Sometimes, it seems the only thing preventing retailers from pushing their winter holiday products out on the first day of October is that their display areas are still reserved for Halloween products. It makes sense to keep seasonal products out for as long as possible to maximize the enormous impact their sales can have on margin.

But while it’s one thing to try to extend high-margin seasonal sales, it’s another to manage seasonal merchandise planning properly. For example, a retailer shouldn’t allocate all their promotional space for Christmas-themed products in October if they won’t sell in large volumes until November.

Accurately forecasting the right quantities to allocate is even more critical to avoid compromising sales for other products in the assortment. In order to prevent this, retailers must be able to account for the interplay between retail space and replenishment. As retailers set space aside for their holiday and year-end items, they must also be able to replenish that space accordingly.

Common challenges with seasonal merchandise planning

When it comes to stocking up for a season, almost every retailer is all too familiar with one or both of two outcomes:

- Excess stock at the season’s end, resulting in either waste or capital tied up in dead or slow-moving inventory.

- Insufficient stock, resulting in lost sales during the season.

Most retailers know these risks, and many already have excellent forecasting processes and good allocation management in place. But while they might have solved the initial problem of getting the right amount of stock to stores, they can’t address the root of the problem without optimizing their space and replenishment as well.

Typically, retailers who lack a clear, fleshed-out process for seasonal merchandise planning end up in one of the following situations:

- Stock idles in the back room while shelves empty quickly.

- An army of merchandisers is needed to maintain consistently full shelves, creating a nightmare for store operations.

Ultimately, the retailer loses sales due to poor space management or throws all their resources toward battling empty shelves, jeopardizing customer service levels. The question becomes, how should retailers adjust their planning processes to avoid these common pitfalls?

The Solution: Demand-driven retail space allocation

As the season progresses, the space that retailers allot to seasonal products must be increased and reduced in line with ramp-up and ramp-down plans, as well as updated demand forecasts for each store. Leveraging localized demand forecasts is especially important when your stores all have different shapes, sizes, and sales volumes that won’t be served well by a “one size fits all” plan.

Consider Valentine’s Day chocolates, for example. Demand forecast analysis may reveal that they should only have limited space allocated at the start of the season because demand hasn’t yet risen for them. As the season moves into full swing and forecasts for that product increase, their presentations should expand to multiple locations—shelves, endcaps, tables, and so on—to maximize sales opportunities.

Retailers usually experience a pronounced sales peak, after which the season winds down and forecasts decrease. This slow-down period is the natural time to start reducing space, placing the seasonal chocolates only at strategic locations to encourage discount or impulse purchasing. In doing so, retailers can preserve usable space while clearing unsold product and even free up space for the next season or campaign that may be ramping up.

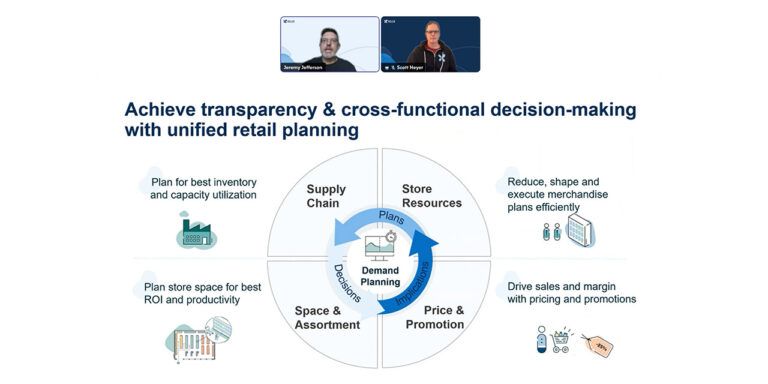

Watch the full unified planning video.

But there are other benefits that space optimization has to offer.

Drive additional sales: Make the most of “shopper missions”

Each store with unique floor plans and display areas has specific locations where holiday-themed products won’t just sell—they’ll drive sales for other products in the assortment.

Many shoppers visit stores with a specific goal, what retailers often call a “shopper mission.” Because people are so responsive to visual cues, presenting additional items related to seasonal shopper missions can prove quite effective at increasing basket size and driving additional sales.

For example, a shopper who picks up Valentine’s Day chocolates rather than ordinary chocolates may be on a mission to buy everything they need to create a special evening. This mission likely includes ingredients for dinner, champagne, flowers, and candles to create ambience.

Even shoppers on a mission with a specific shopping list are often enticed by purchasing additional items when positioned and merchandised correctly. But how can all these considerations be implemented in stores automatically, without time-consuming manual planning during an already stressful season?

An automated retail space planning solution maximizes seasonal revenue

A good space planning solution can analyze how different spaces function within each store and automatically calculate how to maximize revenue and improve sales at those locations. That means, for instance, placing higher-margin seasonal items where they’re most likely to sell while ensuring the year-round assortment is also properly presented. Not only can retailers increase seasonal sales, but they can also boost sales for regular assortment products.

To capitalize on these opportunities, retailers need to plan at a granular level—store by store, cluster by cluster, and week by week. In some cases, even intra-day changes can be impactful—swapping out lunch items for dinner items in the food-to-go section of a grocery store, for example. Unfortunately, manually executing planning at this level is enormously labor intensive, even with all the associated benefits.

Luckily, modern planning systems can automate most seasonal merchandise planning processes. In the hands of a central planning team, a solution that’s been provided with sufficiently detailed store-level information can be exceptionally powerful. The result is a holiday season where you know you’re making the most of your space so you can concentrate on other things—above all, your customers.