Grocery is among the most complex sectors in retail

Under one roof, grocers must manage fresh, ultra-fresh, and center store categories, each with different shelf lives, supplier requirements, and shopper expectations. Adding multiple fulfillment channels, in-store, click-and-collect, and home delivery, increases complexity.

“Yeah, that store is ok, but their produce is not very good.” It’s common for customers to mention produce or another fresh category to judge an entire store, or even a grocery brand. Meanwhile, costs are rising, margins are tight, and price sensitivity is high. The stakes are clear: get fresh right, and the rest follows. Get it wrong, and you’re discounting your way to falling margins and unhappy customers.

Modern AI-powered planning platforms can help grocery retailers gain unprecedented visibility into their supply chains, enabling them to match supply with demand more precisely than ever before. This approach tackles the root causes of waste and inefficiency without sacrificing the high standards customers expect.

The RELEX platform: Unified, AI-powered planning for the entire store

Before diving into specific fresh retail challenges, it’s essential to understand the foundation that makes sustainable optimization possible. The challenges in fresh and ultra-fresh categories are deeply interconnected and cannot be managed in silos.

- Shrink connects to forecast accuracy.

- Inventory accuracy determines availability.

- Production planning affects labor efficiency.

- Promotion planning impacts waste.

- Execution consistency determines whether any plan succeeds.

RELEX brings these functions together on a single, unified AI-native platform. Instead of managing disconnected systems, RELEX synchronizes demand, supply, and execution in real time across your entire operation.

The power of an integrated approach

Traditional grocery operations rely on fragmented systems that create blind spots and inefficiencies. Legacy solutions provide essential functionality but weren’t designed for optimization. They can’t respond to the dynamic challenges facing today’s grocers: supply constraints, shifting consumer expectations, margin erosion, labor shortages, and sustainability demands.

The RELEX unified platform fundamentally changes grocery retail planning:

- Forecasting and replenishment work together, not in silos. Weather impacts on produce are immediately reflected in adjusted orders for complementary center-store items.

- Inventory accuracy becomes the foundation for every downstream process, from customer-facing availability to replenishment triggers.

- Production planning synchronizes with demand patterns, so prepared food departments make what customers actually want to buy.

- Promotion planning connects to replenishment, preventing the all-too-common scenario of post-promotion dumpsters full of unsold inventory.

- Space and assortment decisions leverage demand data, transforming shelf space into profit space through evidence-based allocation.

- Omnichannel fulfillment coordinates with replenishment, reducing labor costs and substitution rates across all channels.

This unified approach is particularly powerful because it enables grocers to start with their most challenging categories, fresh and ultra-fresh, and extend benefits across the entire store.

Critical challenges for fresh grocery retailers

Fresh and ultra-fresh categories drive approximately 40-50% of sales for the average grocery store, but they also account for 60-65% of shrink due to spoilage. Solving for fresh requires addressing these challenges with accurate forecasting, reliable inventory management, and consistent execution.

Shrink: The visible cost of disconnected planning

“Every rotten banana started as an ordering decision.” Shrink is a symptom of poor demand alignment and weak stock rotation. When forecasting doesn’t align with replenishment, and replenishment doesn’t sync with in-store execution, profit is literally thrown away.

Why it hurts: The real cost of shrink extends beyond the immediate write-off. It represents wasted labor and ties up working capital due to ordering and replenishment inefficiency and inaccuracy. Most importantly, it signals to customers that freshness can’t be relied upon, eroding trust.

The root cause: Disconnected planning systems create a cascade of inefficiencies. When demand forecasting operates separately from replenishment planning, orders become disconnected from actual sell-through patterns. When replenishment decisions overlook shelf life and rotation requirements, fresh inventory becomes stale. When execution varies by store or shift, even good plans fail in practice.

Shelf life: cold chain and operational discipline determine freshness

“If it’s warm when it arrives, it’s waste with a barcode.” Every degree matters. Temperature discipline determines actual shelf life, not the date printed on the package. The data exists, including timestamps, temperature logs, and dwell times at receiving, but process ownership is inconsistent across locations.

Why it hurts: Temperature abuse creates a hidden tax on fresh operations. Products that arrive outside temperature specifications have compromised shelf life, even if they look acceptable initially. This leads to accelerated spoilage, disappointed customers, and increased waste throughout the supply chain.

The root cause: Cold chain integrity requires coordination across multiple handoffs: supplier loading, transportation, receiving, storage, and display. Each transition point introduces risk, and manual monitoring creates gaps in oversight. Without real-time visibility and automated controls, temperature excursions become inevitable, and their impact compounds over time.

Ordering constraints: Case-pack and minimum order quantity misfit

“We’re buying for the supplier, not the shopper.” Rigid supplier pack sizes and order minimums create a built-in bias toward overstock, and stores need replenishment that prioritizes sell-through over delivery partners’ preferences.

Why it hurts: Case-pack constraints force a choice between stockouts and overstocking. The result is systematic overordering that turns into systematic waste. Breaking bulk might seem expensive, but it’s cheaper than discarding unsold inventory.

The root cause: Legacy systems can’t model the trade-offs between pack-size constraints and demand requirements. Unless retailers can accurately and quickly analyze the cost of waste against the cost of stockouts, they cannot make informed decisions about when to accept supplier minimums and when to negotiate alternatives.

Prepared foods: Effective production planning and labor efficiency

“We prep by tradition, not by data, and the oven’s always full, even when the counters are too.” In-store bakeries, delis, and prepared food departments run on habits formed years ago, when a different customer base had different preferences.

Why it hurts: Overproduction creates a double hit, wasting ingredients and labor hours. Underproduction means lost sales and disappointed customers. Without demand-driven production planning, prepared food departments operate reactively, making decisions based on intuition rather than data.

The root cause: In-store production planning doesn’t align with actual demand drivers, such as weather, events, and promotional activity, compromising efficiency and freshness. Predictive analytics can optimize production schedules to match expected demand throughout the day, reducing waste while ensuring availability.

4 game-changing plays for success in fresh and the entire store

The operational excellence developed through fresh optimization not only addresses those specific challenges, it creates a foundation for success across all categories. While center-store products don’t face the same spoilage pressures, they benefit enormously from the precision, responsiveness, and integration that fresh optimization demands.

Forecasting and demand planning

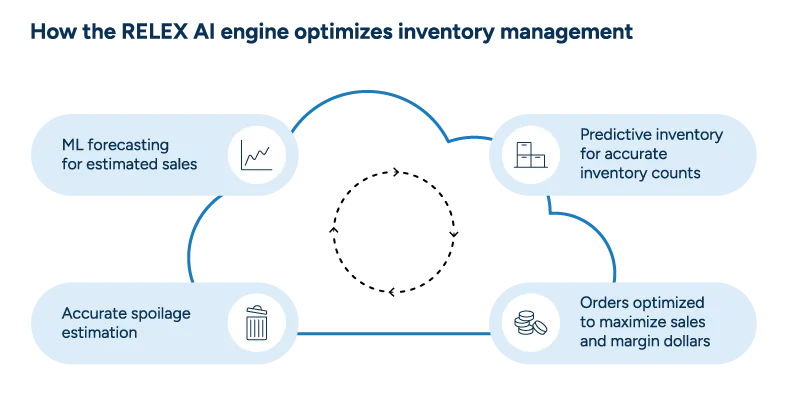

Fresh foundation: Mastering fresh forecasting requires incorporating multiple variables, such as weather, events, seasonality, and perishability, into demand predictions. AI-based forecasting accounts for a multitude of demand-influencing factors that are beyond human planners’ abilities to analyze efficiently and promptly.

RELEX algorithms are trained on years of grocery data, analyzing consumer trends and product behaviors. Then, for each customer, the system uses up-to-date data, such as weekday demand variations and varying spoiling times, to fine-tune its calculations.

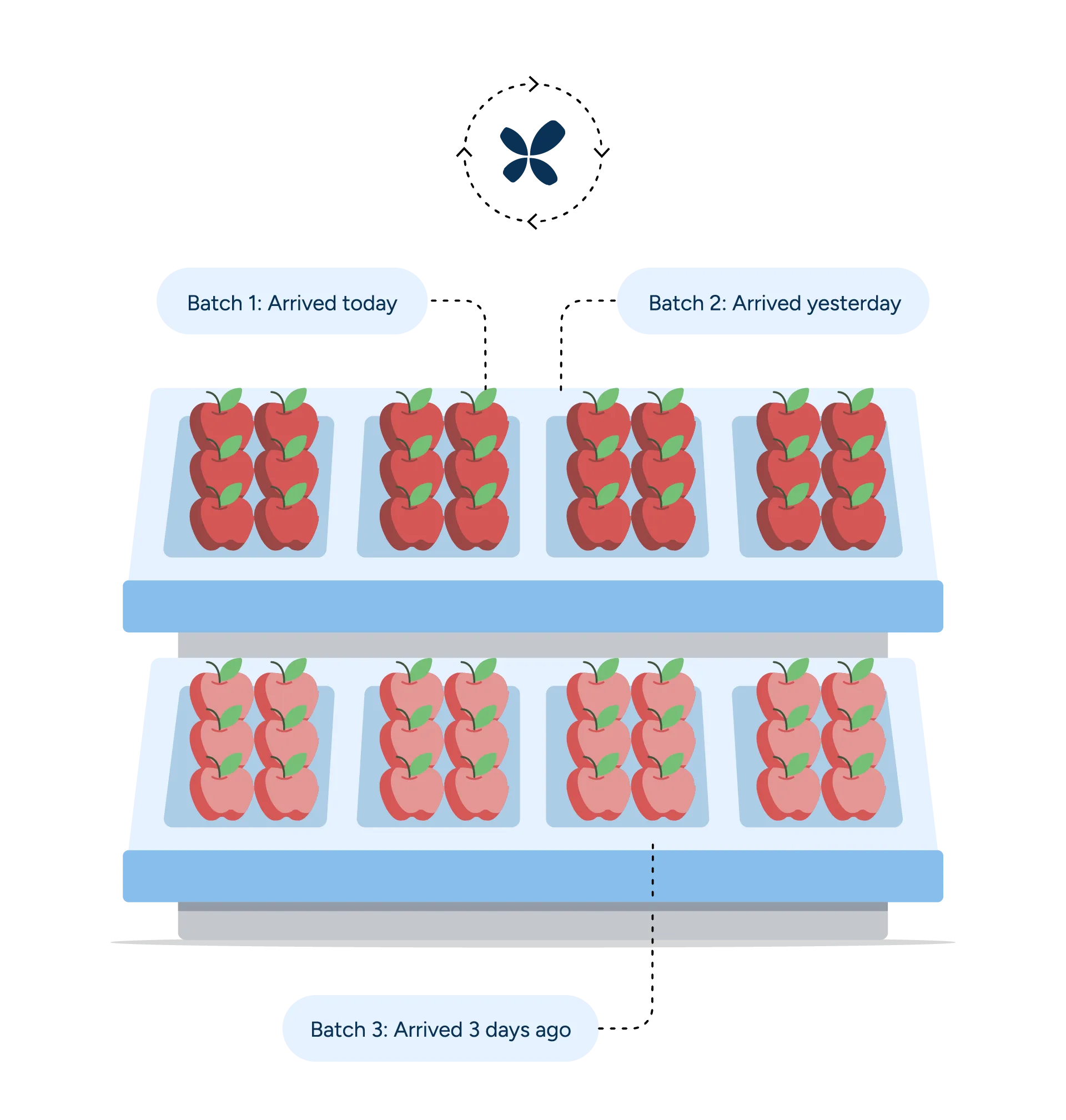

For example, the RELEX solution tracks the expiration date for each batch based on the delivery, sales, and spoilage data. If the batches are not consumed before expiring, they are expected to spoil and are considered in the order projections. RELEX uses the defined FIFO rate to fill demand from the oldest batch first.

Center store benefits: The same AI algorithms that predict demand for fresh produce also optimize orders for packaged goods, household items, and seasonal merchandise, where the same external factors influence customer behavior. Better forecasting accuracy across all categories reduces overstock, prevents out-of-stocks, and improves working capital efficiency.

Unified impact: When all categories share the same forecasting intelligence, cross-category insights become possible. Promotion planning for pasta can automatically adjust forecasts for complementary fresh items, such as tomatoes and herbs. Weather-driven demand changes cascade appropriately across related products, creating a responsive supply chain that matches supply with demand more precisely than ever before.

Key RELEX capabilities:

- Fresh optimization with spoilage prediction and adaptive safety stocks.

- Weather-based forecasting incorporating external factors.

- Retail Bill of Materials for ingredient and component management.

- Machine learning-driven demand sensing across all categories.

Real-world results: ICA Sverige enhances inventory efficiency and forecast accuracy with RELEX

ICA Sverige AB (ICA), Sweden’s largest and leading grocery retailer, has five main distribution centers (DCs) and some 1,300 stores across Sweden. The independent ICA retailers own and operate their own stores and benefit from coordinated sourcing, logistics, market communication, and store development.

ICA adopted RELEX for forecasting and replenishment in 2017 and, more recently, initiated a project focused on forecast accuracy and safety stock. These strategic initiatives exceeded expectations, driving operational efficiency and cost savings, ensuring ICA remains a leader in the grocery retail business while maintaining the efficiency of its distribution network.

Results include:

- 32% decrease in safety stock inventory.

- 6.69pp increase in forecast accuracy.

“Relying on RELEX Solutions to help us achieve our goals has proven to be a great choice. Not only has our collaboration produced tangible results, but working with RELEX has been easy and innovative.”

Andreas Persson, Head of Replenishment, ICA

Replenishment and store execution

Fresh foundation: Managing fresh categories requires precise coordination between ordering, inventory counts, and in-store execution, and avoiding spoilage depends on moving inventory efficiently based on near real time demand and capacity.

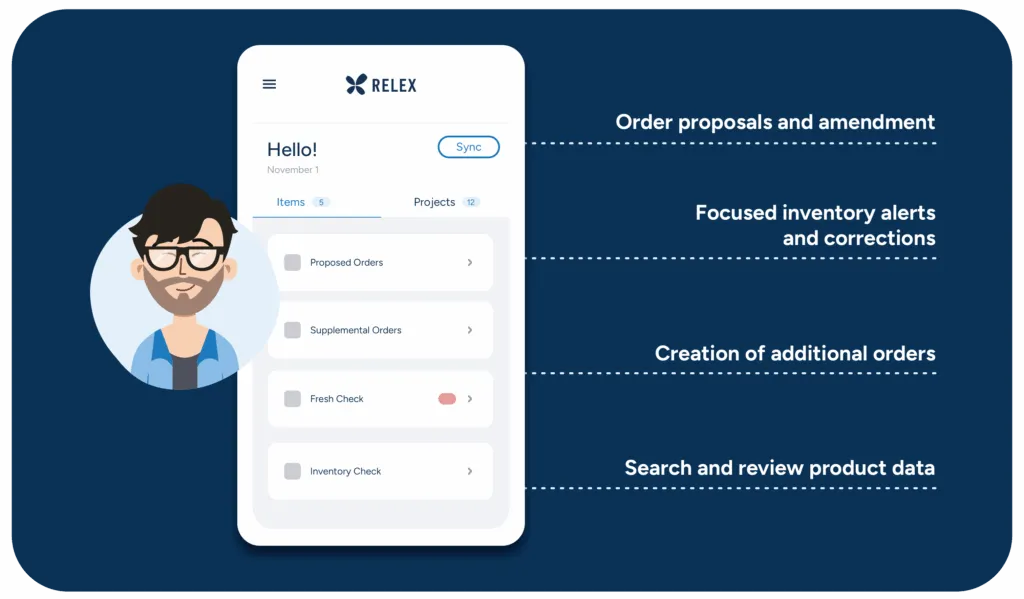

RELEX Fresh Store Ordering, available as a web app, focuses on handling and ordering for non-barcoded products, such as loose (or bulk) fruits and vegetables, meat, seafood, bakery items, deli items, and prepared foods. The application turns imperfect data into clear, actionable recommendations, enabling store teams to optimize orders and inventory from supplier to shelf. The intuitive UI provides quick views of fresh product data and order recommendations, allowing users to adjust or create store orders to respond to special events or local demand.

Center store benefits: Accurate inventory signals are critical for every downstream process in both fresh and center-store operations. When inventory data is reliable, everything that depends on it, forecasting, replenishment, picking, and customer experience, becomes exponentially more reliable.

RELEX Mobile supplies store employees with a single, easy-to-use tool for taking action. Used in conjunction with RELEX True Inventory, it puts comprehensive capabilities in the hands of store associates, enabling in-store teams to manage stock, prioritize tasks, and place orders directly from one integrated platform.

Role-based dashboards provide tailored views for store directors, department managers, and regional managers, enabling transparency and accountability through advanced analytics such as modification rate analysis and order vs. delivery comparisons.

Unified impact: Enhanced replenishment capabilities, such as delivery flow smoothing, prioritize ultra-fresh deliveries on peak demand days while smoothing center-store deliveries during less busy periods. This reduces receiving congestion, improves store efficiency, and ensures optimal inventory levels across both fresh and center-store categories.

Further, unified workload forecasting incorporates projected demand surges leading up to holidays or events, enabling proactive adjustments to replenishment and workforce planning.

Key RELEX capabilities:

- Fresh Store Ordering with AI-driven daily forecasts and recommendations.

- Mobile Replenishment with guided workflows and AI agent support.

- True Inventory with predictive anomaly and root cause detection.

- Role-based dashboards and analytics for store-level accountability.

- Delivery flow smoothing to optimize inbound logistics.

- Workload forecasting incorporating multiple demand drivers.

Real-world results: Coop Estonia harmonizes operations across 18 cooperatives with unified planning from RELEX

Coop Estonia, comprised of 18 consumer cooperatives operating approximately 320 stores across the country, ranging from hypermarkets to small village stores, holds roughly 23% of the market share. They needed an approach that respected local preferences while centralizing key supply chain decisions. Achieving this balance was essential to maintain their customer-first cooperative model while improving operational performance.

Each stage of their journey with RELEX was guided by their goal of replacing guesswork with data-driven precision and building a seamless, unified system that every cooperative could rely on. By unifying all cooperatives into one centralized platform, Coop Estonia achieved operational consistency and significant efficiency gains. The system’s accuracy allowed store teams to trust the automated recommendations, freeing staff to focus on customer engagement and merchandising rather than daily manual ordering.

Results include:

- 95.7% product availability in stores.

- 15,000 working hours saved per month through automated replenishment.

- 4% reduction in inventory levels.

“Our goal is to build a supply chain that works smarter every year, and RELEX has helped us make that possible.”

Kerli Rõõmus, Supply Chain Director, Coop Estonia

Grocery-specific merchandising optimization

The RELEX unified platform also connects promotional planning and space management to forecasting, replenishment, and operations, driving margin protection and customer satisfaction.

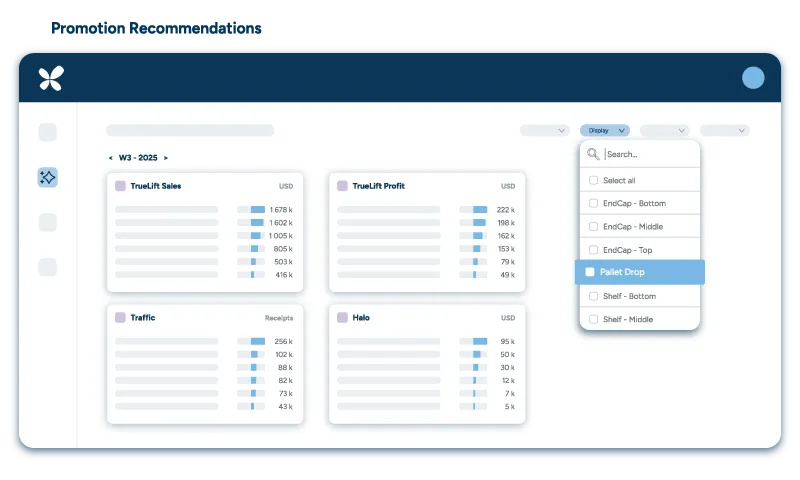

Promotion planning and price optimization

Fresh foundation: Fresh category promotion planning requires a careful balance between driving demand and managing perishability. AI-enabled systems provide real-time insights into price elasticity and promotional effectiveness, understanding the relationship between fresh produce sales and complementary center-store items for more effective cross-merchandising and promotion planning.

Center store benefits: AI-driven promotion optimization across all categories leverages the same analytical rigor required for fresh categories. Understanding true promotional ROI, including post-promotion inventory costs, leads to smarter promotional strategies. Better uplift forecasting prevents excess inventory, emergency markdowns, and eroded baseline sales in both fresh and dry goods.

Unified impact: When promotion planning connects to replenishment and space management, cross-category promotional effects are captured and optimized rather than ignored, aligning merchandising teams with operations to minimize waste.

Space planning and assortment management

Fresh foundation: Space allocation for fresh categories requires constant adjustment based on seasonality, local preferences, and demand volatility. Using actual demand patterns to maximize sales per square foot creates dynamic merchandising opportunities for fresh departments with flexible display tables that connect directly to promotional planning and replenishment decisions.

Center store benefits: AI-driven space optimization transforms center-store performance by generating store-specific planograms based on actual demand patterns. When space planning integrates with demand forecasting and replenishment data, allocation decisions are evidence-based rather than intuitive, leading to higher turns and increased sales per square foot.

Unified impact: Space planning decisions are based on demand data across all categories, transforming shelf space from a static resource into a dynamic profit-optimization tool. Integration between space planning, assortment, and replenishment decisions creates evidence-based allocation that maximizes both fresh appeal and center-store efficiency.

Key RELEX capabilities:

- True promotion ROI analytics, including costs and benefits and scenario testing.

- Cross-category modeling of promotion impacts.

- Store-specific planogram optimization based on local demand patterns.

- Dynamic space allocation responding to seasonal and promotional requirements.

Real-world results: Vallarta Supermarkets leverages RELEX to support growth with data-driven decision-making

Vallarta Supermarkets is a regional grocery retailer based in Los Angeles, California. It specializes in Hispanic and Latin American foods and serves customers through 54 stores across the state.

In this customer video, David Hinojosa, Vallarta COO, discusses the company’s growth and how RELEX is helping them utilize data for store floor planning, improve pricing and promotions, and reduce food waste while maintaining quality and margins.

“Since we started to use RELEX, it has really changed the dynamics of what we’re trying to achieve. Price and promotions have gotten much, much better.”

David Hinojosa, COO, Vallarta Supermarkets

Omnichannel fulfillment

Fresh foundation: For grocery retailers, providing a seamless omnichannel experience requires unprecedented coordination across traditionally separate functions. The ability to account for distinct shopping patterns and forecast for multiple fulfillment options is critical for fresh categories. Substitution quality for online orders and availability during intraday demand spikes directly impact customer satisfaction.

AI-enabled forecasting and replenishment from RELEX provides the channel-specific forecasting granularity needed to optimize inventory levels for both in-store and online shoppers. RELEX provides comprehensive, real-time inventory visibility across all locations and channels. The platform integrates data from stores, distribution centers, suppliers, and third-party partners to create a single, accurate view of inventory availability.

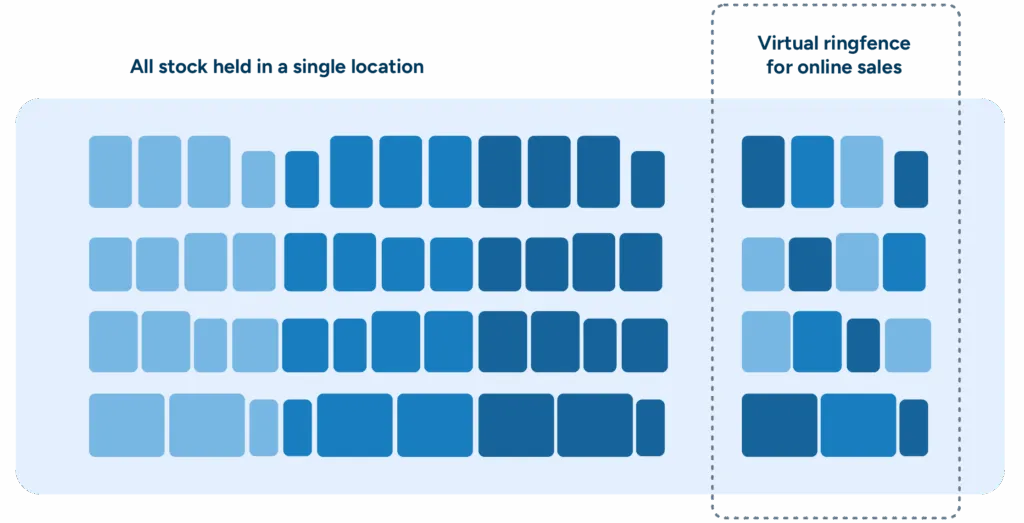

Center store benefits: Virtual ringfencing ensures appropriate stock levels for each channel without requiring additional inventory investment. This capability allows retailers to hold inventory centrally while “reserving” stock allocated to online demand, preventing distribution centers from sending items reserved for online orders to brick-and-mortar stores.

The result is high availability across channels without the cost of maintaining separate inventory pools. Unified inventory visibility prevents conflicts between online and in-store fulfillment, ensuring customers see accurate availability whether shopping in-store or online.

Unified impact: End-to-end inventory visibility prevents conflicts between online and in-store fulfillment. When stores know what needs replenishing first, which orders should be picked when, and how to minimize searching and backtracking, omnichannel operations become seamlessly efficient.

Key RELEX capabilities:

- Channel-specific demand forecasting for online and in-store sales.

- Virtual ringfencing for inventory allocation across channels.

- Workload forecasting for omnichannel labor optimization.

- Integration with Distributed Order Management Systems.

- Mobile replenishment coordinated with fulfillment workflows.

Real-world results: Bünting AG unifies inventory and category planning across channels with RELEX

Bünting AG is a traditional family-run business located in Leer, Ostfriesland, Germany. Founded in 1806, the company owns several retail brands, operates approximately 200 stores, and supplies more than 400 independent retailers and e-commerce channels.

In this customer video, Bünting Group Managing Director Helge-Christian Eilers took time to share how RELEX is helping them unify inventory and category planning for more than five million products, including fresh.

“We take a holistic view of our processes from the industry to the store shelf and, via our e-commerce, even to the doorstep of our customers. The key to success in this project is certainly the technical and methodological expertise that RELEX brought to the table.”

Helge-Christian Eilers, Managing Director, Bünting Group

Putting it all together: Fresh consistency builds customer loyalty

Fresh loyalty is fragile. Customers judge your entire store by the state of your fresh categories, and when freshness varies by day, hour, or store, shoppers quickly learn they can’t rely on consistency.

But when you solve for fresh, with accurate forecasting, reliable inventory management, optimized replenishment, and consistent execution, you create a foundation for success across all categories.

That foundation is built on all functions working together instead of in isolation, enabling grocers to respond to market changes with unprecedented speed and accuracy:

- Weather impacts on produce translate immediately into adjusted orders for complementary center-store items.

- Promotional uplift in fresh categories automatically adjusts forecasts for related products.

- Space allocation changes trigger replenishment parameter updates.

- Production schedules synchronize with both ingredient availability and finished goods demand.

RELEX helps grocery retailers protect margins by unifying demand planning, inventory management, production scheduling, and store execution on a single AI-powered platform. The result is a competitive advantage that’s difficult to replicate and profitable operations that scale efficiently.