In my experience, most inventory planners could reduce the time spent managing orders to only 20% of their overall workload.

Many planners I know spend significant time managing demand and inventory plans. But traditional processes and legacy solutions often create unnecessary work, forcing inventory planners to run down data, manually update orders and forecasts, and wrestle with disconnected systems.

The right inventory planning software saves planners from this tedium, taking on tedious tasks like inventory tracking and order fulfillment so users can work more strategically and collaboratively with peers and stakeholders — all while simultaneously increasing the accuracy and efficiency of forecasts and orders.

The RELEX approach to inventory planning

Inventory planners I meet typically fall into two camps:

- Teams that focus on purchasing and procurement.

- Teams that combine demand planning with purchasing but are stuck using legacy systems or Excel spreadsheets.

Both face similar challenges. Pure purchasing teams make decisions based on historical orders and “gut feel.” Forecasting teams spend countless hours building models, testing them, and manually adjusting purchase orders.

With RELEX, the solution automatically handles the heavy lifting for purchasing and forecasting teams.

Purchasing-focused organizations use RELEX to:

- Generate optimal order proposals based on actual demand patterns

- Account for supplier constraints, lead times, and order minimums

- Highlight opportunities to consolidate orders and optimize transportation

- Project stock levels to prevent overbuying and stockouts

And demand planning teams can use RELEX to:

- Define the ideal forecasting model for each product

- Use artificial intelligence (AI)/machine learning (ML) to identify true demand drivers

- Show product performance across locations and channels

- Ensure forecast accuracy and alignment with business needs

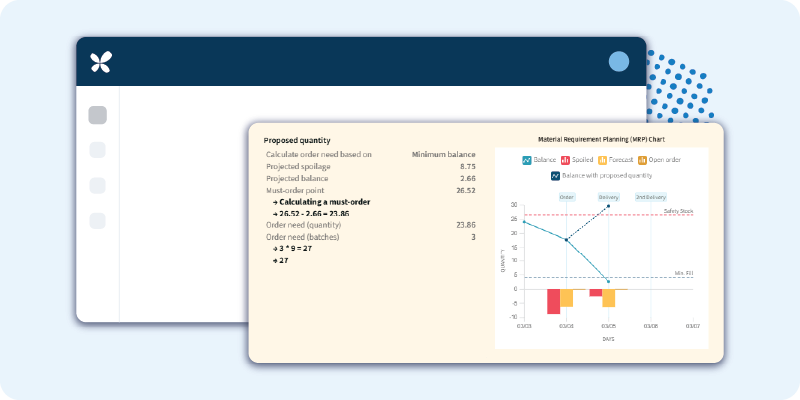

Based on the customer’s data, forecasts and the dependent suggested orders are updated every night to automatically capture the latest changes in the demand trends and inventory positions. Instead of manually reviewing thousands of forecasts and orders, planners set up rules and thresholds for the system to evaluate each one automatically.

What could your team do with 12-32 hours a week repurposed for strategic thinking?

RELEX would only highlight the exceptional instances — where a human needs to complement the AI’s decision-making, including scenarios like:

- Balancing orders within budget or allocating more funds for increased inventory to boost sales.

- Overriding automated thresholds to manage sudden demand spikes efficiently.

- Opting to relax budget constraints during peak seasons to maximize sales or maintain long-term financial stability.

RELEX users can focus more on answering questions like these instead of manually reviewing and editing thousands of forecasts and order proposals. Just imagine: what could your team do with 12-32 hours a week repurposed for strategic thinking?

Maximize efficiency with advanced inventory planning features

RELEX converts this complementary relationship between AI and the end user into exceptional value for inventory planning and beyond — and all within a single solution. No more bouncing between tools or wondering if your Excel formulas are correct. Every variable that influences a decision is right there in black and white, complete with visuals that make sense of your supply chain data.

Let’s break down how these automated capabilities translate into real planning power.

| RELEX capability | Features | Benefits |

|---|---|---|

Multi-echelon demand, supply, & purchase planning Synchronized inventory across all tiers for optimal demand and supply planning |

Unique ML algorithms built for purpose in demand, supply, and purchase planning workflows – Intuitive, configurable, alert-based UI for any workflow over any time horizon – AI enablement platform for optimizing across supply chain and adjacent functional areas |

– Improved forecast accuracy at product-location level to reduce stockouts, improve availability, and bolster sales – High order auto-acceptance rate for improved planner productivity – Optimized inventory levels and supply chain processes to lower carrying and handling costs |

| RELEX Diagnostics Automated root-cause analysis for excess inventory, stockouts, and spoilage | – Real-time data monitoring system with exceptions-based alerts – Configurable, comprehensive analytics dashboards for reporting and acting on findings – Inventory disposition coding – Detailed root-cause analysis (RCA) coding across supply chain, commercial, and merchandizing functions | – Reduced stockouts and spoilage to improve sales and customer satisfaction – Minimized over-inventoried positions to optimize stock levels – Enhanced enterprise decision-making from actionable, cross-departmental insights |

| RELEX True Inventory Automated identification of phantom inventory for improved replenishment and store labor productivity | – Prioritized anomaly detection – Suggested order proposals using “synthetic” inventory to account for forecasted inventory drift – Optimized inventory cycle count suggestions based on product-specific drift and demand characteristics | – Less time spent performing store inventory checks – Timely stockout correction to prevent lost sales and overstock – Improved store labor productivity |

| RELEX Merchandizing Financial Planning, (MFP), RELEX Open-to Buy (OTB), & RELEX Purchase Optimization Intelligent alignment of long-term financial plans with daily operations and supplier optimization | – Top-down, long-term financial planning – Real-time, bottom-up demand and receipt reconciliation against financial plans – Ordering constrained to inventory budgets | – Proactive prevention of budgetary breaches and surpluses – Identification of OTB opportunities to improve capital productivity – Minimized sales loss and margin impact within order constraints |

| RELEX Fresh Optimization Fresh-focused logic for streamlining replenishment and inventory optimization across all perishable categories | – Store lot/batch estimates – FIFO percentage tracking – Fresh safety stock optimization – Proactive spoilage projections | – Higher automation levels and intelligent insights to reduce errors and manual work – Reduced spoilage and inventory levels across the value chain – Improved shelf-life availability and product freshness to improve sales and customer satisfaction |

| RELEX Supplier Collaboration & coordinated ordering Enhanced availability through data sharing and collaboration across a cohesive supplier network | – Supplier collaboration dashboards and automated data sharing reports – Multi-supplier purchase contracts – Automated supplier ordering compliance | – Improved collaborative planning to increase product availability – Mitigated overstocks to decrease average inventory levels and expenditures – Proactive course-correction when managing supplier closures, outages, and out-of-stocks |

Multi-echelon demand, supply, and purchase planning

Most retailers I meet struggle to gain supply chain visibility with so many moving parts. They can’t see how changes in demand or supply will ripple through their network until it’s too late. I’ve watched any number of planning teams try to piece together insights from disconnected systems while problems compound downstream.

RELEX instead creates a digital twin of your entire supply chain network. This model shows you exactly how decisions and disruptions will impact every tier of your business in real-time.

The solution’s integrated planning engine:

- Generates distribution center (DC) forecasts from projected store orders instead of historical shipments

- Optimizes cross-dock operations by aligning supplier-DC and DC-store delivery schedules

- Distributes limited DC stock to stores based on true business impact

- Projects upstream supply constraints through the entire network

- Calculates optimal DC safety stock levels using store-level demand patterns

When a supplier flags a delay or constraint, you’ll see exactly which DCs and stores are affected. The system automatically adjusts orders and reallocates inventory to minimize the impact. And this data is available to everyone, with every stakeholder — from suppliers to DC managers to store teams — working from the same information in a single environment.

Case in point: planning for a new product introduction. RELEX generates store-level demand and supply plans based on a reference item or sub-category for the new product. Planners can then influence the demand plan and model how those changes impact their supply plan.

But stores often lack an understanding of how these changes play out at the warehouse level. RELEX also provides DC-level forecasts and projections, allowing planners to visualize both their own and their DC’s demand and supply changes side-by-side.

Sometimes, planners need more than an aggregated view of supply and demand. With RELEX, users can quickly drill into tables and charts to understand the impacts of individual store changes and their subsequent effect on total demand at their supplying DC.

For companies struggling with capacity constraints, delivery flow smoothing (DFS), can be layered on top of core RELEX planning capabilities. This advanced functionality “smooths” delivery schedules and aligns multi-tier deliveries to enhance operational efficiency, reduce bottlenecks, and ensure consistent inventory accuracy and responsiveness.

RELEX Diagnostics

Every stockout tells a story. Most retailers I work with just can’t piece it together fast enough to make it matter.

Our diagnostics solution automatically analyzes your order proposals and inventory data to pinpoint exactly why you see stockouts, spoilage, or excess stock. You’ll get clear breakdowns for issues at both stores and distribution centers.

Importantly, RELEX focuses on prevention — not reaction. Our real-time monitoring tracks KPIs like availability, inventory value, and spoilage across your entire network. When something looks off, you’ll know:

- Which products face availability risks

- Where excess inventory threatens profits

- How spoilage patterns impact specific categories

- What’s driving scarcity at your distribution centers

And it all happens without introducing additional consultants or separate analytics tools into the equation. RELEX Diagnostics integrates directly with your planning workflows, allowing you to drill down from any dashboard to see the full story behind the numbers.

An example: RELEX can execute a root cause analysis to identify the key drivers across stores and DCs. If the system identifies negative trends by geography or time period, teams can use bespoke dashboards to collaborate and act accordingly.

Alternatively, teams can use the solution to align inventory usage with strategic initiatives. They can analyze inventory, suggested orders, and even forward-looking simulations with inventory disposition codes to understand how that inventory is being or will be used. This analysis can be done at an aggregate business level or for product-locations to, say, better manage inventory breaches or surpluses and bring them in line with MFP/OTB targets.

RELEX True Inventory

Phantom inventory impacts almost every retailer I’ve worked with. Their solution shows products on the shelf when they’re nowhere to be found. Meanwhile, customers walk away empty-handed, and the retailer’s forecasting takes a hit. Store teams waste hours on blanket inventory counts that address the symptom but not the cause.

RELEX True Inventory spots inventory anomalies and prioritizes the most critical counts to bring clarity to this chaos. Store teams receive targeted task lists through RELEX Mobile, focusing their efforts where they’ll have the biggest impact on sales and availability.

The solution works behind the scenes to:

- Track inventory drift patterns at the SKU level

- Generate probabilistic balance estimates

- Automate corrections for common discrepancies

- Create targeted counting schedules

- Maintain perpetual inventory where data gaps exist

We designed True Inventory to help our customers identify the categories and locations where phantom inventory runs most rampant. They can view associated metrics at a level of aggregation, ranging from the entire business all the way down to a given product-location.

The solution can then send store operations teams alerts via their in-store devices or an inventory reconciliation portal. This feedback loop ensures higher in-stock levels in the store without negatively impacting labor costs.

RELEX Merchandise Financial Planning, Open-to-Buy, and Purchase Optimization

Nearly every retailer I meet struggles with some version of the same financial planning headache. They need to balance inventory budgets against sales targets while keeping their cash flow healthy. Traditional approaches force planners to juggle disconnected systems and manually reconcile budgets with actual stock levels.

RELEX Merchandise Financial Planning (MFP) streamlines this process. The solution focuses on high-level, manual financial planning, but it seamlessly integrates with our AI-powered forecasting engine to provide precise, bottom-up predictions during in-season execution. This integration ensures planners can bridge the gap between aggregate financial targets and store-level reality, using real supply constraints and network capacity to stay on track.

The Open-to-Buy (OTB) functionality adds another layer of control. The system tracks purchase budgets in real-time and alerts planners before they exceed financial limits. When budgets get tight, the platform suggests smart actions:

- Delay or reduce purchase orders

- Adjust safety stock on lower-priority items

- Trigger markdowns to free up cash

- Increase budgets based on sales potential

Rounding out this financial toolkit is RELEX Purchase Optimization, which automatically:

- Selects optimal suppliers based on costs and constraints

- Times purchases to capture promotional pricing

- Adjusts for seasonal network changes

- Maintains supply splits across multiple vendors

These systems work together so planners can spend their time evaluating opportunities instead of reconciling spreadsheets. The system handles the math; your team, the strategic thinking.

RELEX Fresh Optimization

Fresh items make or break grocery retailers. Every spoiled product hits the bottom line twice — first in waste costs and then again in lost sales. But when I meet with planning teams, so many of their systems still rely on rough averages and “gut feel” to manage fresh inventory.

RELEX Fresh Optimization takes the guesswork out of perishable planning. Our system tracks batch-level inventory and calculates precise spoilage projections for every SKU, meaning you’ll know exactly when products expire so you can adjust orders automatically.

Consumer behavioral modeling is at the heart of this process. The system analyzes how customers select products, like their tendency to pick items with longer shelf lives. These insights drive more precise predictions and better alignment between inventory and actual demand.

The AI-driven engine handles the complexity behind the scenes:

- Projects remaining shelf life for each batch

- Calculates optimal safety stock levels based on actual demand patterns

- Adjusts orders to balance availability against spoilage risk

- Forces out aging DC inventory before it expires

- Estimates FIFO rates to match real consumer behavior

Teams can leverage these features to generate store-suggested orders that balance demand with minimum fill requirements, spoilage considerations, and safety stock levels. They can also automate the DC pick-to-zero allocation process to ensure stores always get the freshest produce.

Additionally, our Fresh Safety Stock logic balances the trade-offs between service level targets, customer demand variability, and the costs of ordering, holding, and spoiling inventory. It dynamically adjusts safety stock based on factors like demand patterns, spoilage rates, and lead times to minimize waste while ensuring product availability.

RELEX Supplier Collaboration and coordinated ordering

On more than one occasion, inventory planners have described their jobs to me as a daily juggling act. They bounce between forecasting tools, ordering systems, and supplier portals while trying to balance fluctuating demand against complex ordering rules. RELEX eliminates this chaos by unifying every stakeholder in a single, intelligent platform.

RELEX Supplier Collaboration helps suppliers gain immediate access to point-of-sale data, demand forecasts, and upcoming promotions. Meanwhile, retailers receive real-time updates on availability, constraints, and lead times. This two-way visibility empowers both parties to spot and solve supply issues before they impact the business.

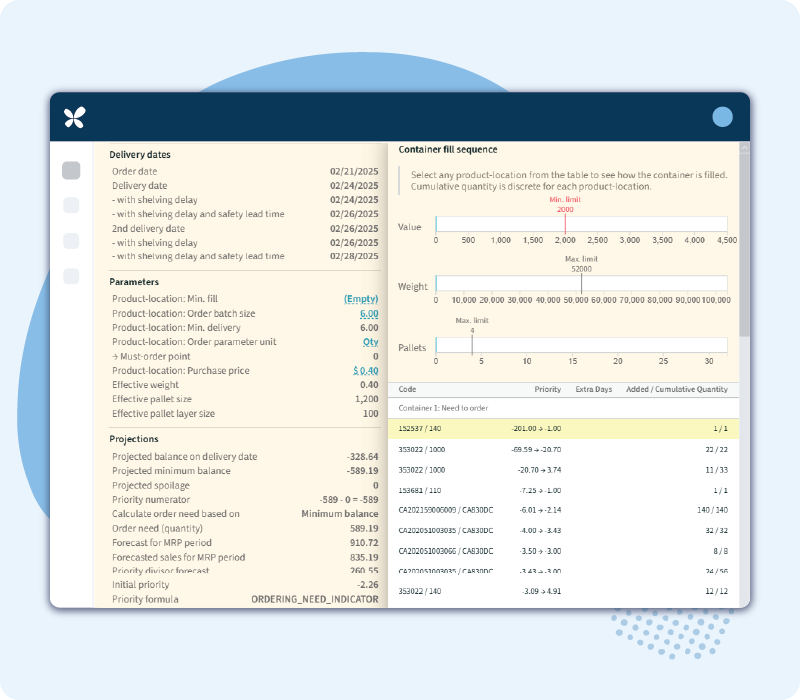

Our system’s automated order suggestions account for:

- Current demand

- Inventory levels

- Supplier-specific ordering rules

- Shelf-life requirement

- Merchandizing strategies

— and all without manual calculations.

The platform also identifies opportunities to coordinate orders, creating additional efficiencies across your supply chain. For example, RELEX can automatically build truck or container fill sequences based on the unique ordering requirements between given suppliers and distribution centers. It can do the same for groups of suppliers and multiple locations based on similar ordering requirements and product assortments.

Teams can also leverage the solution to create consensus forecasts and communicate supplier constraints or retail changes in demand or strategy. Stakeholders can even use the Supplier Collaboration portal to align on the key performance indicators that keep both suppliers and retailers happy.

RELEX: A complete inventory planning system

“Can’t we just plug these systems together?”

I hear this question all the time from teams struggling with disconnected tools. In reality, connecting separate systems creates more problems than it solves.

RELEX is a single powerful platform that fundamentally changes how teams work. No more switching between systems or manual workarounds. Instead, the RELEX platform provides streamlined, intelligent workflows that connect every aspect of your planning process.

The power of a unified platform

I’ve seen companies use one system for forecasting, another for replenishment, and then separate tools for workforce and space planning. It’s a mess.

RELEX handles every aspect of planning to avoid this convoluted setup. When category managers update assortments, the system adjusts forecasts automatically. When marketing launches a promotion, orders and space plans update instantly. Every department works from the same data, in real time.

AI that works for you

I’ve watched too many planners waste time adjusting thousands of forecasts manually. Our ML algorithms handle this heavy lifting automatically. RELEX learns from daily sales patterns, factors in promotional uplifts, and even accounts for weather impacts. And when conditions change, the solution adjusts orders and stock levels in real-time.

Many of these planners have expressed understandable reservations about offloading a primary function of their role to AI. But at RELEX, we focus on the power of AI-powered planning software to complement, not replace. Our strategy involves:

- Using AI to handle time-consuming, repetitive tasks…

- …so actual planners can focus on strategic business decisions that require a human touch.

Imagine you’re deciding whether to increase inventory for better sales, which might raise labor costs and affect utilization rates. An AI-powered planning platform can determine the optimal inventory levels to balance sales potential and labor costs, but it cannot consider the broader impact on staff or customer experience.

In this and other cases, RELEX places equal emphasis on both sides of the coin: the essential human expertise for sound decision-making and the requisite AI-powered inventory planning software.

Configure without coding

Every retailer I work with operates differently. RELEX adapts to your needs through simple configuration, with no expensive custom coding required. Our visual rule engine puts you in control. You can implement your exact business logic without IT support. As operations grow or change, the system scales smoothly. You maintain full flexibility while avoiding the limitations of rigid, one-size-fits-all solutions.

Built for growth and innovation

The supply chain never stands still. Fortunately, neither does RELEX. Research and development has always been one of our major priorities, and we consistently invest 25-30% of our revenue back into our R&D projects.

Our dedicated R&D team constantly enhances the platform based on emerging trends and customer needs. Regular updates grant immediate access to new capabilities, and when questions arise, our global support team provides expert guidance. This combination of innovation and support ensures your company stays competitive as markets evolve.

RELEX consistently invests 25-30% of our revenue back into our R&D projects.

RELEX inventory planning success stories

All bells and whistles aside, an inventory planning solution is only as powerful as the change it effects. That’s why it’s so easy for me to champion RELEX in this space. RELEX has helped real businesses achieve some truly incredible transformations, where every percentage point improvement means better customer service, reduced waste, and more efficient operations.

Whether you’re dealing with manual complexity, fresh item challenges, or centralization needs, these success stories reveal one important truth: there’s a clear path forward with the right technology partner.

Speed to value

Take WHSmith. The famous British retailer needed immediate help with their fresh food-to-go items across 350 stores. We implemented a complete forecasting and replenishment system in under four months. This rapid deployment matters, and our customers typically see significant improvements within their first quarter using RELEX.

When we mentioned the opportunity to use airport traffic numbers, the RELEX team was quick to find an innovative way to utilize this data in our demand forecasts.

Jag Banwait, Merchandise Controller, WHSmith

Fresh item management solved

Booths supermarkets faced the complex challenge of fresh product management. Our forecasting and replenishment tools cut their overall spoilage by 10%, with fresh cabinet items seeing a 20% reduction. These improvements directly impacted their bottom line while maintaining their high quality standards.

Optimize your inventory management with RELEX inventory planning software

Good software alone doesn’t transform supply chains. Plenty of promising implementations fail because companies focus too much on features and not enough on finding the right partner. The truth is, you’re not just choosing technology. You’re choosing the team that will help you cultivate and retain a competitive edge.

After years of optimizing operations across global markets, RELEX has perfected this partnership approach. Our success comes down to three key elements:

- We deliver rapid results. Most customers see returns within nine months. Quick deployment and powerful optimization mean you’ll drive measurable improvements while building momentum for broader transformation.

- We make success repeatable. Every RELEX implementation has succeeded. That’s 100% of customers willing to serve as references. We achieve this by treating your challenges as our own and tailoring solutions to your unique vision.

- We keep innovating. Our R&D team constantly enhances our platform to tackle emerging challenges. Combined with our global support network, you’ll stay ahead of industry trends and establish yourself as a supply chain leader.

Transforming your supply chain operations is a massive undertaking. But with RELEX, you’re not just getting proven technology. You’re partnering with a supply chain software expert who’s navigated companies from countless backgrounds and unique agendas to the same result: resounding inventory planning success.