Mastering the peak hour challenge: How intelligence transforms grocery operations

Jul 28, 2025 • 4 min

Saturday afternoon, 2 p.m. A customer’s cart is half-full when they discover the promoted product they were counting on is out of stock, despite the app showing “in stock” just 10 minutes ago. Their frustration builds as they consider whether to ask when to expect a restock, substitute with a less desirable alternative, or go to another store entirely.

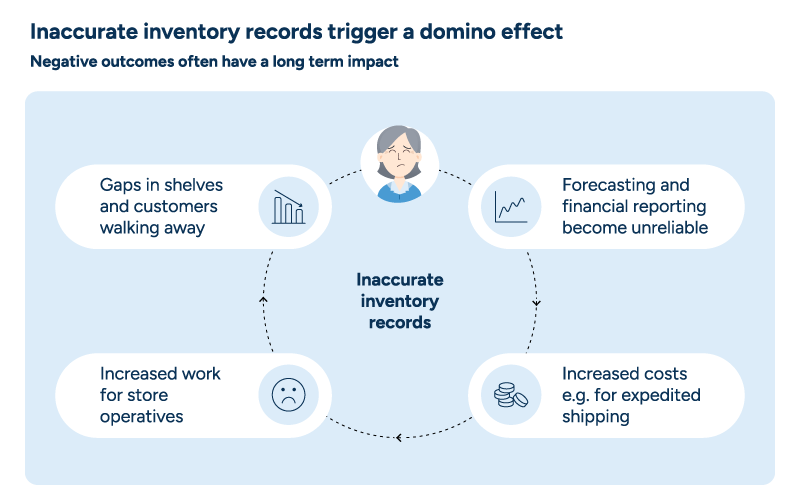

This scenario plays out thousands of times daily across retail locations worldwide. What begins as a simple inventory mismatch can create a domino effect: disappointed customers, overwhelmed staff scrambling to check backroom inventory, and lost sales during the most crucial shopping windows.

Peak hours are when grocery relationships are won or lost. These concentrated periods — weekend surges, lunch-hour dashes, and promotional traffic spikes — determine whether customers become loyal advocates or frustrated defectors. Modern grocery success requires modern tools that match today’s shopping patterns.

The complexity of modern grocery operations

Shopping has rapidly evolved. Economic pressures drive customers to shop deals aggressively, creating concentrated shopping windows that strain traditional systems.

The rise of hybrid shopping behavior adds another layer of complexity. Online ordering and in-store pickup create dual pressure on inventory systems, requiring seamless coordination between digital platforms and physical operations. Traditional systems simply can’t adapt to changing promotional responses or unexpected events that characterize today’s retail environment.

Store teams juggle restocking, customer service, and order fulfillment without updated guidance. This reactive approach to operations means problems are addressed only after impacting customers. Task prioritization becomes guesswork during crunch time, and planning based on broad daily forecasts misses the critical intraday demand spikes that define peak-hour performance.

The result is a familiar cycle: customers discover empty shelves during peak demand, staff scramble to check backroom inventory, and sales opportunities evaporate while customer frustration builds. But perhaps the most damaging issue is phantom inventory — the disconnect between what systems think is available and what’s actually on the shelves.

The phantom inventory problem

Phantom inventory represents one of the most insidious challenges facing modern grocers. Customers arrive for pickup orders that can’t be fulfilled, while store personnel spend time hunting down products that aren’t there. Online systems display availability that doesn’t exist in stores, creating a false promise that erodes customer trust and wastes employee time.

This disconnect between digital promise and physical reality has far-reaching consequences. When customers can’t rely on inventory information, they lose confidence in the entire shopping experience. The convenience that drove them to shop online or use mobile apps becomes a source of frustration, pushing them toward competitors who can deliver on their digital promises.

Intelligence for peak performance

Addressing these challenges requires a fundamental shift from reactive to proactive operations. The solution lies in three interconnected capabilities that transform peak-hour performance.

Intraday forecasting

Meeting customer expectations requires going beyond daily averages to provide store-level demand prediction that anticipates the nuances of shopping patterns. This granular timing distinguishes between the 2 p.m. Saturday rush and the 6 p.m. weekday pattern, enabling stores to prepare for specific demand spikes rather than operating on broad generalizations. Near real-time adjustment to promotional responses and unexpected events ensures that forecasts remain accurate even when conditions change rapidly.

Empowered staff

When employees have the right tools, they can transform operational efficiency. Up-to-date inventory visibility accessible to store employees eliminates the guesswork that leads to customer disappointment. Task prioritization based on current conditions ensures that staff focus on the most critical activities during peak periods. Delivery tracking and stock level alerts prevent surprises by providing advance warning of potential issues.

True inventory visibility

The key to peak-hour success is eliminating phantom inventory with near real-time stock tracking powered by advanced machine learning and AI. This synchronized approach ensures that online and in-store availability information remains accurate and current. Customers gain confidence through access to updated information they can trust.

The competitive advantage of peak-hour mastery

Organizations that implement modern intelligence solutions see fast benefits. Operational efficiency improves through the ability to handle unexpected demand without breaking down, while better demand prediction reduces waste and optimizes resource allocation.

Labor optimization becomes possible when staff work smarter, not harder, during peak periods. Proactive operations replace reactive problem-solving, allowing teams to address issues before they impact customers. This shift from crisis management to strategic execution transforms the entire store experience.

Revenue protection occurs naturally when fewer sales are lost during high-value shopping windows. Peak hours represent the most profitable periods for grocery operations, and maintaining availability during these critical moments directly impacts the bottom line.

Perhaps most importantly, customer lifetime value increases when trust is built through consistent availability during critical moments. Grocers who master peak-hour execution stand out in a crowded market and build customer loyalty that extends far beyond individual transactions.

Building the future of grocery operations

The difference between reactive and proactive operations comes down to up-to-date intelligence. Stores that embrace this technology gain the ability to anticipate challenges, optimize resources, and deliver consistent customer experiences even during the most demanding periods.

Peak-hour challenges don’t have to be operational nightmares. With the right tools and approach, they can become competitive advantages that differentiate your operation and build lasting customer relationships.