Inventory planning in an unpredictable world: How to prepare for demand fluctuations

Jul 11, 2025 • 6 min

When unpredictable events strike, traditional inventory planning methods often fall short. Whether it’s a hurricane barreling toward the coast, a global pandemic, or another market disruption, retailers face the challenge of managing sudden demand spikes without the luxury of reliable forecasting data.

The solution lies in adopting a more flexible, data-driven approach that can adapt to real-time conditions.

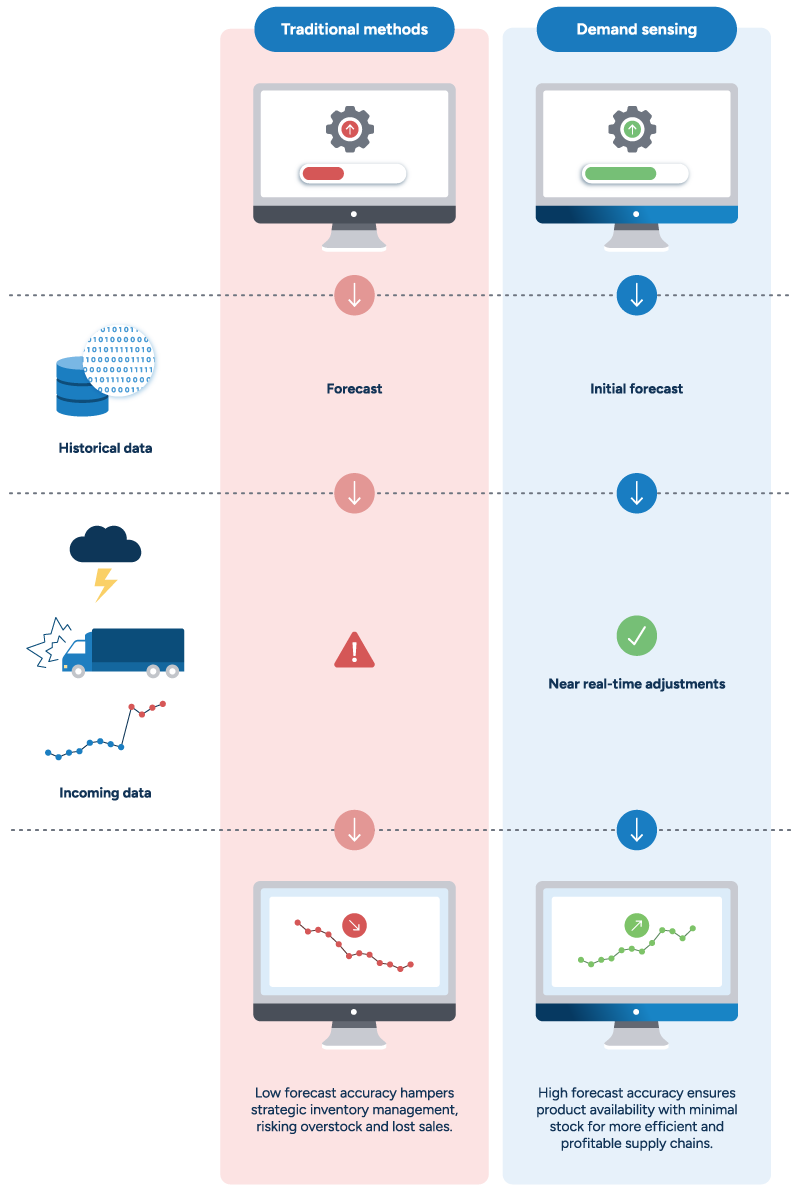

The problem with traditional forecasting

Traditional forecasting methods fail during unpredictable demand fluctuation events. Manual spreadsheet-based planning leads to stockouts and overstocks when accurate inventory management is most critical.

Take hurricanes as an example: Traditional hurricane management has often involved manual calculations on standalone spreadsheets, with planners basing decisions on yearly forecasts, personal experiences, and guesswork. This approach assumes that all locations will be equally affected and that demand patterns will mirror previous events — but that’s almost never what actually happens.

Instead, decision-making usually becomes inconsistent across locations and some stores receive unnecessary inventory while others face critical shortages. Retailers lose the ability to respond quickly to changing conditions as manual processes struggle to keep pace with rapidly evolving situations.

Granular, localized inventory management

The key to managing demand fluctuations effectively lies in two main principles that directly address these shortcomings.

First is a granular, localized approach that treats each location individually. This recognizes that a hurricane making landfall in Florida doesn’t create the same demand patterns in Miami as it does in Jacksonville, even if both cities are in the storm’s path. Local factors — population density, demographics, proximity to the coast, and customer preferences — all influence how demand will fluctuate during and after the event.

Second is using an inventory management system that enables data-driven decisions with manual adjustments, rather than broad, company-wide inventory changes that unnecessarily impact stock levels across unaffected locations. This might mean increasing emergency supply inventory at coastal stores while maintaining normal stock levels at inland locations, based on specific local data rather than regional assumptions.

How to put the system into practice

Successfully managing demand fluctuations requires a systematic approach that moves beyond reactive measures.

To prepare for future events, any past event (like a hurricane) should already be marked in your historical data. Any past hurricanes should be marked as events, that way your first automated forecast will be ready to calculate when the next hurricane approaches, the work is already done and the system is ready for what’s to come.

Inventory managers must also account for any operational disruptions, such as store closures during hurricanes, delivery delays, and supplier disruptions. During hurricanes, for example, this means not only preparing for increased demand for emergency supplies but also planning for the operational challenges that affect the entire supply chain.

Managing uncertainty presents the real challenge. The specifics about when spikes in demand will occur, the extent to which items will be impacted, and how long sales will be affected isn’t always predictable. This uncertainty is why the real work begins after the event starts, not before.

Data collection and analysis forms the heart of effective demand fluctuation management. The process follows three key steps:

- Verify that past events have been applied.

- If a hurricane is coming in the future, apply a similarly categorized event for the future period.

- Machine learning forecasting automatically creates an accurate forecast for the future hurricane period.

The key is to wait until after the hurricane hits before analyzing which products are truly affected. This helps avoid making decisions based on panic buying that happens before the storm, which doesn’t reflect actual ongoing demand.

Modern inventory management systems can automatically identify when actual sales patterns deviate significantly from forecasted demand, flagging these anomalies for immediate attention.

Establishing an “event” in the system helps identify categories with abnormal demand patterns and analyze them against recent data by evaluating the level of impact from the event compared to the baseline. This systematic approach allows retailers to respond to emerging trends as they develop rather than waiting for weekly or monthly reports to reveal problems.

Adapting as conditions change

Effective demand fluctuation management doesn’t end once the initial response is in place. Ongoing management requires continuous adaptation as conditions evolve.

Retailers must monitor demand trends for already identified categories, since demand fluctuation events often have no predictable end date. During the early months of the COVID-19 pandemic, for example, initial demand spikes for cleaning supplies eventually gave way to increased demand for home office equipment as consumers adapted to new lifestyle patterns.

The key strategy involves focusing planner attention on event-affected items while relying on the system to manage broader inventory automatically. This prevents planners from becoming overwhelmed while ensuring that the most critical items receive appropriate human oversight.

As events progress and their impact diminishes, successful retailers gradually limit monitored categories as the event’s impact diminishes to avoid incorrectly flagging normal demand fluctuations as ongoing event effects. This prevents the system from becoming overly sensitive to routine variations in customer behavior.

Product availability when it matters most

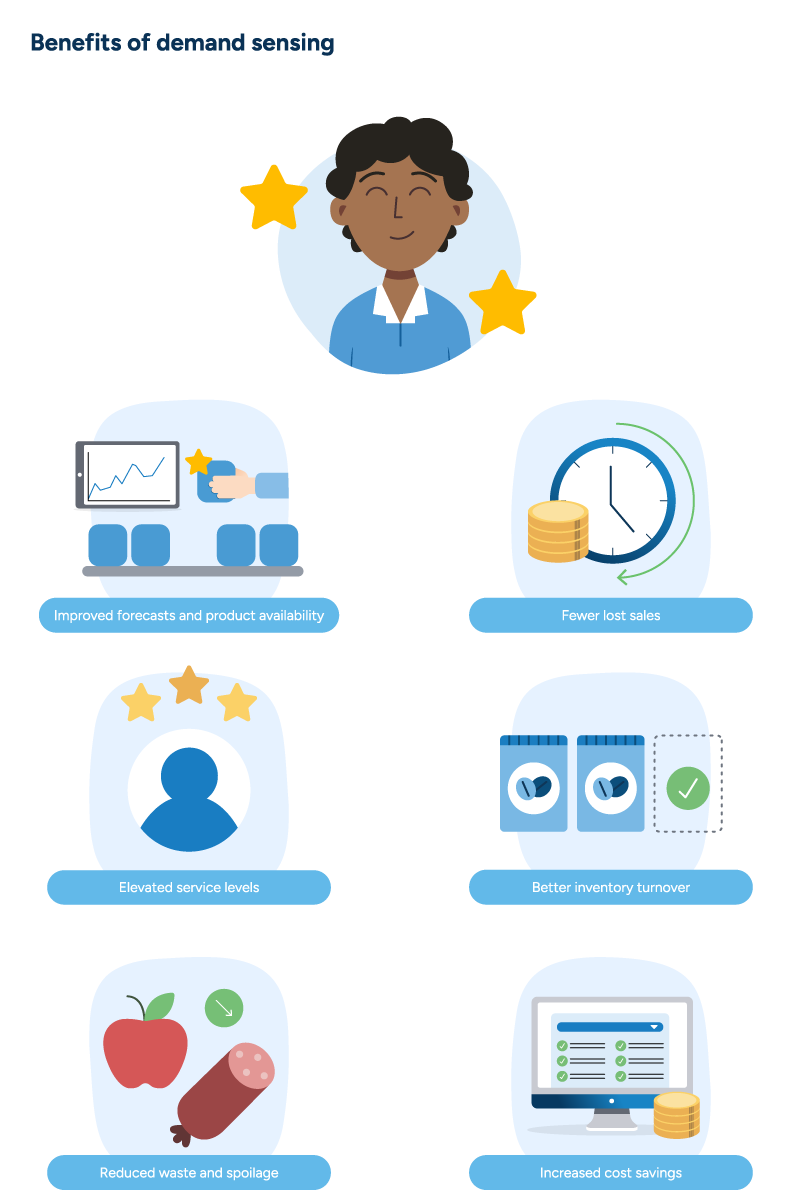

This approach saves planner time, improves product availability during critical periods, ensures adequate stock at each location, and maintains customer service levels during disruptions. By automating routine inventory decisions and focusing human attention on genuinely exceptional situations, these systems free up valuable planner time while dramatically improving product availability when customers need it most.

The same methodology applies to any unpredictable demand event without a finite end date, whether it’s extreme weather like hurricanes, global crises like COVID-19, or other market disruptions caused by supply chain interruptions or economic shifts.

If the event has happened in the past (as hurricanes have), and those are tagged in the system, RELEX can automatically forecast them based on historical patterns. The system learns from each event, continuously improving its ability to predict and respond to similar future situations. If something truly unpredictable happens, the system will alert the users, so they can start adjusting and monitoring the situation in the RELEX platform, ensuring the system remains responsive even in completely novel circumstances.

Be ready for anything

When customers need products most, retailers who have implemented these systems can respond effectively, maintaining both business performance and customer trust during challenging times. When customers can find what they need when they need it most, trust in the retailer strengthens, creating loyalty that extends far beyond the immediate crisis period.