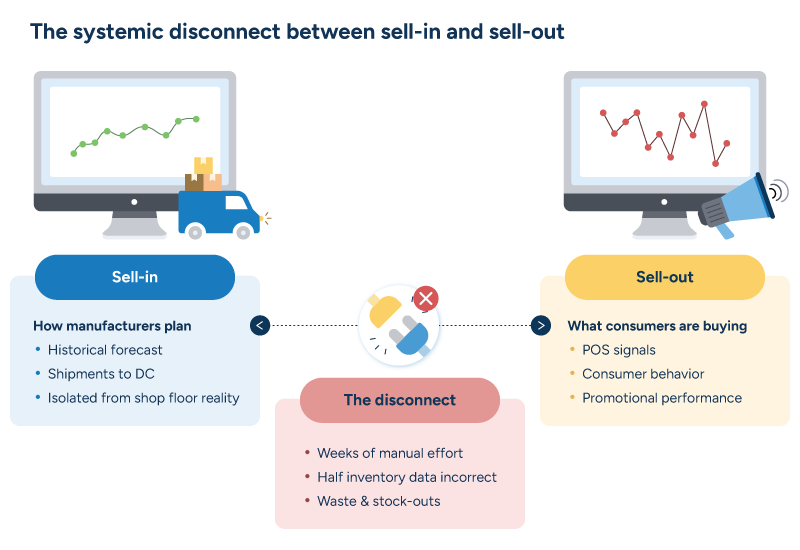

At the intersection of manufacturing and retail lies a systemic disconnect: sell-in (what manufacturers ship) rarely aligns with sell-out (what consumers buy). Manufacturers plan based on historical shipments, hoping the past predicts the future. Consumers shop based on fleeting needs that manufacturers can’t see until it’s too late.

This disconnect gives rise to a series of issues: Stockouts during promotions, excess inventory, waste, and strained commercial relationships. Retailers face inconsistent on-shelf availability. Consumers experience disappointment and stop trusting brands they were once loyal to.

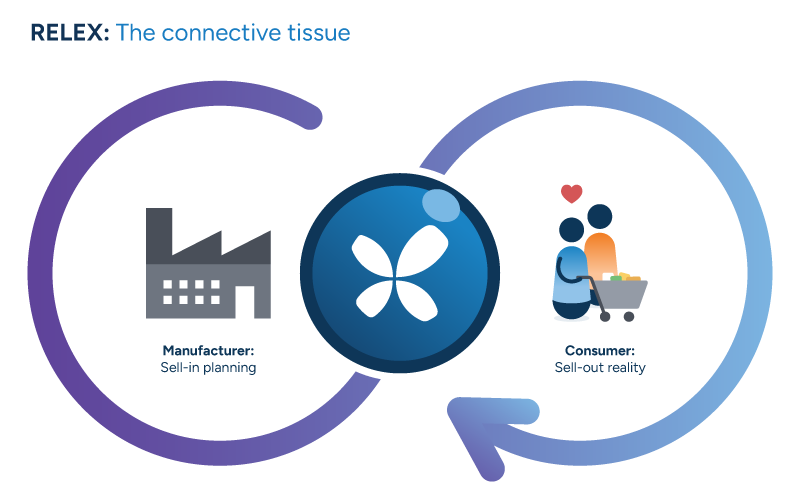

Retail Connected Planning flips the script. It fuses sell-in with sell-out through point-of-sale data and real-time forecasting, transforming disconnected collaboration into coordinated execution—creating winners at every stage of the value chain.

How manufacturers find themselves planning in the dark

Manufacturers traditionally look at three years of historical sell-in data—such as shipments to retailer distribution centers (DCs)—and project future demand accordingly. Without visibility into retail sell-out, this backward-looking approach produces substantial risk:

- Emerging trends and demand shifts go undetected.

- Stockouts at DCs quickly undermine active promotions, cutting into ROI.

- Production and purchasing plans consistently miss the mark, overproducing or running short on raw materials.

Consider the following scenario: A manufacturer launches a promotion based on historical patterns but underestimates this year’s demand. Retailers downstream soon face empty shelves during the peak promotional period. Both parties lose revenue, and consumer trust erodes. For the manufacturer, the impact courses through the operation, affecting production planning and material procurement while warping financial projections.

The portal predicament in planning

Manufacturers recognize that accessing shared retail data is a prerequisite to planning success. But every retailer shares data differently. Commercial teams spend hours logging into multiple portals, converting formats, and manually aligning spreadsheets. When teams finally consolidate the data, the market has already moved on. Delayed responses strain retailer partnerships, while planners waste hours on administrative tasks that automation could perform instantly.

The breakdown: Consequences of disconnected planning

The impact of disconnected planning is comprehensive. Manufacturers lack visibility into true demand, leading to unreliable fulfillment. Retailers measure success through on-shelf availability and are confronted by frustrated customers pointing to empty shelves. Yet manufacturers report high on-time-in-full scores, a metric that measures shipments to DCs, not what’s actually available to consumers.

| Who | The consequences |

| Manufacturers | – Forecast blind spots – Demand-supply mismatch – Stockouts during promotions – Penalties, chargebacks, disposal costs |

| Retailers | – Misaligned KPIs with suppliers – Empty shelves and dissatisfied customers – Costly emergency shipments – Brittle supplier relationships |

| Consumers | – Products unavailable when needed – Forced substitutions or disappointments – Inconsistent shopping experiences – Ruined brand trust |

There’s a better way, one that unites manufacturers and retailers around a shared reality: what consumers are buying and how to plan for it.

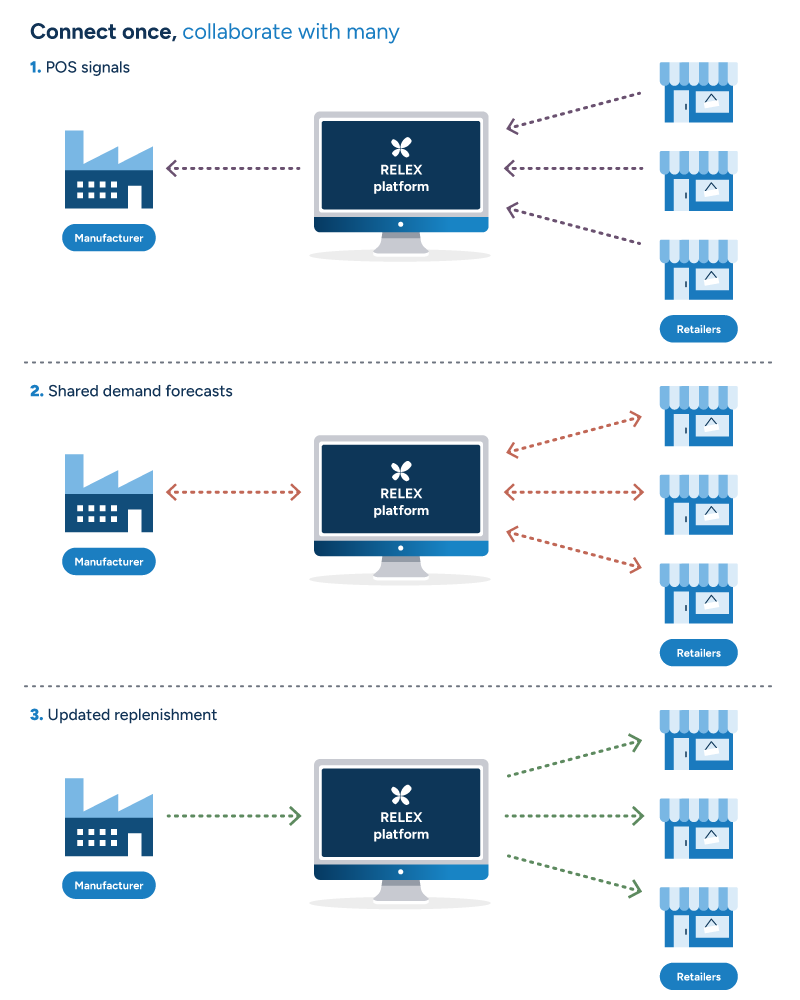

This is Retail Connected Planning from RELEX. Manufacturers sense real-time demand directly from store networks, collaborate with multiple retail partners on a single platform, and execute with confidence. The solution achieves this through a one-to-many network model, which enables the manufacturer to connect once and interact with multiple retail partners.

Learn more: How suppliers and retailers share data and collaborate seamlessly

The advantages of a one-to-many network model

Once a commercial agreement is in place, a one-to-many network serves as the connective tissue between manufacturer and retailer, allowing information to flow freely, securely, and in real time.

What makes this planning approach truly valuable?

Underpinned by a deep retail heritage

RELEX was born in retail, designed to handle high-SKU complexity, data intensity, and execution speed at the store level, including intraday replenishment for some stores. The platform processes the same granular POS signals that retail partners see daily, turning transaction data into coherent demand insights for production and distribution.

This retail underpinning solves a previously intractable challenge for manufacturers. While traditional systems can’t process granular retail data at scale, RELEX handles this complexity as a standard capability, allowing manufacturers to understand actual consumer purchases rather than approximations from DC shipments or historical patterns.

Provides one network for multiple collaborations

The retail connected planning network effect replaces fragmented planning processes with highly organized collaboration. Rather than logging into five, ten, or fifteen separate retailer portals, each with different formats and data structures, manufacturers connect once to RELEX and can access multiple retail partners through a single, harmonized system. Every partner operates from the same synchronized dataset with a transferable format.

When manufacturers connect with retailers already using RELEX, setting up collaboration becomes more straightforward. The shared platform removes the hassle of negotiating divergent technical specifications or investing in custom integrations for each retail partner. Instead, manufacturers can expand their retail network via a single, consistent interface, with each new connection following the same standardized process.

Automated data translation makes this standardization frictionless, converting different product identifiers and formats behind the scenes. Once manufacturers and retailers connect, data sharing becomes as simple as turning on a faucet; no manual mapping, lengthy IT projects, or costly integrations required.

Powered by explainable AI & collaborative intelligence

Forecast accuracy is pivotal to retail connected planning, but trust in those forecasts matters just as much. Without transparency into how forecasts are generated, confidence weakens, grinding any collaboration to a halt.

RELEX addresses these transparency issues with explainable AI. Forecasts break down into understandable components—base demand, trend, seasonality, and promotion uplift—showing exactly what drives each projection. Both manufacturers and retailers see where the numbers come from, replacing opaque black-box predictions with crystal clear, shared reasoning.

This transparency amplifies manufacturers’ intrinsic advantage. While retailers manage 30,000-100,000 items across their stores, manufacturers focus on the specific products they produce, giving them deeper category expertise and attention to each SKU than retailers can. With RELEX providing retail-quality data from their partners, manufacturers can apply this focused expertise to spot trends early, adjust for seasonality, and improve on-shelf availability downstream.

Learn more: The toolkit for business leaders implementing AI in the supply chain

Unifying planning, from production to the shop floor

Manufacturers have traditionally worked on separate solutions: one for demand planning, another for supply, and a third for production scheduling. Connecting these systems requires expensive middleware, yet conflicting forecasts and data silos still emerge. This leads teams to waste time on manual reconciliation, using spreadsheets to fill operational holes that shouldn’t even exist.

RELEX eliminates these silos with a unified platform where demand, supply, and production planning operate on the same AI-native infrastructure. Data flows uninterrupted from retail shelves through the entire supply chain. When demand fluctuates, RELEX automatically adjusts replenishment orders, production schedules, and raw material requirements without the discrepancies or conflicts inherent to isolated technologies.

The system’s machine learning continuously improves forecasts, while autonomously executing routine decisions, allowing manufacturers to respond to market changes in real time. Freed from repetitive manual work, planning teams are able to focus on strategic initiatives that drive growth.

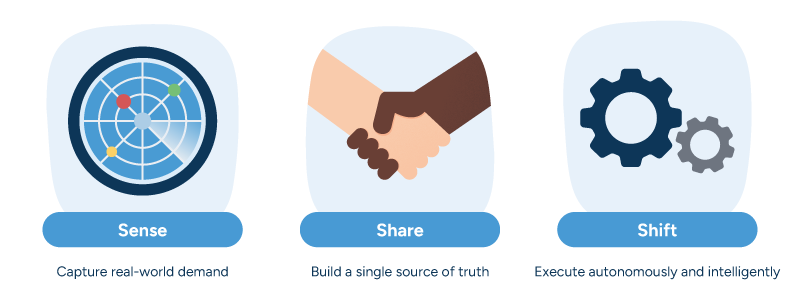

The three stages of retail connected planning

Retail connected planning bridges production, distribution centers, and retail stores by interlacing the three key stages—sensing, collaborating, and shifting—in an ongoing cycle. Demand is identified through unified POS intelligence and real-time forecasting. It blends sell-in with sell-out, enabling harmonious collaboration between manufacturers and retailers.

Let’s deconstruct the stages.

Sense: Capture real-world demand

Every day, millions of purchases—online and in stores—reveal what consumers want. Unfortunately for manufacturers, these critical signals are often obscured by incomplete, outdated data riddled with inventory inaccuracies.

RELEX addresses this through integrated capabilities that work together:

Unified retail intelligence: POS transactions, store inventory levels, promotion calendars, and event data reveal what’s happening at the shelf level. Manufacturers can tap into emerging trends, catch promotional performance issues early, and adjust before inventory runs dry. As a result, planning becomes responsive to market shifts.

Context enrichment: With the addition of insights into weather patterns, social trends, and competitive signals, manufacturers gain a deeper understanding of how demand patterns evolve and how to respond. RELEX fuses these contextual indicators with retail data, capturing influences that historical patterns alone miss, such as sudden hot temperatures driving cold beverage sales or viral moments that cause unexpected demand spikes.

Inventory checks & diagnostics: Powered by specialized AI, True Inventory detects and fixes inventory data discrepancies, phantom stock, and errors peppering inventory records. Root cause analysis identifies the drivers of stockouts and excess, revealing whether issues stem from forecasting errors or data problems. Finally, forecasts reflect what’s happening along the value chain, no longer distorted by flawed data.

Real-world results: Atria captured demand more efficiently and with greater precision through advanced forecasting

Atria, a major Northern European meat manufacturer, experienced poor forecast accuracy and excessive manual adjustments, hindering market responsiveness. Dealing with short shelf-life products required precise day-level forecasts to ensure high retailer availability while minimizing waste.

ML-powered forecasting from RELEX helped them plan more effectively for high-volume holiday periods and demand shifts driven by external regressors, incorporating retail price data and partner assortments to generate automatic projections.

Results include:

- 98.1% forecast accuracy at week level.

- 13% reduction in manual forecast changes.

“We were extraordinarily impressed to see just how much further RELEX algorithms could improve our forecast accuracy and stability.”

Tapani Potka, SVP, Delivery Chain Management.

Share: Build a single source of truth

Accurately sensing demand solves only part of the problem. Manufacturers and retailers must stop planning in isolation and start operating from a single source of truth.

For many partnerships, collaboration falls short because the technological foundation isn’t there. Retailers share data through scattered portals while manufacturers consolidate spreadsheets manually. Commercial teams schedule monthly meetings to reconcile forecasts that have already diverged. By the time alignment happens, the market has moved on.

RELEX changes this by synchronizing sell-in planning with real-time sell-out data:

Data sharing and forecasting alignment: Once bilateral agreements are in place, RELEX provides a centralized platform that connects manufacturers and retailers. Data flows securely and continuously between partners, eliminating delays and minimizing inconsistencies. Both parties work from a synchronized view, seeing the same POS data, inventory levels, and demand drivers, so there’s no more conflicts from differing forecasts.

Shared dashboards for coordinated planning and inventory: Role-based dashboards allow commercial teams and planners to merge demand plans, agree on replenishment strategies, and coordinate promotions, supporting CPFR, VMI, and DSD collaboration models. This creates a proactive partnership dynamic: manufacturers can recommend reducing orders when excess inventory accumulates or to increase stock when promotions fuel demand—all backed by shared data.

Automated cross-system data harmonization: Manufacturer-retailer collaboration only works if their systems can talk to each other. RELEX acts as the universal translator, matching product identifiers and converting formats, so when one retailer calls an item “Product_X_001” and another calls it “ProductX-Large-Blue,” the platform recognizes them as the same item and synthesizes them instantly.

Real-world results: Samworth Brothers unified retail and supply chain planning

Samworth Brothers, a British food manufacturer operating 19 sites with over 12,500 employees and £1.3 billion in annual turnover, sought to replace its legacy planning solution with AI-driven solutions to reduce food waste, automate operations, and minimize manual labor across their 300 SKU portfolio.

RELEX, alongside Atheon and Logic, enabled unified planning with AI-driven forecasting and customer-level demand visibility. Standardized KPIs and integrated analytics created a single source of truth, allowing for more successful collaboration with retail partners.

Results include:

- Unified planning for all sites.

- Standardized planning metrics.

- Established a single source of truth.

“RELEX has a proven track record of improving on-shelf availability, reducing waste, and optimizing inventories. We are realizing our vision to deliver solutions that will increase sales and revenue.”

Rob Muir, Group Digital Director, Samworth Brothers

Shift: Execute autonomously and intelligently

Sensing demand and establishing collaboration set the stage. The operational shift occurs when store-level signals flow directly into execution: demand changes trigger DC replenishment and adjust factory production automatically. For instance, RELEX manages replenishment and scheduling on its own without human oversight and optimizes raw material purchasing through constraint-aware planning.

AI-powered replenishment and constraint-aware planning: RELEX automates DC replenishment based on true demand, as multi-echelon planning connects store needs directly to factory production. For perishables, fresh optimization balances shelf life with sales velocity. Production scheduling and raw material purchasing respond to sell-out in real time, reducing reliance on sell-in assumptions. Exception-based management only alerts planners to decisions that require human judgment.

Real-time scheduling and sequencing optimization: When a product sells rapidly at stores, RELEX sends this signal directly upstream to the manufacturer. DCs automatically adjust orders; supplier DCs recalibrate shipments; and production schedules adapt. It works like pulling a rope: the consumer tugs one end at checkout, and the factory feels it immediately at the other end, responding in real time to real consumption patterns.

Generative and agentic AI: RELEX uses AI at multiple levels to enhance or automated decision-making. Generative AI copilots, such as Rebot, function as on-demand advisors, analyzing patterns, highlighting exceptions, and recommending optimal actions. Agentic AI goes further, executing decisions autonomously within defined parameters and coordinating system interactions without human intervention. Specialized agent networks handle diagnostics, supplier management, and complex workflows at scale.

Learn more: How AI diversification builds scalable, profitable tech stacks

Real-World Results: Mesterbakeren achieved touchless planning for fresh bread production

Mesterbakeren, a leading Norwegian fresh bread producer operating 9 bakeries, manages direct-store-delivery to a major grocery retailer—controlling both production and store replenishment. The problem it had was its custom-built forecasting, which lacked the accuracy and speed needed to synchronize production with shelf-level demand across hundreds of stores.

The company replaced it with ML-based forecasting from RELEX, which incorporated promotions and seasonality to deliver accurate demand visibility. This meant they could align production with retail, balancing shelf life with demand, optimizing for fresh products, and preventing stockouts caused by system inaccuracies. Finally, Mesterbakeren used exception-based planning to automate routine decisions, so the team could focus on strategic priorities.

Results include:

- 95%+ forecast accuracy.

- 30% waste reduction.

- Improved product freshness at shelf.

“RELEX gives us the visibility to plan with confidence. This helps us cut waste and use our resources more effectively.”

Terje Jensløkken, Head of Sales Planning and Analysis.

A win-win-win for manufacturer, retailer, and consumer

Retail Connected Planning from RELEX creates value across the entire value chain. With every decision based on a shared, aligned reality, manufacturers replace uncertainty with precision, retailers achieve higher service levels and stronger profitability, and consumers experience the reliability and consistency they expect from modern stores.

This isn’t a zero-sum game. Closing the loop between demand, supply, and execution leads to better outcomes for manufacturers, retailers, and consumers alike. With retail connected planning, everyone wins.

| Benefits | Outcomes | |

| Manufacturer | – Fewer returns and deductions – Reduced waste and obsolescence – Improved inventory turns – Lower carrying costs – Stronger retailer relationships | – Improved OSA – Higher percentage of customer POs fulfilled on-time-and-in-full – Fewer manual interventions; boosted planner productivity – Sales enabled by better allocation – Decrease in retailer penalties for non-compliance |

| Retailer | – Reliable supplier relationships – Waste reduction supporting ESG goals – Higher store service levels – Improved promotional ROI through better collaboration | – Improved OSA, fewer expedites – Reduced supply chain cost-to-serve – Less spoilage of perishables – Revenue uplift and customer retention |

| Consumer | – Fresh, high-quality products – Consistent shopping experiences – High product availability – Sustainable product choices | – Products available when and where needed – Fewer substitutions or disappointments |

The value of retail connected planning is clear

Manufacturers cannot keep their heads in the sand. The disconnect between sell-in and sell-out needs a scalable, systematic transformation. As this guide has shown, they can go a long way toward achieving this transformation by implementing a retail-connected planning solution.

- Store demand shifts become opportunities rather than crises.

- Coordination with multiple retailers becomes seamless.

- Better forecasts drive bottom-line results and high OSA.

- Planners move from pure execution to needle-moving strategy.

RELEX enables manufacturers to sense demand, collaborate seamlessly, and automate execution on one connected platform. It’s time to stop planning in the dark and start executing on real-time consumer demand in lockstep with retail partners.