when understocked. These procurement challenges directly disrupt production scheduling, creating idle capacity or overtime requirements.

The resulting inventory imbalances further strain warehouse capacities and distribution networks, ultimately manifesting as elevated carrying costs for excess inventory or missed revenue opportunities when products are unavailable.

Due to unprecedented market volatility, it’s crucial for manufacturers to understand how to reduce the bullwhip effect in their supply chain.

Today’s global supply chains operate in an environment characterized by compounding disruptive factors: geopolitical tensions from trade disputes and conflicts; increasingly frequent extreme weather events linked to climate change; and accelerated shifts in consumer behavior driven by increased e-commerce. From the COVID-19 pandemic to unpredictable US tariff policies, the ceaseless challenges of the past decade have proven that disruption is not an exception — it’s the norm.

Beyond responding to amplified demand signal distortions, manufacturers must simultaneously navigate shortened product lifecycles requiring frequent production changeovers and meet intensified just-in-time delivery expectations despite unreliable supply conditions. And the stakes have never been higher as competition intensifies and profit margins shrink.

This turbulent landscape underscores a fundamental reality for manufacturers: even when current disruptions subside, the next supply chain disruption is just around the corner, whether we see it coming or not. Mitigating the bullwhip effect is not just a temporary strategy but an ongoing operational necessity.

4 ways to avoid the bullwhip effect in the supply chain

Because of inherent supply chain complexities, such as demand variability, lead times, and human decision-making, the bullwhip effect cannot be eradicated entirely. However, manufacturers can significantly mitigate its impacts by implementing four intelligent strategies:

- Demand sensing.

- Retail planning and collaboration (downstream planning).

- Production planning and collaboration (upstream planning).

- Inventory planning and distribution.

1. Demand sensing

Demand sensing is an advanced forecasting technique that uses real-time data and machine learning to inform responsive short-term demand planning.

Unlike traditional forecasting methods that rely heavily on historical data, demand sensing incorporates dynamic signals such as point-of-sale (POS) data, weather patterns, local events, and other external factors to capture shifts in consumer behavior as they happen. This accurate and reliable visibility enables manufacturers to get closer to the point of consumption and adapt quickly to demand fluctuations, limiting the impact of the bullwhip effect.

Manufacturers use demand sensing to minimize the risk of stockouts and excess inventory, especially for products influenced by the weather, promotions, and other external factors. Leveraging demand sensing elevates service levels, reduces waste, and improves inventory turnover.

READ MORE: Demand sensing; How to conquer CPG supply chain chaos

2. Downstream planning

Retail planning and collaboration is a systematic approach for connecting manufacturers with retail partners to improve supply chain visibility. Partners share critical data, including store-level demand forecasts, on-hand inventory, promotional and campaign information, and assortment changes. This approach helps identify demand fluctuations and eliminates conflicts in planning that can cause the bullwhip effect.

Through effective downstream supply chain collaboration, manufacturers receive clearer insights into changes in consumer demand patterns rather than relying on historical orders. These insights improve the accuracy of various manufacturing processes, such as production scheduling, replenishment planning, and delivery scheduling.

READ MORE: How to achieve successful supply chain collaboration

3. Upstream planning

Efficient production planning and supplier collaboration ensure accurate demand signals flow to production facilities, suppliers, and contract manufacturers. Similar to retail planning and collaboration, this upstream planning approach optimizes production by using better-coordinated demand signals as inputs for decision-making.

The primary goal is to transform accurate demand needs into specific material and production requirements. Early visibility into demand gives suppliers time to respond, helping manufacturers avoid last-minute bullwhip surprises and secure alternative sources when disruptions occur.

Greater visibility into the holistic supply chain allows manufacturers to reduce delays, minimize costly disruptions, optimize inventory levels, and improve production scheduling. The result is more reliable downstream fulfillment, improved service levels, and happier retail partners.

READ MORE: Production planning without the headaches

4. Inventory planning and distribution

Inventory planning focuses on optimizing stock levels across the network to ensure the right quantity of goods is available at the right place and time. It involves calculating safety stocks, replenishment frequencies, and stock levels to balance varying costs while maintaining high product availability.

Based on an accurate understanding of demand fluctuations and downstream delivery needs, manufacturers can plan inventory placement and safety stocks at the right level. This balanced approach minimizes stockout risks caused by bullwhip fluctuations while controlling inventory costs, helping avoid unnecessary expenses, obsolescence issues, and waste.

Safety stocks should be optimized for different products by understanding their strategic importance and level of demand uncertainty. Products with stable demand patterns require lower safety stocks than those with unpredictable fluctuations. This strategic differentiation ensures efficient resource allocation across the supply chain.

READ MORE: How to take inventory planning to the next level

AI-powered planning: The key capabilities for taming bullwhip impacts

For manufacturers looking into how to reduce the bullwhip effect in supply chain, advanced technology is at the core of the solutions that can provide them with a competitive edge.

As global supply chains become increasingly volatile, manufacturing companies that persist with manual planning will struggle to keep up with their competitors. However, those who use RELEX’s AI-powered capabilities will be able to proactively solve supply chain issues and thrive in the chaos.

Granular data for accurate and scalable demand planning

RELEX demand planning and sensing software leverages highly sophisticated machine learning algorithms to capture true demand patterns at source. Offering a granular level of precision down to individual store and POS data, supply chain partners can quickly identify bullwhip distortions and act to stabilize them.

What sets RELEX apart is its ability to handle complex forecasting scenarios that traditionally confound planning systems. The highly scalable platform excels at predicting demand during overlapping promotions, new product introductions and terminations, and for slow-moving products. This advanced capability ensures manufacturers aren’t overreacting to false signals that could trigger supply chain oscillations.

The system continuously improves through automatic and continuous learning from historical data, automatically cleansing anomalies and outliers. This enables truly touchless forecasting where planners need minimal intervention, freeing them to focus on exceptions and strategic decisions rather than routine adjustments that can inadvertently amplify the bullwhip effect.

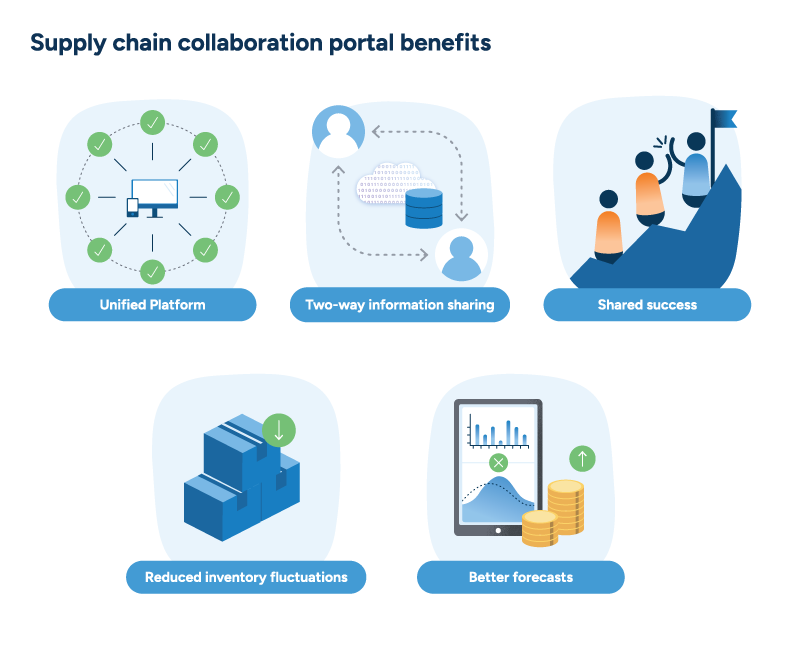

Bi-directional collaboration for connecting the entire supply chain

The bullwhip effect thrives in environments where information is siloed, incomplete, or delayed. RELEX addresses this through comprehensive bi-directional collaboration capabilities that connect both downstream retail partners and upstream suppliers.

Our collaboration portal supports:

- Seamless data sharing and consolidation between all supply chain partners.

- Bi-directional information exchange (demand forecasts, on-hand inventory, promotions, assortment changes).

- Predictive inventory modeling for accurate understanding of true replenishment needs.

- Automatic translation of raw material requirements into purchase orders.

- Optimized production scheduling with constraint consideration.

- Root cause analysis of stockouts and excess inventory through RELEX Diagnostics.

- Collaborative problem-solving before issues cascade into larger disruptions.

What makes this bi-directional approach powerful is the real-time visibility it provides for future needs and potential gaps across the entire supply chain. This transparency enables collaborative problem-solving that prevents the typical pattern that results in bullwhip amplification.

How RELEX connected Atria Finland to its retail partners

Atria Finland has certainly reaped the rewards of using RELEX to improve collaboration further downstream. A market-leading company in the meat industry and a RELEX client since 2013, Atria expanded its use of the system in 2022 to enhance collaboration with its many retail partners, such as Minimani.

Looking to improve shelf life and minimize spoilage, the company replaced its previous pre-ordering system and introduced retail data integration as part of its demand forecasting solution.

Thanks to access to retail forecasts, Atria was able to gain greater visibility into promotional planning, save time on manual tasks, and improve collaboration with retailers. Minimani noted a 3 percentage point increase in promotion availability of Atria products, which are now freshly delivered closer to the start of any given campaign. Given its successful implementation, Atria intends to extend this strategy to more of its retail partners, allowing them to make better informed planning decisions.

With RELEX, the transparency we have into our retailers’ forecasts has genuinely put us on the pulse of the end-customer demand. Seeing the changes in short-term demand – almost in real time – gives us more time to adjust and time our production accordingly.

Mikko Soinio, Planning Manager, Atria Finland

Tame the bullwhip effect in manufacturing with RELEX

Technology alone cannot solve every manufacturing planning challenge. Executive sponsorship and aligned incentives across the supply chain are equally crucial. Successful manufacturers establish shared KPIs with retail partners for mutual accountability, such as sell-through rates, on-shelf availability, and inventory turnover.

That said, manufacturers must embrace collaborative technologies to avoid getting left behind. RELEX supply chain collaboration software empowers manufacturers to take control over the unpredictable and costly bullwhip effect, managing operations proactively rather than reacting to distorted demand signals.

Manufacturers who combine RELEX’s powerful capabilities with strategically aligned goals aren’t just reacting to disruptions. They’re confidently turning supply chain challenges into competitive advantages for all stakeholders involved.