For those of us who manage food-retail supply chains holiday periods are often so stressful that they’re hardly a holiday at all. For most people holidays mean good company and good food. You hardly need a degree in rocket science to work out that this means higher demand and that demand often shifts away from standard items. Meeting this higher demand is often made more difficult because stores and factories are closed and delivery fleets are enjoying a well-earned rest. With short shelf-life items, such as fresh food, this becomes a particularly knotty problem because people necessarily buy perishables as close to the date they expect to use them as possible – and when volumes are high and the margin for error is low the potential for costly errors is consequently very real.

In the food retail supply chain we have found it best to separate holiday supply planning into three steps:

- Forecast demand for the holiday period

Before, during and after the holiday - Use delivery schedules and intended inventory profiles to create a supply plan

Ensure your capacity is equal to your plans – that your supply chain can withstand the stresses of the season

i. Capacity to pick, deliver and receive all goods

ii. Work closely with suppliers to make sure their capacity is sufficient - Always deliver to stores based on the latest and best information

Demand Forecasting for Holidays

The critical ‘seasonal forecast’ period will vary quite a lot depending on the products and holiday period in question. In the food sector the longest holiday forecast period is that for Christmas and New Year, where successive holidays make maintaining supply chain efficiency quite challenging. Demand for almost all products rises sharply, delivery volumes to stores are consequently very high, so stock building has to be started well in advance. Thus the season-specific planning period needed is at least six weeks, and usually rather higher. Easter is usually the next-longest season, but there the planning can largely be limited to the week or two before and the week after the holiday.

The aim of demand forecasting is to build the most accurate forecast possible of future POS- demand for each store on a product-day-level basis. For holiday-season planning one actually needs several different kinds of forecasts and on different levels, but the store-product-day -level demand forecast is still the foundation on which all others can be built.

One aspect of fresh-food seasonal forecasting that makes a tricky job a little easier is that assortment turnover is generally quite a lot lower than in most other retail sectors. Usually fewer than 20% of products are new introductions, and so there is a demand history for most products. For this majority of products we’ve found that the highest forecast accuracy is achieved using each product’s own demand history with statistical seasonal time-series models, building in price and assortment role changes only if major changes have been made for that product compared with previous years.

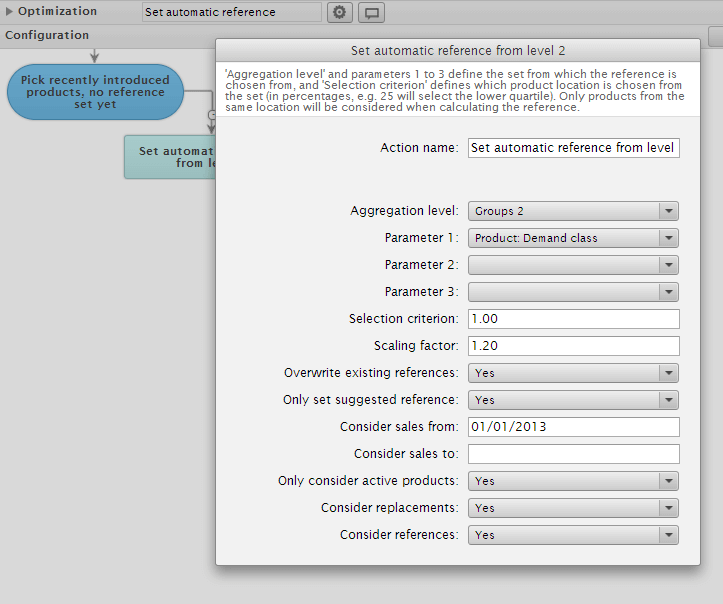

With new products we make use of automatic reference picking – i.e. letting the system pick a similar product with demand history. We have achieved good results by using very basic data such as picking a median demand product from a certain product group and price range as a comparator. Well thought out basic rules work in practice in almost all cases other than those where huge marketing campaign propels a product to the top sales spot in its category, and in such cases you simply can’t bypass manual planning.

New products’ seasonal sales patterns are usually borrowed from the product group from which the system has picked the reference product. The basic demand volume is taken from the product itself and future demand for the forthcoming season from the aggregate group.

The demand forecast is then allocated to individual days using day profiles. Day profile calculation is straightforward for most holidays and can be done quite easily as set out in the our previous white paper on day-level replenishment control. However Christmas is often a quite different story. For in 2013 Christmas Eve fell on a Tuesday. It last fell on a Tuesday in 2002, 11 years earlier. The overall market, as well as local conditions, can change a lot in 11 years.

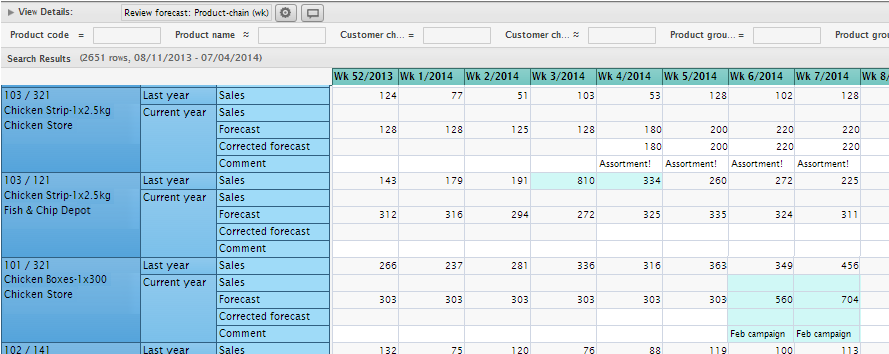

For Christmas we find it works best to let the system forecast day-level demand according to set or calculated day profiles. However, a good forecast analyst can usually increase the quality of the forecast by adjusting it based on his or her experience. We’ve found that the best results are achieved when the forecast can be reviewed and modified via several different groupings such as:

- Product-store location type (centre, rural)

- Product group -store

- Product-chain

The modification of forecasts on different levels is robust if the disaggregation of the changes is transparent and understandable. With RELEX systems forecast review and updates can be done by any logical grouping and the system disaggregates the manual forecast reviews based on the relation of current forecasts, and the system makes the change history absolutely clear.

Foodservice and Wholesale – Different Clientele, Different Challenges

In retail demand forecasting is the main challenges of holiday planning come from the large number of items and differing store profiles. In wholesale and foodservice sectors the number of depot-SKU combinations is often far lower than in retail. However difficulties arise from the diverse nature of the clientele. For example schools and nurseries that close for the holidays have to be accounted for quite differently than restaurants that are often fully booked during an annual peak. For wholesalers and foodservice companies it’s therefore advisable to review and modify forecasts separately for different customer chains or client sectors to increase the accuracy of holiday planning.

Build a Supply Plan with the Capacity to Deliver

So, after we have the best demand forecast we think we can build we can give ourselves a small pat on the back as we are about half way there. The next step is to start to plan how to fulfil that demand most efficiently.

Building a Supply Plan

In practice a supply plan is the ‘store delivery forecast’ for all goods. It is built from demand forecasts at SKU-Store-Day level, and the order-delivery calendars spanning the holiday in question. The end result is a demand-, order-, delivery-, and stock-forecast that can be reviewed at Store-SKU-level or at any higher level for any day.

Furthermore, in food retail the supply plan and capacity planning normally needs to be a holistic affair for seasons, as fresh and ambient products share supply chain resources at the DC, delivery, or store reception stages.

The supply plan is usually reviewed at different levels to ensure that the supply chain has enough capacity to fulfill the demand within the planned supply schedule. The supply forecast needs to be reviewed for potential stress points, especially:

- Receiving capacity at individual stores

Usually the amount of total goods / pallets arriving is key - DC picking capacity

Usually the number of picked delivery lines is critical - DC warehousing space

The number of pallets forecast to be in stock

For wholesalers and foodservice businesses capacity planning is just as important to ensure delivery capability during holiday seasons, and to make best use of available warehousing space for the seasonal assortment. Our customers also share the day-level order/delivery forecast with their suppliers to ensure suppliers’ capability to meet holiday demand.

Smoothing Material Flows

Very often demand during the holiday season is so high that the supply chain is not sufficiently efficient for deliveries to be strictly driven by demand, and by other considerations such as the need to build displays ahead of peak demand. To improve seasonal control, we have used ‘initial seasonal purchases’ to smooth material flows. In practice it means prioritizing the delivery of a selected group of products. Usually the delivery is calculated on-the-fly from the estimated total volume for the season, and is usually used to move products with a long shelf-life to stores in advance to ensure that there’s additional capacity for fresh food during the high-demand holiday season.

From Demand to Execution

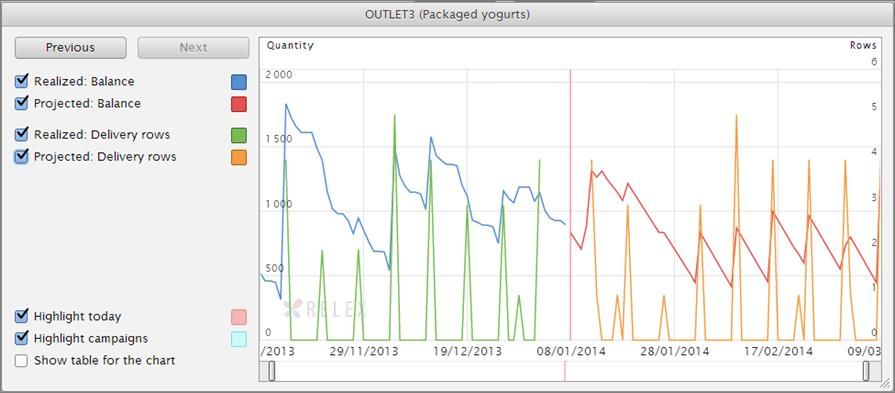

Via the demand and supply plan you order the products from your suppliers and manage your supply chain capacity. Invariably, however, your information and forecasts become more accurate as time goes on, and one can often find possibilities to use this improved intelligence in the supply chain. A good example is of fresh goods orders delivered through retail DCs.

It’s often the case that products are ordered from the supplier with a 2-day lead time, one day of which is reserved for DC handling and delivery to stores. However, the stock and demand situation for products ordered is more accurate for the following day than for two days hence. In such situations we’ve used allocation features, where the goods are ordered based on the SKU-chain level order forecast for the delivery day, but the store-level allocation of the products is done using the most recent SKU-store level information once the products are in the DC. In some cases this has proved even more important, as the suppliers have not been able to increase their deliveries of new products with unexpectedly high demand, and the most effective allocation of scarce products enabled maximises sales that might have otherwise been lost due to errors in the initial season forecast.

Remember It Is a Multi-level Affair, and You Grow Wiser

So, successful season management in the food-retail supply chain essentially demands you review different forecasts and review those forecasts on several different levels to ensure both the availability of products and supply chain capacity. Furthermore, you can always increase the accuracy of your forecasts as the season goes on – and sometimes you can even use these more accurate forecasts to good, and profitable, effect. Look out for those possibilities!