Inventory optimization: The key to improving your bottom line

Apr 12, 2024 • 16 min

Inventory inefficiency is the underlying problem in many supply chain challenges. Inventory that is misaligned with demand derails network operations, ties up working capital in costly overstock, and loses customers. And all amid increasing competition.

Managing inventory levels that meet customer demand efficiently requires an honest assessment of existing roadblocks, followed by clearly defined goals and a carefully considered roadmap.

To illustrate the challenges, best practices, and benefits of inventory optimization, let’s follow Tori, an inventory analyst, as she implements a new optimization strategy.

What is inventory optimization?

Inventory optimization is the process of managing and positioning stock to satisfy customer demand while minimizing costs.

Optimizing inventory has become increasingly critical as companies navigate complex global supplier networks, volatile consumer demand, and rising storage costs. The ability to precisely balance inventory across locations can mean the difference between leading the market and losing customers to more efficient competitors.

To achieve inventory optimization, Tori needs to implement a strategy and solution that will get the right amount of inventory to the right place at the right time.

With the hyper-accurate, AI-driven forecasts and automated planning in the RELEX platform, Tori’s organization can save money and drive customer satisfaction while avoiding overstock, spoilage, and lost sales.

Inventory management vs. inventory optimization

Inventory management handles the day-to-day tasks that keep products flowing through your supply chain, while inventory optimization takes a more strategic and data-driven approach.

Inventory management involves tracking on-hand stock, reordering items when levels get low, and ensuring orders are fulfilled on time. Practitioners of inventory management focus on the immediate logistics of storing, moving, and selling goods so there’s always enough inventory to meet customer demands.

Inventory optimization balances stock levels across the entire network to meet demand efficiently while minimizing costs. By analyzing sales trends, forecasting demand, and evaluating supply constraints, inventory optimization helps companies eliminate wasteful overstock and avoid stockouts, maximizing overall profitability.

Tori’s organization, like many others, has historically focused on inventory management, but a lack of an optimization strategy has prevented them from transforming their operations. She aims to tie management best practices and optimization tactics together to achieve next-level supply chain performance.

The 7 benefits of inventory optimization

Tori has recognized a few troubling situations within her supply chain. In some locations, sales and profits are low despite high inventory levels. In others, stores are losing sales due to low availability. Her teams are encountering bottlenecks along the supply chain, from suppliers to stores, and she needs a way to move inventory smoothly through the distribution network. Plus, current inventory levels require a lot of working capital, restricting network expansion and narrowing profit margins.

Tori needs an inventory optimization solution that will help her achieve:

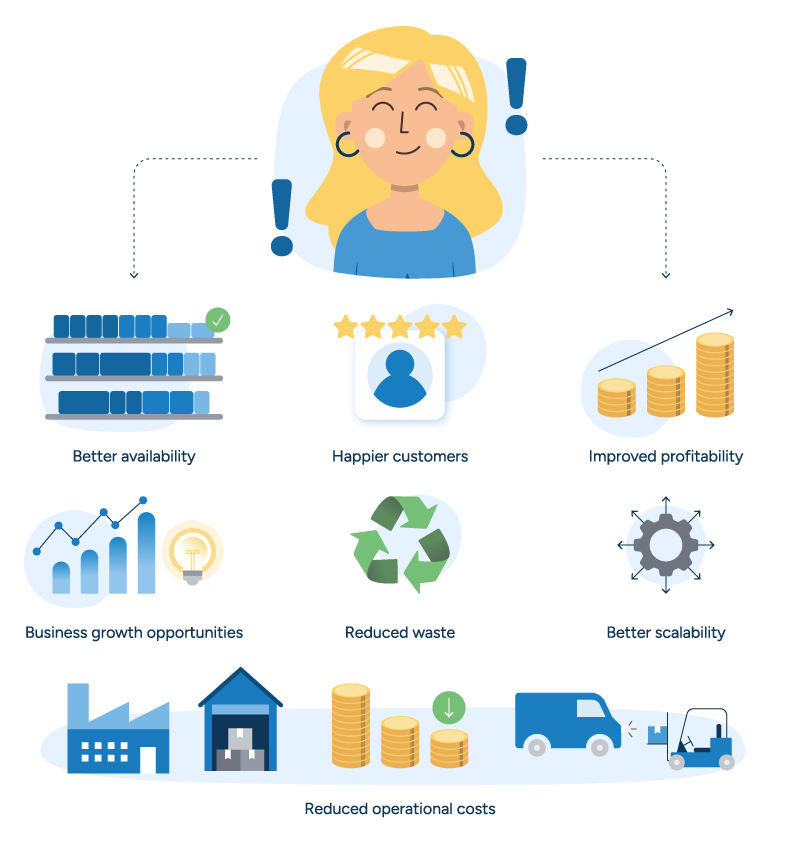

- Better availability and higher customer satisfaction: Smart inventory positioning ensures products are on shelves when customers need them. This keeps customers happy, improving brand loyalty and honing the company’s competitive edge.

- Improved profitability: By balancing inventory levels, teams maximize sell-through while investing less working capital in inventory, widening their profit margins.

- ROI reinvestment opportunities: Increased profitability and more flexible working capital can be used to fuel future business growth and invest in product development or network expansions.

- Reduced waste: By knowing how much inventory needs to be where, planners can pinpoint and eliminate overstock for more sustainable supply chains.

- Enhanced visibility: Interdepartmental communication and a clear, network-wide view of inventory help planners align with other operations and measure the impact of business decisions and market fluctuations on demand.

- Reduced operational costs: With AI delivering rapid, data-driven insights, teams balance inventory needs and costs with available supply, labor, storage, and space.

- Better scalability: More efficient use of inventory helps companies scale to meet the demands of expanding distribution networks and changing business requirements.

This all sounds good, but where should Tori start?

Common inventory optimization challenges

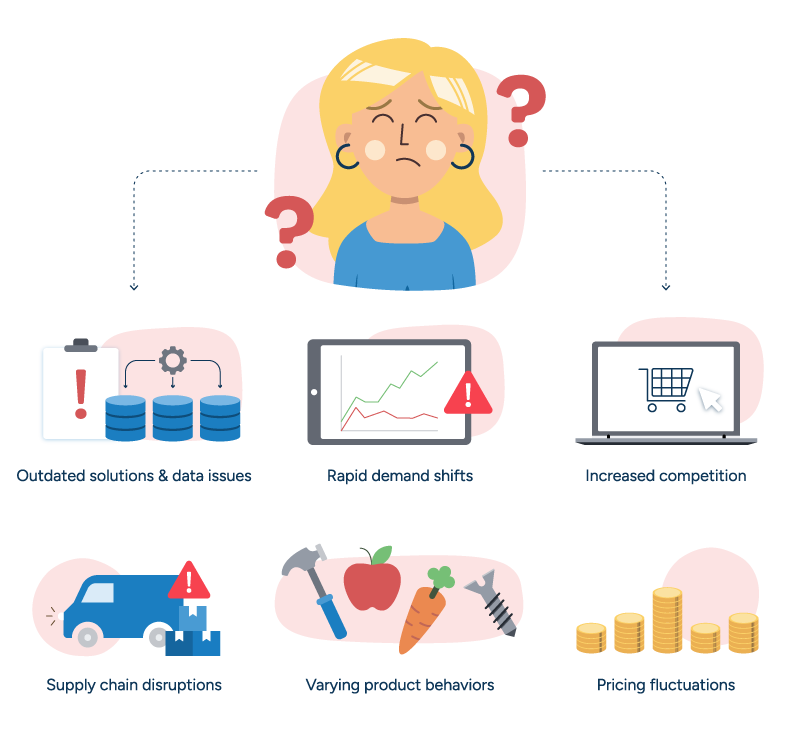

First, Tori needs to consider the roadblocks within her own organization as well as challenges from the industry at large.

Legacy systems and data issues

Proper inventory optimization requires up-to-date, accurate data and visibility across the enterprise. But many companies are hobbled by outdated legacy planning systems that make it difficult to collect, analyze, and disseminate information.

Without end-to-end visibility, Tori’s team is siloed. Lack of data makes forecasting demand difficult and increases the risk of inventory-related costs.

Tori needs a modern solution designed to pull data from the entire supply chain, process it quickly, and deliver actionable insights across operations.

READ MORE: Supply chain transformation: The complete guide

Fast-moving demand shifts

In the world of supply shortages and social media trends, consumer behavior can shift suddenly and dramatically. Tori and her team cannot rely on sales history alone for an accurate forecast.

She needs a system that can quickly and accurately integrate a variety of demand factors into her forecast calculations.

Phantom inventory

Stock that appears in the system but doesn’t physically exist on shelves (commonly called phantom inventory) creates a cascade of operational failures that undermine Tori’s optimization efforts. These inventory discrepancies arise from theft, damage, misplacement, or data entry errors, leading systems to believe products are available when they’re not.

When Tori’s system shows 50 units on hand but only 30 exist, the replenishment algorithm delays reordering, creating stockouts that frustrate customers and lead to lost sales. Meanwhile, her forecasting accuracy deteriorates as the system attempts to reconcile why products aren’t selling despite apparent availability. This phantom stock problem is particularly acute in high-shrink categories like electronics or cosmetics, where a 2-3% discrepancy can represent millions in lost revenue.

Tori needs a solution that incorporates regular cycle counting, RFID tracking, and automated discrepancy detection to maintain inventory accuracy and ensure her optimization algorithms work with real, not imaginary, stock levels.

Increased competition

Consumers are spoiled for choice. In the age of omnichannel, BOPIS, curbside pick-up, and two-day delivery, one bad shopping experience can mean losing a customer to a competitor for good.

Tori needs to increase availability to stay competitive and boost customer loyalty without risking costly overstock.

Supply chain disruptions

From extreme weather to geopolitical upheaval, supply chain disruptions have become the norm. These events can rapidly deplete supply or delay fulfillment.

Tori needs a planning solution that will allow her to adapt to changing market conditions, adjust forecasts quickly, and reposition inventory strategically.

Tricky product behaviors

Tori’s product portfolio contains varying demand patterns and shelf lives. Some products are perishable and move quickly, like fresh goods. Grocery stores often struggle with fresh inventory planning due to inventory shrinkage and poor (or nonexistent) inventory data. Additionally, the absence of expiration dates for some fresh products results in poorly balanced stock and uneven spoilage.

Other products are slow-moving, “long tail” items that experience intermittent demand. For example, DIY retailers may have a selection of lawnmowers that experience an uptick in demand when spring arrives. However, that demand is spread over multiple SKUs, meaning demand for a specific lawnmower may be rather low. This cannibalization can make it difficult to stock the product variety needed to satisfy picky shoppers without overstocking slow-moving items.

Both product types are affected by regional consumer behaviors, promotions, and seasonality. Often, each product type requires its own inventory management strategy, further complicating optimization efforts. Plus, the sheer number of SKUs complicates the planning process.

Tori needs a way to measure the impact of unique demand behaviors and promotional activities to determine the optimal amount of inventory for each product at each location.

READ MORE: How to improve fresh food inventory management

Pricing

Pricing can change drastically and cause dramatic shifts in demand. The price of an item may skyrocket if its supply suddenly plummets. The price may come down if planners are running promotions to drive a sudden spike in sales and avoid spoilage or obsolescence.

Tori needs to be able to respond to price elasticity by having visibility into supplier constraints, pricing, and promotions.

Components of a successful inventory optimization strategy

By assessing these challenges, Tori can design an optimization approach with specific goals in mind. She identifies six high-level goals that will guide her tactical strategy. She needs:

- A unified platform that increases visibility and gathers data from departments and partners across the organization for accurate, agile inventory planning.

- Granular, accurate forecasts that incorporate a wealth of demand data to drive efficient inventory use at each location.

- Cost-effective inventory levels and safety stock calculations that reduce inventory and avoid overstocks without resulting in lost sales.

- Strategically positioned and allocated inventory that meets network-wide demand, while taking advantage of bulk orders to lower costs.

- Optimized warehouse and store capacity that smooths replenishment operations while alleviating pressure on labor constraints and reducing bottlenecks.

- Future-proof capabilities that ensure scalability and justify the investment in a long-term solution.

With these goals in mind, Tori has the direction she needs to implement the best practices and technological solutions to optimize her inventory.

Inventory optimization techniques and best practices

So how does Tori make these goals a reality? She implements the RELEX platform.

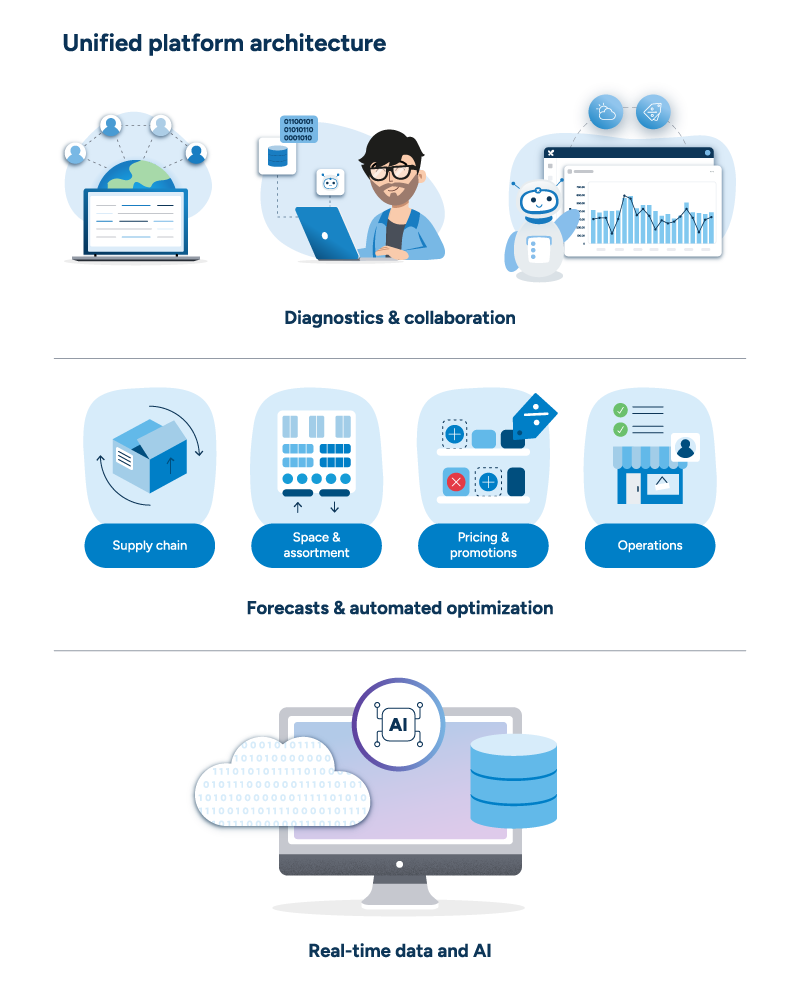

Unified data and cross-departmental planning

Because RELEX unifies data, Tori increases visibility along her end-to-end supply chain using a single data pool that compiles, formats, and processes data from across the business. With the RELEX unified platform, all functions use the same up-to-date information for their business decisions.

The solution also enables cross-functional collaboration. RELEX provides a more accurate, nuanced picture of inventory levels and requirements by seamlessly incorporating space, inventory, purchasing price, and operations considerations into the replenishment process.

Collaboration with upstream and downstream trading partners

From the retail perspective, Tori can bolster supplier relationships by sharing her forecast and other critical information with suppliers. In this way, she and her supply chain partners can align business objectives, increase end-to-end planning accuracy, improve efficiency, and circumvent possible disruptions.

Tori can also integrate external vendor information into her process (e.g., how much a vendor is planning to order or what promotions a retailer is running) for greater visibility. With this information, Tori can pass along bill of material insights and forecast expectations to suppliers and ensure she has enough inventory on hand to fulfill orders.

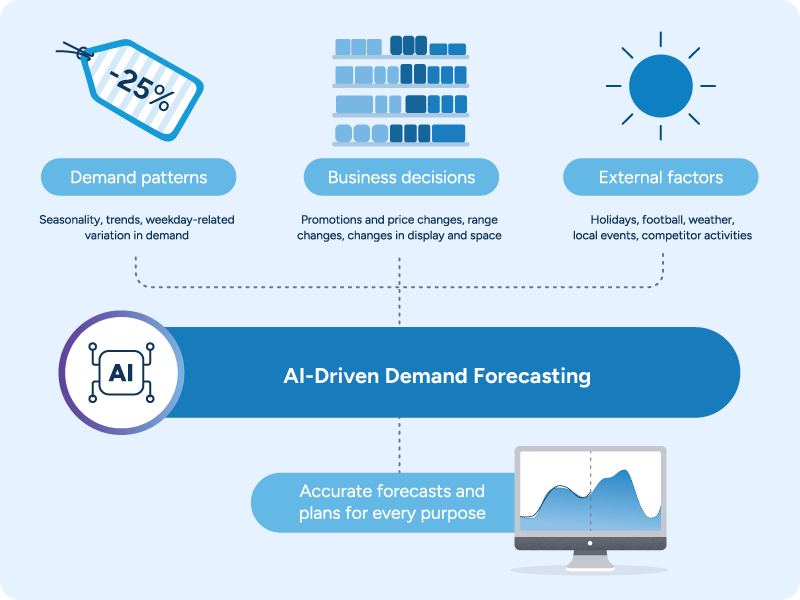

AI-driven demand forecasting

A machine learning-based forecast on the RELEX platform underpins the entire supply chain planning process, absorbing near real-time data and accounting for a range of demand-influencing factors (e.g., seasonality, weather, promotions, etc.).

Machine learning in the RELEX platform offers a granular look at product demand for each store or warehouse, so Tori’s team can determine how much of each product should be in each location, even for fresh products with intraday forecasting and slow movers with intermittent demand.

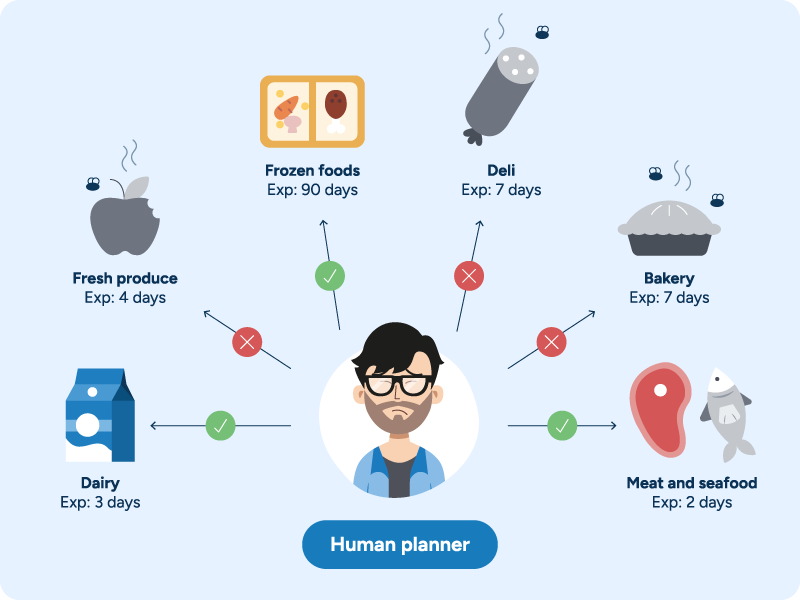

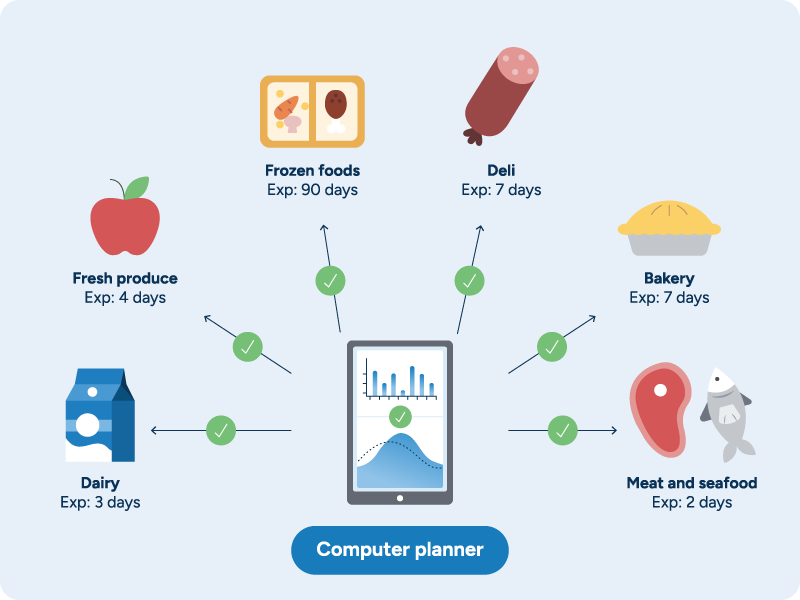

For instance, suppose Tori is planning products in her fresh category.

Each product exhibits different perishability, pricing, and promotional behaviors. This is more data than Tori can manage with spreadsheets.

With AI doing the heavy lifting, Tori can manage by exception and attend to the alerts and anomalies that require human judgment calls. She gets the advantage of rapid, AI-driven data analysis while still maintaining control of her optimization process.

Automated replenishment and inventory management

Tori’s new automated replenishment system from RELEX generates intelligent replenishment orders and allocations using the AI-powered forecast to guide its calculations.

By understanding expected demand, planned inventory levels, and supplier availability, the solution can identify supplier price breaks, discounts, and bulk ordering opportunities, reducing overall costs.

Automation enables Tori’s team to delegate repetitive grunt work to the system, so they can focus their expertise where it is most needed.

Predictive inventory accuracy and anomaly detection

By implementing predictive inventory capabilities within the RELEX platform, Tori transforms phantom inventory from an invisible drain into a manageable, measurable challenge. RELEX continuously analyzes patterns in sales data, inventory movement, and historical discrepancies to predict where phantom inventory is most likely to occur, preventing disruptions to operations.

The unified RELEX platform monitors signals across Tori’s network, looking for instances when a product’s sales pattern doesn’t match its supposed inventory level. For instance, if a high-velocity item shows zero sales for three days despite the system inventory count of 100 units, RELEX alerts Tori’s team to verify physical stock before the next replenishment cycle.

This proactive approach maintains inventory accuracy above 98% and learns from each correction, becoming increasingly accurate at predicting shrink patterns by location, category, and even time of day. Rather than discovering phantom inventory during quarterly counts, Tori’s team addresses discrepancies within hours, maintaining the data integrity that powers effective inventory optimization.

Storage and space optimization capabilities

Enhanced visibility and automated replenishment in the RELEX platform also help optimize storage and space use, communicating changes in store product portfolios and accounting for capacity needs, delivery and resource requirements, and supply restrictions.

For example, suppose another team in Tori’s organization has reduced the store count for a particular product from 600 stores to 400.

Tori has visibility into this decision and, therefore, isn’t planning for an extra 200 stores, avoiding costly waste. She knows which products should be heading to which stores, so she can plan the inventory levels that will best achieve on-shelf availability without overloading DCs or back rooms.

Moreover, the team can use this information to smooth store deliveries, scheduling them throughout the week to reduce bottlenecks, lower costs, and free up store associates for more customer service-oriented tasks.

Intuitive tools and configurability

Tech implementations are an investment of time, money, and resources.

Tori selects the RELEX unified platform, an adaptable solution with a user-friendly interface and intuitive dashboards, to improve efficiency and increase user adoption. RELEX allows for easy configuration, meaning the team can configure and alter business rules independently, avoiding the cost and time associated with rewriting code.

It also separates the configuration layer from the software application for easy upgrades with minimal business interruption. In this way, the company can keep growing while adapting quickly to marketplace changes.

Multi-echelon inventory optimization

Before RELEX, Tori approached optimizing inventory at each distribution center and store individually, but that method created expensive redundancies across the network.

When Tori’s distribution centers, regional warehouses, and stores each calculate their own safety stock levels based on local demand patterns, they’re essentially playing it safe in isolation. This approach leads to excessive inventory sitting idle at multiple points in the network, tying up working capital that could be better deployed elsewhere.

But RELEX uses multi-echelon inventory optimization (MEIO), which considers the whole supply chain together and optimizes inventory across the entire supply chain, strategically positioning safety stock where it delivers the most value. Instead of each location protecting against the same risks, RELEX determines optimal buffer points based on lead times, demand variability, and service level requirements at each echelon.

After applying a multi-echelon approach to inventory optimization, Tori might have warehouses holding more safety stock for slow-moving items with long supplier lead times, while stores maintain minimal buffers for these products. Conversely, fast-moving items with predictable demand patterns might require less centralized safety stock, with inventory pushed closer to the customer for rapid fulfillment.

By implementing MEIO alongside her other optimization strategies, Tori achieves network-wide efficiency gains that individual location optimization simply cannot deliver, including lower total inventory costs, improved cash flow, and the agility to respond quickly to demand changes anywhere in the network.

How RELEX helps organizations optimize inventory

Tori may be a hypothetical person, but the results gained from smart inventory optimization are not.

Take Norway’s largest discount variety retailer, Europris, which partnered with RELEX to develop an inventory optimization strategy focused on enhanced visibility.

“Before we implemented RELEX, it was difficult for us to measure things like availability other than by going out to stores to take a look or by monitoring customer complaints,” said Marco Pair, Supply Chain Manager at Europris. “We were being told that our campaign items had sold out even though they were still being advertised. That sort of thing inevitably has an impact on customer loyalty.”

By improving supply chain and inventory visibility with RELEX, Pair’s teams achieved significantly more accurate replenishment, demand forecasting, and campaign management. Inventory levels fell sharply, availability rose dramatically, and Europris’s ability to plan its logistics and staffing requirements improved markedly.

Getting started with inventory optimization

If you’re looking to optimize your inventory, start by identifying your main challenges. Is your network clogged with bottlenecks? Are you plagued with overstock, or are you struggling to keep high-demand items on shelves? Are departments able to communicate easily with each other? Does your team have the technology they need to make optimal inventory decisions? Identify the most critical goals and highlight your roadmap milestones.

And remember, when it comes to choosing a solution, the technology is only one piece of the puzzle; the best strategies are backed by the right technology partner that can guarantee successful implementation and provide the most cutting-edge solutions with continuing ROI.

With RELEX, you can join the hundreds of customers who have improved efficiency, profitability, and customer service while boosting and future-proofing their supply chain performance.

Inventory optimization FAQs

What's the secret to inventory optimization?

Successful inventory optimization combines smart strategy with the right tools. You should have an inventory optimization platform with the following capabilities:

- Unified data sharing that enables intelligent, collaborative end-to-end planning.

- AI-driven forecasting that uses machine learning to calculate accurate, granular forecasts despite demand variability.

- Replenishment and inventory planning automation that compiles and analyzes data for actionable insights and reduces strain on planning teams.

- Storage and space optimization that communicates important business decisions to inventory planners, reducing bottlenecks and improving on-shelf availability.

- Configurable planning platforms for easy user adoption and future-proof adaptability.

How can companies reduce inventory costs without risking stockouts?

You have to find the right balance between having enough inventory to prevent stockouts and avoiding excess stock that ties up capital or leads to waste. By analyzing factors like demand variability, forecast accuracy, lead times, and supply chain disruptions, RELEX calculates the ideal safety stock for each product and location, dynamically adjusting it based on real-time data and trends.

How can businesses balance inventory across multiple locations?

RELEX AI-driven forecasting and automated replenishment take the guesswork out of inventory allocation by considering actual demand patterns, delivery lead times, and what’s realistic for each location. The RELEX platform is specifically designed to handle this complexity, using AI to manage the countless variables and interdependencies that would overwhelm manual planning systems.

Can inventory optimization tools handle seasonal demand fluctuations?

The RELEX platform adjusts inventory plans dynamically using historical sales data as well as current performance data, all while factoring in external influences like weather patterns and local events. No more scrambling during peak seasons or sitting on excess inventory during slow periods.

Does inventory optimization work for businesses with complex supply chains?

Complex supply chains actually benefit the most from inventory optimization. When you’re managing multiple suppliers, distribution centers, and sales channels, automated replenishment and dynamic safety stock adjustments become essential.

How do you measure the success of inventory optimization efforts?

Common metrics for evaluating inventory optimization success include inventory turnover (how quickly stock is sold and replaced), spoilage rate (percentage of inventory lost to expiration or damage), service level (percentage of orders fulfilled on time), and estimated lost sales (value of sales missed due to stockouts). RELEX can also track reductions in operational costs, improved forecast accuracy, and enhanced inventory visibility across locations.