4 ways to use AI to master DIY retail supply chain challenges

May 27, 2024 • 6 min

You’re barely into your second cup of coffee, and the supply chain woes at your DIY retail stores have already mounted. An inventory miscalculation has left your shelves bare of essential paints, causing a wave of customer complaints. A stockout of power tools — your second this month — has cost you several major sales. Now, you’ve received word that your primary supplier for garden furniture faces production delays and will likely miss the delivery window for the upcoming all-important spring sales season.

If this hits a bit too close to home, it’s time for a major revamp of how you approach DIY supply chain planning — and DIY retailers will find no better way to do so than using AI-powered planning software. Here are four ways to use a robust planning solution to bolster operational efficiency, increase customer satisfaction, and boost profitability.

1. Automate planograms to manage variety in DIY store formats and assortments

DIY stores vary significantly in store and assortment size — even within the same company. A neighborhood hardware store may take up 30,000 square feet and offer a limited assortment of tools and products for everyday fixes around the house. That same retailer may operate a 100,000-square-foot location in the same city offering a lumber yard, a garden center, ceiling fans, refrigerators, tool sheds, and more.

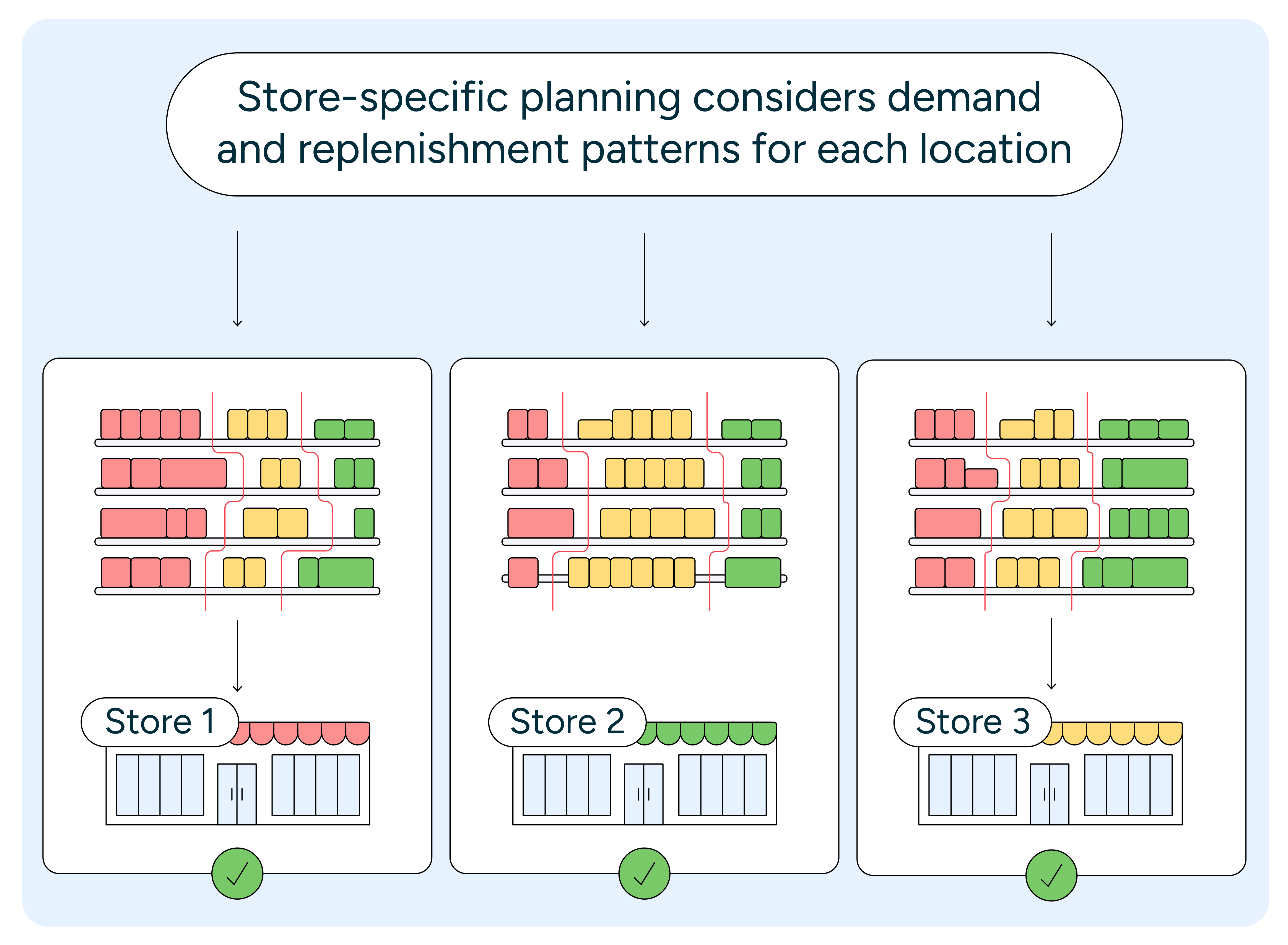

Planogram-centric strategies are crucial in managing diverse store formats. They ensure that products are not only accessible but also presented appealingly, enhancing the customer shopping experience. AI-powered planning tools enable retailers to automate the creation and adjustment of planograms to reflect real-time sales data and inventory levels, minimizing overstock and stockouts.

Integrating store-specific planograms into the retailer’s planning systems enables direct-to-shelf replenishment, reducing operational costs and maximizing shelf efficiency. This approach allows for a tailored experience in each store, ensuring products are where they need to be and in the quantities required. As a result, retailers can maintain a consistent level of service across their network, turning logistical challenges into competitive advantages.

UK convenience retailer One Stop automated over 30,000 store-specific planograms annually, resulting in a 49% increase in like-for-like product sales.

Leading UK convenience retailer One Stop fully automated their planogramming to great success. The company automated over 30,000 store-specific planograms annually, resulting in a 49% increase in like-for-like product sales. As a bonus, the ability to customize store layouts and product assortments more accurately to local customer needs increased customer satisfaction and loyalty across the brand.

READ MORE: Unified retail space optimization drives tangible value

2. Embrace AI to improve low margins in DIY retail

DIY retailers face fierce competition and intense pressure to improve margins due to high competition, rising procurement costs, and the continued shift toward online shopping. Implementing a flexible, AI-powered solution that matches continuously evolving demand to ever-shifting supply will raise margins and unlock omnichannel profitability.

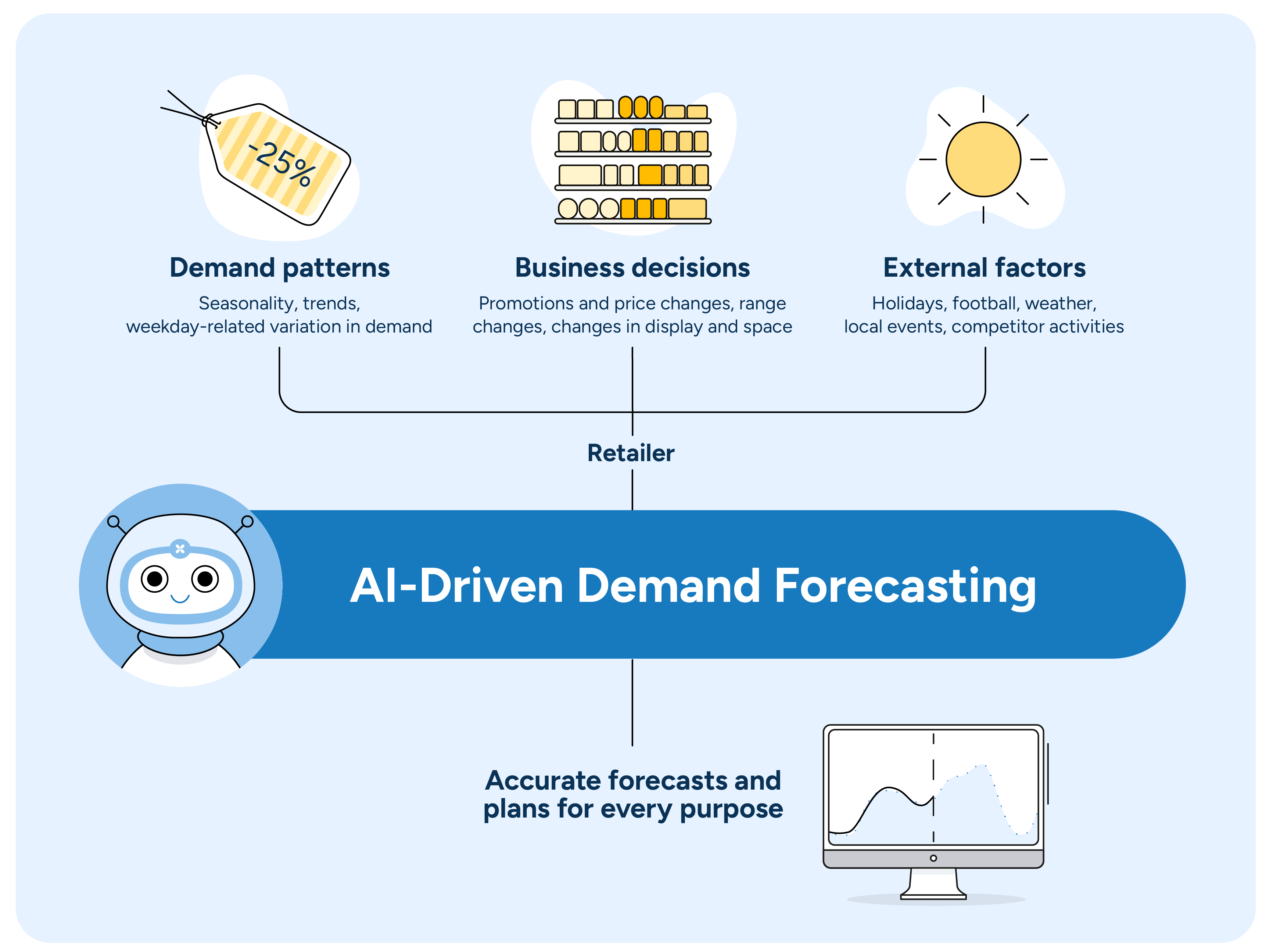

AI-driven technology enhances forecast accuracy and improves inventory management to streamline supply chain logistics. This optimization is especially crucial for moving large, heavy items in the DIY sector. Solutions like RELEX can anticipate inventory needs before demand spikes at local levels and then optimize the most efficient distribution paths to reduce unnecessary storage and handling costs. These points are crucial as delays and fluctuating logistics costs still impact the global supply chain and the businesses within it.

AI tools can also provide more granular insights into customer behavior, enabling retailers to tailor marketing efforts and stock levels more accurately. Companies can use predictive analytics to identify which products will be in demand based on trends and seasonality to better plan promotions and stock allocation. This capability allows retailers to adjust their inventory management and promotional strategies dynamically, protecting margins through improved responsiveness to market changes and enhanced customer satisfaction.

3. Manage scale and complexity in DIY assortments

Home improvement retailers manage a larger, more complex supply chain than many other sectors, and they can’t do so efficiently without the use of the right planning software.

Many DIY retailers carry 20,000–80,000 products per store and up to a million SKUs online. This includes many items that present intensive inventory challenges, including slow-moving, out-of-season products. (Think snowblowers in the summertime.)

Slow-moving products require a different inventory management approach than fast-moving ones, as overstocking increase holding costs and reduce shelf space. The opposite is also true, with the understocking of high-demand items resulting in lost sales, customer dissatisfaction, and potential damage to a retailer’s brand reputation.

Home improvement projects also often involve many high-value goods, making any single trip to the store a potentially lucrative one for the retailer. Understocking can derail these basket sales, as just one out-of-stock product could send the customer fleeing to a competitor who managed to stock every item on their shopping list.

Then there’s the issue of products like table legs, sold both individually and in sets. This dual selling mode complicates inventory decisions, requiring precise forecasts to avoid overstocking one while understocking the other. The challenge intensifies as errors in either direction can significantly disrupt project completion for customers, exacerbating the risk of lost sales.

Balancing this vast and varied assortment requires software that utilizes AI and machine learning for precise forecasting. A machine learning forecast can handle different product types in one model, massively simplifying user processes. Robust AI-powered solutions learn across products and locations to better forecast all product types, including slow-moving and seasonal items.

A machine learning forecast can handle different product types in one model, massively simplifying user processes.

The right digital solution can also help shape replenishment strategies that improve inventory management. For example, retailers can use RELEX to set adaptive, forward-looking safety stocks to ensure product availability amidst demand fluctuations and supply chain uncertainties. They can also take advantage of an automatic, self-updating categorization system to dynamically adjust product classifications based on sales trends and demand patterns, ensuring optimal stock levels across their diverse assortment.

READ MORE: Demand forecasting for retail and consumer goods: The complete guide

4. Capture the impact of seasonality and weather on DIY retail demand

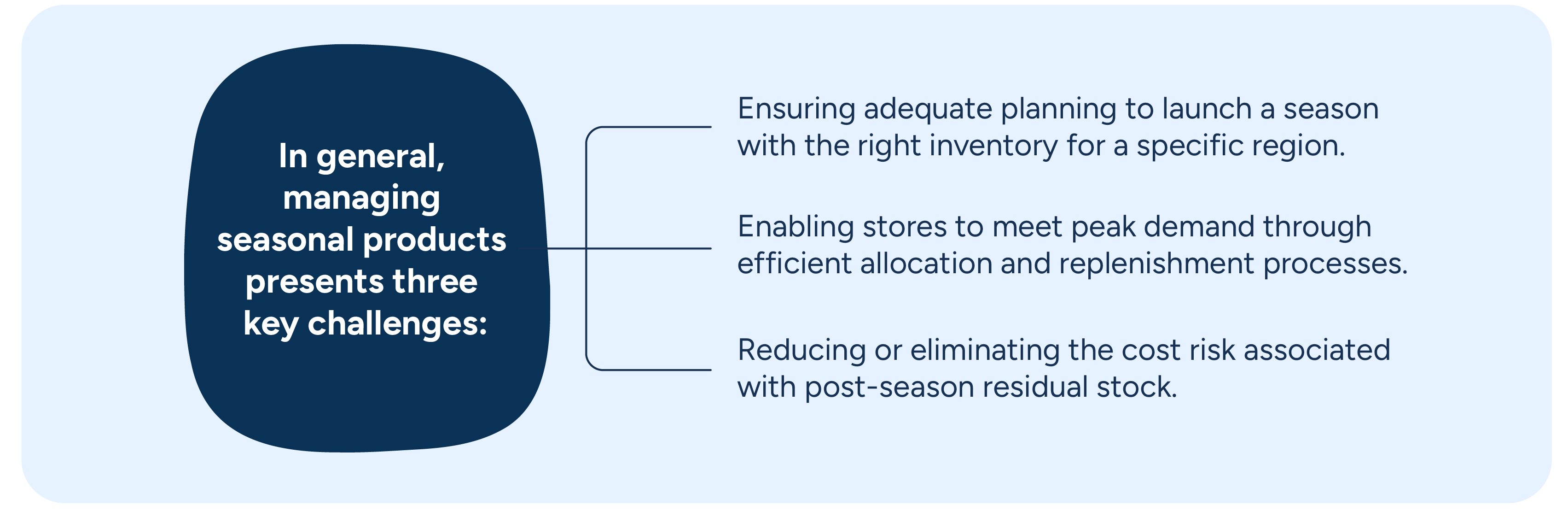

Seasonality and weather trends heavily impact DIY demand. Seasonality refers to the predictable, long-term patterns in consumer behavior — like increased lawn and garden equipment purchases in spring or heating products as winter approaches.

These seasonal trends are crucial for planning major sales and inventory cycles in DIY retail, where a large share of annual sales occur during the high-volume spring season when demand for home improvement products is highest. Because of this, a good sales day in spring can have a more significant impact on a DIY retailer’s supply chain than their best sales day in winter.

Weather impacts are more immediate and can cause short-term spikes in demand that deviate from average patterns — like an unseasonable late summer cold snap boosting sales of winterizing products. Effective supply chain planning must anticipate the regular seasonal peaks while remaining agile enough to respond to these weather-driven demands.

Both seasonal and weather-related challenges require an advanced forecasting and replenishment solution. Capable AI-powered platforms anticipate long-term consumer behavior trends to help retailers plan inventory and sales strategies around predictable seasonal peaks. This ensures that stores are well-stocked for their most lucrative sales periods, maximizing profitability.

Capable AI-powered platforms anticipate long-term consumer behavior trends to help retailers plan inventory and sales strategies around predictable seasonal peaks.

A robust system will also come equipped with real-time data analytics to swiftly and automatically adjust inventory levels in response to sudden weather changes. This agility allows DIY retailers to capitalize on unexpected demand spikes, ensuring they are prepared to meet customer needs without overstocking.

Navigate DIY supply chain complexity with RELEX

Addressing critical pain points in the DIY supply chain extends beyond averting inventory-related catastrophes. It also helps set a foundation for sustained growth and customer satisfaction. For DIY retailers, the transformation begins with AI-powered planning software — especially a solution that optimizes every link in the supply chain. Accurate demand forecasting and automated inventory management minimize stockouts and excess inventory while dynamically aligning your supply chain with changing market demands, ensuring operational efficiency and resiliency.

The DIY retail supply chain is already complex enough without adding the burden of finding the right technology partner to navigate it — but fortunately, there’s RELEX. RELEX offers a robust set of tools specifically designed for the DIY and home improvement sector, making it an ideal choice for retailers seeking to enhance operational efficiency and customer satisfaction. With RELEX, retailers can better match supply with ever-changing demand, transforming their supply chain headaches into substantial competitive advantages.