The tale of disconnected DIY retail planning

Converging forces in the DIY and home improvement industry in recent years are demanding a fundamental rethink of how its retail sector should operate. Among these forces are four core and interconnected shifts that are creating both challenges and opportunities:

- Macroeconomic uncertainty, like inflation, tariffs, and shifting taxes, is impacting mortgage rates and consumer spending power. Homeowners are staying in their existing homes longer and greatly reducing their spending on remodelling.

- Seasonality and increasingly unpredictable weather patterns are putting a strain on accurate forecasting methods that rely on historical patterns. Retailers are left with unsold seasonal products, and slow movers increase storage costs.

- Customer expectations are changing, with shoppers researching products online and checking same-day availability, creating pressure to ensure a seamless customer experience across all shopping and fulfilment channels.

- AI advancements provide retailers with opportunities to respond more quickly and accurately than manual processes allow. However, developing solid strategies for implementing and adopting AI capabilities at scale proves increasingly challenging.

These shifts create margin pressure as capital becomes trapped in the wrong locations, markdowns increase, and service gaps negatively impact customer satisfaction. This guide explores best practices for DIY retailers to enhance margins by integrating decisions end-to-end, leveraging AI-powered solutions that learn from outcomes and continually adapt.

The DIY retail challenge: Why traditional approaches are failing

The global DIY and home improvement retail market is expected to reach USD 1.17 trillion by 2030. Yet growth has begun to slow across the U.S. and Europe, with major DIY retailers reporting weaker demand and intensifying margin pressure from inflation, logistics costs, and reduced discretionary spending.

Most DIY retailers lack visibility into their end-to-end inventory due to legacy platforms that are unable to unify all processes, including space, assortment, forecasting, supply chain, pricing, and store execution. This results in a fragmentation problem, creating:

- Excess stock in some locations while shelves remain empty in others, leading to carrying costs and disappointed customers.

- Erosion in customer trust due to gaps in “online” versus “in-store” availability.

- Increased markdowns that chip away at margins and profitability for seasonal items.

- Rising costs for labor and transportation to correct stock imbalances.

DIY retailers need unified, AI-driven planning that is purpose-built to meet their unique needs, such as:

- Seasonal and regional variability planning that utilizes AI-driven forecasting that anticipates demand sensitivity at the product-location level, driving localized assortments for diverse climates and customer needs.

- Weather-driven demand forecasting that incorporates actual and forecast weather data with category-specific impacts, enabling fast response to severe weather or regional natural events.

- Bulky products with special handling or holding requirements are managed through space-aware replenishment that aligns inventory with planograms.

- Slow-moving products and those with “lumpy” demand that require highly accurate, localized forecasts to ensure availability when peaks occur, but minimize holding and overstocks when demand is low.

- Store execution strengthened by a mobile solution that provides real-time inventory visibility directly to store associates.

- Truckload optimization by assessing diverse product variables, capacity, and minimum requirements to increase efficiency and decrease transportation costs.

- Supplier volatility for a vast product range, consisting of short- and long-lead time products, that needs to be able to respond rapidly to changing economic conditions and constraints.

DIY retailers who adopt advanced, truly AI-enabled platforms for connected planning across forecasting, replenishment, pricing, promotions, allocation, and space will surpass those who continue to rely on legacy systems.

The RELEX Platform: Unified, AI-driven planning

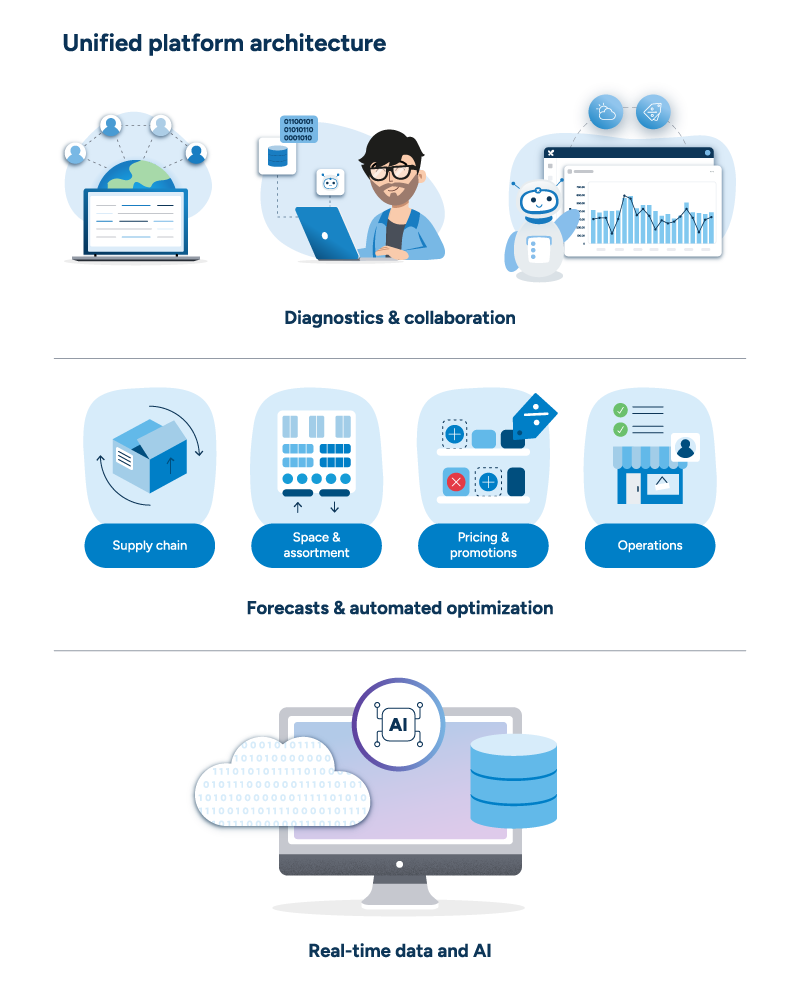

When all solutions work as one unified platform, the value multiplies. Forecasting informs replenishment, pricing, and space allocation. Promotions take into account inventory position and space constraints. Space planning reflects demand patterns. Store execution connects to upstream planning. Supply chain aligns with merchandising strategy. Every decision reinforces others rather than creating conflicts.

RELEX delivers an end-to-end AI-native platform that connects all retail planning and execution processes in a single solution:

| Capability | What It does |

| AI-driven forecasting | Demand forecasts at the product-location level incorporate seasonality, weather, and promotional plans. |

| Automated replenishment | Forecasts propagate through the supply network to create optimal, capacity-based replenishment recommendations. |

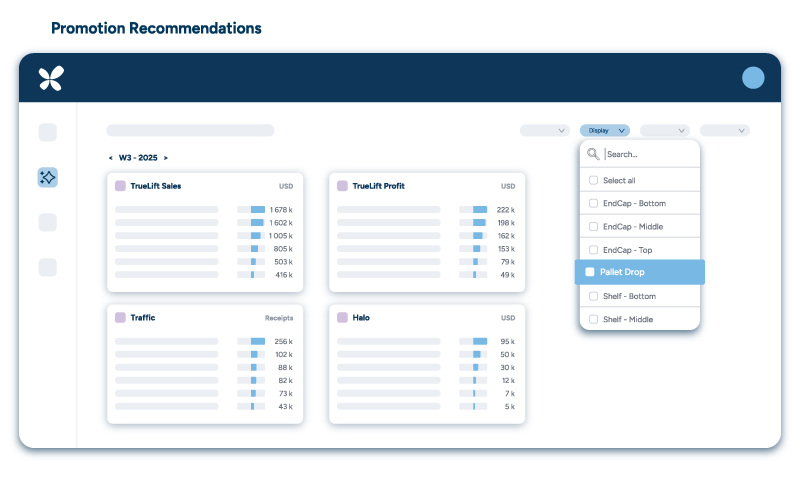

| Pricing & promotion optimization | Coordinated pricing considering inventory position, space constraints, and demand forecasts. |

| Space & assortment optimization | Product assortment and space allocation are to local demand patterns for store-level planning. |

| Supply chain optimization | Digital twin modeling propagates demand across all echelons, optimizing inventory flow from suppliers to stores. |

| True Inventory | Real-time visibility of stock positions across stores, DCs, and channels, acting as the single source of truth. |

| RELEX Mobile | HQ plans are directly connected to store teams for consistent execution and planogram compliance. |

| RELEX Diagnostics | Root cause identification surfaces issues early and enables scenario testing before changes are made. |

Automation at scale

Managing 10,000 SKUs across 100 stores means one million product-location decisions. And as retail continues to scale across assortments, regions, and channels, manual processes cannot keep pace.

RELEX enables retailers to automate manual processes as they grow, combining the power and speed of AI to allow planners to focus on strategic initiatives and manage exceptions.

- Forecasting at the product-location-channel level ensures that the impact of demand drivers on a specific SKU is maintained at a very granular level. The RELEX system can automatically generate thousands of order recommendations daily, which users can monitor and adjust as needed.

- Data management and processing power are critical for running granular forecasts, especially as store counts and product ranges expand. RELEX manages massive data sets efficiently, at minimal cost, providing on-demand results with in-memory computing and in-database processing, all without requiring additional headcount.

- Empowering users with the autonomy to adapt faster, solve planning challenges, and seize sudden market opportunities, RELEX Business Rule Engine enables teams to automate and customize processes, proactively monitoring supply chain performance and activating strategic responses to recurring challenges and market shifts.

- Surfacing exceptions and providing explainable calculations fosters users’ trust in the system’s output. Eliminating “black box” calculations and putting users in ultimate control establishes the credibility needed for any automated system, encouraging its adoption and continued use as the business grows.

Unified data & visibility

A unified data layer provides a single source of truth across the organization, integrating all systems, including ERP, WMS, POS, e-commerce, and merchandising tools through shared capabilities, including:

- Digital twin modeling mirrors real conditions in real-time across the entire supply network, providing insights into the impacts of potential changes before they are made.

- Scenario planning tests supply chain scenarios using live data; understand cascading impacts before implementation.

- Predictive analytics provide forward-looking inventory projections, demand sensing, and risk identification of situations such as stockouts, overstocks, and obsolescence.

- Configurable dashboards can be easily adjusted by users to display inventory health, service levels, forecast accuracy, financial metrics, or any operational metrics required based on current business needs.

- Data transparency drives confident decision-making with every forecast showing contributing factors and every recommendation delivering logic and clear root cause analysis.

RELEX agents: Real AI, real results

The journey from traditional automation to agentic AI is a transformative one. Traditional automation follows rigid rules, and machine learning makes predictions. Agentic AI, on the other hand, is poised to change the entire landscape of retail decision-making.

For example, in traditional root-cause analysis, a dashboard flags supplier delays that planners must manually investigate, adjust parameters across potentially hundreds of affected SKUs, and wait to see if the changes work. RELEX AI agents can autonomously rectify detected issues and continuously monitor outcomes, learning from each intervention to prevent similar issues from recurring.

RELEX AI agents deliver four critical benefits for retail executives evaluating AI investments:

- Speed: Agentic AI operates at machine speed while maintaining human oversight for strategic decisions.

- Scale: Agents handle millions of micro-decisions that would overwhelm human planners.

- Consistency: Every decision follows best practices while adapting to local context.

- Evolution: The system becomes more intelligent with every interaction, without requiring new implementations.

Real-world results: Supplyhouse.com boosts supply chain efficiency and accuracy with RELEX

SupplyHouse.com, a privately owned e-commerce business focusing on the U.S. market, improved their long-term forecast accuracy using the REELX platform’s AI-powered algorithms to analyze demand drivers and generate accurate forecasts that better align inventory with actual demand.

The company also implemented a process to balance delivery schedules, preventing bottlenecks and ensuring a steady flow of goods to the distribution centers. Additionally, automated replenishment processes have significantly reduced the need for manual order maintenance, allowing staff to focus on more strategic tasks.

Improvements include:

- Decreased split shipments significantly due to more accurate forecasting and efficient replenishment.

- Optimized inventory levels, which led to greatly reduced inventory investment and holding costs.

- Improved primary fill rate over the previous year, ensuring timely availability of inventory and reducing obsolescence.

“RELEX has allowed us to greatly improve our efficiency in the day-to-day tasks of a demand planner. This has made room for the team to evolve into more of a strategic partner to the organization.”

Kaytee Grey, VP Fulfillment Operations, SupplyHouse.com

5 critical DIY retail challenges and how to solve them

Challenge 1: Seasonality & product lifecycle

Seasonal products represent significant opportunities and substantial risks. Up to 35% of annual DIY sales are concentrated within narrow 8- to 12-week seasonal windows. With so much of their success dependent on seasonal execution, DIY retailers are fully aware that missing that narrow window means full-price selling opportunities evaporate, leaving markdowns as the only alternative.

Further, weather dependency and space constraints add pressure, as unseasonable conditions can devastate carefully planned seasonal strategies. And seasonal merchandise often requires a substantial amount of floor space and efficient transitions between seasons.

The RELEX platform utilizes a connected three-phase approach that coordinates pre-season, in-season, and end-of-season decisions, ensuring consistent availability during peak seasons and maximizing customer experiences.

Pre-season planning

Front-loading risk requires inventory commitments to be made up to 18 months prior to the start of the season. Using legacy systems, these commitments are based on broad forecasts that have little flexibility once the orders are placed.

With RELEX, AI-driven forecasting predicts the timing and magnitude of seasonal peaks at the store level using historical patterns, weather data, and regional profiles. The result is the right seasonal products available when customers want them. Grills are available when the weather warms, snow blowers are stocked before the first snowfall, and décor and green life are abundant at just the right time for customers to start their projects.

In-season execution

Once the season begins, actual sales may not align with pre-season forecasts due to various factors, such as shifting weather patterns or regional economic fluctuations. Plans made with legacy systems and manual processes are too rigid and time-consuming to adjust mid-season without incurring significant labor and transportation costs.

The RELEX platform continuously monitors the entire network and automatically makes recommendations for reallocating inventory from slow-selling to fast-selling stores. Inventory can be moved where it is needed most, efficiently and accurately, maximizing sell-through and minimizing over- and understocks throughout the season.

The system also recommends any supplemental orders that may be needed if actual demand appears to outpace the initial plan. Further, capacity optimization prevents these bottlenecks by modeling store and distribution center workloads and adjusting delivery schedules accordingly.

Post-season transition

Although all retailers strive for perfect sell-through, markdowns are an inevitable part of the highly seasonal retail landscape. Retailers relying on legacy systems are often challenged with reactive markdowns, where clearance pricing is applied uniformly without considering local inventory or remaining demand.

End-of-season optimization with RELEX enables retailers to identify the optimal markdown timing by store, taking into account local inventory positions and remaining selling opportunities. Retailers can set the best prices possible for remaining inventory at the store level, reducing excess inventory holding, minimizing waste, and protecting margins.

Real-world results: Plantasjen achieves remarkable gains in availability, sales, and inventory turnover

Plantasjen, Scandinavia’s largest garden center chain, faced several challenges after rapid growth: Store personnel were responsible for manually replenishing year-round items. At the same time, a central team handled seasonal items, often pushing the entire available stock into stores well ahead of the season.

After partnering with RELEX, they introduced a “push-pull-push” strategy for seasonal items, combining pre-season allocation, in-season replenishment, and end-of-season allocation. This approach ensured high availability and attractive store presentation while minimizing residual stock.

Improvements include:

- 10% increase in central warehouse service level in many categories.

- 32% decrease in total in-store inventory value.

- Increased accuracy of pre-season allocation, enabling more efficient stock clearance.

“While time spent on ordering is a fraction of what it used to be, the gains in availability, sales, and inventory turnover are remarkable.”

Anna Ståhle, Nordic Supply Planning Manager, Plantasjen

Challenge 2: Demand volatility & visibility

Multiple factors compound the complexity of demand forecasting for DIY retailers. For example:

- Seasonal swings move products from top sellers to dead inventory in weeks.

- Weather variability negatively impacts categories, such as warm winter killing snow equipment sales, or a rainy summer dropping demand for patio furniture.

- Extreme events and natural disasters create instant demand spikes, such as hurricanes, which drive a sudden need for generators and roofing materials.

- For builders and commercial customers, housing market dynamics have a direct impact on project spending.

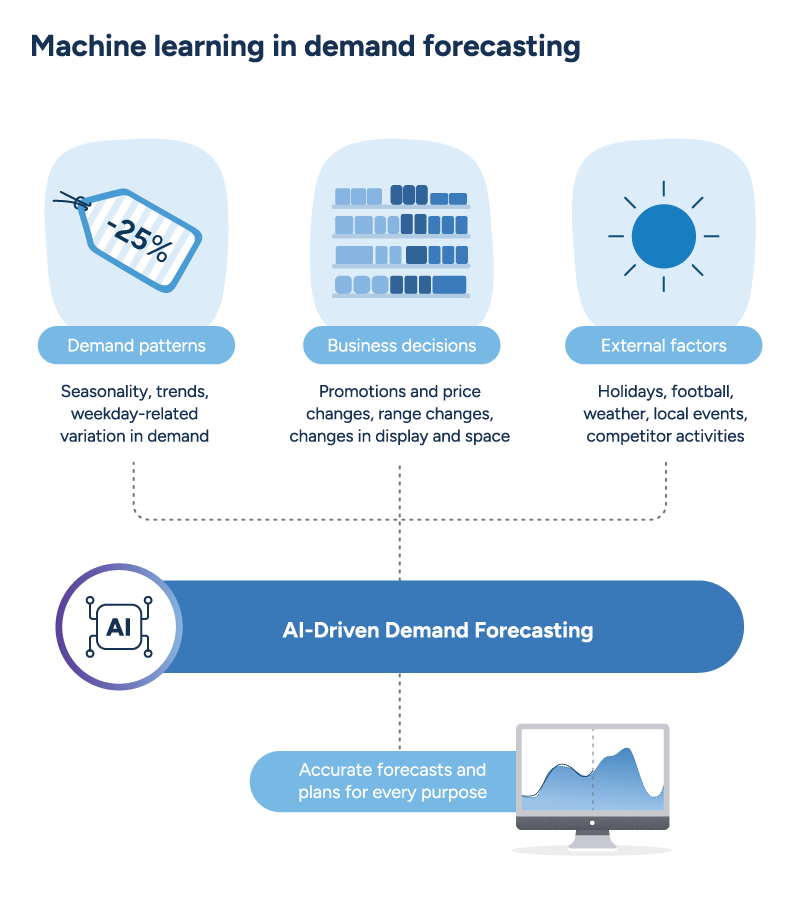

Traditional forecasting, primarily based on historical patterns, can’t factor in sudden weather, seasonality, and extreme events simultaneously. Machine learning-based forecasting incorporates recurring patterns, internal business decisions such as promotions, supplier diversity, and assortment changes, as well as external factors like weather, holidays, and competitor activities. The AI-enabled system learns to recognize anomalies and adapts, increasing accuracy over time.

The nature of many DIY and home improvement products is not only highly seasonal, but also highly regional. One of the biggest challenges caused by inventory visibility gaps is overstocking in some stores while understocking in others on the same items.

RELEX True Inventory reconciles system inventory records with physical reality, delivering accurate stock positions across the entire network, including stores, DCs, and e-commerce channels, ensuring consistent availability across all channels.

True Inventory enhances store operations by freeing staff from the burden of constant manual counting and enabling them to focus on serving customers and driving sales. Instead of being stuck in a perpetual state of reacting to events, store managers utilize data-driven insights that enable them to prevent problems before they occur.

All retailers struggle with reactive problem-solving, discovering issues after they’ve already impacted customers and scrambling to fix them.

RELEX Diagnostics uses automated reasoning to identify data inconsistencies, detect outliers, and prioritize issues by impact, proactively surfacing problems most likely to cause stockouts or excess inventory.

This proactive approach enables interventions when they are most likely to drive results. When RELEX Diagnostics identifies root causes, such as potential stock-out risks for a key promotional or seasonal product, buyers can expedite deliveries or adjust order timing rather than disappointing customers and losing sales.

The data granularity for newly introduced, seasonal, or slow-moving products is often quite limited. This data scarcity makes it challenging to distinguish the effects of demand influencers, such as weather, price adjustments, display changes, seasonality, or competitor actions, when forecasting demand.

The most effective method for overcoming low volumes and sparse data at the product-store/channel level involves data pooling. This technique requires the retailer to aggregate or “pool” the data they generate across various dimensions, such as:

- Sales channels

- Product types

- Store locations

- Time periods

- Customer behavior, preferences, and demographics

- Promotional data

The pooling of this data enables machine learning algorithms to draw on a richer dataset, ensuring that the collective insights contribute to a better understanding of demand influencers and minimize the impact of long-tail demand variations.

Data pooling also serves as a foundational technique for multilevel modeling, which facilitates a high degree of automation and robustness, enabling algorithms to adaptively choose the appropriate level of analysis — be it product-store, product-region, or product-chain — without manual intervention. This approach not only mitigates the risks associated with sparse data but also enhances the scalability and accuracy of demand forecasting for long-tail products.

Real-world results: porta achieves 96% availability while cutting inventory investment

porta, to maintain market leadership as a leading German furniture retailer, needed to overcome significant supply chain planning obstacles. The company faced frequent stockouts, resulting in lost sales, which was particularly challenging given their mix of high-value furniture and faster-moving accessories.

Working with RELEX transformed how porta managed their inventory across their product range. Product availability increased to over 96%, while sales rose by nearly 9%. Most impressive was porta’s ability to reduce their inventory investment by almost 10% while selling more products, achieving the retail goal of higher sales with lower stock levels.

Improvements include:

- 7.8% increase in availability.

- 8.9% increase in sales.

- 9.8% reduction in inventory value.

“With our constantly evolving furniture assortment, we needed a solution that could keep pace with our dynamic business. RELEX has helped us better manage our inventory while maintaining high product availability for our customers.”

Stephan Hermes, Managing Director Purchasing at porta

Challenge 3: Multi-tier network & supplier volatility

DIY supply chains span import centers, regional distribution centers, specialized facilities, and hundreds of store locations. Yet, most manage each echelon independently, using disparate data and objectives, which creates systemic inefficiencies.

The bullwhip effect is a supply chain phenomenon in which small, temporary changes in consumer demand at the retail level create larger fluctuations, and can be caused by several different issues, including:

- Misinterpreted demand signals that skew forecast accuracy, amplify upstream fluctuations, and drive over- and under-ordering.

- Large, infrequent order batching that creates uneven demand patterns.

- Price fluctuations from promotions that cause temporary spikes in demand, leading to overreactions in replenishment.

- Longer lead times that amplify the impact of demand changes, as upstream actors adjust orders based on outdated information.

- Poor coordination between supply chain partners that leads to misaligned responses to demand changes.

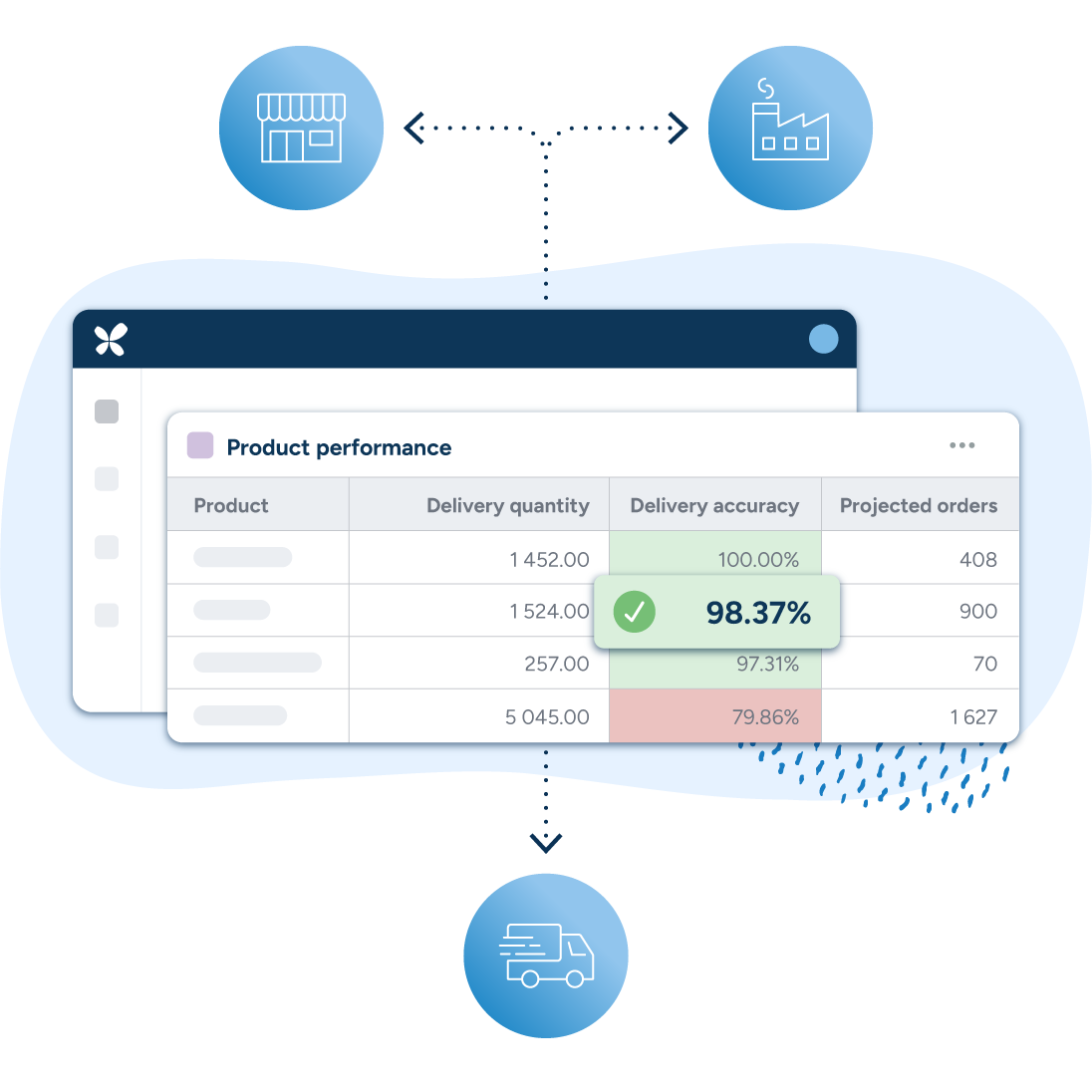

One of the RELEX Supplier Collaboration solution’s core features is its ability to automatically share crucial data among all stakeholders, whether internally or externally with trading partners. This includes channel-level demand forecasts, inventory levels, and POS data.

Beginning at the store level, closest to the customer, every tier aligns with true consumer demand rather than distorted order signals. Aligning on future inventory needs based on shared forecasts allows trading partners to collaboratively plan their operations and commitments. This visibility enables all parties to make informed, joint decisions that optimize the supply chain and improve margins.

Network optimization calculates the optimal stock levels at each echelon, minimizing inventory across the supply chain. The result is that products are available when and where needed, without excess inventory driving up costs and, eventually, prices. This optimal inventory flow across DCs, import centers, and stores eliminates the need for emergency freight to fix planning failures.

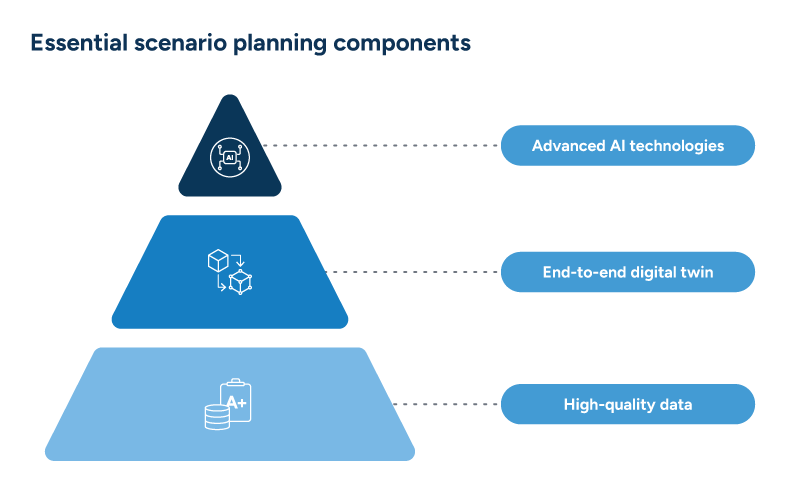

One way to achieve this level of optimization proactively is with digital twin modeling. A digital twin creates a virtual model of the entire supply chain that continuously mirrors real conditions. Scenario testing capabilities using digital twin environments with real-world data enable retailers to test “what-if” scenarios before implementation, thereby validating plans without market risk.

RELEX digital twin capabilities support the creation of unlimited scenarios, with both private and shared options available. The platform offers static snapshot modes that preserve scenario integrity during analysis, as well as dynamic updates when fresh data is required. This gives planners complete freedom to test a wide range of hypothetical scenarios in a sandbox setting.

Advanced AI algorithms enhance scenario planning capabilities by processing more variables simultaneously than human planners can manage. These technologies identify patterns in historical data and external signals, enabling more sophisticated predictive modeling and optimization.

AI integration allows for rapid scenario calculation, automated constraint analysis, and intelligent recommendation generation. Machine learning algorithms continuously improve forecasting accuracy and optimization results, while generative AI assists planners in interpreting complex scenario outcomes and identifying optimal strategies.

Real-world results: K Group’s building and technical trade division

K Group (Rautakesko), Finland’s leading building and home improvement products company, sought to increase the level of automation in their replenishment process and enhance the accuracy of inventory management.

With RELEX, they were able to achieve a high degree of automation within a short timeframe – roughly 90 percent of all order lines are currently ordered automatically. As the volumes of some of their suppliers are extremely small, achieving a well-balanced mix of orders to fill a transport unit or meet the minimum order limit became much faster.

The system automatically determines the correct order quantity and time, regardless of any agreed-upon restrictions with the supplier. These process changes have resulted in improved efficiency and performance of the replenishment process, which translates into lower inventory levels.

Improvements include:

- Approximately 90% order line automation.

- Reduced inventory value.

- Maintained inventory availability.

“The implementation of the coordinated replenishment ordering logic took the replenishment process to a new level of efficiency.”

Olli Salmivaara, Logistics Director

Challenge 4: Omnichannel execution

Modern DIY shopping is complex, and a single purchase may span several channels:

- Customers research products and check real-time inventory at nearby stores online.

- Purchases are made online or in-store with multiple fulfillment methods, including BOPIS, curbside pickup, same-day delivery, or ship-to-home.

- In the case of returns or exchanges, customers will use any channel, depending on the size of the products and their convenience.

While every new channel introduces new ways to serve customers, it also opens retailers up to new ways to erode margins through duplicate inventory, incremental labor, and higher transportation costs. There are several essential areas of omnichannel execution that DIY retailers cannot afford to get wrong.

Inventory allocation across channels

Without real-time demand signals across all channels, stock cannot be allocated effectively, critical deliveries can’t be scheduled with warehouse and store teams, and online fulfillment teams can’t verify availability.

RELEX provides comprehensive inventory planning across all locations and channels in real time. The platform integrates data from stores, distribution centers, suppliers, and third-party partners to create a single, accurate view of inventory availability.

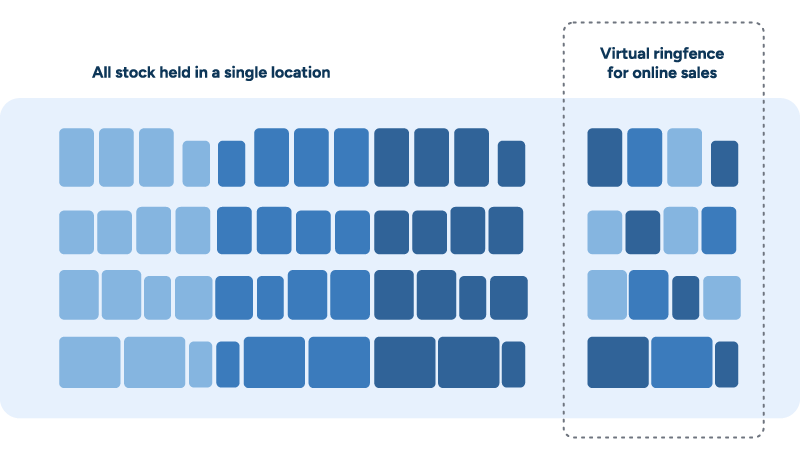

Virtual ringfencing takes visibility a step further by intelligently protecting inventory for priority channels or high-value customers. The system can automatically reserve stock for online orders, protect inventory for upcoming promotions, or ensure that key items remain available for in-store customers during peak shopping periods.

Connected inventory planning with virtual ringfencing also helps DIY retailers mitigate availability issues with their professional and B2B customers. Builders and customers who purchase in bulk need special considerations. When planning coordinates all demand across stores, e-commerce, and pro/B2B segments, contractors can be confident that they can get job-lot quantities while retail customers can find products in-store.

Further, Dynamic rebalancing capabilities automatically reallocate inventory across channels and regions when trends shift, ensuring the right inventory is in the right place and channel for the right customers.

Safety stock optimization

Customers expect real-time inventory accuracy across all locations. When the inventory system indicates that five units are available, but the shelf is empty, trust is compromised. Dynamic safety stock automatically adjusts at the product-location level based on forecasts and actual orders.

Advanced inventory optimization from RELEX juggles multiple variables simultaneously, factoring in:

- Holding costs

- Service levels

- Lead times

- Demand patterns

- Order constraints and requirements, such as batches or pallets

The RELEX solution utilizes multi-echelon inventory optimization (MEIO), which optimizes inventory strategically across the entire supply chain, positioning safety stock where it delivers the most value. The solution automatically determines optimal buffer points based on lead times, demand variability, and service level requirements at each echelon:

- Warehouses hold more safety stock for slow-moving items with long supplier lead times, while stores maintain minimal buffers for these products.

- Fast-moving items with predictable demand patterns might require less centralized safety stock, with inventory pushed closer to the customer for rapid fulfillment.

Store execution

Even when HQ plans are sound, if they are disconnected from store operations, execution failures create inconsistent availability.

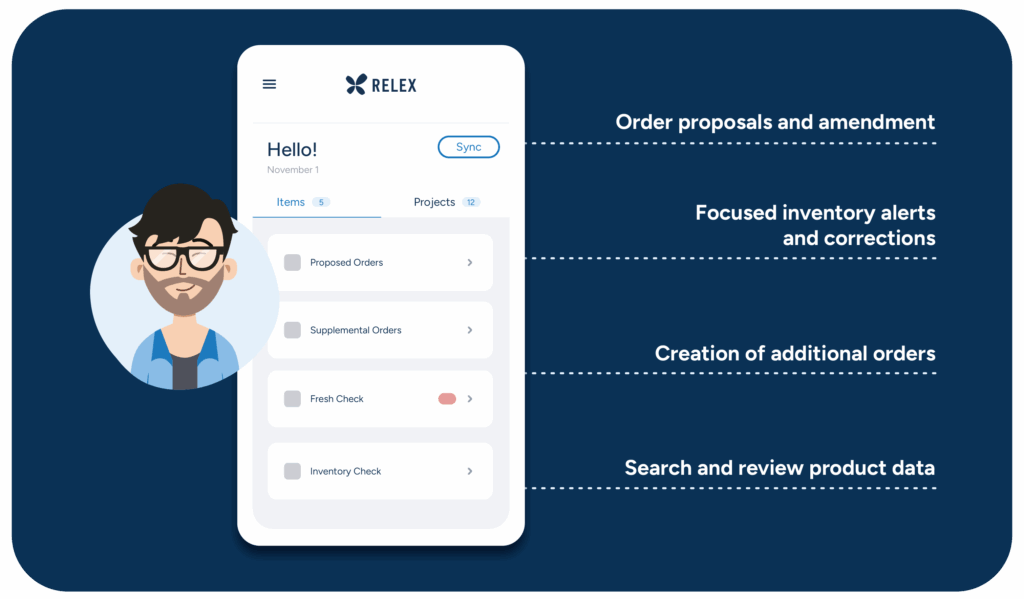

RELEX Mobile connects HQ plans directly to store teams, providing real-time execution visibility and aligning staffing to demand, which enables better execution during peak periods.

The solution features AI-assisted ordering capabilities that integrate algorithmic recommendations with local expertise. Store associates can easily adjust orders based on local conditions, special events, or customer feedback while ensuring that their decisions are captured and fed into the system for continual learning.

Near real-time insights enable faster decision-making and better coordination between stores and planning teams. When unexpected situations arise, associates can quickly understand the impact and take appropriate action rather than waiting for guidance from central planning.

Space-aware replenishment aligns inventory with store-specific planograms, minimizing shelf breaches. Associates know what needs to be restocked and when, ensuring customers aren’t met with empty shelves while inventory sits hidden in a back room.

Real-world results: Granngården balances stock between online and stores

Granngården, a nationwide retail chain in Sweden in the pets and gardening sector, had been unable to maintain separate safety stocks for its e-commerce channel but wanted to honor its same-day delivery guarantee on orders placed before 11:00 a.m.

The RELEX system helped Granngården achieve a crucial goal, establishing individual virtual ring-fences around stock. Specified quantities of stock can now be reserved for each of its channels, online and physical, while remaining part of a single inventory held in one location. This allows imbalances between the two to be adjusted as soon as they emerge, and without the need to move any of the stock.

Improvements include:

- 7% decrease in store stock value.

- 10% decrease in central warehouse stock value.

- 17% increase in sales.

“We’d hit a problem, we’d ask for the RELEX team’s advice, and they’d solve it. Simple. They understood our business and our challenges in no time.”

Jimmy Olsen, Logistics Manager at Granngården

Challenge 5: Sustainability & waste optimization

Growing consumer expectations and increasing regulations around sustainability are driving all retailers to establish advanced plans for waste reduction. Waste management costs are increasing due to several issues, all of them stemming from poor planning accuracy:

- Forecasting inaccuracies that drive excess inventory.

- Incorrect products in the wrong locations requiring rebalancing.

- End-of-season markdowns or disposal costs due to overbuying.

- Emergency freight requirements to rectify stockouts.

However, many retailers struggle to accurately identify waste sources, measure their sustainability performance, or track progress against targets. The RELEX platform, a unified and AI-powered solution, enables retailers to achieve these goals.

Improved forecasting accuracy delivers reduced waste and protects margins simultaneously by mitigating over- or underbuying, reducing markdowns, disposal costs, and unnecessary inventory movements.

Cross-functional optimization aligns orders to demand to optimize truckloads, reduce reactive inventory corrections, and smooth deliveries, all of which decrease emissions and logistics costs.

AI-driven automation enhances efficiency, helps identify and correct problems before they occur through advanced diagnostics, and optimizes capacity and workforce planning.

CO₂ tracking in the platform monitors waste reduction progress against targets to build trust with customers and drives profitability alongside sustainability, not in conflict with it.

The path forward: RELEX for DIY retail

Growth is slowing, and margin pressure is intensifying across the DIY sector. As customer expectations continue to rise, omnichannel capabilities that were once differentiators are now baseline requirements.

Connected planning delivers compound benefits: better forecasting enables more effective inventory positioning, which in turn enables better service, ultimately driving customer loyalty. Lower costs, achieved through optimized truckloads and waste reduction, enable competitive pricing. Each improvement reinforces others.

Questions to consider:

- How integrated are your planning processes across forecasting, replenishment, pricing, space, and execution?

- Where are your biggest margin leaks: markdowns, stockouts, emergency freight, excess inventory?

- What could connected planning mean for your availability, costs, and profitability?

RELEX has helped DIY and home improvement retailers worldwide achieve measurable improvements in availability, efficiency, and profitability through unified, AI-driven planning.

| The RELEX difference | What it means for DIY retail |

| Purpose-built for DIY complexity | Efficient management of bulky products, seasonal peaks, weather volatility, regional variation, and long lead times. |

| End-to-end AI-native platform | Every planning process is connected in one cohesive environment. |

| Unified inventory visibility | Accurate, real-time stock across the entire network: DCs, stores, and online. |

| Space-aware replenishment | Inventory decisions align with floor and shelf space, ensuring the right products are on shelves when customers want them. |

| Embedded mobile execution | A direct, real-time connection between HQ and stores ensures consistent in-store execution and increased availability. |

| Real-time diagnostics | Root cause analysis and proactive issue identification enable teams to solve problems before they become costly. |

| Multi-agent system | Multiple agents with specialized focus areas operate in live workflows to drive speed and accuracy to planners. |

Discover how RELEX can help your organization:

- Improve forecast accuracy and reduce inventory waste

- Strengthen availability across all channels

- Optimize space productivity and store execution

- Reduce costs while improving service levels