How to tackle the causes of grocery store food waste

Dec 2, 2025 • 8 min

Grocery store food waste is a doubly costly issue. There’s the obvious monetary cost to grocers, who toss millions of tons of food every year and destroy margins.

But there’s a more globally concerning cost associated with food waste as well: the environmental impact. A staggering 8-10% of global greenhouse gas emissions come from producing food that will never be consumed. And according to ReFED, retailers generate approximately 4.45 million tons of food waste in a single year.

Retailers face mounting pressure to balance customer expectations, but the need to maintain inventory availability often contributes to food waste, conflicting with sustainability goals.

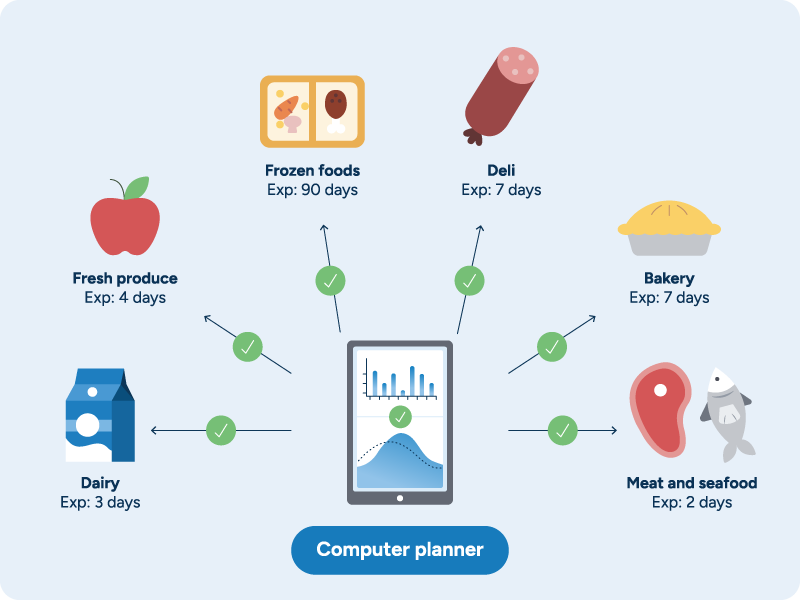

These two goals don’t need to be at odds, though. Modern planning platforms that leverage advanced analytics and machine learning can help grocery retailers gain deeper visibility into their supply chains than ever before. This visibility enables businesses to better match supply with demand, tackling the major causes of grocery store food waste without sacrificing the high standards their customers expect.

3 major causes of grocery store food waste

Before grocers can effectively tackle their food waste dilemma, they need to understand its primary sources. A clear analysis of the biggest contributors to waste enables companies to develop targeted strategies and deploy the right technologies for each challenge, reducing costs while reducing waste.

In grocery retail, the three major factors driving food waste are:

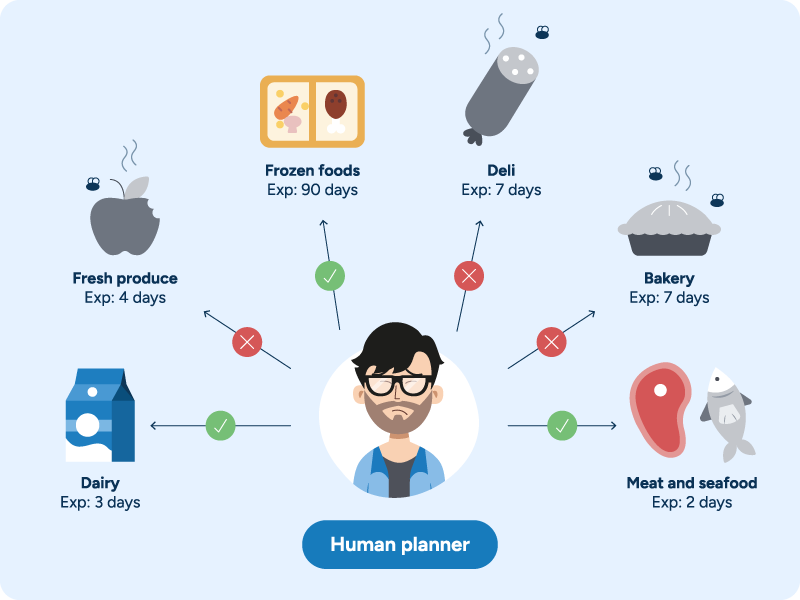

1. Overordering rooted in decentralized planning

Properly assessing demand requires grocery retailers to understand both macro and micro trends across locations. For instance, ingredients for baked goods may climb in demand nationwide right before the holidays. But the popularity of fillings for these goods may differ from region to region.

Unfortunately, store ordering is often handled locally by managers who base their buying decisions entirely on manual observations and records. This decentralized approach sidesteps macro trends that could be addressed by technology implemented at the store’s headquarters, leading to over-ordering of goods that the store may not need, and ultimately, unnecessary waste.

READ MORE: 7 grocery store inventory management good habits

2. Overstocking stemming from consumer perception

Food merchandising is a tricky business, especially for the products customers would typically find around the supermarket’s outer ring, such as fresh produce, meat and dairy. Customers are unlikely to purchase bruised or over-ripened fruits and vegetables. Short shelf-life products nearing their sell-by dates are also often rejected in favor of food that will stay good for another week or longer.

WATCH: Cut Food Waste. Protect Margins. Improve Profitability.

These perceptions put supermarkets in a cycle of waste: they have a constant supply of new products coming in to ensure these aisles are appealing, but that doesn’t mean the food is selling at the same rate. The leftovers, often caused by overstocking in the first place, are tossed in the garbage in favor of more visually appealing food. And while businesses are trying to get some of these unwanted goods to consumers, there’s still plenty of work to be done to prevent overstocking of time-sensitive goods on store shelves.

READ MORE: How to improve fresh food inventory management

3. Limited agility due to outdated, manual planning processes

For grocery stores, the last few years have been one of the most turbulent periods on record. Global disruptions led to supply shocks in every corner of the retail marketplace — and grocery stores felt the heat. Meat suppliers went offline because of outbreaks, and demand soared for products that don’t typically fly off the shelves.

An adherence to manual process left too many grocery stores frozen and unable to adapt to radically shifting circumstances. Even now, individual stores only order based on their recent data, lacking the technology to pivot if conditions were to change again.

If any lessons retailers have learned in the last few years, it’s to expect the unexpected. Failing to leverage demand data creates an environment ripe for food waste, with stores order too many of the wrong (or too few of the right) products to address the demand swing.

How to reduce food waste in grocery stores

At the heart of each contributing factor lies a common thread: manual processes and disconnected systems that can’t keep pace with today’s dynamic retail environment. Grocery retailers have historically accepted this version of inventory planning and management simply because there weren’t better alternatives.

That’s not the case today. Advancements in planning technology have created new, more efficient alternatives that help grocers reduce waste while protecting revenue and maintaining the high product availability customers expect.

1. Harness machine learning in inventory planning and management

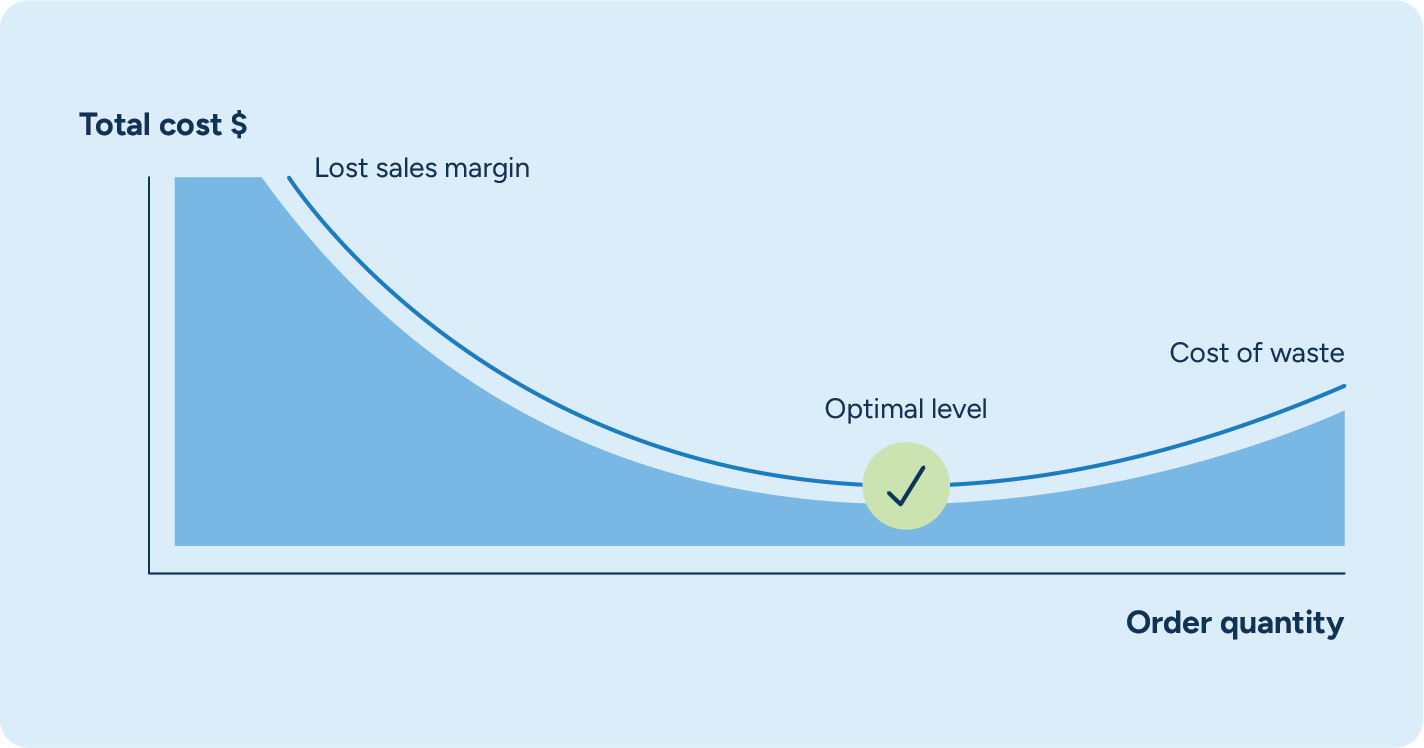

In the current Age of AI, buzzwords abound. But machine learning earns its buzz and can help grocers transform fresh item management. These advanced systems analyze both macro and micro demand patterns across locations, enabling stores to order the right quantities at the right time.

This ultimately results in higher product availability with less waste. Stores using these tools can spot emerging trends before they impact the bottom line, helping them stay ahead of demand swings that previously led to overstocking.

READ MORE: How can AI enhance sustainability in supply chain?

2. Enhance visibility into fresh inventory

Modern supply chain tools, like RELEX, give grocery stores unprecedented visibility into their fresh inventory. Instead of relying on gut feelings, managers can now track stock levels and expiration dates in real-time, enabling smarter markdown decisions before food spoils. This proactive approach helps stores clear fresh goods at the optimal time, maximizing sales while minimizing waste. A 2025 RELEX grocery consumer survey found that 93% of shoppers support discounting items approaching their sell-by date and 58% of shoppers actively look for these discounts.

RELEX specifically has a feature that helps grocers track product expiration dates and sell the oldest items first to minimize waste. RELEX batch balance management uses a First In, First Out (FIFO) approach and predicts spoilage based on sales forecasts. This ensures fresh products for customers and reduces waste and overstocking.

3. Connect ordering and replenishment with demand data

The days of managing fresh goods orders through endless spreadsheets are over. The RELEX unified platform connects ordering directly to demand data, creating a streamlined system that responds to actual customer buying patterns.

This integration goes a long way toward reducing waste. A bonus benefit: it also frees up staff time previously spent on manual ordering, allowing them to focus on serving customers and maintaining store quality.

Making a real impact on food waste and emissions

The impact of addressing food waste extends far beyond individual store operations. In 2024 alone, RELEX helped prevent approximately 350 million kilograms of food waste for our customers, resulting in a reduction of 1.2 million metric tonnes of CO2 equivalents in greenhouse gas emissions. To put this in perspective, that’s equivalent to removing about 600,000 cars from the road for an entire year.

Modern planning technology extends beyond achieving efficiency. It also enables sustainable practices that benefit both business and the environment. Grocery retailers no longer have to choose between maintaining a high product availability or contributing to a more sustainable future.

As global challenges in food security and environmental sustainability continue to grow, the grocery industry has a unique opportunity to lead the way in reducing waste and emissions. With the right strategies in place and the RELEX platform, grocery retailers can create a future where economic success and environmental responsibility work together seamlessly.

Grocery store food waste FAQ

What percentage of global greenhouse gas emissions come from grocery store food waste?

Food waste contributes to 8-10% of global greenhouse gas emissions, with a significant portion coming from grocery stores that throw out millions of tons of food every year. And a 2025 RELEX grocery store sustainability survey found consumers are deeply concerned about retailer sustainability and eager to participate in preventing food waste, like actively seeking out items that are discounted because they’re close to their sell-by dates.

What are the main causes of grocery store food waste?

The primary causes include:

- Overordering: Decentralized planning often relies on manual observations, leading to inaccurate forecasts and excess inventory.

- Overstocking for visual appeal: Fresh produce and perishables are overstocked to create attractive displays, increasing spoilage risks.

- Outdated planning processes: Manual systems lack agility to adapt to fluctuating demand, promotions, or external factors like weather and holidays.

How can grocery stores reduce food waste while maintaining product availability?

Grocery stores can leverage the RELEX platform to optimize supply chain planning. RELEX uses machine learning to forecast demand accurately, balance inventory levels, and automate replenishment processes. Features like spoilage projections, adaptive safety stocks, and real-time visibility into inventory help stores reduce waste while ensuring shelves remain stocked with fresh products.

What's the real ROI of investing in food waste reduction technology and programs?

RELEX customers have reported significant reductions in waste (up to 40% in some cases) while simultaneously increasing availability and sales. These solutions not only cut costs but also enhance sustainability, aligning with consumer demand for environmentally responsible practices. For example: By implementing RELEX, DoorDash’s on-demand grocery service (DashMart) improved availability while reducing spoilage.

How can we optimize our ordering and inventory management to minimize waste without risking stockouts?

Optimizing ordering and inventory management requires accurate demand forecasting, real-time inventory visibility, and automated replenishment.

Key capabilities include:

- AI-powered forecasting to predict demand with high accuracy, accounting for factors like weather and promotions.

- Real-time inventory tracking to monitor stock levels and expiration dates to minimize spoilage.

- Batch balance management to implement FIFO (First In, First Out) principles to ensure older stock is sold first.

- A unified planning platform to integrate merchandising, supply chain, and store operations for seamless decision-making.

How much can technology reduce grocery store food waste?

Technology can deliver measurable results. For instance, RELEX helped prevent 350 million kilograms of waste in 2023 alone. This equates to cutting 1.2 metric tonnes of CO2 emissions, which is comparable to removing about 600,000 cars from the road for a whole year.

Which department-specific interventions yield the fastest and most significant waste reductions?

Fresh produce and perishable departments often yield the fastest waste reduction results due to the short shelf life of their products. RELEX helps retailers manage these categories by aligning inventory levels with real-time demand, reducing overstock and spoilage. Collaboration between merchandising and replenishment teams, supported by integrated systems, also ensures that promotions and assortments are aligned to minimize waste.

Can grocery stores balance sustainability goals with profitability?

Absolutely! Reducing food waste enhances both sustainability and profitability. By ordering more accurately, stores lower disposal costs, improve margins through optimized markdowns, and free up staff time for customer service.

Editor’s note: This article has been updated since it was originally published in Food Logistics.