Minding the gap between sensing and execution

Today’s manufacturers have invested heavily in digital infrastructure. According to last year’s MHI Industry Report, 55% of supply chain leaders have increased technology spending, with 42% investing over $10 million. IoT sensors track equipment performance, POS systems capture real-time demand, supplier networks share inventory levels, and machine health indicators predict maintenance.

However, despite all these sophisticated data streams, production planning and scheduling (PPS) remains rudimentary, limited by static spreadsheets, drawn-out planning cycles, and manual workflows. In a world marked by disruption, traditional systems can no longer handle the pressures of today’s changes or constraints.

The issue isn’t data scarcity but converting information into action. Factories possess vast amounts of operational data, yet without responsive planning, this potential remains untapped. Manufacturers find it hard to turn data into quick, informed decisions to ensure product quality, meet demand, and maximize profit. Instead of strategic assets, these potentially valuable insights become background noise.

The answer is transforming PPS from a rigid back-office tool into a responsive, intelligent system through purpose-built AI, agents, and autonomous solutions that seamlessly incorporate sensory signals into execution.

What issues are manufacturers grappling with?

Several major issues currently face manufacturers, increasing the urgency to modernize their planning and scheduling processes.

1. Demand volatility

Modern consumer demand tends to shift quickly and unpredictably, meaning manufacturers must be able to anticipate and adapt production to accommodate these changes in purchasing. But without high-quality demand signals and real-time forecasts, they risk producing based on outdated assumptions, leading to the costly cycle of misaligned production, waste, and service failure. This creates what is known as the ‘signal decay effect’ — when outdated signals leak through production systems, causing operational misalignment that compounds over time and ripples across the business.

Related reading: How signal decay amplifies the bullwhip effect across your supply chain

2. Supply chain shocks

Global supply chains face relentless disruption — pandemic outbreaks, crop failures, geopolitical jockeying. These events share two distinct features: they can occur unexpectedly and rapidly escalate into global production crises. Traditional planning systems, built for predictable cycles, cannot keep pace and trigger costly consequences, from missed orders to excess inventory and rising material costs.

What supply chain shocks do is expose the brittleness of static planning — they are unable to recalibrate when constraints shift in a short space of time.

3. Pressure to hit sustainability goals

Sustainability has shifted from mere boardroom goals to tangible practices on the factory floor. Manufacturers face increasing pressure to achieve specific waste reduction and carbon footprint goals, which influence daily production choices. Each batch planned and ingredient substituted plays a role in fulfilling these environmental commitments. Additionally, upcoming environmental reporting regulations and climate-related disruptions are elevating waste-aware planning to mission-critical status for manufacturers.

However, legacy planning cannot handle the delicate balancing act necessary for maintaining sustainability and profitability — such as balancing shelf-life limitations against overstock risks, reducing spoilage while keeping service levels, or decreasing changeovers without affecting product quality.

Without sophisticated planning, sustainability mandates and profitability often compete, entangling manufacturers in suboptimal zero-sum decisions between ecological goals and margins.

4. Scaling bottlenecks

Manufacturers face a fundamental challenge: pursuing aggressive growth targets while managing rising costs and persistent labor shortages. Unpredictable supply chains and volatile demand have intensified this pressure, while the manual planning processes that many manufacturers still rely on make cost-effective scaling nearly impossible.

As operational complexity grows, manufacturers find themselves needing more resources to manage an increasing volume of routine, manual tasks — from demand forecasting to scheduling. Traditional approaches to expanding this capacity drive up costs through higher personnel investments while failing to address the underlying inefficiencies that prevent scalable growth.

5. Tech investment without ROI

C-suite leaders demand demonstrable value from technology investments without lengthy implementation cycles. This requires clear KPIs upfront — specific, measurable targets that guide implementation and track progress. However, efficient implementation alone doesn’t guarantee long-term returns. Success hinges on organizational adoption, requiring a fundamental shift from hands-on control to systematic decision-making. Stakeholders must trust new systems enough to follow recommendations rather than override them. Without this trust, even promising technology investments fail to deliver transformative results.

The push for autonomous, intelligent systems often faces strong resistance, making organizational inertia a major obstacle to tech ROI.

The critical gaps closed by AI-driven PPS?

There are some key roadblocks preventing manufacturers from achieving operational excellence today. AI-enabled PPS directly addresses these, transforming how factories sense, respond, and optimize their operations.

Separating the signals from the noise

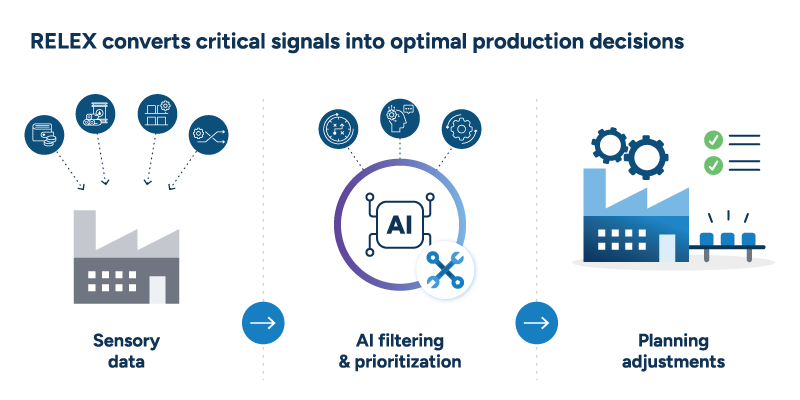

Modern factories generate thousands of data points hourly — from demand forecasts to supply alerts and product quality metrics. But without real-time alignment or intelligent filtering, few manufacturers are able to prioritize what matters most and act on it in time. They struggle to distinguish critical signals from the cacophony of noise. Known as signal overload, the issue often creates confusion and guesswork, leading to production misfires, downtime, and missed market opportunities.

Read more: Overcoming the problem of downtime

A PPS solution like RELEX:

- Captures high-fidelity signals like POS data and weather patterns.

- Through AI, it filters out the ‘noise’ and amplifies signals that require immediate action and matter most to production.

- Automatically feeds these signals directly into production, adjusting schedules to reflect real-time consumption patterns.

RELEX turns the most business-critical indicators into optimized planning decisions. Apparel manufacturers, for instance, can leverage real-time sell-through data to detect changes in seasonal demand or new fashion trends, facilitating quick production adjustments to capitalize on these shifts and effortlessly meet customer demand.

Advanced PPS transforms noisy data into impactful planning decisions, ensuring the right products are ready when customers need them, improving on-time delivery by up to 20%.

Further reading: The path toward production line optimization

Real-world results: Atria used advanced demand forecasting to enhance planning accuracy and efficiency

Atria is one of Finland’s largest suppliers of meat products and the leading food company in Northern Europe. Perishable meat products demand precise daily forecasting to prevent both stockouts and spoilage. Atria needed to synthesize complex, constantly changing information from retail partners into actionable production decisions.

RELEX machine learning capabilities allowed Atria to automatically process and prioritize vast amounts of external data from retail partners. The system instantly identifies and responds to sudden demand pattern changes.

“Following the introduction of machine learning, we were extraordinarily impressed to see just how much further RELEX algorithms could improve our forecast accuracy and stability — improvements critical to our ability to manage the complexity specific to our industry and business model,” said Tapani Potka, SVP, Delivery Chain Management for Atria.

Atria achieved 98.1% weekly forecast accuracy and a 13% reduction in manual forecast adjustments.

Navigating volatility across the supply chain

The reality for supply chains includes global shocks, fluctuating input costs, and limited resources. In fact, from the MHI report mentioned earlier, 50% of companies reported supply chain disruptions and shortages as a top challenge.

Long-term certainty is obsolete. Manufacturers still operating on weekly or monthly schedules — while the world changes by the hour — find that every disruption breaks the link between plan and execution, forcing them into costly cycles of missed orders, excess inventory, and inflated material costs.

Business leaders recognize that something needs to change. Yet, many remain trapped in outdated planning approaches that can’t keep pace with volatility. So, what can they do?

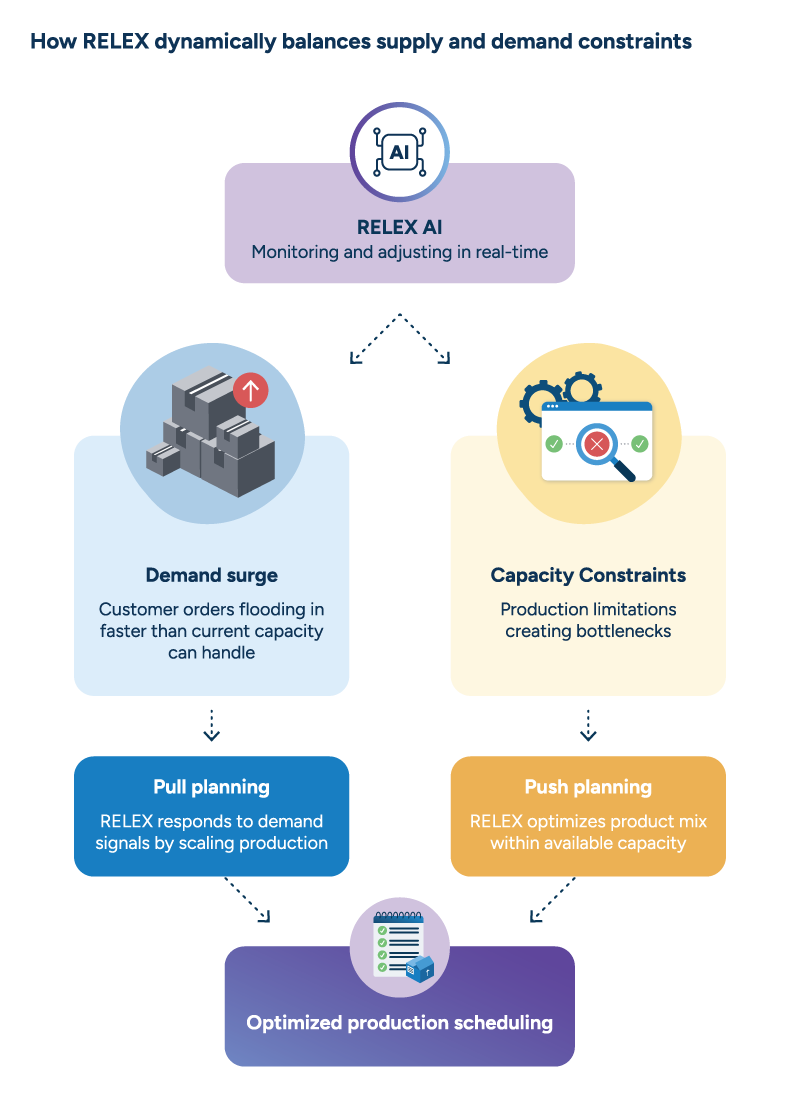

It’s worth considering constraint-aware planning (production planning that adapts to real-time operational limits) from platforms like RELEX, which enables manufacturers to break costly patterns by reconfiguring production plans by the day or hour in response to emerging disruptions. As RELEX integrates forecast-driven production with real-time demand signals, planners can:

- Swiftly rebalance priorities and reorder sequences.

- Respond to market changes while keeping efficiency high.

- Perform at a high level in high-volume, high-variability settings.

The RELEX system can also dynamically switch between push planning (optimizing around available materials) and pull planning (responding to demand signals), automatically adjusting this balance as constraints change. This ensures production always aligns with current reality rather than being locked into rigid planning.

Discover: How touchless planning transforms manufacturing with AI-driven solutions

Real-world results: Tegel Foods optimized production amid supply constraints and changing market conditions

Tegel Foods commands over 50% of New Zealand’s chicken market, processing 50+ million birds annually across three facilities.

The company struggled with input and yield variability—each chicken carcass is different—creating constant challenges in balancing demand for various cuts while minimizing waste. Excel-based planning left teams unable to respond effectively. “We had a lot of data, but the quality was questionable. The planning capabilities were limited, and we had neither the time nor the tools to analyze our plans properly,” says Arijit Saha, General Manager of Supply Chain.

RELEX constraint-aware planning delivers weekly production targets for all three plants with daily demand forecast breakdowns that inform line scheduling decisions. Planners now proactively identify shortages and address surplus situations while working with sales to leverage promotions and substitutions as conditions change.

“To make a profit in our industry, you must use all parts of the chicken in the best way possible. We needed a longer planning horizon and more accurate forecasting to ‘balance the bird’ better,” Saha explains. Line sequencing optimization increases throughput and yields while reducing inventory, waste, and margin erosion—enabling dynamic demand response rather than rigid production schedules.

Seizing the AI opportunity

According to the MHI report, 58% of supply chain companies plan to invest in AI over the next five years, with 27% already deploying some in their plants. But many AI projects never move beyond pilots, leaving production floors reliant on spreadsheets and guesswork. Critical signals slip through cracks, eroding forecast accuracy and service levels while budgets are wasted on errors and haphazard planning.

The gap between AI potential and AI reality has become a costly waiting game that manufacturers can no longer afford. However, the technology to bridge this gap already exists.

RELEX has been developed as an AI-native platform that supports and integrates various intelligent capabilities. From specialized AI to generative and agentic tools, the platform equips companies with market-ready AI solutions that can redefine how they predict, plan, and respond to the challenges they face.

Specialized AI: Instant scheduling with future-ready planning

AI at RELEX centers on purpose-built algorithms — specialized AI designed for specific planning problems and integrated into core functions. Using optimization capabilities and machine learning, this AI performs tasks rapidly and accurately, replacing legacy systems and spreadsheets that can’t handle modern manufacturing’s complex needs. It drives automation like auto-scheduling, which generates schedules based on priorities, rules, and constraints, and tools such as scenario planning to help manufacturers prepare for uncertainty.

Specialized AI relies on the robust tech foundation of RELEX. Strong network security and AI guardrails ensure safe decision-making, while the cloud-native platform delivers high scalability and growth capacity. Intuitive UI makes configuring how these AI capabilities work effortless, with flexible integration for hundreds of ERPs and other systems.

As a unified platform, RELEX can process and leverage data across all planning functions. Linked AI-driven planning modules empower planners to share plans, improving both accuracy and visibility. Every function uses a single database of near-real-time data, enabling more effective AI training, refined calculations, and better business outcomes.

Generative AI: Planning insights sourced through simple dialogue

RELEX adds generative AI capabilities through copilots like Rebot that democratize planning insights across the production process. Through natural conversation, business users can explore multiple scenarios and get answers to critical planning questions without needing to understand the underlying algorithms.

Rebot will soon connect directly to production and customer data to provide insights based on real operational conditions. Combined with its curated knowledge of value chain optimization, access to relevant documentation, and ability to analyze planning data, Rebot will quickly become an integral part of daily planning workflows.

Agentic AI: Acts independently, optimizes continuously

Agents are intelligent systems that autonomously pursue goals using planning and reasoning to take purposeful actions with minimal human oversight. They can solve complex multi-step problems and adapt to changing conditions in near-real-time. From providing various scenarios and their outcomes to delegating tasks to specialized use case agents and implementing changes to business rules, agents can continuously optimize operations.

Let’s say a shipment of necessary raw materials is delayed. Agents will automatically reroute volumes to that factory, making up for the gap in supply, leaving humans to deal with anomalies and exceptions.

Forward-thinking manufacturers utilizing RELEX AI experience improved throughput, reduced downtime, and 25% greater resource utilization without added capex or headcount.

Learn more: A deep dive into AI at RELEX

Real-world results: MAAG Foods embraced AI-driven forecasting, boosting efficiency and planning excellence

MAAG Food is Estonia’s leading meat producer, producing 89,000 tonnes of meat products annually across three manufacturing sites with brands like Rakvere, Tallegg, and Rigas Miesnieks.

In 2023, MAAG Food faced escalating complexity managing over 300 SKUs with volatile seasonal demand using disconnected spreadsheets and manual coordination. The company adopted RELEX AI-driven touchless forecasting, which automatically tracks demand signals and makes planning decisions without human input.

The results demonstrate the power of AI in action: 96% of demand forecasts require zero manual adjustment, leading to a 22% increase in planning efficiency.

“The transformation in our operations has been truly remarkable, and the exceptional support and dedication to enhancing our KPIs have made a tangible impact,” said Martin Küüsmaa, Director of Business Development at MAAG Food. “We are fully committed to leveraging the software to its fullest potential, treating it as our single source of truth for demand planning.”

Delivering on the sustainability promise

With tight profit margins and rising competition, sustainability goals have become much more challenging to reach. Manufacturers face a daily reality where customers and investors demand waste reduction while executives insist that service levels and margins are protected.

However, sustainability isn’t just a corporate value — it’s an operational imperative that directly impacts the bottom line. Resource efficiency influences the management of shelf-life risks, compliance with regulations, and responses to supply shocks, all of which impact growth. Moreover, poor sustainability harms brand reputation, directly affecting revenue as consumers and investors prefer environmentally responsible suppliers.

Yet sustainability goals and business targets are often treated as conflicting forces.

RELEX flips this dynamic, turning waste reduction into an optimization advantage. When ingredient costs spike or supplies get disrupted, manufacturers can instantly simulate recipe alternatives, testing for:

- Environmental impact

- Supply chain efficiency

- Sourcing complexity

The system can also model tariff scenarios alongside sustainability metrics to find more profitable, less wasteful outcomes.

As RELEX includes product attribute data into inventory planning, current stock is rotated based on shelf life to prevent waste and stockouts. Additionally, accurate demand forecasting allows manufacturers to maintain lower safety stock levels while fulfilling customer orders and reducing waste.

Reverse Bill of Materials (BOM) — essentially working backward from customer orders to raw material needs — boosts profitability while eliminating waste. For instance, when a meat processor receives an order for specific beef cuts, RELEX calculates carcass cut requirements to match POS data and optimizes its allocation, ensuring nothing is wasted while keeping supply and demand balanced.

Learn more: How can AI enhance sustainability?

Waste-aware planning helps manufacturers reduce waste by up to 30% while maintaining production quality.

Real-world results: Blount Fine Foods massively reduced food waste through touchless forecasting

Blount Fine Foods, a family-owned manufacturer of premium fresh prepared foods, produces restaurant-quality soups and entrées.

Since implementing RELEX in 2023, Blount has transformed its approach to sustainable manufacturing across operations, managing around 1,500 SKUs. The company achieved waste-aware production planning, reducing finished goods waste by 35% while improving production efficiency by 2% through optimized scheduling that minimizes changeovers and maximizes resource utilization.

“Seeing how changes to sales forecasting impact potential service levels on a longer horizon has allowed us to strategize proactively,” says Jonathan Wells, Sr. Director of Demand Management at Blount Fine Foods. “This has allowed us to make better decisions and explore alternate paths while linking all of our constraints within our manufacturing and supply chain ecosystem to understand the true impact of decisions.”

From static to strategic: The evolution of PPS

While traditional production planning systems lock manufacturers into rigid schedules that crumble at the first disruption, AI-enabled platforms create dynamic operations that adapt and optimize in real-time.

| Traditional PPS | AI-Enabled PPS |

| Static, spreadsheet-based plans Plans and schedules are built and managed on spreadsheets, making them inflexible and unable to adapt to real-time changes. When disruptions emerge, they quickly become outdated. | Dynamic, real-time optimization Production schedules are continuously adjusted in real-time based on evolving constraints, demand shifts, and operational conditions without manual intervention. |

| Siloed, static decisions When planners manually make countless scheduling decisions, bottlenecks emerge and teams become overwhelmed by their workloads, slowing the entire planning process. | AI-driven, guard railed decisions AI autonomously manages complex scheduling decisions within predefined business rules, enabling planners to become more strategic, focusing on work that require human judgement over mundane tasks. |

| Costly changeovers and reworks Traditional systems lead to frequent, expensive equipment changeovers and quality reworks, which drain operational budgets while destroying production efficiency and profitability. | Intelligence sequencing to maximize throughput Smart PPS systems group similar products, slashing changeover time and costs while maintaining production quality and preserving operational margins. |

| Factory as a static node Operating as isolated, unchanging units, factories are disconnected from real-time demand signals, IoT data, equipment status, and shifting market conditions. | Factory as a responsive, self-correcting system Factories become interconnected digital nodes that automatically detect upstream constraints and market shifts while learning from execution data to improve planning accuracy. |

| Demand signals disconnected from production Demand forecasts and production plans exist in separate systems, requiring data to be “massaged and moved” between signal and execution. | Fully connected, signal-to-execution ecosystems All data flows seamlessly from demand signals through production schedules within a unified platform, eliminating manual transfers and ensuring coordinated supply chain decisions. |

The PPS transformation roadmap at a glance

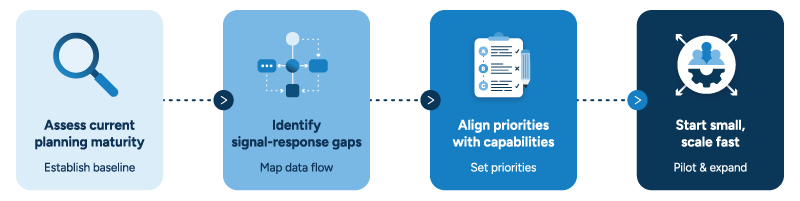

Moving from manual planning to AI-powered operations requires a strategic, phased approach that delivers value at every step. This roadmap shows how manufacturers can systematically evolve from spreadsheet clunkiness to intelligent planning orchestration with minimal disruption.

Assess current planning maturity: Evaluate existing planning capabilities to establish your transformation baseline and identify the biggest operational or capability gaps.

Identify signal-response gaps: Map where valuable data isn’t converting into fast production decisions.

Align priorities with capabilities: Determine which production challenges should be addressed first based on achieving overarching business objectives for growth.

Start small, scale fast: Begin with focused pilots demonstrating clear value quickly, then expand successful use cases across the operation.

The RELEX approach: We deploy in phases that deliver measurable value quickly while avoiding lengthy cycles. Clear KPI targets are established upfront, with demonstrated improvements at each milestone and continuous optimization support throughout.

The strategic core of the smart factory

Volatility will always exist, but production planning can, and should, react accordingly. Manufacturers who integrate sensing, planning, and execution in one connected, adaptive system will build the resilience needed to thrive amid disruption.

What next-generation planning delivers

Advanced PPS solutions like RELEX unlock new possibilities:

- Stability through demand volatility: Market fluctuations become profit opportunities as dynamic scheduling captures upside while protecting against downside risk.

- Supply shocks lose their sting: Multi-layer resilience activates automatically —switching suppliers, reformulating recipes, resequencing production — maintaining operations when competitors stumble.

- Waste reduction becomes tangible: Every production run optimizes the balances between freshness, fulfillment, and financial performance — a sustainable operation that improves the bottom line.

- Turn planners from manual schedulers into strategists: By deploying automation to handle routine optimization, teams can focus on more critical tasks, such as supplier negotiations, network design, and competitive positioning.

Of course, PPS transformation cannot happen through good intentions and strong vision only. It requires the right capabilities to process complex constraints in real-time, connect demand signals to execution, and deliver value from day one.

You’ve modernized the signals. Now modernize the response.

Ready to see how AI can streamline your operation?